Professional Documents

Culture Documents

US1153992 - Collumn Still

Uploaded by

etyseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

US1153992 - Collumn Still

Uploaded by

etyseCopyright:

Available Formats

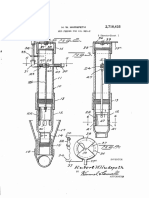

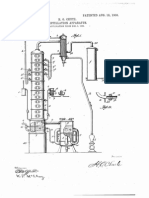

A. WOOLNER, JR.

DISTlLLATlON.

1915399920

APPLICATION FILED JUNE 27. 1914.

PatentedSept. 21, 1915.

45

527

nae/2271'

4%

STATES AE TQFFIQE

ADOLPH WOOLNER, JR., 0F PEORIA, ILLINOIS.

DISTILLATION.

' Speci?cation of Letters Patent.

1,153,992.

Patented. Sept._21, 1915.

Original application ?led November 3, 1910, Serial No. 590,571. Divided and this application ?leu J'uneiw;

1914.

Serial No. 847,573.

ous distilling apparatus and method which

Be it known that I, ADOLPH VVooLNnR, permit a prolonged heating of the beer

Jr., a citizen of the United States, residing thereby assuring the production of highly

at Peoria, in the county of Peoria and State ?avored spirits as by the old pot still proc

T0 all whom it may concern:

.of Illinois, have invented certain new and

ess, without reducing the steam economy of 60

useful Improvements in Distillation, of the continuousstill referred to, and in my

which the following is a speci?cation, this new apparatus and method the heating of

being a division of my co-pending applica the slop is done indirectly and a more con

tion Serial No. 590,571, patented July 28, centrated slop is produced than in those

stills in which the heating is done by direct

'10 1914, No. 1,104,948.

This invention relates to the art of dis steam. The distillation of the beer, fer

tilling, its leading and principal objects be! mentedmash or wort, without the intro

ing the distillation of spirits in such a man

duction of the steam into the same is not

'1 ner that a spirit of improved ?avor is eco

. new and there are various constructions of

65

is nomically obtained and the residue or slop stills provided with a system of steam-heat

70

of distillation is concentrated to a higher ing pipes for the purpose of boiling the beer

degree than has heretofore been customary ' with the indirect steam, and also providing

for mechanical agitation. It has been

In order to obtain a full and complete found, however, that when this indirect

understanding of the various advantages method or apparatus is used the heating 75

and bene?ts of this invention and its place surface becomes coatederather quickly with e

in the industry of distillation it is necessary a thick crust of organic matter, which ad

to brie?y review the development of this heres to the heating surface and prevents

art. Formerly the distillation of alcoholic the economical transmission of heat there

or usual,

20

25 liquors was carried on in so-called pot

through, consequently making this method

80.

stills an apparatus in which the fermented of indirect heating ineffective and unsatis

wort or mash,the so-called beer, was heat

factory. My present invention avoids this

difliculty by maintaining the slop continu

count of the comparatively long heating and ously in rapid circulation by running the

ed by the direct action of the ?re.

30

On ac

boiling of the beerby such apparatus and Slop in a thin ?lm over the heated surface,

process highly ?avored .spirits were pro

preferably with the aid of a circulating

duced containing compounds agreeable both pump. Such a clean heating surface by the

to taste and smell, and'bringing, about the forced circulation of the slop as obtained by

distillation of higher alcohols and fatty this invention is not only important because

35

40

acids essential or necessary to the produc of the more e?icient heat transmission, but

tion of ?ne ?avor. Obviously this method it also avoids the detrimental in?uence

of distillation was both uneconomical and which incrustation on the steam heated sur

quite unhandy and was consequently grad face has on the quality of the distillate, be

ually supplanted or displaced by steam dis

cause an overheated burnt crust causes a

tillation, the steam being delivered directly

burnt taste and smell in such distillate.~

90

In order that those skilled in the art may

this process of distillation was carried out have a thorough understanding of this im

into the beer or fermented mash. At ?rst

by successive charges placed in the pot stills proved process and novel apparatus, I have

45

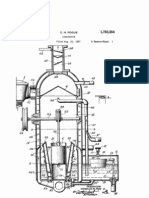

and later on the continuous beer still was illustrated in the accompanying drawing an

developed, the same being a more economical embodiment-of the invention capable of, car

construction and method. The earlier still rying out the improved method of distilling.

operated by charges produced a better ?a

In this drawing the view illustrates the

vored product because the beer or mash

was boiled during a longer time, but more

parts of the apparatus partially in elevation

50 steam was used, however, than. was em

and partially in section.

