Professional Documents

Culture Documents

Parametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture Use

Uploaded by

Anonymous pKuPK3zUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture Use

Uploaded by

Anonymous pKuPK3zUCopyright:

Available Formats

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.

4, November 2015

PARAMETRIC DESIGN ANALYSIS AND FEA

SIMULATION OF A CHISEL PLOW FOR AN

AGRICULTURE USE

Pawan Sharma1 and Prof. (Dr.) Manish Bhargava2

1,2

1,2

Department of Mechanical Engineering

Maharishi Arvind Institute of Engineering and Technology, Jaipur, India

ABSTRACT

CAD Software for the structural analysis is basically used for the application of CAD/CAM in design

optimization of tillage tools, which is based on the simulation method and Finite Element Method. The

various components of the tillage tools are simulated with help of actual field performance rating

parameters which are prepared by solid models along with actual boundary conditions. The planned work

outcomes of sufficient tolerance in varying the working parameters of Chisel Plow sections for ejecting the

extra weight in a solid section and also to increase the weight of plow for a consistent potency.

In this paper parametric study of two different kinds of Chisel Plow for an agriculture use in designing

from stress, strain, deformation and fatigue analysis has done. One is Old Chisel Plow & another is New

Generation Chisel Plow. The old working model of Chisel Plow is compared with new design parameters

with change of its geometry for the maximum weed exclusion efficiency by showing its realistic results from

the actual field performance.

KEYWORDS

Stress, Strain, Deformation, Fatigue, Modeling, Analysis & Shape Optimization.

1. INTRODUCTION

The development of field is very costliest process in farming. It includes forest cleaning, soil

aperture using bottomless tillage tools, movements of soil from high to low places, farm road

construction, land leveling etc. These all operations can be performed by using self propelled and

heavy equipments such as crawler tractors, high horsepower tractors, scrapers, ditchers, chisel

ploughs, levelers etc. To gain the required seedbed to provide optimal atmosphere for start

germination and plant development, mechanical exploitation of soil is required, known as tillage

operations and for minimize the design optimization and manufacturing errors of the components,

design analysis and optimization is necessary.

Particularly blades and spread parts must be consistent in field the concert against to working

conditions. Forecasting of Stress Analysis must be required for manufacturers, designers and

researchers. The optimization in design of a chisel plow can be obtained by decreasing its weight,

cost and by improving the weed exclusion rate. In industries, CAD softwares are used for the

designing the desired model and FEA softwares are used for the solid analysis of the model.

Thus after the analysis of stress, strain, safety factor, displacement, fatigue etc. on FEA software,

the simulation results shown in terms of safe results or in terms of breakdown and failure due to

high stresses and deformation.

The planned work shows an experimental way for model testing and validation of agriculture

tools and equipments. The selected model of a chisel plow is measured with actual dimensions

and its solid model is prepared on Autodesk Inventor 2014 and the simulation is done on ANSYS

v14.5. [1]

DOI : 10.14810/ijmech.2015.4404

45

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

1.1 Types of Chisel Plows

Animal Drawn Mouldboard

Bullock Drawn Disc Harrow

Melur

Disc Harrow

Improved Iron

Blade Harrow

Animal Drawn Bose

Bullock Drawn Puddler

Khargaon

Animal Drawn Puddler

Dabra

Animal Drawn Helical Blade

Rau

Puddler

Chisel

Bullock Drawn Land Leveler

MP Iron Wedge

Bullock Drawn Cultivator

Birsa Animal Drawn Ridger

Tractor Mounted Mouldboard

Kapas Ridger

Tractor Drawn Disc

Bullock Drawn Ridger

These are the various types of Chisel Plows used in agriculture field for different types of soils.

2. MATERIALS

The materials are taken from the engineering database of Chisel Plow production system

specification drawn by Industry. The properties of Material and Soil are taken as per the

following data:

Table 1. Material Properties

Stainless Steel

Material Name

Material Properties

Density

7750 Kg/m3

Youngs Modulus

1.93 X 1011

Poisson Ratio

0.31

Bulk Modulus

1.693 X 1011

Shear Modulus

7.3664 X 1010

Tensile Yield Strength

207 MPa

Compressive Yield Strength

207 MPa

Tensile Ultimate Strength

586 Mpa

Table 2. Soil Properties

Sandy Soil

Soil Resistance

(Kg/m2)

2000

Optimum Moisture

Content (%)

3.5

Sandy Loam

3000

5.8

Silt Loam

3500-5000

5.8

Clay

4000-5600

7.18

Heavy Loam

5000-7000

13.30

S. No.

Type of Soil

46

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

2.1 Soil Parameters

The properties of the soil related to the desired chisel plow were recognized as types of soil,

wetness, mass concentration and cone index. The measurement and categorization methodologies

are discussed in the subsequent section. Black type of soil is used in this research work for the

chisel plow analysis. The humidity substance of soil performs a significant task for the

development of the crops therefore subsequent Soil resistance and humidity substance of soil are

taken as per the table 2. [6]

3. MODELING AND DESIGNING METHODS

The modeling and designing methods include the number of various parameters, methods and

steps for model construction. The input boundary conditions will be required for the pre

processing stage of the desired chisel plow.

