Professional Documents

Culture Documents

3.TRANSUNGUAL DRUG DELIVERY SYSTEM - Article PDF

Uploaded by

iajpsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.TRANSUNGUAL DRUG DELIVERY SYSTEM - Article PDF

Uploaded by

iajpsCopyright:

Available Formats

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

CODEN (USA): IAJPBB

ISSN 2349-7750

ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

Available online at: http://www.iajps.com

Research Article

FORMULATION AND EVALUATION OF NAIL LACQUER

CONTAINING TIOCONAZOLE FOR TRANSUNGUAL DRUG

DELIVERY SYSTEM

Deepak Singh Bisht*1, Ganesh Kumar Bhatt2, Preeti Kothiyal3

Division of Pharmaceutical Sciences, Shri Guru Ram Rai Institute of Technology,

Uttarakhand Technical University, Dehradun (Uttarakhand), India.

Abstract:

In this present work, a medicated antifungal nail lacquer of tioconazole had been developed. The main objective of

nail lacquer formulation was to provide a sustained release of medicament over extended period of time and reduce

the frequency of administration by improving patient compliance. Topical delivery of nail diseases is limited by the

poor permeability nail plate. Only few permeation enhancers are used to enhance the permeation, such as

thioglycolic acid and urea hydrogen peroxide act by reducing the disulphide bonds in nail plate. In- vitro

permeation studies were carried out across human nail plate by Franz diffusion cell using phosphate buffer pH 7.4

as medium. The percentage cumulative drug released was determined by UV spectrophotometer. FTIR studies

revealed that drug and all excipients are compatible. The % drug permeated at 8hr through the nail was 64.93for

tioconazole with thioglycolic acid and urea H2O2 respectively. As can be seen, significantly higher permeation was

achieved in the presence of thioglycolic acid. Topical delivery of nail diseases is limited by the poor permeability of

the nail plate but few ungula enhancers increase the nail permeability of topically applied tioconazole drug by

reducing the disulphide bonds in nail plate, such as thioglycolic acid and urea hydrogen peroxide.

Key words: Nail lacquer, Tioconazole, Thioglycolic acid.

Corresponding author

QR code

Deepak Singh Bisht,

Shri Guru Ram Rai institute of Technology and Sciences,

Patel Nagar Dehradun

E mail- deepak.bisht41@rediffmail.com

Please cite this article in press as Deepak Singh Bisht et al , Formulation and Evaluation of Nail Lacquer

Containing Tioconazole for Transungual Drug Delivery System, Indo Am. J. Pharm. Sci, 2015;2(11).

www.iajps.com

Page 1474

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

INTRODUCTION:

The major constrains of the preungual drug delivery

(drug delivery through the nail) to nail is lack of

understanding about barrier property related to the

nail and formulations. Topical drug delivery system

owes many advantages in case of anti fungal drugs

such as it avoids hepatotoxicity, high tissue

concentration which is required for the treatment of

fungal infection of nails. Most of topical formulations

in form of gels, lotions etc pose limitations such as

removal by whipping, rubbing and less adherence of

formulation to the affected site of nail [1].

Conventional nail lacquers are mostly used mainly

for the cosmetic purpose. Nail drug delivery can be

made as effective route for the treatment of fungal

infections of nails. Human nail is a complex

structure. It protects the nail bed and the parts which

are under the nail plate filled with blood vessels.

Medicated nail lacquer is an excellent alternative for

the treatment of fungal infection of nails and high

efficacy of drug can be achieved. It also provides a

optimized and sustained release of drug by formation

of an occlusive film which acts as depot after the

application of lacquer on the nail [2].

Tioconazole is a broad spectrum anti fungal drug. It

is a triazoles derivative, its chemical formula is 1-[2[(2-Chloro-3-thienyl)

methoxyl]-2-(2,4dichlorophenyl)ethyl]-1H-imidazole.

The present work investigated the amount of

Tioconazole released from different formulations

containing different concentration of Thioglycolic

acid and different proportions of Thioglycolic

acid and urea solution in H2O2 for treatment of

onychomycosis. The best formulation was evaluated

for anti fungal sensitivity test against the Candida

albicans. Kinetics release studies as well as stability

studies were carried out on the best formulation for

evaluation of kinetic model

for release of drug through the formulation and to

check the stability of formulation.

MATERIALS AND METHODS:

Tioconazole and Thioglycolic acid was obtained as a

gift sample from Themis medicare Pvt. Ltd.

Haridwar, India. Propylene glycol, Glycerine,

Ethanol, Ethyl cellulose, Urea and Hydrogen

peroxide was purchased from Central drug house Pvt.

Ltd. Delhi (IND).