A suitable pump 11.is connected by a pipe

100

105

ployed .in the continuously operating still 12 to a beer heater 13, the latter in turn be

and obviously both produced a slop diluted ing connected to a reservoir 14, of substan

by the condensed water derived from the tial capacity, by a pipe 15, the lower end of

such reservoir being in communication with

steam.

55

My present inventionprovides a continu

a still or distilling column 16,,of any suit

10

1,153,992

able and desirable type, by a pipe 17, sup

tated in the usual manner by a belt not

plied with a controlling valve 18. The top shown. This reservoir is also equipped with

end of this still 16 is in communication with a thermometer 55, and a standing-glass 56.

The carrying out of my improved proc

the vapor compartment or chamber 19 of the

beer heater 13 by a pipe 20, it being under ess or method by this-form and type of ap

70

stood that this vapor compartment has ex paratus takes place in substantially the fol

tended therethrough a plurality of passages lowing manner: The pump 11 continually

21, through which the fermented wort or feeds the beer or fermented wort or mash,

beer is forced. The lower end of this vapor to the beer heater 13 and through the pas

compartment or chamber 19, is connected by sages 21 thereof to the pipe 15, to the reser .75

a pipe 22with the top portion of the still voir 14, and from the latter through the pipe

as indicated, and at a point higher up the

compartment 19 is connected to a condenser

15

v23 by a pipe 24, such condenser having the

condensing water inlet and outlet pipes 25

and 26 respectively; such condenser being

also supplied with a discharge pipe 27 for

the high wines or alcoholic liquors.

17 to still 16. The heated steam or vapor

from the steam boiled slop in the concentra

tor acts upon the heated beer or fermented

mash in the still and drives off the volatile 80

constituents or alcoholic vapor which arises,

through the pipe 30 to the vapor compart

ment 19 of the-beer heater 13, acting in such

In the lower portion of the still 16 there compartment to heat the beer pumped

20. is a steam chamber 28 below the still and through the passages 21. A portion of such 85

in communication therewith, I employ a vapors, that is the heavier ones, are con

steam-heated slop boiler or concentrator densed and ?ow back through the pipe 22

having an outer shell 29, a steam chamber to the still, while the lighter vapors or vola-v

30 at one end between an end wall 31 and an tile constituents pass through the pipe 24

apertured header 32 having secured in its and are lique?ed in the condenser 23, be 90

holes a plurality of comparatively long ing discharged through the pipe 27, being _

steam pipes 33 open at their remote ends, understood that condensing water 1s con

steam being admitted to the compartment 30 tinually forced through the condenser 23 by

through an inlet pipe 34. Between the means of the pipes 25' and 26. After the

.80 header 32 and another header 35 is an ex fermented wort or beer has passed through 95

haust chamber 36 in communication with the heater 13 and been raised to a tempera

the various pipes 37 surrounding and spaced ture approximating the boiling point it is

away from the pipes 33, and closed at one retained for some time'in the reservoir 14,

end and in communication at the other end the dimensions of the reservoir being suchv

85 ~with the chamber 36. A heating coil 38 in as to hold a quantity of beer equivalent to

100

coil 38 in turn having a discharge 40. The to a prolonged heating at a temperature ap

upper portion of the slop boiler or concen proximating the boiling point by coil 38 and.

40 trator has a distribution chamber 41, the agitated by the mechanical stirrer 30. Such

105

the reservoiror receptacle 14, is connected three or four times the hourly capacity of

to this exhaust chamber 36 by a pipe 39, the the still, so that the beer is therein subjected

lower wall of which is disposed above the prolonged heating as has been described

steam pipes 33, 37, and is composed of a above develops the formation of compounds

perforated partition or distributing plate particularly pleasing to the taste and smell,

14:2. The slop free, or substantially free from and brings about the subsequent distillation

45 alcohol, is delivered from the still 16 into a of certain higher alcohols and fatty acids cup or pan 43 from which it over-?ows onto essential to the production of a ?ne ?avor,

and this feature of the process forms the

the perforated or apertured plate 42.

