Professional Documents

Culture Documents

Classification of Hazardous Locations

Uploaded by

MehdiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classification of Hazardous Locations

Uploaded by

MehdiCopyright:

Available Formats

Appendix E: Classification of Hazardous Locations

Appendix E: Classification of Hazardous Locations

The following discussion provides a basic understanding of approval issues and how they

relate to heat tracing.

For complete information on the use of electrical equipment in hazardous locations, refer to

the most recent issue of the National Electrical Code or the Canadian Electrical Code.

Tyco Thermal Controls heating systems are approved and certified for use in nonhazardous

and hazardous locations by many agencies, including FM Approvals, CSA International, UL,

PTB, Baseefa (2001) Ltd., DNV, and ABS.

How are Hazardous Areas Defined?

According to the National Electrical Code, Article 500 and Section 18 of the Canadian Electri-

cal Code, “Locations shall be classified depending on the properties of the flammable vapors,

liquids, or gases, or combustible dusts or fibers that may be present and the likelihood that a

flammable or combustible concentration or quantity is present.”

Areas where fire or explosion hazards may exist due to flammable gases or vapors, flamma-

ble liquids, combustible dusts, or ignitable fibers or flyings are defined by the National Elec-

trical Code (NEC) and the Canadian Electrical Code (CEC) as hazardous locations.

The class and division of an area are based on the type of hazard (Class) and the expected

frequency of the hazard (Division).

Class

The class of a location defines the type of explosive danger that exists or may exist in the

location. Table E.1 explains how the classes are defined.

Table E.1 Hazardous Location Classes

Class Explosive danger

Class I Flammable gases or vapors

Class II Combustible dusts

Class III Combustible fibers or flyings

H56895 8/03 (800) 545-6258 www.tycothermal.com Tyco Thermal Controls 1 of 4

Appendix E: Classification of Hazardous Locations

Division

The division of a location defines the frequency that the hazard exists or may exist in a location.

Table E.2 Hazardous Location Divisions

Division 1 Areas where one or more of these conditions exist:

1. Ignitable concentrations of flammable gases or vapors can exist under normal operating

conditions.

2. Ignitable concentrations of such gases or vapors may exist frequently because of repair,

maintenance operations, or leakage.

3. Breakdown or faulty operation of equipment or processes might release ignitable concentra-

tions of flammable gases or vapors and might also cause simultaneous failure of the electri-

cal equipment in such a way as to directly cause the electrical equipment to become a source

of ignition.

Division 2 Areas where one or more of these conditions exist:

1. Volatile flammable liquids or flammable gases are handled, processed, or used, but in which

the liquids, vapors, or gases will normally be confined within closed containers or closed

systems from which they can escape only in case of accidental rupture or breakdown of such

containers or systems, or in case of abnormal operation of equipment.

2. Ignitable concentrations of gases or vapors are normally prevented by positive mechanical

ventilation, and which might become hazardous through failure or abnormal operations of

the ventilating equipment.

3. Areas are adjacent to a Class I, Division 1 location, and to which ignitible concentrations of

gases or vapors might be communicated unless such communication is prevented by ade-

quate positive-pressure ventilation from a source of clean air, and effective safeguards are

provided against ventilation failure.

NEC Group

The NEC Group of a hazard is based on specific characteristics of the explosive hazard

present. Different sealing techniques are required depending on the molecular size of the

hazardous materials and other criteria.

Flammable gases and vapors are placed into NEC Groups based on a determination of explo-

sion pressures and maximum safe clearance between parts of a clamped joint under several

conditions. See NEC Article 500–505 for details. The various groups (A, B, C, and D for flam-

mable gases and vapors, E, F, and G for combustible dusts) are described in Article 500 of

the NEC.

The autoignition temperature and the NEC Group of a large number of explosive gases,

vapors, and combustible dusts can be found in Article 500 of the NEC; also see Appendix F:

Hazardous Gases and Vapors.

The temperature identification number (often called T-rating) is based on the maximum oper-

ating temperature of the equipment.