Tioconazole nail lacquer was prepared by simple

mixing method. Wherein the Tioconazole

concentration (1g) was kept constant. 4 formulations

were prepared and given in Table 1. Formulations F1,

F2, F3, F4 contained 1% of propylene glycol,ethanol,

www.iajps.com

ISSN 2349-7750

glycerine along with the different concentrations of

Ethyl cellulose, Thioglycolic acid and Urea solution.

Preformulation Studies [6,7,8]:

Preformulation:

Testing is the first step in the rational development

of dosage form of a drug. It can be defined as the

investigation of physical and chemical properties if

drug substances alone or in combination with

excipients. The overall objective of preformulation

studies is to generate information useful to formulator

in developing stable and bioavaliable dosage form

which can be mass produced.

Melting Point

The sample was loaded in to sealed capillary (melting

point capillary) which was then placed in melting

point apparatus. The sample was then heated and as

the temperature increase the sample was observed to

detect the phase change from solid to liquid phase.

The temperature at which the phase changes occur

gives the melting point.

Preparation of Calibration Curve of Tioconazole

A stock solution of 10g of tioconazole was prepared

in methanol and scanned by UV spectrophotometer

(200-400nm) for the determination of max of

tioconazole. For selection of media the criteria

employed were sensitivity, ease of sample

preparations, solubility of drug and cost of solvents

and applicability of method to various purposes. An

UV spectroscopic scanning run (200-400nm) was

carried out to select the best UV wavelength for

detection of tioconazole in methanol. The analysis

was carried out using Distilled water as blank.

Absorbance of tioconazole was determined.

Calibration Curve of Tioconazole:

Accurately weight 50 mg of drug was dissolved in 50

ml of methanol and thus 1000 mcg solution was

prepared now from this different dilutions were made

and different concentrations were prepared in the

range of 1-25 mcg/ml of tioconazole in methanol for

standard curve.

Drug - Excipient Compatibility Study:

The objective of this investigation was to identify a

stable storage condition for drug in solid state and

identification of compatible excipients for its

information. This can be confirmed by carrying out

by infrared light absorption scanning spectroscopy

studies (IR).Drug and polymer was mixed in the

equal ratio and finally grounded and intimately mixed

with approximately 100 mg of dry potassium

bromide powder. Grinding and mixing can be done

with mortar and pestle. The mixture is then pressed

into a transparent disk in an evacuable die at

sufficiently high pressure. Suitable KBr disks or

pellets can often be made using a simpler device such

as a hydraulic press. The base line correction was

done using dried KBr. Then, the spectrum of dried

Page 1475

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

mixture of drug and potassium bromide was scanned

from 2000cm-1 to 400 cm -1.

Evaluation of Nail Lacquer [3]:

Nonvolatile Content:

1gm of sample was taken in a glass Petri dish of

about 8cm in diameter. Samples were spread evenly

with the help of tared wire.

Drying Time:

A film of sample was applied on a glass Petri dish

with the help of brush. The time to form a

drytotouch film was noted using a stopwatch.

Smoothness of Flow:

The sample was poured to approximately 1.5 inches

and easily spread on a glass plate and made to rise

vertically.

Gloss:

Gloss of the film was visually seen, comparing it

with a standard marketed nail lacquer formulation.

Water Resistance:

This is the measure of the resistance towards water

permeability of the film. This was done by applying a

continuous film on a surface and immersing it in

water. The weight before and after immersion was

noted and increase in weight was calculated. Higher

the increase in weight lowers the water resistance

In vitro Transungual Permeation Studies:

Hooves from freshly slaughtered cattle, free of

adhering connective and cartilaginous tissue, were

soaked in distilled water for 24 h. Membranes of

about 1mm thickness were then cut from the distal

part of hooves. In vitro permeation studies were

carried out by using Franz diffusion cell, the hoof

membrane was placed carefully on the cell, and the

surface area available for permeation was 1.23 cm.

Then the test vehicle equivalent to 200 g was

applied evenly on the surface of the nail membrane.

The receptor compartment was filled with solvent

(phosphate buffer, pH 7.4; and methanol, in the ratio

of 4:1), and the whole assembly was maintained at

37C with constant stirring (600rpm) for 12 h. The 5

ml aliquot of drug sample was taken after a time

interval of 1h and was replaced by the fresh solvent.

Each experiment was replicated at least thrice. The

drug analysis was done by using single-beam UV

spectrophotometer.

Stability Studies:

According to ICH guidelines at 40 2C/75 5%

RH sample was stored in stability chamber for one

month. The sample was evaluated for non volatile

content, drying time, gloss, and smoothness of flow,

water resistance and diffusion across artificial

membrane.

Kinetic Release Studies [4,5] :

The in- vitro release data were analysed by zero

order, first order, Higuchi and Kosmeyers and Peppas

equations.

Zero Order Release Kinetic: To study the zero

order release kinetics the release data was fitted into

the following equation.

dQ/dt = Ko

Where Q is the amount of drug release, Ko is the

zero order release rate constant andt is the release

time. The graph is plotted percentage cumulative

drug release (%CDR) verses time.

First Order Release Kinetic: To study the first

order release kinetics the release rate data are fitted

into the following equation.

dQ/dt = K1 Q

Where, Q is the fraction of drug release, K1 is the

first order release rate constant andt is the release

time. The graph is plotted log %CDR remaining

verses time.

Higuchi Release Model: To study the Higuchi

release model the release rate data are fitted into the

following equation.

Q = KH t 1/2

Where, Q is the fraction of drug release, KH is the

release rate constant and t is the release time. The

graph plotted % CDR verses square root of time.

Kosmeyers and Peppas Kinetics: To study

Kosmeyers and Peppas release kinetics the release

rate data are fitted into following equation:

Mt/M = KKP tn Where, Mt/M is the fraction of

drug release, KKP is the release rate constant and

t is the release time and n is the diffusion

exponent related to mechanism of drug release. The

graph is plotted log %CDR verses time.

Formulation of Nail lacquer:

Preparation of Master formula.

Table 1: Formulation Plan for Tioconazole Nail Lacquer

Ingredients

F1

F2

F3

1g

1g

1g

Tioconazole(g)

2g

2g

1g

Ethyl cellulose(g)

1 ml

1 ml

1 ml

Propylene glycol(ml)

1 ml

1 ml

1 ml

Glycerine(ml)

100 ml

100 ml

100 ml

Ethanol(ml)

1 ml

2 ml

3 ml

Thioglycolic acid(ml)

1 ml

2 ml

3 ml

Urea Solution (1 gm in 1 m H2O2 (ml)

F1- F2 = low viscosity and low permeability. F3-F4 = high permeability with average viscosity.

www.iajps.com

ISSN 2349-7750

F4

1g

1g

1 ml

1 ml

100 ml

4 ml

4 ml

Page 1476

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

Preparation of Nail lacquer by Simple Mixing

Method

Tioconazole nail lacquer (1% nail lacquer) was

prepared by simple mixing method. Tioconazole

concentration (1gm) was kept constant. 4

formulations were prepared F1, F2, F3, and F4

contained 1- 2% w/v of ethyl cellulose and 1 ml of

glycerine along with the different concentrations of

Thioglycolic acid.

Preformulation Studies

ISSN 2349-7750

RESULTS AND DISCUSSION:

Four formulations of Tioconazole were formulated

using different drug polymer ratios. The formulation

is subjected to evaluation parameters like drug

content, non- volatile content, drying time,

smoothness of flow, gloss, water resistance, in- vitro

permeation studies,stability, kinetic release studies.

Identification of Drug by FTIR:

19

18

16

14

471.06cm-1

844.01cm-1

592.53cm-1

1725.25cm-1

12

890.10cm-1

%T

1795.90cm-1

10

1974.69cm-1

1936.95cm-1

1296.99cm-1

1348.80cm-1

1686.23cm-1

1704.33cm-1

1778.52cm-1

1658.33cm-1

1185.08cm-1

970.80cm-1

924.62cm-1

905.27cm-1

715.23cm-1

548.05cm-1

5 1 6 . 5 2 c m

1552.17cm-1

1627.79cm-1

1372.95cm-1

1 2 0 9 .1 8 c m -1

1085.99cm-1

1389.19cm-1

1067.05cm-1

1338.24cm-1

1107.29cm-1

1466.55cm-1

1076.31cm-1

1220.46cm-1

1422.16cm-1

1229.71cm-1 1120.02cm-1 993.96cm-1

1098.40cm-1

1434.64cm-1

1252.47cm-1

1137.88cm-1 1022.49cm-1

1279.84cm-1

1503.04cm-1

1588.89cm-1

1562.43cm-1

4

2

1

2000

1800

1600

1400

1200

- 1

430.74cm-1

455.77cm-1

875.43cm-1

858.87cm-1

5 6 4 . 1 6 c m

- 1

691.74cm-1

828.50cm-1

627.89cm-1

814.56cm-1

735.98cm-1

784.98cm-1

658.81cm-1

1000

800

600

400

cm-1

Name

Tioconazole_001

Description

Sample 000 By Administrator Date Wednesday, April 29 2015

Fig 1: FTIR Spectrum of Tioconazole

Fig 2: FTIR Spectrum of Tioconazole (with reference B.P. 2010).

www.iajps.com

Page 1477

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

ISSN 2349-7750

Table 2: Characteristics Peaks of Tioconazole

S.No.

Reference peaks (cm-1)

Obtained peaks (cm-1)

Functional Group

Stretching/Bending

1.

1675-1600

1627.79

C=C(Alkenes)

Stretching

2.

1470-1430

1466.55

C-H

Deformation

3.

1335-1250

1279.84

C-N

Stretching

4.

1450-1400

1434.64

C=C

Stretching

5.

