Professional Documents

Culture Documents

Detailing of Reinforcement

Uploaded by

sorowareCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailing of Reinforcement

Uploaded by

sorowareCopyright:

Available Formats

3

CHAPTER THREE

COLUMNS

3- R.C. COLUMNS

A reinforced concrete column is a structural members designed

to carry compressive loads, composed of concrete with an embedded

steel frame to provide reinforcement. For design purposes, the

columns are separated into two categories: short columns and

slender columns.

3.1 Detailing rules that conform to BS EN 1992-1-1, Euro code 2:

3.1.1 Design and detailing notes Concrete grade.

Concrete grades less than 28/35 MPa (cylinder strength/cube

strength) are not normally used. Care should be taken to ensure that

the design strength of concrete required in a column does not exceed

1.4 times that in the slab or beam intersecting with it unless special

measures are taken to resist the bursting forces.

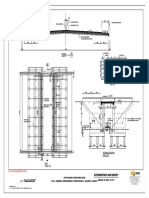

Figure (3.1-a): Construction details in columns

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Figure (3.1-b): Construction details in columns

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

3.1.2 Reinforcement guidelines by BS EN 1992-1-1, Euro code 2

i.

Bar diameter:

Recommended minimum bar diameter is 16mm for very small

section columns. Minimum number of bars for rectangular columns

is 4. Minimum number of bars for circular columns is 6 for very small

diameter columns, and the minimum of 4 for less than 200mm.

ii.

Maximum area of main reinforcement:

Maximum area of reinforcement should not exceed 0.04 Ac unless it

can be shown that any resulting congestion of reinforcement does

not hinder the ease of construction. At laps the maximum area of

reinforcement should not exceed 0.08 Ac. Mechanical splices should

be considered where congestion becomes a problem.

iii.

Bar spacing:

Preferred minimum spacing

Main bars 75mm (bars 40mm size and greater: 100mm)

Pairs of bars

100mm

When considering the minimum spacing of bars of 32mm size or

greater, allowance must be made for lapping of bars.

Preferred maximum spacing

Compression bars 300mm, provided that all main bars in the

compression zone are within 150mm of a restrained bar.

Tension bars

175mm

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

iv.

COLUMNS

Links

The size of link should be the greater of a quarter the maximum

size of longitudinal bar and 8mm (for very small diameter columns,

less than 200mm, the minimum of 6mm may apply).Bundled main

bars may be represented by a single bar for the purpose of

calculating link size and spacing. This single bar has an equivalent

size to give it the same cross section area as the bundle.

An overall enclosing link is required together with additional

restraining links for alternate main bars or bundle of bars. Provided

that all other main bars in the compression zone are within 150mm

of a restrained bar no other links are required .Otherwise additional

links should be added to satisfy this requirement. Additional links are

not required for circular columns.

Maximum spacing of links

The least of:

20 times the size of the longitudinal bars, or

The lesser dimension of the column, or

400 mm.

The maximum spacing should be reduced by a factor 0.6 in sections

within a distance equal to the larger dimension of the column crosssection above and below a beam or slab.

Where the direction of the longitudinal bars changes (e.g. at laps), the

spacing of links should be calculated. The spacing of links should

ensure that there is a link close to the cranking positions of the main

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

bars. These effects may be ignored if the change in direction is 1 in 12

or less.

Requirement of links in columns

v.

Moment connection between beam and edge column:

Wherever possible U-bars which can be placed within the

depth of beam should be used. These are fixed in position and

concreted with the beam, and thus do not require precise fixing when

the column is being concreted. L-bars which penetrate down into the

column should be used when the distance A (see Figure ) is less

than the anchorage length for that bar diameter. These bars must be

fixed accurately at the top of the column lift which is a difficult and

unattractive site task. A standard radius to the bend may normally be

used provided a bar of the same size or greater is placed inside the

corner normal to it. A non-standard bend may be required if a corner

bar is not present. If so, a thorough check should be carried out to

ensure that the reinforcement fits and will perform as intended. The

critical effective depth may not be obvious, and various locations may

need to be assessed.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Special care should be taken by the Designer and Detailer to make

sure that this reinforcement does not conflict with any beam

reinforcement passing through the column in the other direction.

