Professional Documents

Culture Documents

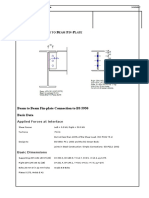

E 200mm Thick Slab - Pa2

Uploaded by

ihpeterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E 200mm Thick Slab - Pa2

Uploaded by

ihpeterCopyright:

Available Formats

Profis Anchor 2.5.

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

11/4/2015

Specifier's comments:

1 Input data

Anchor type and diameter:

HIT-HY 200-R + HIT-Z M12

Dynamic set or any suitable annular gap filling solution

Effective embedment depth:

hef,opti = 63 mm (hef,limit = 90 mm)

Material:

DIN EN ISO 4042

Evaluation Service Report:

ETA 12/0028

Issued I Valid:

3/15/2013 | 2/10/2017

Proof:

Design method Engineering judgement SOFA BOND - based on ETAG BOND testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 25 mm

Anchor plate:

lx x ly x t = 200 mm x 700 mm x 25 mm; (Recommended plate thickness: not calculated)

Profile:

Pipe; (L x W x T) = 140 mm x 140 mm x 13 mm

Base material:

cracked concrete, C30/37, fc = 37.00 N/mm2; h = 150 mm, Temp. short/long: 30/40 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12 + close mesh (stirrups, hangers) s <=

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

11/4/2015

2 Load case/Resulting anchor forces

Load case: Design loads

Compression

y

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

6.237

3.824

0.750

2

8.261

3.824

0.750

3

11.030

3.824

0.750

4

13.054

3.824

0.750

max. concrete compressive strain:

0.21 []

max. concrete compressive stress:

6.39 [N/mm2]

resulting tension force in (x/y)=(0/-66):

38.583 [kN]

resulting compression force in (x/y)=(91/266): 13.583 [kN]

2

Shear force y

3.750

3.750

3.750

3.750

x

Tension

3

3 Tension load (EOTA TR 029, Section 5.2.2)

Utilization bN [%]

36

Status

OK

80.067

49

OK

38.760

100

OK

39.388

98

OK

Load [kN]

13.054

Capacity [kN]

36.667

Combined pullout-concrete cone failure**

38.583

Concrete Breakout Strength**

38.583

38.583

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

55.000

gM,s

1.500

NRd,s [kN]

36.667

NSd [kN]

13.054

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

129600

A0p,N [mm2]

32400

2

tRk,ucr,25 [N/mm ]

22.00

scr,Np [mm]

180

ccr,Np [mm]

90

yc

1.000

2

tRk,cr [N/mm ]

20.00

k

2.300

yg,Np

1.000

yg,Np

1.000

ec1,N [mm]

0

yec1,Np

1.000

ec2,N [mm]

66

yec2,Np

0.664

ys,Np

1.000

N0Rk,p [kN]

45.239

NRk,p [kN]

120.100

gM,p

1.500

NRd,p [kN]

80.067

NSd [kN]

38.583

cmin [mm]

113

hef,Helix [mm]

60

yre,Np

1.000

3.3 Concrete Breakout Strength

Ac,N [mm2]

142884

A0c,N [mm2]

35721

ccr,N [mm]

95

scr,N [mm]

189

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

66

yec2,N

0.664

N0Rk,c [kN]

21.900

gM,c

1.500

NRd,c [kN]

38.760

NSd [kN]

38.583

Ac,N [mm2]

142884

A0c,N [mm2]

35721

ccr,sp [mm]

95

scr,sp [mm]

189

yh,sp

1.016

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

66

yec2,N

0.664

ys,N

1.000

N0Rk,c [kN]

21.900

gM,sp

1.500

NRd,sp [kN]

39.388

NSd [kN]

38.583

ys,N

1.000

yre,N

1.000

k1

7.200

yre,N

1.000

k1

7.200

3.4 Splitting failure

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

11/4/2015

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

3.824

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

21.600

Utilization bV [%]

18

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

15.297

116.800

14

OK

Concrete edge failure in direction x+**

15.297

112.650

14

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

27.000

VRd,s [kN]

21.600

gM,s

1.250

VSd [kN]

3.824

4.2 Pryout Strength (Concrete Breakout Strength controls)

Ac,N [mm2]

142884

A0c,N [mm2]

35721

ccr,N [mm]

95

scr,N [mm]

189

k-factor

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

1.000

N0Rk,c [kN]

21.900

gM,c,p

1.500

VRd,c1 [kN]

116.800

VSd [kN]