_

The lower portion of the concentrator is principal subject matter of the parent ap- v

connected by a pipe 44 to a pump 45, which plication, of which this is a division.

50 in turn is connected to the distributing , The slop when it reaches the concentrator 115

chamber 41 by another pipe 46. Near one or boiler 29, after passing through the per

end of this concentrator is a discharge pipe forated distributing plate 42, comes in- con~

47 in communication with the lnterior of tact with the steam-heating pipes 37 , pass

55

this slop boiler, such pipe having a. control-h ing over the same in the form vof a thin ?lm,

which is governed by the actuation of a the action of the circulating'pump 45, caus-v

ing a constant-heavy torrential rain of slop

ling valve 48, the opening and closing of the distributing plate in conjunction with

on the pipes, the washing effect of which is

to

prevent the formation of any incrustation

ceptacle 14, it will be noticed that the lower

portion of the same beneath the heating on such pipes thereby maintaining an e?i

coil 38, is equipped with a rotary stlrrer or cient transmission of heat from the pipes to

120

Referring again to the reservoir or re

agitator 50 mounted on a revoluble shaft 51

the slop and preventing the development of

one of which is on a drive shaft

late, due to an over-heated or burnt crust.

125

' rotated "by meansof interme'shing gears 52, an objectionable taste or smell in the distil

sup

plied with pulleys 54, this shaft being ro

The discharge of the concentrated slop 18*:{3

333

1,153,992

controlled by the ?oat 49, the movement of vapor developed by said concentration being 65

which is necessarilygoverned by the amount substantially free from qualities which

of slop accumulated iii'ithe bottom of the would tend to injure the ?avor of the mash

concentrator, but under ordinary working and being employed to effect such distllla

conditionsthe discharge of slop would be tion, substantially as described. 2. The method of distilling, which consists

substantially continuous and uniform. The

in

distilling the volatile constituents from 70

chamber 28 is connected through the pipe 57

10

with a pressure gage 58, which shows the saidmash, and concentrating the resulting

pressure prevailing in the column, and a slop by circulating the same for an eXtend-- .

slop tester 59 which shows whether the va , ed period rapidly in a thin ?lm over a heat

por coming from the slop boiler 28 is free ed surface, the vapor resulting from such

of alcohol. This pressure gage and slop concentration being substantially free from 75

tester are of known construction, and do objectionable qualities which would tend to .

not form part of my present invention. It injure the developed ?avor and being em

15 should be understood therefore that in this ployed to effect said distillation, substan

process and in the operation of this appa~ tially as described.

3. The method of distilling, which consists 80

ratus the fermented wort or beer is heated

in

distilling the volatile constituents from

by the action of the hot volatile constituents

of the mash delivered from the still, and the mash, and concentrating the resulting

20 that the beer is subsequently subjected to slop by applying the same in the form of a

an'extended or prolonged heating and agita heavy rain to a heated surface, the vaporre

tion in the reservoir 14, in time passing to sulting from such concentration being sub 85

the still and having its volatile constituents stantially free from objectionable qualities

or alcoholic vapors driven off by the action which would tend to injure the developed

25 of the steam or vapor from the boiling slop ?avor and being employed to effect said dis

in the concentrator, its volatile constituents tillation, substantially as described.

4. The method of distilling, which consists 90

in turn heating another portion of the con

in

distilling the volatile constituents from

tinuously pumped or conveyed beer. The

action of the steam heated concentrator is the mash, and concentrating the resulting

30

continuous and it operates in such a manner

that the heated surfaces are maintained sub

35

40

stantially clean and free from incrustation,

the condensed steam of such concentrator in

turn being used to heat the beer or ferment

ed mash in the reservoir. Clearly then this

process is carried out and this apparatus

slop by projecting the same forcibly against

a heated surface, the vapor resulting from

such concentration'being substantially free

from objectionable qualities which would

tend to injure the developed ?avor and be

95

ing employed to effect said distillation, sub

stantially as described.

'

5. The method of distilling, which consists 100

is operated at a maximum of economy with

a resulting ?nely ?avored alcoholic or spirit in continuously distilling the volatile con

uous liquor and the slop concentrated to a stituents from the mash, continuously conhigher degree than has heretofore been ac centrating the resulting slop by applying

complished.

