Professional Documents

Culture Documents

Saes B 060

Uploaded by

essence1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saes B 060

Uploaded by

essence1Copyright:

Available Formats

Engineering Standard

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Loss Prevention Standards Committee Members

15 March 2006

Ashoor, Esam Ahmed, Chairman

Fadley, Gary Lowell, Vice Chairman

Churches, David Kenneth

Karvois, Edwin Frank

Solomon Jr, Clarence Ray

Zahrani, Mansour Jamman

Sultan, Sultan Abdul Hadi

Hassar, Fahad Abdullah

Ageel, Adel Abdulaziz

Seba, Zaki Ahmed

Janaby, Mohammad Taqy

Ghobari, Ali Mahdi

Anderson, Sidney Vincent

Utaibi, Abdul Aziz Saud

Sayed, Salah Moh'D Al-Housseiny

Cole, Anthony Richard

Saudi Aramco DeskTop Standards

Table of Contents

1

2

3

4

5

6

7

8

9

10

11

Scope............................................................. 2

Conflicts and Deviations................................ 2

References.................................................... 2

Definitions...................................................... 5

General.......................................................... 6

Pier Construction........................................... 7

Drainage........................................................ 8

Emergency Isolation...................................... 8

Piping, Loading Arms, and Cargo Hose........ 9

Static Electricity and Stray Currents............. 10

Access for Operation,

Maintenance, and Firefighting.............. 10

12 Fireproofing.................................................. 11

13 Fire Protection.............................................. 11

14 Fire Water Pumps........................................ 14

Previous Issue: 30 January 2002

Next Planned Update: 15 March 2007

Page 1 of 17

Primary contact: Ashoor, Esam Ahmed on 966-3-8728431

CopyrightSaudi Aramco 2005. All rights reserved.

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Table of Contents (Cont'd)

15 Portable Firefighting Equipment................... 15

16 Hose Reels................................................... 15

17 Fire and Gas Detection................................ 16

Table 1 - Fixed Fire Protection Guidelines

for Hydrocarbon Loading Facilities...... 17

Scope

This Standard defines the minimum mandatory safety requirements governing the

design and installation of piers, wharves, and sea islands.

Exception:

Dry cargo, maintenance, and recreational piers are not included.

Conflicts and Deviations

2.1

Any conflicts between this Standard and other applicable Saudi Aramco

Engineering Standards (SAESs), Materials System Specifications (SAMSSs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Loss Prevention Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this Standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager of the Loss Prevention Department of

Saudi Aramco, Dhahran.

References

The selection of material and equipment and the design, construction, maintenance, and

repair of equipment and facilities covered by this Standard shall comply with the latest

edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco Engineering

Requirement

Page 2 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Saudi Aramco Engineering Standards

SAES-A-103

Discharges to the Marine Environment

SAES-B-005

Spacing and Diking for Atmospheric and LowPressure Tanks

SAES-B-006

Fireproofing in Onshore Facilities

SAES-B-009

Fire Protection and Safety Requirements for

Offshore Production Facilities

SAES-B-014

Safety Requirements for Plant and Operations

Support Buildings

SAES-B-017

Fire Water System Design

SAES-B-018

Air Foam Systems for Storage Tanks

SAES-B-019

Portable, Mobile, and Special Fixed Firefighting

Equipment

SAES-B-054

Access, Egress, and Materials Handling for Plant

Facilities

SAES-B-055

Plant Layout

SAES-B-058

Emergency Isolation, Shutdown, and

Depressuring

SAES-B-063

Aviation Obstruction Marking and Lighting

SAES-B-067

Safety Identification and Color-Coding

SAES-B-068

Electrical Area Classification

SAES-J-505

Combustible Gas and Hydrogen Sulfide in Air

Detection Systems

SAES-J-601

Emergency Shutdown and Isolation Systems

SAES-L-008

Selection of Valves

SAES-L-012

Design of Piping Systems Inside Plant Areas

SAES-L-015

Design of Piping on Offshore Structures

SAES-M-005

Design and Construction of Fixed Offshore

Platforms

SAES-M-100

Aramco Building Code

SAES-P-114

Power System and Equipment Protection

SAES-P-116

Switchgear and Control Equipment

SAES-P-123

Lighting

Page 3 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

SAES-Q-001

Criteria for Design and Construction of Concrete

Structures

SAES-S-020

Industrial Drainage and Sewers

Saudi Aramco Materials System Specifications

3.2

08-SAMSS-003

Oil Suction and Discharge Hoses for Dock Tanker

Loading

21-SAMSS-010

Fireproofing for Valve Actuator Systems

Industry Codes and Standards

National Fire Protection Association (NFPA)

NFPA 11

Low-Expansion Foam

NFPA 15

Fixed Water Spray Systems

NFPA 16

Installation of Deluge Foam-Water Sprinkler and

Foam-Water Spray Systems

NFPA 25

Inspection, Testing, and Maintenance of WaterBased Fire Protection Systems

NFPA 72

National Fire Alarm Code

American Society for Testing and Materials (ASTM)

ASTM E84

Surface Burning Characteristics of Building

Materials

American Petroleum Institute (API)

API RP 2003

Protection Against Ignitions Arising Out of Static,

Lightning and Stray Currents

American National Standard Institute (ANSI) / National Electrical

Manufacturers Association (NEMA)