800-600

627.89

C-Cl

Stretching

The comparison between the peaks of two graphs

Organoleptic Characteristics:

shows that the characteristics peaks of tioconazole

The colour, order and taste of the drug were

(taken from B.P.) was found to be similar to the

characterized and recorded using descriptive

given drug sample, which shows that the drug is

terminology, the results are shown in Table No. :3.

Tioconazole.

Table 3: Results of Organoleptic Properties

S.No.

Properties

Results

1.

Description

Solid

2.

Colour

White to off white

3.

Odour

Odourless

4.

Taste

Tasteless

Solubility:

Tioconazole is soluble in ethyl acetate, chloroform and very soluble in methanol, ethanol as shown in Table No : 4.

Table 4: Results of Solubility Studies

S.No.

Solvent

Solubility

Solubility(mg/ml)

1.

Water

Very slightly soluble

0.2

2.

Methanol

Soluble

48

3.

Ethanol

Soluble

42

4.

Chloroform

Soluble

22

5.

Ethyl acetate

Soluble

28

www.iajps.com

Page 1478

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

ISSN 2349-7750

Melting point determination:

The melting point of tioconazole was found to be 168-170 C. This value is same as that of the literature citation

170-172 C.

Table 5: Results of Melting Point Determination

Observed melting point

168-170C

170-172C

Reported melting point

Partition Coefficient Determination:

The partition coefficient of drug was found to be 5.121.

Spectral Studies

Drug- Excipient Compatibility Study:

19

18

16

14

471.06cm-1

844.01cm-1

592.53cm-1

1725.25cm-1

12

890.10cm-1

%T

1795.90cm-1

10

1974.69cm-1

1936.95cm-1

1296.99cm-1

1348.80cm-1

1686.23cm-1

1704.33cm-1

1778.52cm-1

1658.33cm-1

970.80cm-1

924.62cm-1

1185.08cm-1

905.27cm-1

715.23cm-1

548.05cm-1

5

1552.17cm-1

1627.79cm-1

1588.89cm-1

1562.43cm-1

1372.95cm-1

1

2000

1422.16cm-1

1434.64cm-1

1503.04cm-1

1800

1600

1 2 0 9 .1 8 c m

- 1

1389.19cm-1

1338.24cm-1

1466.55cm-1

. 5

c m

- 1

430.74cm-1

455.77cm-1

875.43cm-1

1085.99cm-1

1067.05cm-1

1107.29cm-1

1076.31cm-1

1220.46cm-1

993.96cm-1

1229.71cm-1 1120.02cm-1

1098.40cm-1

1252.47cm-1

1137.88cm-1 1022.49cm-1

1279.84cm-1

1400

1200

858.87cm-1

. 1

c m

- 1

691.74cm-1

828.50cm-1

627.89cm-1

814.56cm-1

735.98cm-1

784.98cm-1

658.81cm-1

1000

800

600

400

cm-1

Name

Tioconazole_001

Description

Sample 000 By Administrator Date Wednesday, April 29 2015

Fig 3: FTIR Spectrum of Tioconazole

54

52

50

48

815.22cm-1

736.42cm-1

828.75cm-1

46

881.09cm-1

919.67cm-1

%T

44

659.74cm-1

42

564.99cm-1

40

38

1280.49cm-1

36

1444.44cm-1

1376.47cm-1

34

32

1120.12cm-1

1637.94cm-1

30

2000

1098.99cm-1

1800

1600

1400

1200

1000

800

600

400

cm-1

Name

Ethyl cellulose_003

Description

Sample 008 By Administrator Date Wednesday, April 29 2015

Fig 4: FTIR Spectrum of Ethyl cellulose (Polymer)

www.iajps.com

Page 1479

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

ISSN 2349-7750

27

26

24

22

471.14cm-1

20

844.06cm-1

18

592.54cm-1

889.95cm-1

%T

16

1795.70cm-1

14

12

10

1936.86cm-1

430.87cm-1

1297.01cm-1

1686.33cm-1

1778.26cm-1

1704.25cm-1

1657.75cm-1

924.52cm-1

970.84cm-1

905.39cm-1

1185.00cm-1

1588.88cm-1

1562.33cm-1

2

1

2000

1800

1600

- 1

- 1

875.54cm-1

1422.05cm-1

1209.07cm-1

1076.31cm-1

627.87cm-1

691.74cm-1

5 6 4 . 1 9 c m

1137.91cm-1 1030.49cm-1

1338.17cm-1

1107.25cm-1

1389.11cm-1 1279.83cm-1

1503.02cm-1 1372.89cm-1 1252.41cm-1 1119.91cm-1 993.94cm-1

1434.63cm-1

1229.70cm-1 1098.29cm-1

1220.46cm-1

1466.51cm-1

1022.39cm-1

5 1 6 . 6 3 c m

548.11cm-1

4 5 5 .8 8 c m

1552.15cm-1

1627.62cm-1

715.20cm-1

1400

1200

- 1

858.88cm-1

828.48cm-1

735.90cm-1

784.99cm-1 658.82cm-1

814.46cm-1

1000

800

600

400

cm-1

Name

Description

Drug + E.C Sample 009 By Administrator Date Wednesday, April 29 2015

Fig 5: FTIR of Tioconazole + Ethyl cellulose (Polymer)

Table 6: Characteristics Peaks of Tioconazole and Ethyl Cellulose Physical Mixture.

S.No.

Peaks(cm-1) of drug

Peaks(cm-1) of drug +

Functional Group

Stretching/Bending

Ethyl cellulose

1.

1627.79

1627.62

C=C(Alkenes)

Stretching

2.

1466.55

1466.51

C-H

Deformation

3.

1279.84

1279.83

C-N

Stretching

4.

1434.64

1434.63

C=C

Stretching

5.

627.89

627.63

C-Cl

Stretching

The drug-polymer interactions shows that there was

no major shifts in the absorption bands(peaks) of in

presence of polymer and it was observed that all the

characteristics peaks of drug is present in the

combination of drug and polymer spectra indicating

the compatibility of drug with the polymer used.

Preparation of Calibration Curve of Tioconazole

Determination of max of Tioconazole:

UV absorption spectrum showed max to be 240nm.

The graph of absorbance v/s concentration for

www.iajps.com

tioconazole was found to be linear in the

concentration range of

1-25 mcg/ml at 240

nm.Hence, the drug obeys Lambert -beers law in this

range. Fig. 6 shows UV spectrum of Tioconazole and

Fig. 7 shows the calibration curve of tioconazole in

methanol.

The calibration curve was prepared and results were

shown in Table 7..

Page 1480

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

S.No.

ISSN 2349-7750

Fig 6: UV Spectrum of Tioconazole

Wavelength of maximum absorption (max) in methanol was found to be 240 nm.

Table 7: Data for calibration Curve of Tioconazole in Methanol

Concentration(mcg/ml)

Absorbance( =240)

1.

2.

3.

4.

5.

6.

0

5

10

15

20

25

0

0.238

0.483

0.644

0.822

0.978

Fig 7: Calibration Curve of Tioconazole.

www.iajps.com

Page 1481

Deepak Singh Bisht et al

IAJPS 2015, 2 (11), 1474-1485

Line of Equation : y = 0.038x + 0.041

Beers Range: 1-25 mcg/ml

R2 Value: 0.990

max : 240 nm

Evaluation of Nail lacquer

Gloss

Gloss of nail lacquer was evaluated by comparing

with the marketed product. It was found to be

satisfactory when compared to the marketed product.

Smoothness of Flow

Smoothness of flow for formulation F1, F2, F3 and

F4 was found to be good as compared to marketed

formulation.

Drying Time

Drying time for formulation F1 to F4 was found

between 64 to 70 secounds. It was found that as the

ISSN 2349-7750

polymer concentration increases the drying time

increases respectively shown in table8.

Non- Volatile Content

The Non- volatile content of different formulation F1

to F4 was calculated and the Non- volatile content

was found to be in range of 20.2 to 20.6. The results

are shown in Table 9.

Water Resistance Test for Nail Lacquer

From the water resistant test, it can be seen that as the

polymer concentration increases the water resistance

increases and the polymer concentration decreases

the water resistance decreases. Formulation F1, F2

showed lower water resistance as compared to F3and

F4 shown table 10..

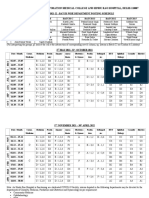

Table 8: Drying Time

S.No.

1.

2.

3.

4.

Formulation

F1

F2

F3

F4

Drying time

64

65

68

70

.

Formulation code

Table 9: Non- Volatile Content of Nail Lacquer

Non- volatile content (%)

F1

20.2 0.15

F2

20.30.05

F3

20.60.25

F4

20.30.05

Formulation code

Table 10: Water Resistance Test for Nail Lacquer

W1(g)

W2(g)

Difference in weight(g)

F1

8.25

8.43

0.18

F2

8.25

8.44

0.19

F3

8.25

8.45

0.20

F4

8.25

8.45

0.20

W1 & W2 are weight of glass slide along with nail lacquer before and after dipping in water respectively.

www.iajps.com

Page 1482

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

In- Vitro Permeation Study:

The in- vitro permeation study on all formulation of

Tioconazole was carried out in Franz diffusion cell

pH 7.4 buffer.The in -vitro drug release of all

ISSN 2349-7750

formulation F1 to F4 are shown in Table. The

cumulative release of drug was determined up to 8

hrs for formulation F1, F2, F3, F4 was 52.48, 53.13,

60.78, 64.93 respectively.

Fig 8 : Zero Order Release Plot of Tioconazole Nail Lacquer

Fig 9 : First Order Release Plot of Tioconazole Nail Lacquer

www.iajps.com

Page 1483

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

ISSN 2349-7750

Fig 10: Higuchi Plot of Tioconazole Nail Lacquer

Fig 11 : Korsmeyer Peppas Plot of Tioconazole Nail Lacquer

Mathematical Modeling:

The data obtained from in- vitro permeation studies

was treated by various conventional mathematical

models (zero order, first order, Higuchi and

Korsmeyer- peppas) to determine the release

mechanism from the designed nail lacquer

formulations. Selection of a suitable release model

www.iajps.com

was based on the values of R2 (correlation

coefficient), k (release constant) obtained from the

curve fitting of release data. In -vitro drug release

data of all four formulations F1 to F4.

The regression coefficient of the all four formulation

F1 to F4 is shown in Table 11. It was found that all

the formulations follows the first order kinetics. The

regression coefficients for the all formulations F1 to

F4 of Higuchi plot was found to be almost linear.

Page 1484

IAJPS 2015, 2 (11), 1474-1485

Deepak Singh Bisht et al

Table 11: Model Fitting Release Profile of Formulation F1 to F4

Formulation code

Zero order

First order

ISSN 2349-7750

Higuchi model

Best fit release

mechanism

F1

0.982

0.990

0.914

First order

F2

0.978

0.986

0.913

First order

F3

0.960

0.974

0.906

First order

F4

0.964

0.981

0.912

First order

CONCLUSION:

FTIR studies revealed that there is no chemical

interaction between the drug and polymer used.

The prepared formulations were subjected to

different evaluation parameters such as drying

time, non volatile content, water resistance,

smoothness of flow, evaluation of gloss, drug

content,, in vitro permeation studies,, drug release

kinetic studies. From the evaluation data it was found

that F4 formulation (4%w/v ethyl cellulose, 4%v/v

Thioglycolic acid, 4% Urea Solution) was best

formulation. It was found that penetration enhancers

concentration increases, percentage drug released

also increases. Drug release kinetics revealed that the

release from formulations was by zero order and

mechanism of release was by Higuchis model. Shortterm stability studies of optimized formulations

indicate that there were no significant changes in the

drying time, drug content and percentage drug release

values after 30 days of storage at 402 C with

755% RH.

5. Bramankar DM, Jaisawal SB: Biopharmaceutics

and pharmacokinetics-A treatise. 2nd edition. 347 48.

6. Simler, R., Walsh, G., Mattaliano, R.J., Guziewicz,

N., and Perez-Ramirez, B. (2008). Maximizing Data

Collection and Analysis During Preformulation of

Biotherapeutic Proteins. BioProcess International vol.

6(10), pp. 38-45.

7. Subramanyam CVS, Text book of physical

Pharmaceutics, thoroughly revised and enlarge;3rd

Edn; Vallabhprakashan, NewDelhi, 124.

8. BioPharm International, Guide to Formulation,

Fill, and Finish, The BioPharm International Guide,

2004.

REFERENCES:

1. Patel RP, Naik SA, Patel NA, Suthar AM: Drug

Delivery across human nail. International Journal Of

Current Pharmaceutical Research 2009; 1(1): 1 7.

2. Sabreen J, Divyakumar B, Kiran B: Preungual

drug delivery systems of terbinfine hydrochloride

nail lacquer. Asian Journal Pharmaceutical 2008;

(2): 53-06.

3. Azharuddhin M, Suresh BH, Shabaraya AS, Prasad

NGZ: Preparation and in vitro evaluation of

Antifungal Nail lacquer. International Journal of

Universal Pharmacy and Bio Sciences July August

2013; 2(4): 78 85.

4. Preethi M, Prathima S, Venkata RR, Sadanandam

M: Formulation and evaluation of Duloxetine

Hydrochloride delayed release enteric coated

capsules: International Journal Of Pharma and Bio

Sci. June September 2011; 2(3): 52 72.

www.iajps.com

Page 1485

You might also like

- Pharmaceutical Sciences: Observation of Metabolism According To The Growth Hormone Control in Mayo Hospital LahoreDocument6 pagesPharmaceutical Sciences: Observation of Metabolism According To The Growth Hormone Control in Mayo Hospital LahoreiajpsNo ratings yet

- 44 Iajps44102020Document4 pages44 Iajps44102020iajpsNo ratings yet

- Pharmaceutical Sciences: Flipping Impacts of Middle School Laboratory in Health School EducationDocument4 pagesPharmaceutical Sciences: Flipping Impacts of Middle School Laboratory in Health School EducationiajpsNo ratings yet

- 50 Iajps50102020Document13 pages50 Iajps50102020iajpsNo ratings yet

- Pharmaceutical Sciences: The Impact of Ox Like Lactoferrin (BLF) On Prevention of The Diarrhoea in YoungstersDocument7 pagesPharmaceutical Sciences: The Impact of Ox Like Lactoferrin (BLF) On Prevention of The Diarrhoea in YoungstersiajpsNo ratings yet

- 42 Iajps42102020Document8 pages42 Iajps42102020iajpsNo ratings yet

- Pharmaceutical Sciences: Management of Proximal Ureteric Stone (10 - 15 MM Size) Via Urs & EswlDocument6 pagesPharmaceutical Sciences: Management of Proximal Ureteric Stone (10 - 15 MM Size) Via Urs & EswliajpsNo ratings yet

- 33 Iajps33102020Document6 pages33 Iajps33102020iajpsNo ratings yet

- Pharmaceutical Sciences: Urinary Sodium and Potassium Discharge and Danger of Hypertension in Pakistani PopulationDocument4 pagesPharmaceutical Sciences: Urinary Sodium and Potassium Discharge and Danger of Hypertension in Pakistani PopulationiajpsNo ratings yet

- Pharmaceutical Sciences: Study To Determine The Pattern of Primary Glomerulonephritis in PakistanDocument5 pagesPharmaceutical Sciences: Study To Determine The Pattern of Primary Glomerulonephritis in PakistaniajpsNo ratings yet

- Pharmaceutical Sciences: A Young Male With Splenic Vein and SMV Thrombosis and Jak 22 MutationDocument12 pagesPharmaceutical Sciences: A Young Male With Splenic Vein and SMV Thrombosis and Jak 22 MutationiajpsNo ratings yet

- Pharmaceutical Sciences: Psychophysiological Features of Students Aerobic Abilities and Maintaining A Healthy LifestyleDocument6 pagesPharmaceutical Sciences: Psychophysiological Features of Students Aerobic Abilities and Maintaining A Healthy LifestyleiajpsNo ratings yet

- 40 Iajps40102020Document4 pages40 Iajps40102020iajpsNo ratings yet

- 37 Iajps37102020Document9 pages37 Iajps37102020iajpsNo ratings yet

- 35 Iajps35102020Document4 pages35 Iajps35102020iajpsNo ratings yet

- 34 Iajps34102020Document7 pages34 Iajps34102020iajpsNo ratings yet

- Pharmaceutical SciencesDocument5 pagesPharmaceutical SciencesiajpsNo ratings yet

- Pharmaceutical Sciences: Teneligliptin Induced Persistent DiarrheaDocument3 pagesPharmaceutical Sciences: Teneligliptin Induced Persistent DiarrheaiajpsNo ratings yet

- Pharmaceutical Sciences: Pharmacotherapeutic Analysis of TuberculosisDocument4 pagesPharmaceutical Sciences: Pharmacotherapeutic Analysis of TuberculosisiajpsNo ratings yet

- Pharmaceutical Sciences: Cognitive Schemes For Clinical Diagnostic Reasoning by Medical StudentsDocument8 pagesPharmaceutical Sciences: Cognitive Schemes For Clinical Diagnostic Reasoning by Medical StudentsiajpsNo ratings yet

- Pharmaceutical Sciences: Frequency of Acute Poisoning Patients Presenting in Holy Family Hospital Medical EmergencyDocument7 pagesPharmaceutical Sciences: Frequency of Acute Poisoning Patients Presenting in Holy Family Hospital Medical EmergencyiajpsNo ratings yet

- Pharmaceutical Sciences: A Cross Sectional Study On Hypoalbuminemia in Cases of Ischemic StrokeDocument5 pagesPharmaceutical Sciences: A Cross Sectional Study On Hypoalbuminemia in Cases of Ischemic StrokeiajpsNo ratings yet

- Pharmaceutical Sciences: A Review On Beta Lactam AntibioticsDocument8 pagesPharmaceutical Sciences: A Review On Beta Lactam AntibioticsiajpsNo ratings yet

- Pharmaceutical Sciences: Massive Inguinal Hernia-A Rare Presentation of Common DiseaseDocument4 pagesPharmaceutical Sciences: Massive Inguinal Hernia-A Rare Presentation of Common DiseaseiajpsNo ratings yet

- Pharmaceutical Sciences: Clinical Manifestations of Sars-Cov-2 (Covid19)Document5 pagesPharmaceutical Sciences: Clinical Manifestations of Sars-Cov-2 (Covid19)iajpsNo ratings yet

- 22 Iajps22102020Document6 pages22 Iajps22102020iajpsNo ratings yet

- Pharmaceutical Sciences: Clinical Features of Enteric Fever in Different Age GroupsDocument4 pagesPharmaceutical Sciences: Clinical Features of Enteric Fever in Different Age GroupsiajpsNo ratings yet