'

"

The invention is not limited to this par

the same with force against a heated sur

face, and continuously withdrawing a por- 105 .

tion of such slop, the vapor resulting from

advantages hereinabove mentioned may be such concentration being substantially free

secured by employing other devices of some from objectionable qualities which would

what similar construction and various modi tend to injure the developed ?avor and be

?cations in the process which may be used ing employed to effect said distillation, sub- 110

, ticular apparatus because the bene?ts and

45

without departure from the heart or essence

of the invention.

While I have herein

stantially as described.

6. The method of distilling, which consists

in distilling the volatile constituents from

the slop boiler or concentrator for heating the mash, concentrating the resulting slop,

the beer or fermented mash in the reservoir and mechanicallyv circulating the slop dur- 115

14, I wish to have it understood that the ing its concentration, the vapor resulting

50

shown the use of the condensed steam from

55

hot spent slop may, if desired, be used for from such concentration being substantially

the same purpose instead of. the condensed "free from objectionable qualities which

steam and in place of the same any other would tend to injure the developed ?avor

suitable heating medium might be employed. and being employed to effect said distilla- 120

I claim:

>

tion, substantially as described.

1. The method of distilling, which con60

sists in distilling the volatile constituents

from the fermented mash, and. concentrat

ing the resulting slop by passing the same

in a thin ?lm over a heated surface, the

'

ADOLPI-I WOOLNER, JR. Witnesses:

WILLIAM BOURKE,

R. G. RYAN.

'

You might also like

- Van - Usen: Geothermal, Exchange SystemDocument6 pagesVan - Usen: Geothermal, Exchange SystemLuis OlivaNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- July 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Document3 pagesJuly 5, 1966 P. H. Koch 3,259,111 : Filed June 25, 1964Anonymous KzJcjGCJbNo ratings yet

- United States 1,781,541 Patent OfficeDocument4 pagesUnited States 1,781,541 Patent OfficeAdam SubhanNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- Us 2498806Document7 pagesUs 2498806regina pramuditaNo ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Rotating double shell heat exchange drumDocument5 pagesRotating double shell heat exchange drumaegosmithNo ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- Improving Distillation with an Apparatus for Separating ImpuritiesDocument3 pagesImproving Distillation with an Apparatus for Separating ImpuritiesHansel Sterling SeverinoNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNo ratings yet

- US1586732 - Collumn StillDocument4 pagesUS1586732 - Collumn StilletyseNo ratings yet

- Illllìlllllll - Ill - Llllliiil: June 27, 1972 D, D. KaysDocument6 pagesIllllìlllllll - Ill - Llllliiil: June 27, 1972 D, D. KaysPrakash GovindanNo ratings yet

- Us 4396789Document7 pagesUs 4396789Elias JúniorNo ratings yet

- Guide to Vaporizing Liquid Fuel for EnginesDocument8 pagesGuide to Vaporizing Liquid Fuel for EnginesXavi Granados ContrerasNo ratings yet

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- P. Profos: Filed April 21, 1959Document3 pagesP. Profos: Filed April 21, 1959Anonymous KzJcjGCJbNo ratings yet

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Document5 pagesGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiNo ratings yet

- 1940 Patent for Hydrochloric Acid Absorption Process Using Air CoolingDocument7 pages1940 Patent for Hydrochloric Acid Absorption Process Using Air CoolingCésarSánchezRosasNo ratings yet

- Counter-pressure filler valve for beveragesDocument3 pagesCounter-pressure filler valve for beveragesbimalishaNo ratings yet

- Once Through Boiler Recirculation PumpDocument6 pagesOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்No ratings yet

- Us 2409624Document6 pagesUs 2409624Giovanni BlancoNo ratings yet

- Teal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210Document4 pagesTeal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210juzmailmaNo ratings yet

- A. A. Maccubbin E Tal: Filed Aug. 14, 1930Document7 pagesA. A. Maccubbin E Tal: Filed Aug. 14, 1930Gökhan Kürşat demirNo ratings yet