ANSI / NEMA Z535.1

Safety Color Code

ANSI / NEMA Z535.2

Environmental and Facility Safety Signs

ANSI / NEMA Z535.3

Criteria for Safety Symbols

ANSI / NEMA Z535.4

Product Safety Signs and Labels

ANSI / NEMA Z535.5

Accident Prevention Tags (for Temporary

Hazards)

Page 4 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Military Specification

MIL-W-25038

General Specification for High Temp, Fire

Resistant, and Flight Critical Electrical Wire

Oil Companies International Marine Forum (OCIMF)

Design and Construction Specification for Marine Loading Arms

International Safety Guide for Oil Tankers & Terminals

Commentary Note:

OCIMF references are available via:

Oil Companies International Marine Forum (OCIMF)

27 Queen Anne's Gate, London, SW1H 9BU

Tel: 44 171 654-1200

Fax: 44 171 654-1205

e mail: ocimf@compuserve.com

website: http://www.ocimf.com

Underwriters Laboratories, Inc. (UL)

UL 162

Standard for Safety Foam Equipment and Liquid

Concentrates

Definitions

AFFF: Aqueous Film-Forming Foam consisting of a fluorinated surfactant with a foam

stabilizer and diluted with water to 3% solution. The solution is used to extinguish fires

involving combustible and flammable liquids. AR-AFFF refers to alcohol-resistant

AFFF foam that contains a gelling agent that helps to prolong its film-forming

characteristics.

Approved: Meets United States Coast Guard Regulations and/or the International

Convention for Safety of Life at Sea (SOLAS).

Berth: A space where a ship is tied when at a pier, wharf, or sea island.

Bollard: A post on a wharf or pier used to fasten mooring lines of ships.

Pier: A structure, usually of greater length than width, and projecting from the shore

into a body of water.

Sea Island: A platform located some distance from shore in navigable waters and

accessible for loading operations by large tankers.

Wharf: A structure having a platform built along and parallel to a body of water.

Page 5 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

General

5.1

5.2

5.3

5.4

Lifesaving devices

5.1.1

Each berth shall be equipped with at least three approved ring life buoys,

as specified by SAMS 21-590-200. One ring life buoy shall be installed

at each set of mooring bits or bollards. One ring life buoy shall be

installed at the gangway location.

5.1.2

Each ring life buoy shall be equipped with an approved automatic

electric water light. The water light shall be attached to the ring buoy

with a 1 to 2 m lanyard. The water light shall be mounted on a bracket

adjacent to the ring life buoy such that when the ring life buoy is cast

loose, the water light will pull free of the bracket.

5.1.3

Manned offshore sea islands shall be provided with approved life jackets,

life rafts, and escape capsules that meet Section 4.19 of SAES-B-009.

Lighting

5.2.1

Normal and emergency task lighting shall be provided for hose, loading

arm, and manifold areas, slops systems, fire pump and foam systems

areas, and mooring bits or bollards to meet Section 4.2, SAES-B-009 and

SAES-P-123.

5.2.2

Normal and emergency egress lighting shall be provided for the gangway

area and escape routes to meet SAES-B-009 and SAES-P-123.

5.2.3

Electrical area classification shall meet SAES-B-068.

Signs

5.3.1

"No smoking/No Naked Light" signs shall be posted in Arabic and

English in all areas handling hydrocarbons. Smoking shall be permitted

only in designated locations. These areas shall be posted with signs

indicating that smoking is permitted only in these areas.

5.3.2

Signs shall be posted showing emergency escape routes from all berth

areas from which escape routes are not obvious.

5.3.3

All permanent and temporary safety signs and symbols shall meet

ANSI/NEMA Z535.1 - Z535.5 and SAES-B-067.

Marine Aids to Navigation and Aviation Obstruction Marking

5.4.1

Marine navigation lights and horns shall be provided in accordance with

Page 6 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

the requirements of SAES-M-005.

5.4.2

Structures over 60 m in height shall be provided with aviation

obstruction lighting in compliance with SAES-B-063.

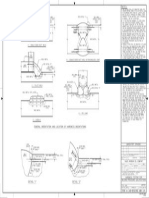

Pier Construction

6.1

The transfer of hydrocarbons over a dock face using hoses shall be permitted in

new or renovated facilities only where the facility handles vessels or barges

under 5000 DWT. All new or renovated facilities handling vessels larger than

5000 DWT shall be designed using loading arms. Refer to Section 9 for other

loading arm requirements.

6.2

Piers, wharves, sea islands, and other offshore loading facilities shall be of

noncombustible or fire-resistive construction as defined by SAES-M-100.

6.3

Pier decks shall be reinforced concrete, or equivalent construction, to afford a 4hr fire resistance rating per ASTM E84. Concrete piers shall meet SAES-Q-001.

6.4

Use of subway grating or similar open construction in decks shall be minimized,

since, in major oil release and/or fire situations, such deck areas rapidly become

untenable. Any subway grating used shall be steel. Solid steel decking

protected by underside water sprays is required for escape routes (See 6.5).

6.5

Escape routes shall have solid steel decking at least 3 m wide and shall

otherwise meet SAES-B-054. Secondary escape routes may be via an adjacent

berth. Escape paths shall be clearly marked for easy identification in an

emergency. Escape routes shall be provided with a weatherproof first aid

cabinet.