- Pharmaceutical Sciences: Ulat Kambal (Abroma Augusta L.) : Therapeutic Uses and Pharmacological Studies-A ReviewDocument4 pagesPharmaceutical Sciences: Ulat Kambal (Abroma Augusta L.) : Therapeutic Uses and Pharmacological Studies-A ReviewiajpsNo ratings yet

- Pharmaceutical Sciences: Congenital Hypothyroidism Prevalence Diagnosis and Outcome in Saudi ArabiaDocument5 pagesPharmaceutical Sciences: Congenital Hypothyroidism Prevalence Diagnosis and Outcome in Saudi ArabiaiajpsNo ratings yet

- 20 Iajps20102020Document5 pages20 Iajps20102020iajpsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wikipedia Names ClearDocument127 pagesWikipedia Names ClearJassim AlblooshiNo ratings yet

- Leaflet of Bach Therapy PDFDocument2 pagesLeaflet of Bach Therapy PDFPrakash VerekarNo ratings yet

- Research EssasyDocument9 pagesResearch Essasyapi-279881900No ratings yet

- Current & Future Status of Herbal MedicinesDocument4 pagesCurrent & Future Status of Herbal MedicinesimmchrNo ratings yet

- Oculus Biom 5 Ophthalmoscope User ManualDocument36 pagesOculus Biom 5 Ophthalmoscope User ManualRoberto FalconeNo ratings yet

- Efficacy and Adverse Events of Oral Isotretinoin For Acne: A Systematic ReviewDocument10 pagesEfficacy and Adverse Events of Oral Isotretinoin For Acne: A Systematic ReviewFerryGoNo ratings yet

- A Brief Review On Foeniculum Vulgare Mill Highlighting Gastroprotective ActivityDocument2 pagesA Brief Review On Foeniculum Vulgare Mill Highlighting Gastroprotective ActivityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Procedure For Leech TherapyDocument5 pagesProcedure For Leech TherapyAlin LabauNo ratings yet

- Organon of Medicine All Years 2marks Question Viva Questions AnswersDocument12 pagesOrganon of Medicine All Years 2marks Question Viva Questions Answersabcxyz15021999No ratings yet

- Wolny 2018Document10 pagesWolny 2018tri cahyani setyowatiNo ratings yet

- External Preparation PharmacyDocument20 pagesExternal Preparation PharmacyShailendra SkNo ratings yet

- IonnyDocument4 pagesIonnyLu KaNo ratings yet

- 301FA33F464A47F98DD32D9A6CC353FE (1)Document2 pages301FA33F464A47F98DD32D9A6CC353FE (1)Belle LucasNo ratings yet

- Forensic Reports and Testimony: A Guide To Effective CommunicationDocument2 pagesForensic Reports and Testimony: A Guide To Effective CommunicationNorfolk JournalNo ratings yet

- Massive Transfusion ProtocolDocument2 pagesMassive Transfusion ProtocolmukriNo ratings yet

- Drug Education NotesDocument75 pagesDrug Education NotesJoshua D None-NoneNo ratings yet

- FB-08 05 2023+furtherDocument100 pagesFB-08 05 2023+furtherP Eng Suraj Singh100% (1)

- Role, Prospects, and Limitation of HomoeopathyDocument43 pagesRole, Prospects, and Limitation of HomoeopathyDr.bhagyaNo ratings yet

- "Undifferentiated Schizophrenia": A Case Study OnDocument81 pages"Undifferentiated Schizophrenia": A Case Study OnHomework Ping100% (1)

- Doctors Order Form D4Document1 pageDoctors Order Form D4Marielle ChuaNo ratings yet

- Drug Therapy in Pregnancy (Soal)Document6 pagesDrug Therapy in Pregnancy (Soal)Yola FebriyantiNo ratings yet

- 2010 - 2016 With AnswersDocument806 pages2010 - 2016 With AnswersIbrahim Abueltaif83% (6)

- Demystifying The Diagnosis and Classification of Lymphoma - Gabriel C. Caponetti, Adam BaggDocument6 pagesDemystifying The Diagnosis and Classification of Lymphoma - Gabriel C. Caponetti, Adam BaggEddie CaptainNo ratings yet

- Occupational Hazards in Health Care ProfessionalsDocument33 pagesOccupational Hazards in Health Care Professionalsdocshirin100% (1)

- DewormingDocument48 pagesDewormingJulie Ann Escartin80% (5)

- Lastearthdistro PDFDocument24 pagesLastearthdistro PDFleonabrahamzapruderNo ratings yet

- Interns 2016 DistributionDocument13 pagesInterns 2016 DistributionKashish ChawlaNo ratings yet

- Acute Limb Ischemia: Clinical PracticeDocument9 pagesAcute Limb Ischemia: Clinical PracticeIndah MaulidawatiNo ratings yet

- TRAMADOLDocument4 pagesTRAMADOLRudie Lee PascualNo ratings yet

- Stem Cell Research ArticleDocument4 pagesStem Cell Research Articleapi-248217035No ratings yet