3.1 Finite Element Method for Chisel Plow

The useful features of finite element methods are as follows [7]:

Discretization of the whole model into small elements, which may be square, rectangle,

and triangle or in polygon shapes.

Derive the governing differential equations for each element of the model.

Assembly of all elements, based on stability of the solution.

3.2 Mesh Generation

The conversion of whole model into number of small elements is known as Mesh generation. The

meshing is a very important step for the accurate solution. Various kinds of meshing are used in

the pre-processing. We are using the mesh generation with a good number of relevance with fine

mesh. For the Chisel Plow elements are used for meshing.

The elements may be rectangular or triangular. We are using triangular mesh for a high accuracy.

The number of elements represents the solution accuracy of the model. The elements can be

increased by increasing the relevance number. So that the run time is less and also the accuracy is

not much affected.

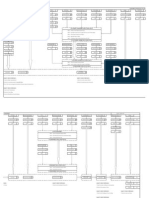

The mesh view of both the Chisel Plows is given below:

Figure 1. Mesh Pictures of the Old Model of Chisel Plow

47

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

Figure 2. Mesh Pictures of the New Generation Model of Chisel Plow

The fine triangular mesh is showing with scale in the above figures shows the accuracy of mesh at

small and large surface areas.

3.3 Model Description

The Model Description for the Chisel Plow is given below:

Table 3. Model Description

Old Model of Chisel Plow

New Generation Model of Chisel Plow

Length X

0.24281 m

Length X

0.10152 m

Length Y

0.55658 m

Length Y

0.23556 m

Length Z

Length Z

0.33916 m

Volume

2.1013e-004 m

Mass

0.25 m

1.0423e-003

m

8.1817 kg

Mass

1.6495 kg

Scale Factor Value

Scale Factor Value

No. of Nodes

32105

No. of Nodes

1751

No. of Elements

16472

No. of Elements

693

Volume

The model description shows in the above table number 3. The model description shows the exact

location and orientation of the model with respect to the global coordinate system. The model

description includes the model length in X, Y & Z direction, Volume & Mass of model, No. of

Nodes & Elements in the model of Chisel Plow after meshing.

4. ANALYSIS OF CHISEL PLOW BY USING ANSYS

The Analysis of the model can be done by using boundary conditions. After applying the

boundary conditions, we can get the required results. Analysis can be done by using the analysis

tool. The Modeling tool is Autodesk Inventor 14 and Analysis tool is ANSYS Workbench 14.5.

There are three steps in ANSYS working procedure used for the analysis are:

Preprocessing

Solution

Post processing

48

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

After preparing a solid geometry of Chisel Plow in Autodesk Inventor 14 the important steps are

meshing (that we have already done) and applying load on inclined face of the Chisel Plow by the

soil and boundary conditions in the preprocessor, so that simulation can be run to get a solution

and generate results in the post-processor.

Figure 3(a). Old Model of Chisel Plow

Figure 3(b). New Model of Chisel Plow

The above figure shows the modeled view of Chisel Plow on the modeling tool Autodesk

Inventor 14. Figure 3(a) showing the Old Model of Chisel Plow and Figure 3(b) showing New

Generation Model of Chisel Plow.

4.1 Boundary Conditions and Input Parameters

The boundary conditions are type of supports and forces on various faces, also various supports &

forces are the input parameters for the Chisel Plow.

4.1.1 Type of Support

Fixed Support will be applied on the face on which the body experiences the resisting force.

Thus, Fixed Support will be applied at the handle of ploughs of both Old Plough & New

Generation Plough.

4.1.2 Force

The Force will be applied by the soil in the opposite direction of motion. Thus, the force will be

applied on the inclined face of both Old Plough & New Generation Plough.

Table 4. Force Description

X Component

500 N

Y Component

0N

Z Component

500 N

The above boundary conditions are used for modeling and analysis of the Chisel Plow.