15.297

a

0.075

b

0.064

yec,V

1.000

yre,N

1.000

4.3 Concrete edge failure in direction x+

lf [mm]

63

dnom [mm]

12.0

k1

1.700

c1 [mm]

113

Ac,V [mm2]

146850

A0c,V [mm2]

57461

ys,V

1.000

yh,V

1.063

ya,V

2.280

ec,V [mm]

0

V0Rk,c [kN]

19.483

gM,c

1.500

VRd,c [kN]

112.650

VSd [kN]

15.297

yre,V

1.400

5 Combined tension and shear loads (EOTA TR 029, Section 5.2.4)

bN

0.995

bV

0.177

a

1.000

Utilization bN,V [%]

98

Status

OK

(bN + bV) / 1.2 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

9.670 [kN]

dN

0.326 [mm]

VSk

2.833 [kN]

dV

0.142 [mm]

dNV

0.355 [mm]

Long term loading:

NSk

9.670 [kN]

dN

0.936 [mm]

VSk

2.833 [kN]

dV

0.227 [mm]

dNV

0.963 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

11/4/2015

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The design method ETAG (filled holes) assumes that no hole clearance between the anchors and the fixture is present. This can

be

achieved by filling the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Characteristic bond resistances depend on short- and long-term temperatures.

The design method SOFA assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by filling

the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

An SLS-check is not performed for SOFA and has to be provided by the user!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

11/4/2015

8 Installation data

Anchor plate, steel: Profile: Pipe; 140 x 140 x 13 mm

Hole diameter in the fixture: df = 14 mm

Plate thickness (input): 25 mm

Recommended plate thickness: not calculated

Cleaning: No cleaning of the drilled hole is required

Anchor type and diameter: HIT-HY 200-R + HIT-Z M12

Installation torque: 0.040 kNm

Hole diameter in the base material: 14 mm

Hole depth in the base material: 93 mm

Minimum thickness of the base material: 123 mm

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

No accessory required

Setting

Dispenser including cassette and mixer

Dynamic set

Torque wrench

100

30

100

350

190

260

190

350

100

30

4

100

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

0

0

0

0

y

320

130

-130

-320

c-x

113

113

113

113

c+x

113

113

113

113

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

11/4/2015

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 57 en 12952-4 2011 PDFDocument21 pages57 en 12952-4 2011 PDFalilka404100% (1)

- 11Document3 pages11ihpeterNo ratings yet

- Hilti Design Report PDFDocument6 pagesHilti Design Report PDFihpeterNo ratings yet

- Anchor Bolt CheckDocument1 pageAnchor Bolt CheckihpeterNo ratings yet

- Expo Favoriteroom 5Document1 pageExpo Favoriteroom 5ihpeterNo ratings yet

- 20180923Document13 pages20180923ihpeterNo ratings yet

- UB457 End PlateDocument4 pagesUB457 End PlateihpeterNo ratings yet

- Fin Plate Connection DesignDocument3 pagesFin Plate Connection DesignihpeterNo ratings yet

- Anchor Bolt CheckDocument1 pageAnchor Bolt CheckihpeterNo ratings yet

- SBBDocument3 pagesSBBihpeterNo ratings yet

- Fin Plate Connection DesignDocument3 pagesFin Plate Connection DesignihpeterNo ratings yet

- 1 Input Data: Profis Anchor 2.6.1Document6 pages1 Input Data: Profis Anchor 2.6.1ihpeterNo ratings yet

- Portal Output 20180718 R2Document60 pagesPortal Output 20180718 R2ihpeterNo ratings yet

- Circular Skylight Splice DetailDocument1 pageCircular Skylight Splice DetailihpeterNo ratings yet

- 20170303Document4 pages20170303ihpeterNo ratings yet

- Software licensed structural analysis reaction forcesDocument1 pageSoftware licensed structural analysis reaction forcesihpeterNo ratings yet

- RRDocument6 pagesRRihpeterNo ratings yet

- 1 Input Data: Profis Anchor 2.6.4Document6 pages1 Input Data: Profis Anchor 2.6.4ihpeterNo ratings yet

- Conn DetailDocument1 pageConn DetailihpeterNo ratings yet

- 1 Input Data: Profis Anchor 2.6.4Document6 pages1 Input Data: Profis Anchor 2.6.4ihpeterNo ratings yet

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateDocument6 pagesUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterNo ratings yet

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateDocument6 pagesUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterNo ratings yet

- Conn ForcesDocument2 pagesConn ForcesihpeterNo ratings yet

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 pagesUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterNo ratings yet