6.6

When used on the underside of the pier deck, fenders, vapor barriers, moisture

shields, coatings, or finishes shall conform to the definition of noncombustible or

limited combustible having a flame spread rating of less than 25 per ASTM E84.

6.7

Provision shall be made to limit the spread of spilled hydrocarbon under the

waterfront facility and to facilitate its removal or treatment. This may consist of

floating booms or bulkheads at water level depending upon the specific design

of the facility, current and tidal effects, and relative cost and efficacy.

6.8

All buildings or rooms shall be of noncombustible construction and shall meet

the requirements of SAES-B-014.

6.9

Where elevators are installed to access elevated loading observation areas, they

shall be paired with a shielded staircase for emergency egress in the event

structural damage prevents the use of the elevator.

Page 7 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

6.10

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Where vessels are expected to come next to and be secured to the pier, a

fendering system designed for this purpose shall be provided. These systems

shall meet 6.6.

Drainage

7.1

Areas subject to hydrocarbon spills or drainage shall be drained via sealed catch

basins per SAES-S-020. In facilities where onshore type designs are not

practicable, an offshore design that meets SAES-B-009, Section 4.4 shall be

used.

7.2

Areas around loading arms and manifolds shall be curbed and sloped a

minimum of 1:65 (1.5%) to dedicated catch basins.

7.3

Collection sumps, if provided, shall have pressure/vacuum vents and automatic

pump-out facilities, and shall be tightly covered. The vent shall discharge a

minimum of 3 m above any platform or equipment within a horizontal distance

of 15 m. The atmospheric end of the vent shall point upward and shall not be

provided with gooseneck, raincap, T-section, or flame arrestor. The vent end

shall be located on the periphery of facilities at a predominately downwind

location. Prevailing wind direction shall be based on a wind rose diagram via

the Chief Environmental Engineer, Environmental Engineering Division,

Environmental Protection Department.

7.4

For crude oil and other flammable liquids, as defined by paragraph 4.0 of SAESB-005, loading arms shall have a drain through valved connections to the sump.

7.5

LPG loading arms shall have a drain to a closed system that is either vented to a

vapor recovery system or to a flare system.

7.6

All waste discharges shall comply with SAES-A-103.

Emergency Isolation

8.1

Emergency isolation valves shall be installed per SAES-B-058 and SAES-J-601.

8.2

An emergency isolation valve (EIV) is required for each loading/unloading hose

and at the base of each riser for a loading arm at a berth.

8.3

An EIV is required on each hydrocarbon line at the shoreside entry to a pier,

wharf, or at the entry point of an underwater pipeline feeding an offshore

loading facility.

8.4

Quick-release valves and connections for loading arms/hoses and quick-release

devices for hawsers shall be provided where specified and approved by the

Page 8 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Proponent Operating Department.

8.5

An audible/visual alarm shall provide personnel in the control room, at the berth

face, and on board the ship with notification that an ESD or emergency release

has been initiated. The signal shall alert control room operators so that they can

monitor and take appropriate action pertaining to disconnecting of loading arms

and release of hawsers.

8.6

Push/pull buttons shall be located in the vicinity of the berth manifold, in a safe

(local-remote) location (refer to SAES-B-058), and in the control room.

8.7

Each loading arm shall be designed such that the emergency release components

remain connected to the ship's manifold. When an emergency release is

activated, the action of the counterweights shall return the loading arm to the

stored position whether full or empty.

8.8

A communication system shall be provided between the ship, loading operation

points, and the onshore shipping pump control room to allow coordination of

normal loading activities and emergency response.

8.9

All emergency isolation valves shall meet paragraph 7.5 of SAES-L-008.

Piping, Loading Arms, and Cargo Hose

9.1

Product piping shall meet the requirements of SAES-L-012 and SAES-L-015, as

applicable.

9.2

Flexibility of piping shall be analyzed to ensure that motion of the pier or wharf

structure resulting from wave action, currents, tides, or the mooring of vessels

will not subject the piping to excessive strain.

9.3

Swivel joints shall be permitted to be used in piping to which hoses are

connected and for loading arm transfer systems, provided that the design is such

that the mechanical strength of the joint will not be impaired if the packing

materials should fail due to exposure to fire.

9.4

Articulated swivel joint loading arms shall be constructed of steel pipe and shall

be counterbalanced for the empty condition.

Exception:

Loading arms with emergency release shall meet 8.7.

9.5

Loading arms shall be capable of accommodating the combined effect of change

of draft and change in tide on all vessels that the facility is designed to load.

Page 9 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

10

11

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

9.6

Loading arms shall be equipped with an overtravel alarm system capable of

indicating when the acceptable envelope of range and drift conditions is being

exceeded and shutting down the loading system per Design and Construction

Specification for Marine Loading Arms (OCIMF).

9.7

Cargo Hoses

9.7.1

Cargo hoses shall meet the requirements of 08-SAMSS-003.

9.7.2

Hoses shall be supported to avoid kinking and damage from chafing.

Static Electricity and Stray Currents

10.1

Guidance in the prevention of ignition due to incendiary arcs caused by static

electricity and stray currents is provided in API RP 2003 and in the International

Safety Guide for Oil Tankers & Terminals (OCIMF).