Connection between beam and edge column

vi.

Shear capacity of column:

The maximum tensile reinforcement in the beam or that part

required for the moment connection to the column is also controlled

by the shear capacity of the column. Where there is no edge beam

intersecting at approximately the same level as the joint, transverse

column reinforcement should be provided within the depth of the

beam (See Figure ). This may be in the form of links or horizontal Ubar extending into the beam. Unless specified by the Designer the

spacing should be as for the links in the column.

vii.

Starter bars:

It is important to recognize at the design stage the implications of the

construction sequence and the level of foundation on the length of

starter bars, e.g.

If the foundation reinforcement is placed at a depth lower than

specified the consequent lap of the first lift of column bars is likely to

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

be too short. For this reason the length of starter bars from pad

footings and pile caps is specified longer than required.

Detailing information:

Design information for detailing should include:

The section dimensions and its position and orientation

relative to particular grid lines.

Outline drawings which show clearly what happens to the

column above the lift being considered.

Kicker height if other than 75mm.

Concrete grade and aggregate size 20mm.

Nominal cover to all reinforcement (standard 35mm internal,

40mm external). Supplementary mesh reinforcement if

required.

A simple sketch of cross-section of column showing the

longitudinal reinforcement in each face of the column, i.e.

1. Number and position of bars.

2. Type of reinforcement and bond characteristics standard (H).

3. diameter of bars.

4. Lap length if other than normal compression laps the linking

reinforcement.

5. Type of reinforcement standard (H).

6. Diameter of links, spacing, pattern of links (if special).

Instructions for lapping of bunched bars if required.

Special instructions for links within depth of slab or beam.

If a mechanical or special method of splicing bars is required

this must be shown in a sketch, otherwise the method given in

the Model Details will be assumed.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Special instructions and sketches should be given where

services are provided within the column.

Details of insertions, e.g. conduit, cable ducting, cladding

fixings, etc., should be given where the placing of reinforcement

is affected.

3.1.3 Presentation of working drawings:

Nominal cover to all reinforcement specified by designer (Normally:

Internal 35, External 40).

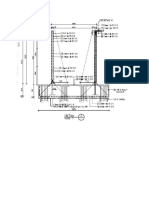

Figure (3.2): Footing to Column connection

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

This detail is used where the column is concentric and of the same

dimensions as the story below. Nominal cover to all reinforcement

specified by designer (Normally: Internal 35, External 40)

Figure (3.3): Column is concentric and of the same dimensions as the

story below

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

This detail applies for stepped or offset columns.

Figure (3.4): stepped or offset columns

Detail A applies when slab depth is not less than:

200 using 20 size of column bars

250 using 25 size of column bars

300 using 32 size of column bars

Otherwise Detail B applies

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

For single story buildings or where splice bars have been used at the

floor below

Figure (3.5): Splice bars details use in columns of single story

building, detail A.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Figure (3.6): Splice bars details use in columns of single story

building, detail B.

Top detail

This detail is used for single story buildings and where splice bars

have been used at the floor below.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Circular columns

Helical binders are used unless circular links are specified by

designer.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

3.2 Detailing rules that conform to (ACI 315-99)

According to ACI Code 2.2, a structural element with a ratio of heightto-least lateral dimension exceeding three used primarily to support

compressive loads is defined as column. Columns support vertical

loads from the floor and roof slabs and transfer these loads to the

footings.

Columns usually support compressive loads with or without bending.

Depending on the magnitude of the bending moment and the axial

force, column behavior will vary from pure beam action to pure

column action.

Columns are classified as short or long depending on their

slenderness ratios. Short columns usually fail when their materials

are overstressed and long columns usually fail due to buckling which

produces secondary moments resulting from the P - D effect.

Columns are classified according to the way they are reinforced into

tied and spirally reinforced columns. Columns are usually reinforced

with longitudinal and transverse reinforcement. When this

transverse reinforcement is in the form of ties, the column is called

tied. If the transverse reinforcement is in the form of helical hoops,

the column is called spirally reinforced. Since failure of columns

often cause extensive damage, they are designed with a higher factor

of safety than beams.