- SHS120 Post FixingDocument6 pagesSHS120 Post FixingihpeterNo ratings yet

- ADocument7 pagesAihpeterNo ratings yet

- ADocument2 pagesAihpeterNo ratings yet

- SHS120 Post FixingDocument6 pagesSHS120 Post FixingihpeterNo ratings yet

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 pagesUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterNo ratings yet

- ADocument9 pagesAihpeterNo ratings yet

- ADocument7 pagesAihpeterNo ratings yet

- Abdalla2003-Design Against Cracking at Openings in Reinforced Concrete Beams Strengthened With Composite SheetsDocument8 pagesAbdalla2003-Design Against Cracking at Openings in Reinforced Concrete Beams Strengthened With Composite Sheets010No ratings yet

- Drying solids fundamentals and equipment selectionDocument30 pagesDrying solids fundamentals and equipment selectionArfel Marie FuentesNo ratings yet

- Service Manual: MU-A07YV - MU-A09YV - MU-A12YVDocument28 pagesService Manual: MU-A07YV - MU-A09YV - MU-A12YValessandroNo ratings yet

- Wind Turbine Blade Design: Joseph Rand The Kidwind Project 877-917-0079Document18 pagesWind Turbine Blade Design: Joseph Rand The Kidwind Project 877-917-0079Ad Man GeTigNo ratings yet

- Sp329a PRIMAAX EX For Mack HDT PDFDocument6 pagesSp329a PRIMAAX EX For Mack HDT PDFJonathan Smith Vargas torresNo ratings yet

- Carbs 101Document5 pagesCarbs 101Ashwin KumarNo ratings yet

- 1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemDocument2 pages1104D-E44T and 1104D-E44TA Industrial Engine Electrical SystemGerman E.100% (1)

- Charcoal TowerDocument9 pagesCharcoal TowerPrathmesh GujaratiNo ratings yet

- CFD Simulation of Cross-Ventilation For A Generic IsolatedDocument14 pagesCFD Simulation of Cross-Ventilation For A Generic IsolatedMohamad HashemNo ratings yet

- Renault Master BrochureDocument37 pagesRenault Master BrochureAdriano Freire SilvaNo ratings yet

- Power Screw ReportDocument15 pagesPower Screw ReportTanvesh PatilNo ratings yet

- 640 DradiatorblindDocument2 pages640 DradiatorblindMaxy ServiçosNo ratings yet

- Shubham Gaikwad 163014 Seminar ReportDocument21 pagesShubham Gaikwad 163014 Seminar ReportShubham GaikwadNo ratings yet

- Don3.0 Software - Proper Assembly of Flange JointDocument3 pagesDon3.0 Software - Proper Assembly of Flange JointJoshua HobsonNo ratings yet

- B30D 4Document150 pagesB30D 4Teknik MakinaNo ratings yet

- User'S Design Requirements For Single Chamber Pressure VesselsDocument8 pagesUser'S Design Requirements For Single Chamber Pressure VesselspjsanchezmNo ratings yet

- AP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98Document4 pagesAP05.30-B-0560F.fm Valve Lash Adjustment 19.06.98LUKASNo ratings yet

- Physics Question Bank Kvpy PDFDocument97 pagesPhysics Question Bank Kvpy PDFaswin sivakumarNo ratings yet

- Chapter-1, Simple StressDocument71 pagesChapter-1, Simple Stresssherlockhisham100% (2)

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Past Board Exam Problems in StaticsDocument15 pagesPast Board Exam Problems in Staticsherbulariojeeanne19No ratings yet

- Niigata Welding GaugeDocument2 pagesNiigata Welding GaugeFriady HalimNo ratings yet

- Yawei Pressbrake ManualDocument54 pagesYawei Pressbrake ManualWayne Hoppe100% (1)

- Technical Data Sheet: Ft041En - A - 0313 - 160atjDocument2 pagesTechnical Data Sheet: Ft041En - A - 0313 - 160atjElaine Malazzab PublikoNo ratings yet

- Lab 2 Torsion Lab Instruction SpringDocument7 pagesLab 2 Torsion Lab Instruction SpringYong JinNo ratings yet

- Directional Soil Improvement Tech for Underground ProjectsDocument38 pagesDirectional Soil Improvement Tech for Underground ProjectsVanDuongNguyenNo ratings yet

- 3314 Ijmech 11Document8 pages3314 Ijmech 11Burak KoyuncuogluNo ratings yet

- Well DiagramDocument2 pagesWell DiagramSanjay KapoorNo ratings yet