10.2

All isolated sections of piping or other equipment shall be grounded. Product

piping shall be connected to a ground run into the water and connected to a

suitable grounding plate. Also refer to SAES-Q-001, 7.5.

10.3

Insulating flanges shall be provided at the shore end of the pier or wharf and at

the loading arm or product hose.

Access for Operation, Maintenance, and Firefighting

11.1

Stairways and access platforms shall be provided to allow access to operating

valves and instruments per SAES-B-054.

11.2

Where provided, roadways on piers and wharves shall be designed for one-way

traffic. Suitable traffic controls shall be installed and passing lanes provided at

suitable intervals to prevent the necessity of backing to resolve conflicts.

11.3

Transient trucks and automobiles shall be permitted to remain on piers and

wharves only long enough to load and unload cargo. Parking areas shall be

marked in such a way that vehicles can be promptly driven off the pier in the

event of emergency. Minimum spacing shall meet SAES-B-055 to ensure

access of firefighting equipment. A designated fire lane is required to be clearly

marked.

Commentary Note:

The number of vehicles permitted upon the pier or wharf at any one time shall be

limited to a number that enables free traffic flow. Parking of such vehicles shall

not interfere with the access of emergency response equipment.

Page 10 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

11.4

12

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Each berth shall be served by a low-level platform suitable for boarding a pilot

vessel or launch or retrieving a man overboard. Access to this platform shall be

by stair.

Fireproofing

12.1

Fire-hazardous zone definition and the use of fireproofing shall be meet

SAES-B-006. Protection via fixed water spray or fire water/foam monitors is

preferred over fireproofing for piers, wharves, and sea islands; the extent of

spray coverage vs. fireproofing shall be decided by consultation with the Chief

Fire Prevention Engineer.

Commentary Note:

The layout and design of fireproofing or water sprays/monitors is critical for these

facilities and specific to each situation. Design specifics shall be done in

consultation with the Chief Fire Prevention Engineer and the Technical Advisor,

Fire Protection Department or their representatives. See Section 13.

12.2

Actuators on EIVs in LNG/LPG service and located within 7.5 m of the dock

face shall be fireproofed to meet 12-SAMSS-010.

Commentary Note:

This requirement is an additional precaution and does not imply the existence of

a fire-hazardous zone, i. e., the loading arm/hose area of marine berths is not

considered to be a fire hazardous zone. Fireproofing is not required for actuators

of EIVs at marine berths except for those in LNG/LPG Service.

13

Fire Protection

13.1

The fire protection system design and equipment specifications shall meet

SAES-B-017 and this Standard. Fire protection systems for facilities under the

scope of this Standard shall be designed by qualified firms or individuals having

expertise in fire protection systems. Drawings and calculations shall be

submitted to the Chief Fire Prevention Engineer or his representative for review.

Commentary Note:

The number and type of fire protection devices required will vary with the size of

the facility and the size and number of vessels using it. General guidance is

given in Table 1 of this Standard and Table 1 of SAES-B-019. Design specifics

shall be done in consultation with the Chief Fire Prevention Engineer or his

representative.

13.2

All designs shall facilitate frequent inspection, testing, and maintenance of

protection systems as described in NFPA 25. Commissioning and testing

procedures shall be submitted to the Chief Fire Prevention Engineer or his

Page 11 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

representative prior to the time of the request to inspect for mechanical

completion.

13.3

Piers, wharves, and sea islands shall meet process area requirements as defined

in SAES-B-017. Dedicated fire water systems shall be provided; process and

utility water shall not be provided through the fire water system.

13.4

Where roadway access is provided, Type 509-K fire hydrants (Refer to SAESB-017, Figure 1) shall be located on 45 m (150 ft) centers in the berth area.

Hydrant spacing along approach trestles shall be on 90 m to 120 m (300 ft to

400 ft) centers. Type 509-G hydrants shall be used on the approach trestle.

13.5

At least one Type 509-E hydrant (Refer to SAES-B-017, Figure 1) or other

valved outlet acceptable to the Chief Fire Prevention Engineer or his

representative shall be installed at each end of each berth for hydrotest water and

fire water back-up.

13.6

Deck protection for loading arm, manifold, and metering skid areas shall consist

of either pre-aimed fixed foam monitors or foam/water spray heads. These shall

be designed to provide a minimum discharge density of at least 0.10 L/ms

(0.15 gpm/ft) sprayed upon the projected area.

13.7

Underdeck protection shall be provided where there is the probability of a fire

involving spilled hydrocarbons on the water surface. While such spills may be

washed away by tidal currents at small facilities, at other facilities the presence of

larger marine vessels will reduce the effectiveness of tidal washing. Protection

may be in the form of fixed foam water spray systems or pre-aimed fire monitor

nozzles connected to a foam proportioning system. These shall be designed to

provide a minimum discharge density of at least 0.10 L/ms (0.15 gpm/ft) based

upon the projected area. Actuation shall be by manually operated valves located

in a protected or shielded area which will remain accessible in the event of a

discharge and or ignition of flammable liquids on the sea surface.

13.8

Protection of the ship's manifold area shall be provided by monitors at the berth

face. Where, due to the size of vessels serviced, monitors must be elevated,

monitors shall be remotely controlled. Either electric or hydraulically remotecontrolled monitors are acceptable.

13.8.1 The control station for remotely controlled monitors shall be located at

least 45 m (150 ft) from the berth face at a point which provides a clear

view of the berth and manifold areas.

13.8.2 If hydraulic systems are used for remotely operated monitors, shielding

from radiant heat or protection within a water spray envelope shall be

provided.

Page 12 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Commentary Note:

Flexible hoses are critical components of the system. Since hydraulic oil

in these circuits is typically not circulating, the oil will quickly vaporize if

exposed to high radiant heat loads or direct flame impingement and

remote control of the monitor will be lost. For that reason, an electric

system is preferred.

13.8.3 If electric systems are used for remotely operated monitors, mineralinsulated cable, MIL-W-25038, or other cable good for a two-hour

hydrocarbon fire, as approved by the Chief Fire Prevention Engineer,

shall be used. Factory-installed terminations for the cable ends shall be

required.

Commentary:

Cable meeting the specifications above is very fireproof and durable if

properly installed. The insulating material in many cables, especially MI

cable, is hygroscopic, so unless the terminations are perfectly made, the

cable will become useless because of moisture.

13.9

Oscillating monitors shall not be used.

13.10 Where more than one berth is installed, a central foam distribution system shall

be incorporated (if foam is required). The foam supply shall be sufficient for

30 minutes to all users at the berth of the greatest demand.

Exception:

Foam systems are not required for all locations, i.e., LPG or LNG loading facilities

do not require foam protection. Refer to SAES-B-017 and SAES-B-019, Table 1.

13.11 Foam systems shall be designed to utilize an AR-AFFF foam concentrate

approved by the Manager, Fire Protection Department. Fixed foam/water spray

systems shall be designed and installed per NFPA 16 and SAES-B-009, Section

4.10.

a)

Foam concentrates shall be UL 162 listed specifically for use with the

foam concentrate proportioning equipment, the discharge devices, and

other system components provided in the system and vice versa.

b)

Type or brand of foam or components shall not be changed without

approval from the Chief Fire Prevention Engineer and the Technical

Advisor, Fire Protection Department, or their representatives.

Exception:

Where "listed" components are not manufactured, the components used shall be

approved by the Chief Fire Prevention Engineer and the Technical Advisor, Fire

Protection Department, or their representatives.

Page 13 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Commentary:

Metallurgy of foam concentrate tanks, concentrate piping, and nozzle

configuration will be different depending on which type of foam concentrate is

used. Refer to SAES-B-018, Section 8, for information on materials selection.

Refer to NFPA 11 for general information on air-foams.

13.12 Exposure protection for loading arms, elevated pipe supports, and other

structures shall consist of pre-aimed fire water monitors. A berth with up to 4

loading arms requires 2 monitors rated for 32 L/s (500 gpm) each. A berth with

more that 4 loading arms requires 2 monitors rated for 63 L/s (1000 gpm) each.

13.13 Where slops tanks are located below the deck, they shall be protected by an

automatically activated fixed water spray system covering the tank and any

related pumps unless exempted in writing by the Chief Fire Prevention

Engineer. Protection for pumps handling flammable liquids shall be at least

0.34 L/ms (0.50 gpm/ft) over an envelope extending 0.6 m (2 ft) from the

periphery of the casing, seals and pump suction and discharge flanges.

13.14 Monitors shall be designed to operate at a nominal design nozzle gauge pressure

of 690 kPa (100 psig).

13.15 Fixed water spray firefighting systems, when provided, shall be designed and

installed per the requirements of NFPA 15.

14

Fire Water Pumps

14.1

Fire pumps and jockey pumps shall meet the process area requirements of

SAES-B-017. The fire water system shall be supplied by pumps taking suction

from the sea.

Exception:

Installations handling vessels less than 5000 DWT may use a shore-based fire

water system as the primary supply, provided adequate flow and pressure are

available to meet the berth demands. The requirements of SAES-B-017

regarding reliability must be met. This may require a looped supply main or the

installation of an unspared diesel-driven pump on the marine facility.

14.2

Total installed fire water pumping capacity, not counting standby capacity, shall

be no less than that required by the single greatest berth demand, including all

fire protection system components protecting that berth, up to a maximum of

190 L/s (3000 gpm).

14.3

Where a fire water system is provided from shore-based facilities, it may be

used as an alternate means of providing pressurization of the marine facility fire

water system. In such a case, the marine fire water system pumps shall be

Page 14 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

arranged to start immediately upon activation of any berth fixed fire protection

system rather than waiting for a pressure drop to occur in the fire water system.

14.4

The fire water requirement for the marine facility shall be provided by two or

more electric submersible or vertical pumps of equal size.

14.5

At least one-third of the electric-motor-driven capacity shall be supplied from a

second bus capable of being tie-breaker-isolated from the normal electrical

supply bus.

14.6

Diesel-driven standby fire pump capacity equal to at least the largest electrically

driven fire pump is required and at least 50% of the total fire pumping capability

(capacity plus standby) shall be diesel-engine-driven.

14.7

Diesel engines and diesel-driven pumps shall meet the requirements of

SAES-B-017.

14.8

The fire water piping system shall meet the requirements of Section 4.8.6 of

SAES-B-009.

14.9

Pump suction protection from marine growth shall meet SAES-B-017, 6.2.3.

14.10 The electrical supply for electrically-driven fire water and jockey pumps shall

meet the requirements of SAES-B-017, SAES-P-114, and SAES-P-116.

14.11 For offshore platforms and piers exceeding 150 m (500 ft) in length, fire boat

connections shall be provided to meet SAES-B-017, 12.12.

15

16

Portable Firefighting Equipment

15.1

Other firefighting equipment consisting of portable dry chemical extinguishers

and wheeled dry chemical extinguishers shall be provided at each berth area.

Refer to SAES-B-019 for general requirements.

15.2

Portable dry chemical extinguishers shall be spaced to limit running distance to

not more than 15 m (50 ft).

15.3

Two nominal 150 lb wheeled dry chemical extinguishers shall be provided at

each berth and shall be located such that there is one on each side of the berth.

Hose Reels

16.1

Live hose reels shall be provided at each berth and spaced such that together

they cover all areas of the berth. Refer to SAES-B-017, Section 8.

Page 15 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

16.2

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Hose reels at berths handling liquid hydrocarbons shall be equipped to deliver

foam. Hose reels shall be capable of discharging either water or foam, with a

push button mounted by each hose reel to start the foam concentrate pump.

Exception:

The hose reel foam-related functions and facilities shall not be provided for

facilities that handle only LPG or LNG. Foam is not effective for LPG or LNG.

17

Fire and Gas Detection

17.1

Fire detection and Alarm systems, where provided, shall be designed and

installed per the requirements of NFPA 72. The detectors shall:

(a)

Consist of listed cross-zoned UV/IR detectors.

(b)

Be arranged to scan the manifold area and loading arm areas.

Exception:

Manual deluge system activation with or without UV/IR detection may be

provided in lieu of automatic activation, depending on size, complexity,

congestion, products handled, manpower available, proximity to fire station,

isolation capability, and concurrence by the Chief Fire Prevention Engineer.

(c)

Meet the requirements of SAES-B-014 for buildings and rooms.

17.2

Output shall be arranged to sound an alarm in the control room in the event of a

single detection and to actuate the fire protection system in the event both zones

are in alarm mode.

17.3

The need for a gas detection and alarm system and the exact location and

number of gas detectors shall be determined by the designated representatives of

the Operations Department; the General Supervisor, Process Instrumentation

Division, P&CSD; and the Chief Fire Prevention Engineer.

17.4

Gas detection systems, where provided, shall meet the requirements of

SAES-J-505.

15 March 2006

Revision Summary

Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued

with no other changes.

Page 16 of 17

Document Responsibility: Loss Prevention

Issue Date: 15 March 2006

Next Planned Update: 15 March 2007

SAES-B-060

Fire Protection for

Piers, Wharves and Sea Islands

Table 1 Fixed Fire Protection Guidelines for Hydrocarbon Loading Facilities

Under 5000 DWT

crude or liquid

hydrocarbons

Over 5000 but

Under 70,000 DWT

crude or liquid

hydrocarbons

On each side of

each berth to cover

the dock- side

loading arm/

manifold area,

metering skid

Over 70,000 DWT

crude or liquid

hydrocarbons

Fixed foam

monitors or

foam-water

spray systems

On each side of

each berth to

cover the dockside manifold

area, metering

skid

Fixed water

monitors or

water spray

systems

Slops tank and

pump area

Pre-positioned for

protection of

structures on dock

face. If access not

possible, use water

spray.

Water spray for

slops tank and

pump

On each side of

each berth to

cover the dockside loading arm/

manifold area,

metering skid.

On each side of

each berth to

cover the ship's

manifold area

(elevated with

remote controls).

Pre-positioned for

protection of

structures on dock

face. If access not

possible, use

water spray.

Water spray for

slops tank and

pump.

International

fire boat

connections

(Minimum)

Number of

connections and

locations to be

as required by

the Chief Fire

Prevention

Engineer or his

representative.

Underdeck

foam

protection

Two each at

opposite ends of

pier, wharf, or

sea island.

Three each at

opposite ends of

pier, wharf, or sea

island.

Four each at

opposite ends of

pier, wharf, or sea

island.

Single line of

sidewall foam

water sprinklers

at berth face

discharging

toward vessel.

Nozzles spaced

at 3 m (10 ft)

intervals

Manually-operated

fixed foam/ water

spray to cover the

underdeck area

beneath the

manifold/loading

arm area

Manually-operated

fixed foam/water

spray systems to

cover the

underdeck area

beneath the entire

berth area

Liquefied

Natural /Petroleum

Gas (LNG or LPG)

only

Required for

LNG/LPG loading

areas only if

bunkering is

permitted at that

berth. If bunkering is

permitted, treat as

hydrocarbon loading

facility.

On each side of each

berth to cover the

dock side manifold

area, metering skid.

On each side of each

berth to cover the

ship's manifold area

(elevated with

remote controls).

Water spray for slops

tank and pump.

Two each at

opposite ends of

pier, wharf, or sea

island.

Not required

Page 17 of 17

You might also like

- Saes A 004Document13 pagesSaes A 004husseinNo ratings yet

- Saes D 100 PDFDocument22 pagesSaes D 100 PDFShajin Mohammed Shamsudhin0% (1)

- Saes B 018Document15 pagesSaes B 018Li PengNo ratings yet

- Saes B 060Document17 pagesSaes B 060laudivelNo ratings yet

- Saes B 063Document6 pagesSaes B 063hasanmnhNo ratings yet

- Design and Installation of Submarine PipelinesDocument8 pagesDesign and Installation of Submarine PipelinesSohail TisekarNo ratings yet

- 34 Samss 122Document13 pages34 Samss 122naruto256No ratings yet

- 17 Samss 008Document8 pages17 Samss 008Cherukunnon JubuNo ratings yet

- (Compare Report) SAES-B-005Document14 pages(Compare Report) SAES-B-005kartik_harwani4387No ratings yet

- Saes B 005Document13 pagesSaes B 005Karu 2100% (1)

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387No ratings yet

- Saes N 004 PDFDocument5 pagesSaes N 004 PDFRampal Rahul Rampal RahulNo ratings yet

- 18-SAMSS-493 - Two Part Polyurethane Duct SealantDocument5 pages18-SAMSS-493 - Two Part Polyurethane Duct Sealantmedication abbasNo ratings yet

- Pressure Relief SAES A 004Document1 pagePressure Relief SAES A 004viswamanojNo ratings yet

- SAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARDocument7 pagesSAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARZahidRafiqueNo ratings yet

- Saes L 130Document5 pagesSaes L 130Ahmed Kabel100% (1)

- Saes L 440Document14 pagesSaes L 440kartik_harwani4387100% (1)

- Saes T 911 PDFDocument76 pagesSaes T 911 PDFjuliusNo ratings yet

- Mechanical Data Sheet For 73-T105C/D Light Naphtha Storage TankDocument9 pagesMechanical Data Sheet For 73-T105C/D Light Naphtha Storage TankGorkem DoraNo ratings yet

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387No ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- SAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARDocument6 pagesSAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARZahidRafique100% (1)

- RT17 Samss 518Document25 pagesRT17 Samss 518ahm3d16n0% (1)

- Saes e 101Document6 pagesSaes e 101AdnanAtifNo ratings yet

- Saudi Arabian Engineering Standards Saes J 904Document45 pagesSaudi Arabian Engineering Standards Saes J 904liuyx866No ratings yet

- Saes L 140 PDFDocument13 pagesSaes L 140 PDFsamsurendran_mech4020No ratings yet

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Saes A 208Document14 pagesSaes A 208nadeemNo ratings yet

- Sabp L 002Document27 pagesSabp L 002yoonchankim0911100% (1)

- 32 Samss 016Document14 pages32 Samss 016naruto256No ratings yet

- 17 Samss 017Document14 pages17 Samss 017Eagle SpiritNo ratings yet

- Saes A 109Document5 pagesSaes A 109SIVANo ratings yet

- 34 Samss 718Document14 pages34 Samss 718Eagle SpiritNo ratings yet

- Info SAEDocument182 pagesInfo SAEwertys90No ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- Fender System: Exxon EngineeringDocument31 pagesFender System: Exxon EngineeringTala RamezaniNo ratings yet

- Materials System SpecificationDocument12 pagesMaterials System SpecificationRami ELLOUMINo ratings yet

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDocument4 pagesSaudi Aramco Pre-Commissioning Form: Testing Guide LinesSathiya SeelanNo ratings yet

- SP-1136 Cathodic Protection DrawingsDocument4 pagesSP-1136 Cathodic Protection Drawingshappale2002No ratings yet

- EPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionDocument140 pagesEPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionkrcomeyNo ratings yet

- 34 Samss 711Document26 pages34 Samss 711Mohamed Ahmed MaherNo ratings yet

- SAIC-K-2026 Rev 0Document2 pagesSAIC-K-2026 Rev 0philipyapNo ratings yet

- Saep 115Document12 pagesSaep 115Anonymous 4IpmN7OnNo ratings yet

- Saes-J-002 - 2012Document32 pagesSaes-J-002 - 2012NSJAa100% (1)

- Saes N 004Document5 pagesSaes N 004Mo'tasem SerdanehNo ratings yet

- Saes J 002 563dc309daabe PDFDocument31 pagesSaes J 002 563dc309daabe PDFعدیل الررحمنNo ratings yet

- 32 Samss 019Document17 pages32 Samss 019Moustafa BayoumiNo ratings yet

- 31 Samss 002Document9 pages31 Samss 002Hatem ShawkiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Ns GroutDocument2 pagesNs Groutpravi343450% (2)

- Appendix H - Sample Form of Request For Non-Destructive Testing In-Lieu of Hydrostatic Test For Facilities Under ConstructionDocument2 pagesAppendix H - Sample Form of Request For Non-Destructive Testing In-Lieu of Hydrostatic Test For Facilities Under ConstructionSOWJANYA KIRANKUMARNo ratings yet

- 01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringDocument4 pages01-SAMSS-023 PDF - Intrusive Online Corrosion MonitoringZahidRafiqueNo ratings yet

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- 32 Samss 006Document22 pages32 Samss 006Vajid MadathilNo ratings yet

- 01 Samss 016Document13 pages01 Samss 016Jeck MaquitedNo ratings yet

- Pipeline Road Crossing SpecificationDocument15 pagesPipeline Road Crossing SpecificationSend Mail100% (1)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- Saes B 062Document32 pagesSaes B 062Neeraj kumarNo ratings yet

- Business Report WritingDocument7 pagesBusiness Report WritingnsrmurthyNo ratings yet

- Welding HandbookDocument48 pagesWelding HandbookMohan Prasad.M93% (27)

- w Ab 036386 硬度检测点要求Document1 pagew Ab 036386 硬度检测点要求essence1No ratings yet

- Arabic Version ISO 9001-2008Document40 pagesArabic Version ISO 9001-2008Mohammed FattoumNo ratings yet

- Project Hse Plan Rev2 Scribd#Archive TrialDocument25 pagesProject Hse Plan Rev2 Scribd#Archive Trialessence1No ratings yet

- Aramco Reference StandardDocument49 pagesAramco Reference Standardessence1100% (1)

- NDT Training Plan 2009 - V9.7Document11 pagesNDT Training Plan 2009 - V9.7essence1No ratings yet

- Lectroetch Electrolyte LNC3Document6 pagesLectroetch Electrolyte LNC3edgarNo ratings yet

- Helideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Document54 pagesHelideck Emergency Response Team Member Hertm Training Standard Available From 1st Jan 2018Ganesh GanyNo ratings yet

- FIRE MCQs IDocument13 pagesFIRE MCQs Imido AANo ratings yet

- Foth Engineering Report - PFASDocument125 pagesFoth Engineering Report - PFASGazetteonlineNo ratings yet

- Fire Technology and Arson InvestigationDocument26 pagesFire Technology and Arson InvestigationJovie Dacoycoy75% (4)

- Upgrade your vessels' foam systems with our IMO-compliant AFFF 3% F-25Document2 pagesUpgrade your vessels' foam systems with our IMO-compliant AFFF 3% F-25ArturNo ratings yet

- Safety data sheet for black laser marking aerosolDocument11 pagesSafety data sheet for black laser marking aerosolpeppeto373137No ratings yet

- OISD-115 Guide Lines in Fire Fighting EquipmentDocument70 pagesOISD-115 Guide Lines in Fire Fighting Equipmentakbavra89% (9)

- MATERIAL SAFETY DATA SHEET FOR ENKLO HLP 46 LUBRICATING OILDocument4 pagesMATERIAL SAFETY DATA SHEET FOR ENKLO HLP 46 LUBRICATING OILRandax BhosdaxNo ratings yet

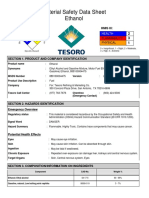

- Material Safety Data Sheet Ethanol: Nfpa: Hmis IiiDocument11 pagesMaterial Safety Data Sheet Ethanol: Nfpa: Hmis IiiNanaris variiNo ratings yet

- msds6 PDFDocument4 pagesmsds6 PDFnecklal soniNo ratings yet

- Safety Data Sheet: - Made Under Licence of European Label System® Msds Software From Infodyne - HTTPDocument11 pagesSafety Data Sheet: - Made Under Licence of European Label System® Msds Software From Infodyne - HTTPSeleccion Tecnico IndustrialNo ratings yet

- Firfighting Operations 2Document606 pagesFirfighting Operations 2San Antonio Fire StationNo ratings yet

- TF Foam Discharge Head: ApplicationDocument2 pagesTF Foam Discharge Head: ApplicationhemantNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilDocument11 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company Decant OilZakyAlFatonyNo ratings yet

- Raudha Technologies Limited: Safety & IT SolutionsDocument22 pagesRaudha Technologies Limited: Safety & IT Solutionshafeez m falkeNo ratings yet

- Atila TDS 5.0 enDocument2 pagesAtila TDS 5.0 enFranciscoVicenteNo ratings yet

- Ansulite A336 USCG 3%x3% AR-AFFF Concentrate: DescriptionDocument2 pagesAnsulite A336 USCG 3%x3% AR-AFFF Concentrate: Descriptionaprk_paulrajNo ratings yet

- Thunderstorm Atc Ar-Afff 1% or 3% Fc-601aDocument8 pagesThunderstorm Atc Ar-Afff 1% or 3% Fc-601aalsan15No ratings yet

- Fire Fighting System PSPDocument7 pagesFire Fighting System PSPYuliana Henny Tamara PurbaNo ratings yet

- Blu SepDocument2 pagesBlu SepChris AndersonNo ratings yet

- EMACO Product Catalog 2018 V 1 d19032018 (LR)Document59 pagesEMACO Product Catalog 2018 V 1 d19032018 (LR)Yasir ArafatNo ratings yet

- Catalogue 2019Document450 pagesCatalogue 2019AntonNo ratings yet

- Dowtherm ADocument9 pagesDowtherm AÖmer LaçinNo ratings yet

- Fire ExtinguisherDocument9 pagesFire ExtinguisherValentin RadulescuNo ratings yet

- Foshan Tian Bao Li Silicone Engineering Technology Co., Ltd. Material Safety Data SheetDocument5 pagesFoshan Tian Bao Li Silicone Engineering Technology Co., Ltd. Material Safety Data SheetShahramNo ratings yet

- Fixed or Semi Fixed Foam...Document35 pagesFixed or Semi Fixed Foam...carybe69100% (1)

- Carbon Remover: Safety Data SheetDocument6 pagesCarbon Remover: Safety Data SheetAnonymous yyjpEsydasNo ratings yet

- F 85144Document2 pagesF 85144Nestor GalianoNo ratings yet

- MSDS DowfrostDocument7 pagesMSDS DowfrosttranhungNo ratings yet