FROM NEC ARTICLE 500

*Marking. Approved equipment shall be marked to show the class, group, and operating

temperature or temperature range referenced to a 40°C ambient. The temperature range, if

provided, shall be indicated in identification numbers, as shown in Table 500.8(B).

Temperature identification numbers marked on equipment nameplates (often called T-rating)

shall be in accordance with Table 500.8(B).

2 of 4 Tyco Thermal Controls www.tycothermal.com (800) 545-6258 H56895 8/03

Appendix E: Classification of Hazardous Locations

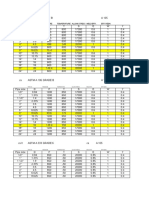

Table E.3 Table 500.8 (B). Identification Numbers

Maximum temperature

°F °C Identification number (T-rating)

842 450 T1

572 300 T2

536 280 T2A

500 260 T2B

446 230 T2C

419 215 T2D

392 200 T3

356 180 T3A

329 165 T3B

320 160 T3C

275 135 T4

248 120 T4A

212 100 T5

185 85 T6

For equipment to be used in a hazardous (classified) area, the equipment should be approved

for both the class and division of the hazardous area and approved for the NEC Group of the

hazard(s) present in the area. Also, the identification number of the equipment must be less

than both the autoignition temperature of the hazard(s) present in the area and less than the

maximum allowed in the area. (See NEC Article 500 reference Division 1 locations. Also, see

NEC article 500.8(B), Exceptions 1–5, for exceptions to this rule.)

EXAMPLES

Acetaldehyde can be found in Table 2-1 of the NPFA 497-1997. The data for Acetaldehyde

and numerous other fluids can also be found in Appendix F: Hazardous Gases and Vapors. The

NEC Group is Group C and the AIT (autoignition temperature) is 175°C. BTV-CR/CT, QTVR-

CT, AND XTV-CT all have approvals for Class I, Division 2, NEC Group C. BTV-CR/CT (85°C)

and QTVR-CT (135°C) have identification numbers (T-ratings) below 175°C (and below 80%

of 175°C for CID1). Therefore, when used with the proper components, BTV-CR/CT or QTV-

CT can be used in a Class I, Division 2 area where acetaldehyde may be present. The identifi-

cation numbers for various XTV-CT products range from T3 to T2C, which is from 200°C to

230°C. Since these are all above the AIT of acetaldehyde (175°C), they should not be used in

a hazardous area where acetaldehyde may be present in explosive quantities.

Benzene can be found in Table 2-1 of the NPFA 497-1997 or Appendix F: Hazardous Gases and

Vapors. The NEC Group is Group D and the AIT is 498°C. Since BTV-CR/CT, QTVR-CT, and

XTV-CT all have approvals for Class I, Division 2, NEC Group D and have temperature identi-

fication numbers well below 498°C, they can be used in a Division 2 area where benzene

might be present. These standard products do not have approvals for Class I, Division 1

areas.

ZONES

The IEC (International Electrical Commission) uses the “zone” system for classifying loca-

tions where fire or explosion hazards may exist due to flammable gases, vapors, or liquids.

The NEC adopted this approach in 1996 and expanded it in 1999 as an alternate to the Class

and Division method previously discussed. It should be noted that the zone classification

covers only flammable gases and vapors (Class I); it does not cover combustible dusts,

fibers, or flyings (Classes II and III). Details on the use of the zone classification system as

an alternative to the division classification system can be found in Article 505 of the NEC.

H56895 8/03 (800) 545-6258 www.tycothermal.com Tyco Thermal Controls 3 of 4

Appendix E: Classification of Hazardous Locations

Division Division 1 Division 2 Nonhazardous

System

Zone Zone 1 Zone 2 Nonhazardous

System

Zone 0 Differences between Divisions and Zones

Zone 2 is equivalent to Division 2. Division 1 is split between Zone 1 and Zone 0. Note that

heating cables can never be placed in Zone 0 areas.

The use of the zone system requires that:

a. Supervision of Work. Classification of areas and selection of equipment and wiring

methods shall be under the supervision of a qualified Registered Professional Engineer.

b. Dual Classification. In instances of areas within the same facility classified separately,

Class I, Zone 2, locations shall be permitted to abut, but not overlap, Class I, Division 2

locations. Class I, Zone 0 or Zone 1 locations shall not abut Class I, Division 1 or Division

2 locations.

c. Reclassification Permitted. A Class I, Division 1 or Division 2 location shall be permitted

to be reclassified as a Class I, Zone 0, Zone 1, or Zone 2 location provided all of the space

that is classified because of a single flammable gas or vapor source is reclassified under

the requirements of this article.

(Extracted from NEC 2002, Section 505.7 (C))

Therefore, the zone system approach will be most useful in new construction and significant

upgrades.

4 of 4 Tyco Thermal Controls www.tycothermal.com (800) 545-6258 H56895 8/03

You might also like

- Corrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurDocument3 pagesCorrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurEddie TaiNo ratings yet

- Ballast TK HempelsDocument15 pagesBallast TK HempelsGeorgios PapakostasNo ratings yet

- PFP's Price Escalation Proposal - R.4 - SubmitDocument4 pagesPFP's Price Escalation Proposal - R.4 - SubmitMj Edin100% (1)

- Jotachar JF750 Product Presentation V2 (NXPowerLite)Document32 pagesJotachar JF750 Product Presentation V2 (NXPowerLite)Nurmalinda SihombingNo ratings yet

- Oisd RP 233Document66 pagesOisd RP 233Arunashish MazumdarNo ratings yet

- 2021-02-09 Approved Coating Systems Letter To Jotun (Signed MHH) - R1Document7 pages2021-02-09 Approved Coating Systems Letter To Jotun (Signed MHH) - R1Mohd Effiezool Yaser100% (1)

- PSBR 1 TemplateDocument2 pagesPSBR 1 TemplatesathishNo ratings yet

- Cafco Fendolite Mii Application Guidelines PDFDocument23 pagesCafco Fendolite Mii Application Guidelines PDFTanmay GorNo ratings yet

- Quotation Swiss Oman 212 Sohar Refinery UNISCODocument1 pageQuotation Swiss Oman 212 Sohar Refinery UNISCODkPrinceNo ratings yet

- Finishing Materials & Cladding: Industrial InsulationDocument19 pagesFinishing Materials & Cladding: Industrial InsulationTariq Latif SaeedNo ratings yet

- Structural Steel Fireproofing Specification SummaryDocument15 pagesStructural Steel Fireproofing Specification SummaryArshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- FIRETEX Passive Fire Protection Brochure PDFDocument6 pagesFIRETEX Passive Fire Protection Brochure PDFPop Andrei IonutNo ratings yet

- Is Your Temporary Refuge Truly SafeDocument10 pagesIs Your Temporary Refuge Truly Safedutru2003No ratings yet

- Engineering Corrosion Protection at Hub Power Station: Tariq Aziz Nace Level 2Document50 pagesEngineering Corrosion Protection at Hub Power Station: Tariq Aziz Nace Level 2Hasan AhmedNo ratings yet

- MODU Part 4 E-Apr17 PDFDocument180 pagesMODU Part 4 E-Apr17 PDFValentina AntohiNo ratings yet

- Dep 37.81.21.34-Gen-Feb-2017 Thermal-Sprayed Ceramic Coating RequirementsDocument22 pagesDep 37.81.21.34-Gen-Feb-2017 Thermal-Sprayed Ceramic Coating RequirementsDevam Raj100% (1)

- S-006 NorsokDocument28 pagesS-006 NorsokYesid Diaz CastroNo ratings yet

- Long-lasting tank coatingsDocument6 pagesLong-lasting tank coatingsjinyuan74No ratings yet

- Fire ProtectionDocument14 pagesFire ProtectionTeguh SetionoNo ratings yet

- Corrosion Protection MeasuresDocument17 pagesCorrosion Protection MeasuresIliyanPetrov100% (1)

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocument6 pagesCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnNo ratings yet

- DNV RP-G101 - 2010Document74 pagesDNV RP-G101 - 2010Mohammad TaherNo ratings yet

- Depressurization WebinarDocument15 pagesDepressurization WebinarMuhammad.SaimNo ratings yet

- Chartek 1709Document4 pagesChartek 1709devangmajithiaNo ratings yet

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 pagesIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaNo ratings yet

- Glass Flake Coatings PDFDocument4 pagesGlass Flake Coatings PDFDinesh ChouguleNo ratings yet

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- COM SU 5191 C February 2017Document91 pagesCOM SU 5191 C February 2017suriya100% (1)

- SP-1246 Part-5Document27 pagesSP-1246 Part-5Rajkumar A50% (2)

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Satip N 110 01Document11 pagesSatip N 110 01jerinNo ratings yet

- Lupranate® T80 Toluene DiisocyanateDocument3 pagesLupranate® T80 Toluene DiisocyanateEnio Miguel Cano LimaNo ratings yet

- Chevron Egypt Lubricants Hazardous Area Classification GuideDocument3 pagesChevron Egypt Lubricants Hazardous Area Classification GuideshujjatNo ratings yet

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Progress in Organic Coating-PaperDocument22 pagesProgress in Organic Coating-Paperjibin k p100% (1)

- Jetfire Darmatt LFTDocument4 pagesJetfire Darmatt LFTHyeong-Ho KimNo ratings yet

- Elastopipe A Flexible Piping SystemDocument2 pagesElastopipe A Flexible Piping SystemRuano StumpfNo ratings yet

- 09 Samss 021Document8 pages09 Samss 021Kalanithi KasirajanNo ratings yet

- ROCKWOOL RockTech B (Blanket) Series LR PDFDocument2 pagesROCKWOOL RockTech B (Blanket) Series LR PDFWasawat JoongjaiNo ratings yet

- CEILCOTE 505 Coroline.Document2 pagesCEILCOTE 505 Coroline.stuart3962No ratings yet

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikNo ratings yet

- C892Document5 pagesC892dinhtung2210No ratings yet

- CUI Risk Factors on Insulated PipingDocument21 pagesCUI Risk Factors on Insulated PipingRenan Soares KieferNo ratings yet

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainNo ratings yet

- Research Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsDocument18 pagesResearch Progress in Organic Zinc Rich Primer Coatings For Cathodic Protection of MetalsJorge Suarez100% (1)

- eBroc-FRP Custom Cooling Towers, YWCTDocument28 pageseBroc-FRP Custom Cooling Towers, YWCTJurizal Julian Luthan100% (1)

- ChemicalDocument5 pagesChemicalisaac2408No ratings yet

- ESD Flooring Audit ReportDocument11 pagesESD Flooring Audit Reportlaiju cs100% (1)

- Lifecycle Assessment of Paint PDFDocument8 pagesLifecycle Assessment of Paint PDFRiz Jomaica Arenas100% (1)

- Tanks and Hold Corrosion Prevention DNVDocument9 pagesTanks and Hold Corrosion Prevention DNVblakasNo ratings yet

- 6.EER Analysis ExternalDocument8 pages6.EER Analysis ExternalkavehNo ratings yet

- NR 15 - Unhealthy Activities and Operations PDFDocument96 pagesNR 15 - Unhealthy Activities and Operations PDFpNo ratings yet

- Electrical Area ClassificationDocument10 pagesElectrical Area Classificationlisaparker45No ratings yet

- Hazardous Area Classification & Intrinsic SafetyDocument35 pagesHazardous Area Classification & Intrinsic SafetyMukesh C ChavanNo ratings yet

- Practical Guidelines For CTG Power PlantsDocument11 pagesPractical Guidelines For CTG Power Plantsandrei12320003181No ratings yet

- Hazardous Location LightingDocument4 pagesHazardous Location LightingwahyuNo ratings yet

- Hazardous Area Classification - Hazardous Locations - Quick Tips #124 - Grainger Industrial SupplyDocument4 pagesHazardous Area Classification - Hazardous Locations - Quick Tips #124 - Grainger Industrial Supplyoctavinavarro8236No ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNo ratings yet

- Lubricant Msds List PDF FreeDocument10 pagesLubricant Msds List PDF FreeAyoubNo ratings yet

- AERO3261 Turbojet: Ass. Prof Dries VerstraeteDocument25 pagesAERO3261 Turbojet: Ass. Prof Dries VerstraeteTuan HoangNo ratings yet

- API Data SheetsDocument7 pagesAPI Data SheetsalfruizpNo ratings yet

- (7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFDocument9 pages(7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFMohamed Wayrah100% (1)

- Case Studies in Thermal Engineering: Kasuba Sainath, T. Kishen Kumar Reddy, Suresh AkellaDocument8 pagesCase Studies in Thermal Engineering: Kasuba Sainath, T. Kishen Kumar Reddy, Suresh AkellaEr Chintan PatelNo ratings yet

- Wash Column - E1172-U81-PS-DS-101408 - B PDFDocument13 pagesWash Column - E1172-U81-PS-DS-101408 - B PDFrutujaNo ratings yet

- 3MS Course NotesDocument84 pages3MS Course NotesJimmy WuNo ratings yet

- Haber Process Questions With AnswersDocument2 pagesHaber Process Questions With AnswersAradhana SivaramanNo ratings yet

- Tugas PPT Chapter 5Document24 pagesTugas PPT Chapter 5lilikNo ratings yet

- HAZIDDocument19 pagesHAZIDRogelio Lazo ArjonaNo ratings yet

- HaldiaDocument33 pagesHaldiaBarunMondalNo ratings yet

- External Flows: Dye StreakDocument8 pagesExternal Flows: Dye StreakClementz WSNo ratings yet

- Wk1-Instruction Manual HB 024 Osborne Reynolds Apparatus (Autosaved)Document37 pagesWk1-Instruction Manual HB 024 Osborne Reynolds Apparatus (Autosaved)iantapia1998No ratings yet

- Design & Flow Analysis of a Convergent-Divergent NozzleDocument43 pagesDesign & Flow Analysis of a Convergent-Divergent NozzleNainan TrivediNo ratings yet

- 4 Design Calculation ASME AD2000 - WeberDocument19 pages4 Design Calculation ASME AD2000 - WeberguslohNo ratings yet

- Tu-100 Basic Refrigeration TrainerDocument1 pageTu-100 Basic Refrigeration TrainerFamela GadNo ratings yet

- Calibrating Pressure Measurement EquipmentDocument6 pagesCalibrating Pressure Measurement EquipmentAbdul AliffNo ratings yet

- Astm D3612 2009 PDFDocument22 pagesAstm D3612 2009 PDFAndressaEmyNo ratings yet

- ASTM Pipe Material Specifications ChartDocument14 pagesASTM Pipe Material Specifications ChartKim JungdaeNo ratings yet

- Multiple Valve Sizing: Example #1Document2 pagesMultiple Valve Sizing: Example #1Susheel WankhedeNo ratings yet

- VentilationDocument9 pagesVentilationSangeet PunNo ratings yet

- Exercise Set 2newDocument16 pagesExercise Set 2newNurye NigusNo ratings yet

- 18ME54 Turbo Machines Module 01 Question No 1a & 1bDocument20 pages18ME54 Turbo Machines Module 01 Question No 1a & 1bThanmay JS100% (1)

- 배관 weight 계산기Document37 pages배관 weight 계산기심판자No ratings yet

- GE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemDocument46 pagesGE Oil & Gas Aeroderivative Gas Turbine: Emission Reduction Techniques DLE1.0 SystemJuan Manuel100% (2)

- Lecture 1 Aerodynamic VariablesDocument19 pagesLecture 1 Aerodynamic VariablessaintanddevilNo ratings yet

- Group 2 Main Circuit: 1. Suction and Delivery CircuitDocument3 pagesGroup 2 Main Circuit: 1. Suction and Delivery CircuitĐạt VươngNo ratings yet

- Refrigeration Screw Compressors and Chilling Units PDFDocument8 pagesRefrigeration Screw Compressors and Chilling Units PDFAmandeep singhNo ratings yet