- US1915354Document6 pagesUS1915354Muhammad Akbar FahleviNo ratings yet

- 2011 PaperA Elec-Mech enDocument19 pages2011 PaperA Elec-Mech enMohammed AbdalrhmanNo ratings yet

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Document3 pagesJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNo ratings yet

- Duplais 1882 SchematicDocument2 pagesDuplais 1882 Schematicmkell369No ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- US3230974 E61 PatentDocument3 pagesUS3230974 E61 Patentspanglish6969No ratings yet

- No. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterDocument5 pagesNo. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterpavandattaNo ratings yet

- April 12, 1966. H. Sanders 3,245,800: Process of Producing Fried Chicken Under PressureDocument3 pagesApril 12, 1966. H. Sanders 3,245,800: Process of Producing Fried Chicken Under PressurezeldaikNo ratings yet

- Steam Plant FundamentalsDocument228 pagesSteam Plant FundamentalsMark Allen San Antonio100% (1)

- Thermal LabDocument11 pagesThermal LabParam MehtaNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Umted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979Document12 pagesUmted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979_Asylum_No ratings yet

- (1975, Sept. 9) US3903963 Heat ExchangerDocument4 pages(1975, Sept. 9) US3903963 Heat ExchangeraegosmithNo ratings yet

- Rasa SystemDocument5 pagesRasa SystemShan SinghNo ratings yet

- Distillation LabwareDocument47 pagesDistillation LabwareMagikFungus100% (3)

- Hargreaves ProcessDocument7 pagesHargreaves ProcessMuhammad BilalNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- March 15,: Distillation Apparatus UsefueforDocument5 pagesMarch 15,: Distillation Apparatus UsefueforsambasivaNo ratings yet

- Us3048465 PDFDocument8 pagesUs3048465 PDFrevider451No ratings yet

- United States Patent (19) : (73) AssigneeDocument7 pagesUnited States Patent (19) : (73) AssigneechenguofuNo ratings yet

- Nov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Document5 pagesNov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Anggara T NugrahaNo ratings yet

- v50 1757-Page 301Document1 pagev50 1757-Page 301anoncbyNo ratings yet

- Jan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952Document3 pagesJan-27, 1959 ' - G. Baecklund 2,870,866: Method of Obtaining Acetaldehyde ' Filed June 14, 1952MuhlisaApriliaNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- Evaporators: Waste Heat RecoveryDocument8 pagesEvaporators: Waste Heat RecoveryJitendra KumarNo ratings yet

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163No ratings yet

- High Pressure BoilersDocument15 pagesHigh Pressure BoilersChaitanya MsrkNo ratings yet

- Murray 1975 Hexano-BencenoDocument8 pagesMurray 1975 Hexano-BencenoJohan Sebastian Quintero RuedaNo ratings yet

- Controlling holding time in infusion heating apparatusDocument26 pagesControlling holding time in infusion heating apparatusalejjavierdelgadoNo ratings yet

- Haynes - Curme - 1923 - Production of EthyleneDocument6 pagesHaynes - Curme - 1923 - Production of EthyleneEdwinAndresRodriguezNo ratings yet

- US2573978Document4 pagesUS2573978Sebastian GonzalezNo ratings yet

- US1306865Document4 pagesUS1306865Kamal Vijay Ram R SNo ratings yet

- US2210720 Rocket PatentDocument3 pagesUS2210720 Rocket PatentGedi MinsterNo ratings yet

- S SSS L, SS S SS SN S SS S: March 19, 1968 N. L. Carr Etal 3,374,280Document4 pagesS SSS L, SS S SS SN S SS S: March 19, 1968 N. L. Carr Etal 3,374,280toastcfhNo ratings yet

- US2643220 - Collumn StillDocument14 pagesUS2643220 - Collumn StilletyseNo ratings yet

- US896434 - Collumn StillDocument5 pagesUS896434 - Collumn StilletyseNo ratings yet

- EP0049584B1 - Distillation SistemDocument11 pagesEP0049584B1 - Distillation SistemetyseNo ratings yet

- US887793 Collumn StillDocument7 pagesUS887793 Collumn StilletyseNo ratings yet

- US1586732 - Collumn StillDocument4 pagesUS1586732 - Collumn StilletyseNo ratings yet

- Lost GoldDocument35 pagesLost Goldetyse100% (1)