3.2.1 Types of Columns

Columns are divided into three types according to the way they are

reinforced.

Tied Columns

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

A tied column, shown in Figure (

), is a column in which the

longitudinal reinforcement bars are tied together with separate

smaller diameter transverse bars (ties) spaced at some interval along

the column height. These ties help to hold the longitudinal

reinforcement bars in place during construction and ensure stability

of these bars against local buckling. The cross sections of such

columns are usually square, rectangular, or circular in shape. A

minimum of four bars is used in rectangular and circular cross

sections.

Tied Columns

Spirally-Reinforced Columns

They are columns in which the longitudinal bars are arranged in a

circle surrounded by a closely spaced continuous spiral, shown in

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Figure ( ). These columns are usually circular or square in shape. A

minimum of six bars is used for longitudinal reinforcement.

Spirally-Reinforced Columns

3.2.2 Design Considerations by ACI CODE

Maximum and Minimum Reinforcement Ratios

ACI Code 10.9.1 specifies that a minimum reinforcement ratio of 1 %

is to be used in tied or spirally reinforced columns. This minimum

reinforcement is needed to safeguard against any bending, reduce the

effect of shrinkage and creep and enhance ductility of columns.

Maximum reinforcement ratio is limited to 8 % for columns in

general to avoid honeycombing of concrete.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

For compression member with a cross section larger than required

by consideration of loading, ACI Code 10.8.4 permits the minimum

area of steel reinforcement to be based on the gross sectional area

required by analysis. The reduced sectional area is not to be less than

one half the actual cross sectional dimensions. In regions of high

seismic risk, ACI Code 10.8.4 is not applicable.

Minimum Number of Reinforcing Bars

ACI Code 10.9.2 specifies a minimum of four bars within rectangular

or circular sections; or one bar in each corner of the cross section for

other shapes and a minimum of six bars in spirally reinforced

columns.

Clear Distance between Reinforcing Bars

ACI Code 7.6.3 and 7.6.4 specify that for tied or spirally reinforced

columns, clear distance between bars, shown in Figure (

), is not to

be less than the larger of 1.50 times bar diameter or 4 cm. This is

done to ensure free flow of concrete among reinforcing bars. The

clear distance limitations also apply to the clear distance between lap

spliced bars and adjacent lap splices since the maximum number of

bars occurs at the splices.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Concrete Protection Cover:

ACI Code 7.7.1 specifies that for reinforced columns, the clear

concrete cover is not to be taken less than 4 cm for columns not

exposed to weather or in contact with ground. It is essential for

protecting the reinforcement from corrosion or fire hazards.

Minimum Cross Sectional Dimensions:

Minimum sizes for compression members were eliminated to allow

wider utilization of reinforced concrete compression members in

smaller size and lightly loaded structures, such as low-rise residential

and light office buildings. When small sections are used, there is a

greater need for careful workmanship. For practical considerations,

column dimensions are taken as multiples of 5 cm.

Lateral Reinforcement:

Ties are effective in restraining the longitudinal bars from buckling

out through the surface of the column, holding the reinforcement

cage together during the construction process, confining the concrete

core and when columns are subjected to horizontal forces, they serve

as shear reinforcement. Spirals, on the other hand, serve in addition

to these benefits in compensating for the strength loss due to spilling

of the outside concrete shell at ultimate column strength.

Ties

According to ACI Code 7.10.5.1, for longitudinal bars 32 mm or

smaller, lateral ties 10 mm in diameter are used. In our country and

in some neighboring countries, ties 8 mm in diameter are used in

column construction.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Tests have proven that spacing between ties has no significant effect

on ultimate strength of columns.

ACI Code 7.10.5.2 specifies that vertical spacing of ties is not to

exceed the smallest of:

16times longitudinal bar diameter.

48times tie diameter.

Least cross sectional dimension.

ACI Code 7.10.5.3 specifies that ties are arranged in such a way that

every corner and alternate longitudinal bar is to have lateral support

provided by the corner of a tie with an included angle of not more

than 135 degrees. Besides, no longitudinal bar is to be farther than 15

cm clear on each side along the tie from such a laterally supported

bar. When longitudinal bars are located around the perimeter of a

circle, circular ties are used. Figure ( ).a shows a number of tie and

spiral arrangements.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

FIG. 9 A (Tie and Spiral Arrangement)

Spirals:

According to ACI Code 7.10.4.2 spirals not less than 10 mm in

diameter are to be used in cast-in place construction. The clear pitch

of the spiral is not to be less than 2.5 cm and not more than 7.5 cm as

dictated by ACI Code 7.10.4.3. The smaller limit is set to ensure flow

of concrete between spiral hoops while the larger limit is set to

ensure effective confinement of concrete core. The diameter of the

spiral could be changed to ensure that the spacing lies within the

specified limits.

Bundled Bars:

For

isolated

situations

requiring

heavy

concentration

of

reinforcement, bundles of standard bar sizes can save space and

reduce congestion for placement and compaction of concrete.

Bundling of parallel reinforcing bars in contact is permitted but only

if ties enclose such bundles. According to ACI Code 7.6.6, groups of

parallel reinforcing bars bundled in contact to act as one unit are

limited to four in any one bundle, as shown in Figure (9.b).

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

FIG. (9.B): Bundled Bars

3.2.3 Column Reinforcement Details

When column offset are necessary, longitudinal bars may be bent

subject to the following limitations.

1. Slope of the inclined portion of an offset bar with axis of

column must not exceed 1 in 6 ,shown in Figure 10.

2. Portion of bar above and below the offset must be parallel to

axis of column.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

3. Horizontal support at offset bends must be provided by lateral

ties, spirals, or parts of the floor construction. Ties or spirals, if

used, shall be placed not more than 15 cm from points of bend.

Horizontal support provided must be designed to resist 1.5

times the horizontal component of the computed force in the

inclined portion of an offset bar.

4. Offset bars must be bent before placement in the forms.

5. When a column face is offset 7.5 cm ,or more, longitudinal

column bars parallel to and near the face must not be offset

bent. Separate dowels, lap spliced with the longitudinal bars

adjacent to the offset column faces, must be provided as

shown in Figure 11. In some cases, a column might be offset

7.5 cm or more on some faces, and less than 7.5 cm on the

remaining faces, which could possibly result in some offset

bent longitudinal column bars and some separate dowels

being used in the same column.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

3.2.4 Column Lateral Reinforcement

Ties

In tied reinforced concrete columns, ties must be located at no more

than half tie spacing above the floor or footing and at no more than

half a tie spacing below the lowest horizontal reinforcement in the

slab or drop panel above. If beams or brackets frame from four

directions into a column, ties may be terminated not more than 7.5

cm below the lowest horizontal reinforcement in the shallowest of

such beams or brackets, shown in Figure 12.

Spirals

Spiral reinforcement must extend from the top of footing or slab in

any story to the level of the lowest horizontal reinforcement in slabs,

drop panels, or beams above. If beams or brackets do not frame into

all sides of the column, ties must extend above the top of the spiral to

the bottom of the slab or drop panel, shown in Figure 13.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

3.3 Details and Detailing of Concrete Columns Reinforcement

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Note: Where column size above is unchanged from below, upside

down offset bars are effective in maintaining full moment capacity at

end of column. In U.S. practice, this unusual detail is rare, and should

be

fully

illustrated

on

structural

drawings

to

avoid

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

misunderstandings, whenever its use is deemed necessary. For

maximum tie spacing, see table in Supporting Reference Data section.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Typical seismic-resistant details: columns.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Typical seismic-resistant joint detailsCase 1: For regions of high

seismic risk. Interior and spandrel beams narrower than column.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Typical seismic-resistant joint detailsCase 2: For regions of

moderate seismic risk. Interior beam wider than column; spandrel

beams narrower than column.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Typical seismic-resistant joint detailsCase 3: For regions of

moderate seismic risk. Interior beam wider than column; spandrel

beam is same width as column.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Notes:

1. Alternate position of hooks in placing successive sets of

ties.

2. Minimum lap shall be 12 in. (300) mm.

3. B indicates bundled bars. Bundles shall not exceed four

bars.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

4. Elimination of tie for center bar in groups of three limits

clear spacing to be 6 in. (150 mm) maximum. Unless

otherwise specified, bars should be so grouped.

5. Note to Architect/Engineer: Accepted practice requires

that design drawings show all requirements for splicing

column verticals, that is, type of splice, lap length if

lapped, location in elevation, and layout in cross section.

6. Note to Detailer: Dowel erection details are required for

any design employing special large vertical bars, bundled

vertical bars, staggered splices, or specially grouped

vertical bars as shown

7. Bars

must

be

securely

supported

to

prevent

displacement suring concreting.

8. Tie patterns shown may accommodate additional single

bars between tied groups provided clear spaces between

bars do not exceed 6 in. (150) mm.

9. Minimum cover to ties, 11/2 in. (40 mm) for

nonprestressed cast-in-place concrete

10.

Spaces between corner bars and interior groups of

three and between interior groups may vary to

accommodate average spacing > 6 in. (150) mm.

11.

For average spacing < 6 in. (150 mm), one untied

bar may be located between each tied group of three and

between a tied group and a corner bar.

Standard column ties applicable for preassembled cages or field

erection, special-shaped columns, and columns with bars in two faces

only.

Guidelines for Detailing of Reinforcement in Concrete Structures

CHAPTER THREE

COLUMNS

Typical seismic resistant details: transverse reinforcement in

columns.

Typical seismic-resistant details: boundary members.

Guidelines for Detailing of Reinforcement in Concrete Structures

You might also like

- Footing Design As Per AstmDocument102 pagesFooting Design As Per AstmZankar R ParikhNo ratings yet

- Proposed 2-Storey Residential BLDGDocument34 pagesProposed 2-Storey Residential BLDGclarkgagui100% (1)

- Eb204 1Document337 pagesEb204 1alikaroutNo ratings yet

- Design of Continuous Beam and Slab Footing Using BS 8110-1:1997Document8 pagesDesign of Continuous Beam and Slab Footing Using BS 8110-1:1997Ubani Obinna Ranks80% (5)

- British Rebar CodesDocument32 pagesBritish Rebar CodesManoj RautNo ratings yet

- Reinforcing Bar Layout For Two-Way SlabsDocument4 pagesReinforcing Bar Layout For Two-Way Slabsaomareltayeb100% (1)

- SP-34-1987 Handbook On Reinforcement and DetailingDocument286 pagesSP-34-1987 Handbook On Reinforcement and DetailingEr Prabhakara B88% (69)

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- Ribbed Slab Design TemplateDocument4 pagesRibbed Slab Design Templateyusuf abdinasir75% (4)

- Earthquake DesignDocument2 pagesEarthquake DesignUmange RanasingheNo ratings yet

- Lecture 10 Analysis and Design of Waffle Slabs - 2011Document62 pagesLecture 10 Analysis and Design of Waffle Slabs - 2011José Pablo Rosales Sánchez100% (1)

- Design of A Steel Roof TrussDocument49 pagesDesign of A Steel Roof TrusseseemNo ratings yet

- Reinforcement Detailing HandbookDocument244 pagesReinforcement Detailing HandbookAhmed Refaey100% (4)

- March 2010 Detailing Corner - Wide Beam Stirrup ConfigurationsDocument3 pagesMarch 2010 Detailing Corner - Wide Beam Stirrup Configurationslattmdy100% (1)

- Types of Stone MasonryDocument28 pagesTypes of Stone MasonryPrashant SunagarNo ratings yet

- Stair Cases DesignDocument19 pagesStair Cases DesignWrishad Zia93% (14)

- Machine Foundations in Oil and Gas IndustryDocument64 pagesMachine Foundations in Oil and Gas IndustryPower PowerNo ratings yet

- Frese Corporate ProfileDocument14 pagesFrese Corporate ProfileAnonymous 6hptH95No ratings yet

- Bridge DrawingDocument1 pageBridge DrawingsorowareNo ratings yet

- How Do Columns in RC Buildings Resist EarthquakeDocument2 pagesHow Do Columns in RC Buildings Resist EarthquakekooaduNo ratings yet

- Chapter 6.0 Slab Design TheoryDocument19 pagesChapter 6.0 Slab Design TheoryMohd Afzal100% (1)

- Labone Office Complex Structural Design Report Rev 01 PDFDocument99 pagesLabone Office Complex Structural Design Report Rev 01 PDFBoris Escubio100% (1)

- Detailing Reinforcement in Concrete StructuresDocument82 pagesDetailing Reinforcement in Concrete StructuresLarissa100% (1)

- Useful Guidelines For Design of RCC Slab Basic Rules For Slab DesignDocument7 pagesUseful Guidelines For Design of RCC Slab Basic Rules For Slab DesignUsman Shahid100% (1)

- Construction Formwork and FalseworkDocument25 pagesConstruction Formwork and FalseworkLoke Kok Foong85% (13)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Chapter 1.0 - Staircase - 2 - 20172018Document55 pagesChapter 1.0 - Staircase - 2 - 20172018nas0% (1)

- Introduction To MeasurementDocument20 pagesIntroduction To MeasurementAamaniVeeranam100% (1)

- Costen SteelReinforcementDocument66 pagesCosten SteelReinforcementKitt SmithNo ratings yet

- 05.40.00 Cold-Formed Metal Framing Specification Updated June 2015Document26 pages05.40.00 Cold-Formed Metal Framing Specification Updated June 2015mishikhanNo ratings yet

- Graded Examples in Reinforced Concrete Design DiasDocument118 pagesGraded Examples in Reinforced Concrete Design DiasAmgad Talal92% (13)

- Guide to designing RCC structural componentsDocument19 pagesGuide to designing RCC structural componentshamz786No ratings yet

- Design of Underground Water TankDocument6 pagesDesign of Underground Water Tanksijuwolaoluranti100% (1)

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 pagesColumn Design As Per BS 8110-1:1997: PHK/JSNJennifer Tang100% (2)

- Design of RCC ColumnsDocument14 pagesDesign of RCC Columnsprashmce100% (1)

- Strip FoundationDocument64 pagesStrip FoundationRuss Pope67% (6)

- Design of RC BeamsDocument42 pagesDesign of RC BeamsHarold Jackson MtyanaNo ratings yet

- Retaining WallDocument7 pagesRetaining WallEdward SmithNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement Detailingsomumallidi100% (1)

- Free-Standing Sawtooth Staircase Design & DetailingDocument8 pagesFree-Standing Sawtooth Staircase Design & DetailingMahesh SNo ratings yet

- Design of Strip FootingDocument8 pagesDesign of Strip FootingJaime Manalili Landingin0% (1)

- Retainning WallDocument14 pagesRetainning Wallahamedtouhid899No ratings yet

- SHORINGDocument10 pagesSHORINGIzzuddin ShahidanNo ratings yet

- Structural Design Brief - Rev 0Document6 pagesStructural Design Brief - Rev 0Umesh ChamaraNo ratings yet

- Lateral Load Resisting SystemsDocument55 pagesLateral Load Resisting Systemssuman33No ratings yet

- METAL REINFORCEMENT ESTIMATEpdfDocument104 pagesMETAL REINFORCEMENT ESTIMATEpdfAljon CabahugNo ratings yet

- 3.1 Metal ReinforcementDocument26 pages3.1 Metal ReinforcementAbestano JadeNo ratings yet

- Reinforcing Steel ReferenceDocument19 pagesReinforcing Steel ReferenceMary Emalaine SerranoNo ratings yet

- Reinforcement DetailingDocument18 pagesReinforcement DetailingRushiNo ratings yet

- Concrete Column Design & ConstructionDocument16 pagesConcrete Column Design & ConstructionVannah Elyssa AustriaNo ratings yet

- ODOT Bridge Design Manual Section 300 DetailDocument108 pagesODOT Bridge Design Manual Section 300 DetailPaulo ParenasNo ratings yet

- Welcome To OurDocument28 pagesWelcome To OurKh Bappi ShahriarNo ratings yet

- Reinforced Concrete DetailingDocument7 pagesReinforced Concrete DetailingGerald MagingaNo ratings yet

- Column DetailDocument3 pagesColumn DetailKmrnKhnNo ratings yet

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Reinforcement Detailing Guide for Concrete StructuresDocument6 pagesReinforcement Detailing Guide for Concrete StructurescherogonyaNo ratings yet

- Chapter 6 - ColumnDocument4 pagesChapter 6 - Columnlau lauNo ratings yet

- Lecture 2 2021-Concrete Reinforcement Details L1Document26 pagesLecture 2 2021-Concrete Reinforcement Details L1Zahim HarkiNo ratings yet

- RAJESHDocument14 pagesRAJESHYedluri RajeshNo ratings yet

- Steel Connections: Research in Building Tech 3Document10 pagesSteel Connections: Research in Building Tech 3Angelica Marie AzucenaNo ratings yet

- AD 350 - Heating Pipes in Composite Floors - Effects On Slab Beam DesignDocument3 pagesAD 350 - Heating Pipes in Composite Floors - Effects On Slab Beam Designsymon ellimacNo ratings yet

- Dcs II NotesDocument46 pagesDcs II NotesAbhilash Thakur (Assistant Professor- Civil)No ratings yet

- Report For On The Jop Training (OJT) SUMMER 2020Document38 pagesReport For On The Jop Training (OJT) SUMMER 2020Shadi OshiNo ratings yet

- Unit-Ii: ColumnsDocument13 pagesUnit-Ii: Columnsdevraj raikarNo ratings yet

- BEAM DETAILING AND REINFORCEMENTDocument14 pagesBEAM DETAILING AND REINFORCEMENTAslam SaifiNo ratings yet

- Neoprene Bearing Pad 749Document6 pagesNeoprene Bearing Pad 749sorowareNo ratings yet

- L E L E E T P W: SPENCER MethodDocument14 pagesL E L E E T P W: SPENCER MethodsorowareNo ratings yet

- Etabs DimentioningDocument1 pageEtabs DimentioningsorowareNo ratings yet

- Analysis of A Slip On A Long Natural SlopeDocument4 pagesAnalysis of A Slip On A Long Natural SlopesorowareNo ratings yet

- Analysis of A Slip On A Long Natural SlopeDocument4 pagesAnalysis of A Slip On A Long Natural SlopesorowareNo ratings yet

- Semi Through BridgeDocument1 pageSemi Through BridgesorowareNo ratings yet

- Abutment Elevation 10m SpanDocument1 pageAbutment Elevation 10m SpansorowareNo ratings yet

- Pile LayoutDocument1 pagePile LayoutsorowareNo ratings yet

- Abutment Sectional Plan 10m SpanDocument1 pageAbutment Sectional Plan 10m SpansorowareNo ratings yet

- Abutment Connecting BeamDocument1 pageAbutment Connecting BeamsorowareNo ratings yet

- Pile Layout RightDocument1 pagePile Layout RightsorowareNo ratings yet

- Abutment HeadDocument1 pageAbutment HeadsorowareNo ratings yet

- Abutment SectionDocument1 pageAbutment SectionsorowareNo ratings yet

- Abutment Elevation Section C 10m SpanDocument1 pageAbutment Elevation Section C 10m SpansorowareNo ratings yet

- Abutment Plan 10m SpanDocument1 pageAbutment Plan 10m SpansorowareNo ratings yet

- PC GirderDocument1 pagePC GirdersorowareNo ratings yet

- Bearing PedestalDocument1 pageBearing PedestalsorowareNo ratings yet

- Abutment DetailsDocument1 pageAbutment DetailssorowareNo ratings yet

- Information Document: Not For ConstructionDocument1 pageInformation Document: Not For ConstructionsorowareNo ratings yet

- 4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductDocument1 page4/3/2012 3:43:26 PM, DWG To PDF - pc3: Produced by An Autodesk Educational ProductsorowareNo ratings yet

- Abutment PlanDocument1 pageAbutment PlansorowareNo ratings yet

- Sheet PilingDocument1 pageSheet PilingRoger SugatanNo ratings yet

- Guard RailDocument1 pageGuard RailsorowareNo ratings yet

- Bridge LayoutDocument1 pageBridge LayoutsorowareNo ratings yet

- Information Document: Not For ConstructionDocument1 pageInformation Document: Not For ConstructionsorowareNo ratings yet

- Construction plan for interchange bridge at feeder road 3Document1 pageConstruction plan for interchange bridge at feeder road 3sorowareNo ratings yet

- Concrete Tech 1 Sample Questions AnsDocument18 pagesConcrete Tech 1 Sample Questions AnsJohn luckyNo ratings yet

- Oceanic HW 443 Series: Key Benefits DescriptionDocument2 pagesOceanic HW 443 Series: Key Benefits Descriptions bNo ratings yet

- Topic 7 Cascade Refrigeration SystemsDocument6 pagesTopic 7 Cascade Refrigeration SystemsJanelle D. Puti-anNo ratings yet

- Air-Conditioning SystemDocument6 pagesAir-Conditioning SystemDay DreamerNo ratings yet

- Design of Underground TankDocument20 pagesDesign of Underground TankhiteshNo ratings yet

- PUB0128 Iss05 - Duct and Grilles Catalogue WebDocument69 pagesPUB0128 Iss05 - Duct and Grilles Catalogue WebAlie RakasiwaNo ratings yet

- Gundu Rao Sanc Plan - A2 SizeDocument1 pageGundu Rao Sanc Plan - A2 SizeBHARATH KUMARNo ratings yet

- Is 1570 7Document18 pagesIs 1570 7Raj K Sharma100% (1)

- Piping System DesignDocument139 pagesPiping System DesignNatty SarathunNo ratings yet

- Sucker Rod PumpDocument5 pagesSucker Rod Pumpwilzy74No ratings yet

- Austar Promotes Cleanroom AdvancementDocument36 pagesAustar Promotes Cleanroom Advancementntt_121987No ratings yet

- Monod Sunpipe MLDocument28 pagesMonod Sunpipe MLAbdi LadiantoNo ratings yet

- Sika PDS - E - SikaGrout - 212 GPDocument2 pagesSika PDS - E - SikaGrout - 212 GPlwin_oo2435No ratings yet

- 02-01 Chap GereDocument17 pages02-01 Chap GereTortelliniTimNo ratings yet

- Installation Procedure T5MaxDocument2 pagesInstallation Procedure T5MaxCarlos Alberto RuedaNo ratings yet

- Tetralon FCP-MV-EN - 002Document3 pagesTetralon FCP-MV-EN - 002Rogério RangelNo ratings yet

- InTech-Convective Heat Transfer Analysis of Solar Chimney Power Plant CollectorsDocument14 pagesInTech-Convective Heat Transfer Analysis of Solar Chimney Power Plant CollectorszangolaNo ratings yet

- Lecture 03Document28 pagesLecture 03Isaac ShinyelaNo ratings yet

- Unit 3 Thermal PhysicsDocument1 pageUnit 3 Thermal PhysicsGajendraNo ratings yet

- B001586 CT ISGEC 103 - Pour - Card - FormatDocument4 pagesB001586 CT ISGEC 103 - Pour - Card - Formatsyed sulemanNo ratings yet

- Joist Girder DesignDocument42 pagesJoist Girder DesignsravanNo ratings yet

- Rajednra 2022 Price List PDFDocument28 pagesRajednra 2022 Price List PDFMurali YNo ratings yet

- Hallscrew BrochureDocument3 pagesHallscrew BrochureAsari Dear SNo ratings yet

- Inspiration 8-5-22Document9 pagesInspiration 8-5-22MUhammadAHmadNo ratings yet

- Macam Macam ValveDocument6 pagesMacam Macam ValveAhmadufiNo ratings yet