49

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

4.2 Types of Analysis

We will use total three types of Analysis for both the Chisel Plows under the fix ranges:

4.2.1 Stress Analysis

At the same magnitude of force and fixed support, the stress analysis is:

Figure 4(a). Old Model of Chisel Plow

Figure 4(b). New Generation Model of Chisel Plow

Above Figure 4(a) shows Old Model of Chisel Plow, in which under the action of the force of 500

N, the maximum stress is 1995.6 MPa and Figure 4(b) shows New Generation Model of Chisel

Plow in which the maximum stress is 797.54 MPa. Thus at the same magnitude of force the

lower stress developed in the New Generation Model of Chisel Plow, hence it is safe then the Old

Model of Chisel Plow.

50

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

4.2.2 Strain Analysis

At the same magnitude of force and fixed support, the strain analysis is:

Figure 5(a). Old Model of Chisel Plow

Figure 5(b). New Generation Model of Chisel Plow

Above Figure 5(a) shows Old Model of Chisel Plow, in which under the action of the force of 500

N, the maximum strain is 0.010801 and Figure 5(b) shows New Generation Model of Chisel Plow

in which the maximum strain is 0.0040332. Thus at the same magnitude of force the lower strain

developed in the New Generation Model of Chisel Plow, hence it is safe then the Old Model of

Chisel Plow.

51

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

4.2.3 Deformational Analysis

At the same magnitude of force and fixed support, the deformation analysis is:

Figure 6(a). Old Model of Chisel Plow

Figure 6(b). New Generation Model of Chisel Plow

Above Figure 6(a) shows Old Model of Chisel Plow, in which under the action of the force of 500

N, the maximum deformation is 31.847 mm and Figure 6(b) shows New Generation Model of

Chisel Plow in which the maximum deformation is 26.935 mm. Thus at the same magnitude of

force the lower deformation developed in the New Generation Model of Chisel Plow, hence it is

safe then the Old Model of Chisel Plow.

52

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

4.2.4 Fatigue Analysis

At the same magnitude of force and fixed support, the life analysis is:

Figure 7(a). Old Model of Chisel Plow

Figure 7(b). New Generation Model of Chisel Plow

Above Figure 7(a) shows Old Model of Chisel Plow, in which under the action of the force of 500

N, the maximum life cycles are 35,426 Cycles and Figure 7(b) shows New Generation Model of

Chisel Plow in which the maximum life cycles are 4,22,440 Cycles. Thus at the same magnitude

of force the maximum life cycles are in the New Generation Model of Chisel Plow, hence it is

safe then the Old Model of Chisel Plow. Thus the above Stress, Strain, Deformation and fatigue

analysis of Chisel Plow shows that under the same magnitude of force and fixed constraint the

Design of Old Model of Chisel Plow get failed and the Design of New Generation Model of

Chisel Plow will safe.

53

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

5. PARAMETRIC RESULTS

The parametric results shows the stress, strain, deformation & fatigue results for old model & new

generation model of Chisel Plow.

5.1 Stress Results on Chisel Plows

The Stress result shows in the comparison of Old Model of Chisel Plow and New Generation

Model of Chisel Plow.

Figure 8. Comparative Stress Results of Both Chisel Plows

Table 5. Stress Results on Chisel Plows

Von Mises Stresses Results

New Generation Model of Chisel

Old Model of Chisel Plow

Plow

Maximum

Stress (MPa)

Minimum Stress

(MPa)

1995.6

797.54

4.0034 x 10-10

5.5616 x 10-16

Thus, the stress result shows that at the same magnitude of force, the maximum von mises stress

developed in Old Model of Chisel Plow is 1995.6 MPa and in New Generation Model of Chisel

Plow is 797.54 MPa.

Thus, the Old Model of Chisel Plow get failure and New Generation Model of Chisel Plow get

safe at the same magnitude of force & fixed support.

54

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

5.2 Strain Results on Chisel Plows

The Strain result shows in the comparison of Old Model of Chisel Plow and New Generation

Model of Chisel Plow.

Figure 9. Comparative Strain Results of Both Chisel Plows

Table 6. Strain Results on Chisel Plows

Maximum Strain (mm)

Minimum Strain (mm)

Elastic Equivalent Strain Results

New Generation Model of Chisel

Old Model of Chisel Plow

Plow

0.0108

0.0040

3.7627 x 10-15

6.514 x 10-21

Thus, the strain result shows that at the same magnitude of force, the maximum strain developed

in Old Model of Chisel Plow is 0.0108 mm and in New Generation Model of Chisel Plow is

0.0040 mm.

Thus, the Old Model of Chisel Plow gets more deformation then New Generation Model of

Chisel Plow at the same magnitude of force & fixed support.

5.3 Deformation Results on Chisel Plows

The Deformation result shows in the comparison of Old Model of Chisel Plow and New

Generation Model of Chisel Plow.

55

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

Figure 10. Comparative Deformation Results of Both Chisel Plows

Table 7. Deformation Results on Chisel Plows

Deformation Results

Maximum

Deformation

Minimum

Deformation

Old Model of Chisel Plow

New Generation Model of

Chisel Plow

31.847 mm

26.935 mm

Thus, the Deformation result shows that at the same magnitude of force, the maximum strain

developed in Old Model of Chisel Plow is 31.847 mm and in New Generation Model of Chisel

Plow is 26.935 mm.

Thus, the Old Model of Chisel Plow gets more deformation then New Generation Model of

Chisel Plow at the same magnitude of force & fixed support.

5.4 Fatigue Results on Chisel Plows

The Fatigue result shows in the comparison of Old Model of Chisel Plow and New Generation

Model of Chisel Plow.

Figure 11. Comparative Fatigue Results of Both Chisel Plows

56

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

Table 8. Fatigue Results on Chisel Plows

Fatigue Results

Failure Occurs

at

Old Model of Chisel Plow

New Generation Model of Chisel

Plow

35,426 Cycles

4,22,440 Cycles

Thus, the Fatigue result shows that at the same magnitude of force, the Failure Occurs in Old

Model of Chisel Plow is at 35,426 Cycles and in New Generation Model of Chisel Plow is at

4,22,440 Cycles.

Thus, the Old Model of Chisel Plow gets failure then New Generation Model of Chisel Plow at

the same magnitude of force & fixed support.

Thus, the Parametric Results on the basis of Stress, Strain, Deformation and Fatigue Results, the

New Generation Model of Chisel Plow is much Safe than the Old Model of Chisel Plow. The

design of New Generation Model of Chisel Plow is much safe design for an agriculture use. Also

the life of New Generation Model of Chisel Plow is greater than Old Model of Chisel Plow.

CONCLUSION

A tillage tool such as Chisel Plow is designed in computer aided design software. The motion of

Chisel Plow and soil surface interaction is considered. The tillage operations introduces a quality

parameters and development scope in obtaining a width of cut , depth of cut, Speed of operation,

field efficiency, field capacity, theoretical draft the rate of work, quality of work, draft

measurement etc. The analysis of stress, strain, deformation and life cycle shows the safe designs

at the same range of input parameters between old model of Chisel Plow and New Generation

Model of Chisel Plow.

REFERENCES

[1]

Quirke, S. Scheffler, O. Allen, (1988), An evaluation of the wear behavior of metallic materials

subjected to soil abrasion Soil and Till. Res. 11

[2] Gill, W.R., and G.E. Vanden Berg, (1996), Design of tillage tool in soil dynamics in tillage and

traction, 211-294, Washington, D.C.,U.S.GPO

[3] Godwin, R.J. (1982), Force measurement on tillage implements 9th Conference of the International

soil Tillage Research organization, Osijek

[4] Jain, S.C., and Philip (2003), Farm machinery an approach, standard publishers distributors Delhi pp.

5-7, 21, 27

[5] Kosutic, S., D Filipovic, and Z Gospodaric. (1996), Rotary Cultivator Energy Requirement

Influenced by Different Constructional Characteristics, Velocity and Depth of Tillage.

Poljoprivredna-Znanstvena-Somatra, vol 61,Pg3-4, 1996, p 239

[6] Krutz, G., L. Thompson and C. Poul (1984), Design of Agricultural machine, John Willey and

Sons, New Delhi. pp.32-36

[7] Ben Yahia, Logue, and M. Khelifi. (1999), Optimum settings for rotary tools used for on-the-row

mechanical cultivation in corn, Transactions of ASAE, 15(6): 615-619

[8] Biswas, H.S. (1993)., Performance Evaluation and optimization of straight blades for shallow tillage

and weeding in black soils, Agric. Mech. in Asia, Africa and Latin America, 24(4) 19-22

[9] Block, J.M. (1986), Performance of power tiller blades, Agric. Mech. In Asia, Africa and Latin

America, 17 (1): 22-26

[10] Spoor. G., Design of soil engaging implements, practice, Farm Machine design Eng J:1419,Dec,1969

57

International Journal of Recent advances in Mechanical Engineering (IJMECH) Vol.4, No.4, November 2015

[11] Thakur T.C., (1991), Design aspects of soil engaging hand tools, Agricultural Engineering

Today.21:15-18

[12] Zhang, J., and R.L.K Khuswala, (1996), Wear and draft of cultivator sweep with hardened edges,

Canadian Agricultural Engineering, 37(1); 41-47

AUTHORS:

Pawan Sharma has completed his B.Tech in Mechanical Engineering, M.Tech in

Machine Design from RTU (Kota), Rajasthan, INDIA. He has published more than 25

research papers in the refereed International journals and conferences. He has

published three Engineering Books in the field of FEA/FEM. His area of research

includes CAD/CAM, FEA/FEM, Composite Materials, CFD and Vibration Analysis.

Prof. (Dr.) Manish Bhargava holds M.Tech. in Manufacturing System Engineering,

Ph.D. in Mechanical Engineering from MNIT, Jaipur. He has published more than 30

research papers in the refereed International journals and conferences. He has a

teaching and research experience of more than 14 years. Currently, He is working as a

Professor in Mechanical Engineering & Principal with Maharishi Arvind Institute of

Engineering and Technology, Jaipur, Rajasthan, India. His area of research includes

CIMS, CAD/CAM, Reliability & Maintenance, Manufacturing Systems and Material

Science.

58

You might also like

- Yasnac Mx-3 Fault Finding GuideDocument70 pagesYasnac Mx-3 Fault Finding Guidechidambaram kasi100% (1)

- Asme B1.3 - 2007 PDFDocument21 pagesAsme B1.3 - 2007 PDFKristin JonesNo ratings yet

- Machine Vision System For Inspecting Flank Wear On Cutting ToolsDocument5 pagesMachine Vision System For Inspecting Flank Wear On Cutting ToolsRaghuNo ratings yet

- Boiler MaintenanceDocument144 pagesBoiler Maintenanceaziz100% (2)

- Including Geometric Feature Variations in Tolerance Analysis of Mechanical AssembliesDocument32 pagesIncluding Geometric Feature Variations in Tolerance Analysis of Mechanical AssembliesnaveenNo ratings yet

- Chapter 4-EDocument42 pagesChapter 4-EMahrouz MadoNo ratings yet

- Machine Tool Technology 1Document2 pagesMachine Tool Technology 1Dhileepan KumarasamyNo ratings yet

- SLTRT Service Level Testing Reporting ToolDocument110 pagesSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- EASA Part 66 Module 7 MCQ and Essay QuestionsDocument4 pagesEASA Part 66 Module 7 MCQ and Essay QuestionsazadairNo ratings yet

- TMM Microscope ChapterDocument38 pagesTMM Microscope ChapterPavan Kumar BittuNo ratings yet

- SS1 v1 PindadDocument4 pagesSS1 v1 PindadAtom Sacau100% (1)

- 2010 Book Three-DimensionalModelAnalysis PDFDocument434 pages2010 Book Three-DimensionalModelAnalysis PDFJhoan Sebastian Tenjo GarciaNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Listening To Customers Through ResearchDocument5 pagesListening To Customers Through ResearchRICARDO JIMENEZNo ratings yet

- Introduction To GDDocument8 pagesIntroduction To GDCatalin FinkelsteinNo ratings yet

- Fundamentals of GD T PDFDocument117 pagesFundamentals of GD T PDFvrushalmaniyarNo ratings yet

- Properties of LPGDocument33 pagesProperties of LPGmukund madhav100% (2)

- Supplier Deviation Request FormDocument2 pagesSupplier Deviation Request Formjainik shahNo ratings yet

- Chapter 5 Embodiment DesignDocument29 pagesChapter 5 Embodiment DesignEphrem AbabiyaNo ratings yet

- The Effectiveness of Program DeliveryDocument15 pagesThe Effectiveness of Program DeliveryAzel M. ValleNo ratings yet

- Starin - Bosch - Conferencing - CCS900 Data BrochureDocument48 pagesStarin - Bosch - Conferencing - CCS900 Data BrochureArie Al SebaiNo ratings yet

- BraginskiiDocument97 pagesBraginskiicordella_francescoNo ratings yet

- Berg The Theory and Application of Precision Mechanical Components 1965 PDFDocument177 pagesBerg The Theory and Application of Precision Mechanical Components 1965 PDFAndré PonceNo ratings yet

- Designing Crushers With A Multi-Objective Evolutionary AlgorithmDocument8 pagesDesigning Crushers With A Multi-Objective Evolutionary AlgorithmRavi Shanker VNo ratings yet

- Measuring University Service Quality by Means of SERVQUAL MethodDocument9 pagesMeasuring University Service Quality by Means of SERVQUAL MethodnurulNo ratings yet

- Standard For Safety UL ADocument49 pagesStandard For Safety UL ANhất NgônNo ratings yet

- B-Modelado Cinemático de Manipuladores Seriales Basado en Cuaterniones Duales LIBRO PDFDocument803 pagesB-Modelado Cinemático de Manipuladores Seriales Basado en Cuaterniones Duales LIBRO PDFeduardodecuba1980100% (1)

- Iso 2692 2006 en FR PDFDocument11 pagesIso 2692 2006 en FR PDF陳錦文No ratings yet

- Garvin: Managing Quality (1988)Document2 pagesGarvin: Managing Quality (1988)ptkpaudniNo ratings yet

- Tutorial (1) Manufacturing Models & MetricsDocument37 pagesTutorial (1) Manufacturing Models & MetricsAbdulaziz almasoudiNo ratings yet

- Tutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8Document5 pagesTutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8lianliang0% (1)

- Mechatronic Systems For Machine ToolsDocument30 pagesMechatronic Systems For Machine Toolsphuongdx100% (1)

- CAD/CAM/CIM IntroductionDocument21 pagesCAD/CAM/CIM IntroductiondpksobsNo ratings yet

- Uncertainty Analysis of Positional Deviations of CNC Machine ToolsDocument8 pagesUncertainty Analysis of Positional Deviations of CNC Machine ToolsAgustin Brau AvilaNo ratings yet

- Manufacturing The FutureDocument915 pagesManufacturing The Futurehy9092No ratings yet

- Manufacturing Processes ForDocument3 pagesManufacturing Processes ForSpartan India0% (5)

- A Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044Document10 pagesA Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044AkshayJadhavNo ratings yet

- ErrorsDocument20 pagesErrorsAnthony LopesNo ratings yet

- Computer Aided Analysis of Vibration in Machine Tool and Design of Damping SystemDocument4 pagesComputer Aided Analysis of Vibration in Machine Tool and Design of Damping SystemInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Me 8513 MM Lab 2022 OddDocument63 pagesMe 8513 MM Lab 2022 OddVelan PrintersNo ratings yet

- Suj 2Document123 pagesSuj 2rahul srivastavaNo ratings yet

- Modeling A Part Using Surfaces: Publication Number Spse01560Document341 pagesModeling A Part Using Surfaces: Publication Number Spse01560buva034No ratings yet

- Educational Service Quality at Public Higher EducaDocument15 pagesEducational Service Quality at Public Higher Educajalan sungaiNo ratings yet

- Performance Measurment of Ramp Door Manufacturing of M113 Armoured Personel CarrierDocument8 pagesPerformance Measurment of Ramp Door Manufacturing of M113 Armoured Personel CarrierNisar Ahmed RanaNo ratings yet

- A Conceptual Model of Service QualityDocument11 pagesA Conceptual Model of Service QualityalbchileNo ratings yet

- Assignment MetrologyDocument8 pagesAssignment MetrologyPratama sudibyo0% (1)

- (Advances in Environmental Microbiology 6) Christon J. Hurst - Understanding Terrestrial Microbial Communities (2019)Document414 pages(Advances in Environmental Microbiology 6) Christon J. Hurst - Understanding Terrestrial Microbial Communities (2019)Valeria HornaNo ratings yet

- Iso230 2 2006Document6 pagesIso230 2 2006Amit Kumar100% (1)

- Magnetic Bearings - Atsushi Nakajima, Prof. Dr. G. SchweitzerDocument386 pagesMagnetic Bearings - Atsushi Nakajima, Prof. Dr. G. SchweitzerLucas S. CarmoNo ratings yet

- Machine Design Chap-1Document27 pagesMachine Design Chap-1Vivek Supriya Bhaskar100% (1)

- 1492Document15 pages1492_Anggyaa_No ratings yet

- Finite Element Modelling and Analysis of Hot Turning OperationDocument55 pagesFinite Element Modelling and Analysis of Hot Turning OperationSangar LingamNo ratings yet

- Machine Tools: By: T.Jahnavi Section CDocument20 pagesMachine Tools: By: T.Jahnavi Section CVenkata Nagabhushana ShastryNo ratings yet

- Gauge Block Selection GuideDocument24 pagesGauge Block Selection GuidedediprayogiNo ratings yet

- Trends in Machinetools PDFDocument6 pagesTrends in Machinetools PDFmohan SRNo ratings yet

- DTSI Technology: Performance and Advantages of Digital Twin Spark Ignition SystemsDocument27 pagesDTSI Technology: Performance and Advantages of Digital Twin Spark Ignition SystemsGopi GopiNo ratings yet

- SpaceClaim2015 SP0 UsersGuideDocument1,240 pagesSpaceClaim2015 SP0 UsersGuideEduardo MedinaNo ratings yet

- IscarDocument158 pagesIscarDOBJAN100% (1)

- Tool Life Determination Based On The Measurement of Wear and Tool Force Ratio VariationDocument9 pagesTool Life Determination Based On The Measurement of Wear and Tool Force Ratio VariationSamy OrabyNo ratings yet

- Design and Development of CNC RouterDocument5 pagesDesign and Development of CNC RouterAnshu ShuklaNo ratings yet

- EIM PPT 1Document17 pagesEIM PPT 1rahul0% (1)

- Solid Edge Vs SolidWorksDocument1 pageSolid Edge Vs SolidWorksManish ShahNo ratings yet

- ManufacturingTechnology I GKVDocument20 pagesManufacturingTechnology I GKVaswin jithuNo ratings yet

- CMMDocument21 pagesCMMJerry EmmattyNo ratings yet

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryNo ratings yet

- Design Analysis of Rotary Tillage Tool Components by CAD-tool: RotavatorDocument6 pagesDesign Analysis of Rotary Tillage Tool Components by CAD-tool: RotavatorVishal NarNo ratings yet

- Upgradation in Hydraulic Press Machine Arun V. Javir, Niranjan N. Manchekar, Rahul D. BelekarDocument9 pagesUpgradation in Hydraulic Press Machine Arun V. Javir, Niranjan N. Manchekar, Rahul D. BelekarddNo ratings yet

- Design, Modeling and Analysis of Rotavator Blade: KeywordsDocument20 pagesDesign, Modeling and Analysis of Rotavator Blade: KeywordsAhsan JunaidNo ratings yet

- Development of Rotary Weeder Blades by Finite Element MethodDocument5 pagesDevelopment of Rotary Weeder Blades by Finite Element MethodijsretNo ratings yet

- Call For Paper-International Journal of Information Technology Convergence and Services (IJITCS)Document2 pagesCall For Paper-International Journal of Information Technology Convergence and Services (IJITCS)ijitcsNo ratings yet

- The International Journal of Multimedia & Its Applications (IJMA) ERA - IndexedDocument2 pagesThe International Journal of Multimedia & Its Applications (IJMA) ERA - IndexedIJMAJournalNo ratings yet

- International Journal of Peer-To-Peer Networks (IJP2P)Document2 pagesInternational Journal of Peer-To-Peer Networks (IJP2P)Ashley HowardNo ratings yet

- International Journal of Wireless & Mobile Networks (IJWMN)Document2 pagesInternational Journal of Wireless & Mobile Networks (IJWMN)John BergNo ratings yet

- ISSN: 2320-7493 (Online) 2320 - 8449 (Print)Document2 pagesISSN: 2320-7493 (Online) 2320 - 8449 (Print)Alejandro CarverNo ratings yet

- Advanced Computing An International Journal (ACIJ)Document2 pagesAdvanced Computing An International Journal (ACIJ)acii journalNo ratings yet

- Hiij 2015Document2 pagesHiij 2015hiijjournalNo ratings yet

- International Journal of Computational Science and Information Technology (IJCSITY)Document2 pagesInternational Journal of Computational Science and Information Technology (IJCSITY)Anonymous F1whTRNo ratings yet

- International Journal of Recent Advances in Mechanical Engineering (IJMECH)Document1 pageInternational Journal of Recent Advances in Mechanical Engineering (IJMECH)Anonymous pKuPK3zUNo ratings yet

- International Journal of Managing Information Technology (IJMIT)Document2 pagesInternational Journal of Managing Information Technology (IJMIT)ijmitNo ratings yet

- International Journal of Advances in Chemistry (IJAC)Document2 pagesInternational Journal of Advances in Chemistry (IJAC)msejjournalNo ratings yet

- International Journal of Advances in Biology (IJAB)Document2 pagesInternational Journal of Advances in Biology (IJAB)ijabairccNo ratings yet

- Call For Paper - International Journal of Information Science & Techniques (IJIST)Document2 pagesCall For Paper - International Journal of Information Science & Techniques (IJIST)Mandy DiazNo ratings yet

- International Journal of Computational Science and Information Technology (IJCSITY)Document2 pagesInternational Journal of Computational Science and Information Technology (IJCSITY)Anonymous F1whTRNo ratings yet

- Ijsea CFPDocument2 pagesIjsea CFPAnonymous rVWvjCRLGNo ratings yet

- ISSN: 2320-7493 (Online) 2320 - 8449 (Print)Document2 pagesISSN: 2320-7493 (Online) 2320 - 8449 (Print)Alejandro CarverNo ratings yet

- Bioscience & Engineering: An International Journal (BIOEJ)Document2 pagesBioscience & Engineering: An International Journal (BIOEJ)bioejNo ratings yet

- International Journal of Network Security & Its Applications (IJNSA) - ERA, WJCI IndexedDocument2 pagesInternational Journal of Network Security & Its Applications (IJNSA) - ERA, WJCI IndexedAIRCC - IJNSANo ratings yet

- IJCAxInternational Journal of Computer-Aided Technologies (IJCAx)Document2 pagesIJCAxInternational Journal of Computer-Aided Technologies (IJCAx)Anonymous YlNWzoENo ratings yet

- International Journal of Artificial Intelligence & Applications (IJAIA)Document2 pagesInternational Journal of Artificial Intelligence & Applications (IJAIA)Adam HansenNo ratings yet

- ISSN:2393 - 8455: Scope & TopicsDocument2 pagesISSN:2393 - 8455: Scope & Topicscaijjournal2No ratings yet

- ISSN: 2320-7493 (Online) 2320 - 8449 (Print)Document2 pagesISSN: 2320-7493 (Online) 2320 - 8449 (Print)Alejandro CarverNo ratings yet

- Advanced Energy: An International Journal (AEIJ)Document1 pageAdvanced Energy: An International Journal (AEIJ)journalaeijNo ratings yet

- Advanced Computing An International Journal (ACIJ)Document2 pagesAdvanced Computing An International Journal (ACIJ)acii journalNo ratings yet

- International Journal of Recent Advances in Mechanical Engineering (IJMECH)Document1 pageInternational Journal of Recent Advances in Mechanical Engineering (IJMECH)Anonymous pKuPK3zUNo ratings yet

- International Journal of Managing Information Technology (IJMIT)Document2 pagesInternational Journal of Managing Information Technology (IJMIT)ijmitNo ratings yet

- International Journal of Peer-To-Peer Networks (IJP2P)Document2 pagesInternational Journal of Peer-To-Peer Networks (IJP2P)Ashley HowardNo ratings yet

- International Journal of Network Security & Its Applications (IJNSA) - ERA, WJCI IndexedDocument2 pagesInternational Journal of Network Security & Its Applications (IJNSA) - ERA, WJCI IndexedAIRCC - IJNSANo ratings yet

- Call For Papers-Informatics Engineering, An International Journal (IEIJ)Document2 pagesCall For Papers-Informatics Engineering, An International Journal (IEIJ)ijsptmNo ratings yet

- Call For Paper-International Journal of Information Technology Convergence and Services (IJITCS)Document2 pagesCall For Paper-International Journal of Information Technology Convergence and Services (IJITCS)ijitcsNo ratings yet

- Messerschmitt Me 262 - Wikipedia, The Free Encyclopedia3Document5 pagesMesserschmitt Me 262 - Wikipedia, The Free Encyclopedia3beta2009No ratings yet

- SQL Server 2008 R2 Express Installation GuideDocument53 pagesSQL Server 2008 R2 Express Installation GuideGersonGamas100% (2)

- Twice As Sharp Operators ManualDocument34 pagesTwice As Sharp Operators ManualLeonardo CHTZNo ratings yet

- d-Copia3500MF 4500MF 5500MFsmY113351-4Document1,051 pagesd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- Presentation FileDocument10 pagesPresentation FileInnoVentureCommunityNo ratings yet

- Sant Gadge Baba Amravati University: Backlog From Session Winter-2019Document2 pagesSant Gadge Baba Amravati University: Backlog From Session Winter-2019Prashant pandeNo ratings yet

- The Magnaflux Advantage (Whole Catalog)Document51 pagesThe Magnaflux Advantage (Whole Catalog)Andy StkNo ratings yet

- Mycom Nims ProptimaDocument4 pagesMycom Nims ProptimasamnemriNo ratings yet

- Ahmed Mohammed EL Desouky 2007Document8 pagesAhmed Mohammed EL Desouky 2007Hazem MohamedNo ratings yet

- Oral and Practical Tests: MechanicDocument19 pagesOral and Practical Tests: MechanicHugo AlmeidaNo ratings yet

- GRAS 46BE 1/4Document9 pagesGRAS 46BE 1/4nino16041973No ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- CPU Vs vCPUDocument14 pagesCPU Vs vCPUainseanNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- EA 4b ArchiMate Views and Viewpoints PDFDocument41 pagesEA 4b ArchiMate Views and Viewpoints PDFanon_834023132No ratings yet

- A JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDocument10 pagesA JIT Lot Splitting Model For Supply Chain Management Enhancing Buyer Supplier Linkage 2003 International Journal of Production EconomicsDaniel Renaldo SimanjuntakNo ratings yet

- Complex Instruction Set ComputerDocument17 pagesComplex Instruction Set ComputerkangkanpaulNo ratings yet

- Sheds Direct Ireland's Wooden BrochureDocument12 pagesSheds Direct Ireland's Wooden BrochureVictor Celestino Montañez CarranzaNo ratings yet

- Elink For Windows: List of Pages in This Trip KitDocument130 pagesElink For Windows: List of Pages in This Trip KitAhmed GvNo ratings yet