- Brandy de MelaoDocument15 pagesBrandy de MelaoetyseNo ratings yet

- Mercury-Free Gold Mining Technologies for the GuianasDocument8 pagesMercury-Free Gold Mining Technologies for the Guianasetyse100% (1)

- GRG2011b - Lista de Runs Pelo Mundo - DestiladosDocument25 pagesGRG2011b - Lista de Runs Pelo Mundo - DestiladosetyseNo ratings yet

- The Craft of Whiskey DistillingDocument128 pagesThe Craft of Whiskey Distillingjossbrown3784100% (4)

- Schippers and Bendrup - Ethnomusicology Ecology and SustainabilityDocument12 pagesSchippers and Bendrup - Ethnomusicology Ecology and SustainabilityLuca GambirasioNo ratings yet

- Interview Questions and Answer or Learning Pega - 39Document11 pagesInterview Questions and Answer or Learning Pega - 39Sharad Mishra100% (1)

- Overview On Image Captioning TechniquesDocument6 pagesOverview On Image Captioning TechniquesWARSE JournalsNo ratings yet

- Section 3.4 The Conditional and Related StatementsDocument11 pagesSection 3.4 The Conditional and Related Statementsmister sparklesNo ratings yet

- Sculptures by The SeaDocument1 pageSculptures by The Seaapi-457802597No ratings yet

- Ethics in ResearchDocument21 pagesEthics in Researchmukku_raviNo ratings yet

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098No ratings yet

- 2023 Grades 10-12 Mathematics ATP MediationDocument14 pages2023 Grades 10-12 Mathematics ATP Mediationkaybeach007No ratings yet

- Azura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFDocument191 pagesAzura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFnurul qNo ratings yet

- Detect and Diagnose HVAC Equipment ErrorsDocument1 pageDetect and Diagnose HVAC Equipment ErrorsCatalin DragomirNo ratings yet

- Bashir Ahmad NewDocument3 pagesBashir Ahmad NewBashir AhmadNo ratings yet

- Introducing The Phenomenon To Be Discussed: Stating Your OpinionDocument8 pagesIntroducing The Phenomenon To Be Discussed: Stating Your OpinionRam RaghuwanshiNo ratings yet

- Air Cooled Screw Chiller Performance SpecificationDocument2 pagesAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- Analisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanDocument25 pagesAnalisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanEma Rina SafitriNo ratings yet

- Flap System RiginDocument12 pagesFlap System RiginHarold Reyes100% (1)

- 5R Invention Activity: Science LabDocument12 pages5R Invention Activity: Science LabricardoNo ratings yet

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDocument10 pagesEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangNo ratings yet

- An Introduction to Heisenberg Groups in Analysis and GeometryDocument7 pagesAn Introduction to Heisenberg Groups in Analysis and Geometrynitrosc16703No ratings yet

- Computer Vision: Chapter 5. SegmentationDocument16 pagesComputer Vision: Chapter 5. SegmentationThịi ÁnhhNo ratings yet

- Mental AspectDocument29 pagesMental AspectBenjii CarlosNo ratings yet

- FMBXXX Quick Manual v3.5Document18 pagesFMBXXX Quick Manual v3.5AMNo ratings yet

- Audi A3 Injeção DiretaDocument109 pagesAudi A3 Injeção Diretawesley candido100% (1)

- Global Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy ProfessionDocument21 pagesGlobal Financial Reporting Convergence: A Study of The Adoption of International Financial Reporting Standards by The Swedish Accountancy Professionihda0farhatun0nisakNo ratings yet

- Designing of 3 Phase Induction Motor Blackbook DoneDocument30 pagesDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- Ajp Microproject ReportDocument9 pagesAjp Microproject ReportRushikesh KanseNo ratings yet

- CitationCJ4-CB Checklists B v1.2Document4 pagesCitationCJ4-CB Checklists B v1.2Joao Vitor RojasNo ratings yet

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Document7 pagesAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYNo ratings yet

- Electronics Today 1977 10Document84 pagesElectronics Today 1977 10cornel_24100% (3)

- 2 Acceleration Questions and AnswersDocument2 pages2 Acceleration Questions and Answersapi-272986951100% (2)

- The historical evolution of organizational behavior and how it shaped modern managementDocument3 pagesThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet