Professional Documents

Culture Documents

How2 Beamsv2 FINAL

Uploaded by

boyzesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How2 Beamsv2 FINAL

Uploaded by

boyzesCopyright:

Available Formats

Euro2-05_BeamsFinal.

qxd

9/2/06

11:03 am

Page 1

4. Beams

How to design concrete structures using Eurocode 2

4. Beams

R M Moss BSc, PhD, DIC, CEng, MICE, MIStructE O Brooker BEng, CEng, MICE, MIStructE

Introduction

The introduction of European standards to UK

construction is a significant event. The ten design

standards, known as the Eurocodes, will affect

all design and construction activities as current

British standards for design are due to be

withdrawn in 2010.

This publication is part of the series of guides

entitled How to design concrete structures using

Eurocode 2. Their aim is to make the transition to

Eurocode 2: Design of concrete structures as easy

as possible by drawing together in one place key

information and commentary required for the

design of typical concrete elements.

The cement and concrete industry recognised that

a substantial effort was required to ensure that

the UK design profession would be able to use

Eurocode 2 quickly, effectively, efficiently and

with confidence. With support from government,

consultants and relevant industry bodies, the

Concrete Industry Eurocode 2 Group (CIEG) was

formed in 1999 and this Group has provided the

guidance for a co-ordinated and collaborative

approach to the introduction of Eurocode 2. As

a result, a range of resources is to be made

available through The Concrete Centre to help

designers during the transition period (see back

cover for details).

Designing to Eurocode 2

This guide covers the analysis and design of concrete beams to Eurocode 21

which is essentially the same as with BS 81102. However, the layout and

content of Eurocode 2 may appear unusual to designers familiar with BS 8110.

Eurocode 2 does not contain the derived formulae or specific guidance on

determining moments and shear forces. This has arisen because it has

been European practice to give principles in the codes and for the detailed

application to be presented in other sources such as textbooks.

The first guide in this series, How to design concrete structures using Eurocode 2:

Introduction to Eurocodes3, highlighted the key differences between Eurocode 2

and BS 8110, including terminology.

It should be noted that values from the UK National Annex (NA) have been

used throughout this guide, including values that are embedded in derived

formulae (derivations can be found at www.eurocode2.info). A list of symbols

related to beam design is given at the end of this guide.

Design procedure

A procedure for carrying out the detailed design of beams is shown in Table 1.

This assumes that the beam dimensions have previously been determined

during conceptual design. Concept designs prepared assuming detailed design

would be to BS 8110 may be continued through to detailed design using

Eurocode 2. More detailed advice on determining design life, actions, material

properties, methods of analysis, minimum concrete cover for durability and

control of crack widths can be found in the accompanying guide How to

design concrete structures using Eurocode 2: Getting started 4.

Fire resistance

Eurocode 2, Part 12: Structural fire design6, gives a choice of advanced,

simplified or tabular methods for determining the fire resistance. Using tables

is the fastest method for determining the minimum dimensions and cover

for beams. There are, however, some restrictions and if these apply further

guidance on the advanced and simplified methods can be obtained from

specialist literature. Rather than giving a minimum cover, the tabular method

is based on nominal axis distance, a (see Figure 1). This is the distance from

the centre of the main reinforcing bar to the top or bottom surface of the

Continues page 3

Euro2-05_BeamsFinal.qxd

9/2/06

11:03 am

Page 2

How to design concrete structures using Eurocode 2

Table 1

Beam design procedure

Step Task

Further guidance

1

2

3

4

5

6

Determine design life

Assess actions on the beam

Determine which combinations of actions apply

Determine loading arrangements

Assess durability requirements and determine concrete strength

Check cover requirements for appropriate fire resistance period

7

8

9

10

11

12

Calculate min. cover for durability, fire and bond requirements

Analyse structure to obtain critical moments and shear forces

Design flexural reinforcement

Check shear capacity

Check deflection

Check spacing of bars

How to guide

Getting started

Getting started

Introduction to Eurocodes

Getting started

Getting started

Getting started and Fire resistance

section of this guide

Getting started

Getting started and Table 3 of this guide

See Flexure section of this guide

See Vertical shear section of this guide

See Deflection section of this guide

Getting started

Standard

NA to BS EN 1990 Table NA.2.1

BS EN 1991 (10 parts) and National Annexes

NA to BS EN 1990 Tables NA.A1.1 and NA.A1.2 (B)

NA to BS EN 199211

BS 8500: 2002

Approved Document B. BS EN 199211: Section 5

BS EN 199211 Cl 4.4.1

BS EN 199211 section 5

BS EN 199211 section 6.1

BS EN 199211 section 6.2

BS EN 199211 section 7.4

BS EN 199211 section 7.3

Note

NA = National Annex

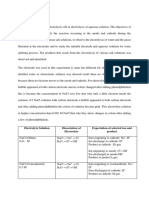

Table 2

Minimum dimensions and axis distances for beams made with reinforced concrete for fire resistance

Standard fire resistance

R60

Minimum dimensions (mm)

Possible combinations of a and bmin where a is the average axis distance and bmin is the width of the beam

Simply supported beams

Continuous beams

A

B

C

D

E

F

G

H

120

160

300

300

120

200

40

35

30

25

25

12a

150

200

300

400

150

250

55

45

40

35

35

25

200

240

300

500

200

300

450

500

65

60

55

50

45

35

35

30

280

350

500

700

280

500

650

700

90

80

75

70

75

60

60

50

bmin =

a=

bmin =

a=

bmin =

a=

bmin =

a=

R90

R120

R240

Notes

1 This table is taken from BS EN 199212 Tables 5.5 and 5.6.

2 The axis distance, asd , from the side of the beam to the corner bar should be a +10 mm except where bmin is greater than the values in columns C and F.

3 The table is valid only if the detailing requirements (see note 4) are observed and, in normal temperature design, redistribution of bending moments does not exceed 15%.

4 For fire resistance of R90 and above, for a distance of 0.3l eff from the centre line of each intermediate support, the area of top reinforcement should not be less than the following:

A s,req (x) = A s,req ( 0 )( 1 2.5 ( x/ l eff ) )

where:

x

is the distance of the section being considered from the centre line of the support.

A s,req ( 0 ) is the area of reinforcement required for normal temperature design.

A s,req (x) is the minimum area of reinforcement required at the section being considered but not less than that required for normal temperature design.

l eff

is the greater of the effective lengths of the two adjacent spans.

5 For fire resistances R120 R240, the width of the beam at the first intermediate support should be at least that in column F, if both the following conditions exist:

a there is no fixity at the end support; and

b the acting shear at normal temperature Vsd > 0.67 V Rd,max .

Key

a Normally the requirements of BS EN 199211 will determine the cover.

Figure 1

Figure 3

Section through structural member,

showing nominal axis distances a and asd

Simplified rectangular stress block for

concrete up to class C50/60 from Eurocode 2

b

x

h>b

h

a

asd

As2

d2

sc

fcd

0.8x

Fsc

Fc

Neutral axis

z

As

Section

s

Strain

Fst

Stress block and forces

Euro2-05_BeamsFinal.qxd

9/2/06

11:03 am

Page 3

4. Beams

member. It is a nominal (not minimum) dimension, so the designer

should ensure that:

a cnom + f link + f bar /2 and asd = a + 10 mm

Table 2 gives the minimum dimensions for beams to meet the

standard fire periods.

Figure 2

Procedure for determining flexural reinforcement

START

Carry out analysis of beam to determine

design moments (M) (see Table 3)

Flexure

The design procedure for flexural design is given in Figure 2; this includes

derived formulae based on the simplified rectangular stress block from

Eurocode 2. Table 3 may be used to determine bending moments and

shear forces for beams, provided the notes to the table are observed.

Determine K from K =

At first interior support

At middle of interior spans

At interior supports

Moment

Shear

25% of span moment

0.45 (G + Q)

No

Is K K ?

0.090 Gl + 0.100 Ql

0.094 (G + Q) l

M

bd 2 fck

Determine K from Table 4 or

K = 0.60d 0.18 d2 0.21

where d 1.0

Bending moment and shear coefficients for beams

Near middle of end span

0.63 (G + Q)a

0.50 (G + Q)

No compression reinforcement required

Key

a 0.55 (G + Q) may be used adjacent to the interior span.

Notes

1 Redistribution of support moments by 15% has been included.

2 Applicable to 3 or more spans only and where Qk G k.

3 Minimum span 0.85 longest span.

4 l is the span, G is the total of the ULS permanent actions, Q is the total

of the ULS variable actions.

Obtain lever arm z from Table 5 or use

z= d

2

[1 +

1 3.53 K

] 0.95d

Values for K

Calculate lever arm z from

z = d 1 + 1 3.53 K

2

Calculate compression

reinforcement required from

As2 =

(K K) fck bd 2

fsc(d d2)

where

Calculate tension reinforcement

required from

M

As =

fyd z

Table 4

% redistribution

Compression reinforcement

required

Yes

0.066 Gl + 0.086 Ql

0.075 (G + Q) l

Outside scope of this guide

Yes

Table 3

Outer support

No

Concrete class

C50/60?

fsc = 700

x d2

x

fyd

d (redistribution ratio) K

1.00

0.205

0.95

0.193

10

0.90

0.180

15

0.85

0.166

20

0.80

0.151

25

0.75

0.136

Check minimum reinforcement

requirements (see Table 6)

0.26 fctm bt d

As,min =

where fck 25

fyk

Calculate tension

reinforcement required from

As =

Kfck bd 2

fyd z

+ As2

fsc

fyd

Check maximum reinforcement requirements As,max = 0.04 Ac

for tension or compression reinforcement outside lap locations

Table 5

z/d for singly reinforced rectangular sections

K

z/d

z/d

Table 6

0.01

0.950a

0.11

0.891

Minimum percentage of required reinforcement

0.02

0.950a

0.12

0.880

fck

fctm

Minimum percentage (0.26 fctm / fyka)

0.03

0.950a

0.13

0.868

25

2.6

0.13%

0.04

0.950a

0.14

0.856

28

2.8

0.14%

0.05

0.950a

0.15

0.843

30

2.9

0.15%

0.06

0.944

0.16

0.830

32

3.0

0.16%

0.07

0.934

0.17

0.816

35

3.2

0.17%

0.08

0.924

0.18

0.802

40

3.5

0.18%

0.09

0.913

0.19

0.787

45

3.8

0.20%

0.10

0.902

0.20

0.771

50

4.1

0.21%

Key

Key

a Limiting z to 0.95d is not a requirement of Eurocode 2, but is considered to be good practice.

a Assuming fyk = 500 MPa

Euro2-05_BeamsFinal.qxd

9/2/06

11:04 am

Page 4

How to design concrete structures using Eurocode 2

Figure 4

Eurocode 2 offers various methods for determining the stress-strain

relationship of concrete. For simplicity and familiarity the method

presented here is the simplified rectangular stress block, which is

similar to that found in BS 8110 (see Figure 3).

Strut inclination method

Concrete strut in compression

Eurocode 2 gives recommendations for the design of concrete up to

class C90/105. However, for concrete greater than class C50/60, the

stress block is modified. It is important to note that concrete strength

is based on the cylinder strength and not the cube strength (i.e. for

class C30/37 the cylinder strength ( fck ) is 30 MPa, whereas the cube

strength is 37 MPa).

Longitudinal

reinforcement in tension

Vertical shear

reinforcement

Vertical shear

Figure 5

Procedure for determining vertical shear reinforcement

Eurocode 2 introduces the strut inclination method for shear capacity

checks. In this method the shear is resisted by concrete struts acting in

compression and shear reinforcement acting in tension.

START

Determine vEd where:

vEd = design shear stress [ vEd = VEd /(bwz) = VEd /(0 9. bwd)]

Determine the concrete strut capacity v Rd, max cot y = 2.5

from Table 7

Is

vEd < vRd,max coty = 2.5?

No

Is

v Ed < v Rd,max cot y = 1.0?

(see Table 7)

Yes

(cot y = 2.5)

No Redesign

section

Yes

Determine y from:

vEd

y = 0.5 sin -1

0.20 fck (1 fck /250)

Calculate area of shear reinforcement:

vEd bw

Asw

=

s

fywd cot y

Check maximum spacing for vertical shear reinforcement:

s l, max = 0.75 d

The angle of the concrete strut varies, depending on the shear force

applied (see Figure 4). The procedure for determining the shear capacity

of a section is shown in Figure 5 (which includes UK NA values) and is

in terms of shear stress in the vertical plane rather than a vertical force

as given in Eurocode 2. Where shear reinforcement is required, then

the angle of the concrete strut should be calculated. For many typical

beams the minimum angle of strut will apply (when cot y = 2.5 or y =

21.8) i.e. for class C30/37 concrete the strut angle exceeds 21.8 only

when the shear stress is greater than 3.27 N/mm2 (refer to Table 7).

As with BS 8110, there is a maximum permitted shear capacity, vRd,max ,

(when cot y = 1.0 or y = 45), but this is not restricted to 5 MPa as in

BS 8110.

Deflection

Eurocode 2 has two alternative methods for checking deflection,

either a limiting span-to-depth ratio may be used or the theoretical

deflection can be assessed using the expressions given in the Code.

The latter is dealt with in detail in another guide in this series, How to

design concrete structures using Eurocode 2: Deflection6.

The span-to-depth ratios should ensure that deflection is limited to

span/250 and this is the procedure presented in Figure 6.

Table 7

Minimum and maximum concrete strut capacity in terms of stress

fck

20

25

28

30

32

35

40

45

50

v Rd,max cot y = 2.5

2.54

3.10

3.43

3.64

3.84

4.15

4.63

5.08

5.51

v Rd,max cot y = 1.0

3.68

4.50

4.97

5.28

5.58

6.02

6.72

7.38

8.00

Flanged beams

Flanged beams can be treated in much the same way as in BS 8110.

The main differences compared with BS 8110 are that the assessment

of the flange width is more sophisticated (see Figures 9 and 10) and

that Eurocode 2 contains a check to confirm that the shear stress at

Continues page 7

Euro2-05_BeamsFinal.qxd

9/2/06

11:04 am

Page 5

4. Beams

Figure 6

Figure 8

Procedure for assessing deflection

Determination of steel stress

START

320

300

Unmodified steel stress, ssu

Determine basic l/d and K from Figure 7

Determine Factor 1 (F1)

For ribbed or waffle slabs

F1 = 1 0.1 ((bf/bw) 1) 0.8

(bf is flange breadth and bw is rib breadth)

Otherwise F1 = 1.0

Determine Factor 2 (F2)

Where the slab span exceeds 7 m and it supports

brittle partitions, F2 = 7/leff 1.0

Otherwise F2 = 1.0

280

260

240

220

200

180

Determine Factor 3 (F3)

F3 = 310/ss

Where ss = Stress in reinforcement at serviceability

limit state (see Figure 8)

ss may assumed to be 310 MPa (i.e. F3 = 1.0)

1.0

2.0

4.0

3.0

Ratio Gk /Qk

Note: As,prov 1.5 As,reqd (UK National Annex)

Increase

As,prov

Is basic l/d x K x F1 x F2 x F3 Actual l/d ?

c2 = 0.8, gG = 1.35

c2 = 0.6, gG = 1.25

c2 = 0.6, gG = 1.35

c2 = 0.3, gG = 1.25

c2 = 0.3, gG = 1.35

c2 = 0.2, gG = 1.25

c2 = 0.2, gG = 1.35

No

Yes

To determine stress in the reinforcement (ss), calculate the ratio

Gk/Qk, read up the graph to the appropriate curve and read across

to determine ssu .

As,req

1

ss can be calculated from the expression: ss = ssu

As,prov d

Check complete

The Eurocode is ambiguous regarding linear interpolation. It is understood that

it was the intention of the drafting committee that linear interpolation be used

and this is in line with current UK practice.

)( )

Figure 7

Basic span-to-effective-depth ratios

36

Notes

34

fck = 50

32

fck = 45

fck = 40

Span to depth ratio (l/d)

30

fck = 35

fck = 32

fck = 30

28

26

1 This graph assumes simply supported span condition

(K = 1.0).

K = 1.5 for interior span condition

K = 1.3 for end span condition

K = 0.4 for cantilevers.

2 Compression reinforcement, r, has been taken as 0.

3 Curves based on the following expressions:

1.5 fck r 0

l

+ 3.2

= K 11 +

r

d

fck = 28

fck = 25

fck = 20

24

fck

( )]

1.5

r0

1

r

where r r 0

22

and

20

1.5 fck r 0

l

+

= K 11 +

d

( r r )

18

fck

12

r

r0

where r > r 0 .

16

14

12

0.40%

0.60%

0.80%

1.00%

1.20%

1.40%

1.60%

1.80%

2.00%

Percentage of tension reinforcement (A s,reqd /bd)

Euro2-05_BeamsFinal.qxd

9/2/06

11:04 am

Page 6

How to design concrete structures using Eurocode 2

Figure 11

Figure 9

Procedure for determining flexural capacity of flanged beams

Definition of lo, for calculation of effective flange width

START

l0 = 0.85 l1

l0 = 0.15 (l1 + l2 )

l1

Determine l0 (see Figure 9) and beff from:

beff = (bw + beff1 + beff2) where

beff1 = (0.2b1 + 0.1 l0) 0.2 l0 b1

beff2 = (0.2b2 + 0.1 l0) 0.2 l0 b2

l2

l3

Figure 10

Effective flange width parameters

Note: The flange width at the support will be

different from that at mid-span.

For symbols refer to Figures 9 and 10

Determine K from K =

l0 = 0.15 l2 + l3

l0 = 0.7 l2

Carry out analysis of beam to determine design

moments, M (see Table 3)

beff

beff,1

bw

b1

b1

M

bd 2 fck

beff,2

b2

b2

where b = bw at support

b = beff in span

Figure 12

Placing of tension reinforcement in flanged cross section

Determine K from Table 4 or

K = 0.60d 0.18 d2 0.21 where d 1.0

beff

As

Calculate lever arm z from

d

z=

1 + 1 3.53 K 0.95d

2

hf

beff1

Calculate depth to neutral axis x from:

beff2

bw

x = 2.5 (d z)

Yes

Is x 1.25hf ?

No

Neutral axis in

flange. Design

as rectangular

section (Figure 2)

and then check

longitudinal shear

(Figure 14)

Figure 13

Neutral axis in web

Calculate moment capacity of flange from:

Notations for the connection between flange and web

MR,f = 0.57 fck (beff bw) hf (d 0.5hf)

and

Kf =

M MR,f

Fd

fck bw d 2

Fd

yf

A

Compressive struts

beff

Dx

No

Is Kf K ?

Redesign section

hf

Longitudinal bar

anchored beyond

this projected point

Yes

Calculate area of reinforcement required from

MR,f

M MR,f

As =

+

fywd (d 0.5 hf )

fywd

Asf

Sf

Check longitudinal

shear

(see Figure 14)

Fd + D Fd

Fd + D Fd

bw

Euro2-05_BeamsFinal.qxd

9/2/06

11:04 am

Page 7

4. Beams

the interface of the flange and web can be resisted by the transverse

reinforcement in the flange. The position of the neutral axis should

be determined, and then the area of reinforcement can be calculated

depending whether it lies in the flange or web (see Figure 11).

Minimum area of shear reinforcement

At supports the tension reinforcement to resist hogging moments

should be distributed across the full width of the effective flange as

shown in Figure 12. The span-to-depth deflection checks using ratio of

tension reinforcement should be based on area of concrete above

centre of tension steel.

where r w,min can be obtained from Table 9.

The minimum area of shear reinforcement in beams, Asw,min should

be calculated from

Asw

4 r w,min

sbw

Figure 14

Procedure for determining longitudinal shear capacity of flanged beams

Longitudinal shear

Calculate the longitudinal shear stress

from: vEd = D Fd/(hf D x)

(see Figure 13)

The shear stress in the vertical plane between the flange and web should

be assessed according to section 6.2.4 and Figure 6.7 of the Eurocode

(reproduced here as Figure 13). The change in force in the flange can

be assessed from the moment and lever arm at a particular location.

The Eurocode states that the maximum length that can be considered

for the change in force is half the distance between the maximum

moment and the point where the moment is zero. Clearly, the maximum

longitudinal force will occur where the change in moment, and

therefore force, is the greatest; for a uniformly distributed load on a

continuous beam this will be the length of beam closest to the support.

No

Determine the concrete strut capacity

from Table 8 or from:

vRd = 0.195 fck (1 fck/250)

Figure 14 shows a flow chart for assessing the longitudinal shear

capacity; in many cases the transverse reinforcement in the slab will be

sufficient to resist the shear force. This check is included to ensure that

where particularly thin flanges are used there is adequate reinforcement.

The longitudinal shear capacity is based on the variable strut inclination

method, which was described in the section on vertical shear.

Rules for spacing and

quantity of reinforcement

Minimum area of longitudinal reinforcement

The minimum area of reinforcement is As,min = 0.26 fc tm b t d/fy k but

not less than 0.0013b td, where b t is the mean width of the tension

zone (see Table 6). For a T-beam with the flange in compression, only

the width of the web is taken into account in calculating the value of b

Maximum area of longitudinal reinforcement

The maximum area of tension or compression reinforcement, outside

lap locations should not exceed As,max = 0.04 Ac

Determine the concrete

strut capacity from Table 8

or from:

vRd = 0.16 fck (1 fck/250)

Yes

Is length of

flange under consideration

in tension?

Is v RD > vEd ?

Yes

Determine y f from:

No

yf = 0.5 sin-1

vEd

0.2 fck (1 fck /250)

No

(cot y f = 2.5)

Is v RD > vEd ?

Yes

(cot y f

= 2.0)

Calculate area of transverse reinforcement from:

vEd hf

Asf

=

s

fyd cot y f

Table 8

Concrete strut capacity for longitudinal shear in flanged beams

fck

20

25

28

30

32

35

40

45

50

v Rd,max (when cot y = 2.5)

Flange in tension

Flange in compression

2.94

3.60

3.98

4.22

4.46

4.82

5.38

5.90

6.40

3.59

4.39

4.85

5.15

5.44

5.87

6.55

7.20

7.80

Minimum spacing of reinforcement

The minimum clear distance between bars should be the greater of:

Bar diameter

Aggregate size plus 5 mm

20 mm

Table 9

Values for r w,min

fck

20

25

28

30

32

35

40

45

50

r w,min x 10 -3 0.72 0.80 0.85 0.88 0.91 0.95 1.01 1.07 1.13

Euro2-05_BeamsFinal.qxd

9/2/06

11:04 am

Page 8

4. Beams

Selected symbols

Symbol

Definition

Symbol

Definition

Ac

Cross sectional area of concrete

Value

lo

Distance between points of zero moment

As

Area of tension steel

l/d

Span-to-depth ratio

As2

Area of compression steel

Design moment at the ULS

As, prov

Area of tension steel provided

Depth to neutral axis

(d-z)/0.4

As, reqd

Area of tension steel required

xmax

Limiting value for depth to neutral axis

(d 0.4)d where d 1.0

beff

Effective flange width

Lever arm

bt

Mean width of the tension zone

a cc

bmin

Width of beam or rib

bw

Width of section, or width of web on flanged beams

Coefficient taking account of long term

effects on compressive strength and of

unfavourable effects resulting from the

way load is applied

Effective depth

d2

Effective depth to compression reinforcement

Ratio of the redistributed moment to the

elastic bending moment

fcd

Design value of concrete compressive strength

gm

Partial factor for material properties

fck

Characteristic cylinder strength of concrete

1.15 for reinforcement (gs)

1.5 for concrete (gc)

fctm

Mean value of axial tensile strength

r0

Reference reinforcement ratio

Rfck /1000

As/bd

hf

Flange thickness

Required tension reinforcement at mid-span

to resist the moment due to the design

loads (or at support for cantilevers)

Factor to take account of the different

structural systems

See table NA.4 in

UK National Annex

As2/bd

leff

Effective span of member

See Section 5.3.2.2 (1)

Required compression reinforcement at

mid-span to resist the moment due to the

design loads (or at support for cantilevers)

acc fck /gc for fck C50/60

0.30 fck(2/3) for fck C50/60

(from Table 3.1, Eurocode 2)

Value

0.85 for flexure and

axial loads

1.0 for other phenomena

(From UK National Annex)

References

1 BRITISH STANDARDS INSTITUTION. BS EN 199211, Eurocode 2: Design of concrete structures Part 11 General rules and rules for

buildings. BSI, 2004.

2 BRITISH STANDARDS INSTITUTION. BS 81101: The structural use of concrete Part 1, Code of practice for design and construction. BSI, 1997.

3 NARAYANAN, R S & BROOKER, O. How to design concrete structures using Eurocode 2: Introduction to Eurocodes. The Concrete Centre, 2005.

4 BROOKER, O. How to design concrete structures using Eurocode 2: Getting started. The Concrete Centre, 2005.

5 BRITISH STANDARDS INSTITUTION. BS EN 199212, Eurocode 2: Design of concrete structures. General rules structural fire design. BSI, 2004

6 WEBSTER, R & BROOKER, O. How to design concrete structures using Eurocode 2: Deflection. The Concrete Centre, 2006.

Further guidance and advice

Guides in this series cover: Introduction to Eurocodes, Getting started, Slabs, Beams, Columns, Foundations, Flat slabs and Deflection. For free

downloads, details of other publications and more information on Eurocode 2 visit www.eurocode2.info

This guide is taken from The Concrete Centres publication, How to design concrete structures using Eurocode 2 (Ref. CCIP-006)

For information on all the new Eurocodes visit www.eurocodes.co.uk

Acknowledgements

The content of this publication was produced as part of the project Eurocode 2: transition from UK to European concrete design standards. This

project was part funded by the DTI under the Partners in Innovation scheme. The lead partner was the British Cement Association. The work was

carried out under the guidance of the Concrete Industry Eurocode 2 Group, which consists of representatives from:

Alan Baxter and Associates Arup British Cement Association British Precast Building Research Establishment Clark Smith Partnership

Concrete Innovation and Design Construct Department for Trade and Industry Office of the Deputy Prime Minister The Concrete Centre

The Concrete Society Quarry Products Association.

For more information on Eurocode 2 and

other questions relating to the design, use

and performance of concrete contact the

National Helpline on:

0700 4 500 500 or 0700 4 CONCRETE

helpline@concretecentre.com

Published by The Concrete Centre

Riverside House, 4 Meadows Business Park,

Station Approach, Blackwater, Camberley,

Surrey GU17 9AB

Tel: +44 (0)1276 606800

Fax: +44 (0)1276 606801

www.concretecentre.com

Ref: TCC/03/19

ISBN 1-904818-29-3

Published February 2006, amended June 2006

The Concrete CentreTM

All advice or information from The Concrete Centre is intended for those who will evaluate the significance and limitations of its

contents and take responsibility for its use and application. No liability (including that for negligence) for any loss resulting from such

advice or information is accepted by The Concrete Centre or its subcontractors, suppliers or advisors. Readers should note that

publications from The Concrete Centre are subject to revision from time to time and they should therefore ensure that they are in

possession of the latest version. This publication has been produced following a contract placed by the Department for Trade and

Industry (DTI); the views expressed are not necessarily those of the DTI.

You might also like

- outokumpu-steel-grades-properties-global-standardsDocument20 pagesoutokumpu-steel-grades-properties-global-standardsboyzesNo ratings yet

- Design_of_Plate_GirdersDocument109 pagesDesign_of_Plate_GirdersboyzesNo ratings yet

- Spring washer dimensions and specificationsDocument2 pagesSpring washer dimensions and specificationsboyzes100% (1)

- Dewatering and Groundwater ControlDocument158 pagesDewatering and Groundwater ControljdhbulseyeNo ratings yet

- Addressing Anchors (Steelwise Article On Anchor Bolt Fixes)Document3 pagesAddressing Anchors (Steelwise Article On Anchor Bolt Fixes)Justin UyarNo ratings yet

- Interpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Document7 pagesInterpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Ashokan Keloth100% (1)

- Scaffolding PDFDocument80 pagesScaffolding PDFLeo Richmond75% (4)

- Tech update on dewatering pump selectionDocument2 pagesTech update on dewatering pump selectionboyzesNo ratings yet

- User Manual Cuplok (10-2006)Document51 pagesUser Manual Cuplok (10-2006)humaidjafri60% (5)

- Sikalastic-1 KMYDocument3 pagesSikalastic-1 KMYboyzesNo ratings yet

- MSMA2ndEdition August 2012Document807 pagesMSMA2ndEdition August 2012Haffiz Welez100% (1)

- CONSTRUCTION DEWATERING TECHNIQUESDocument4 pagesCONSTRUCTION DEWATERING TECHNIQUESAnonymous QSTAL5JpNo ratings yet

- ACI-330 Design Guide For Concrete Parking Lots PDFDocument32 pagesACI-330 Design Guide For Concrete Parking Lots PDFprmrao100% (1)

- Product Brochure Kerberos TPBDocument12 pagesProduct Brochure Kerberos TPBchandan211No ratings yet

- Steelwise - 1 - Anchor Road Too Short ArticleDocument3 pagesSteelwise - 1 - Anchor Road Too Short ArticleboyzesNo ratings yet

- ETAG 001-Annex C 10-08-01Document34 pagesETAG 001-Annex C 10-08-01jpjobduNo ratings yet

- Hilti Malaysia Product Catalogue Chapter 8 - Diamond CoringDocument10 pagesHilti Malaysia Product Catalogue Chapter 8 - Diamond CoringboyzesNo ratings yet

- Asme Section II A Sa 307 PDFDocument8 pagesAsme Section II A Sa 307 PDFboyzesNo ratings yet

- Strength Design of Anchorage To Concrete PDFDocument86 pagesStrength Design of Anchorage To Concrete PDFAl_catraz100% (2)

- Rigid Pavement Dowel Bar Mechanics and DesignDocument22 pagesRigid Pavement Dowel Bar Mechanics and DesignboyzesNo ratings yet

- Selection of Equivalent Steel Materials To European Steel Materials SpecificationsDocument154 pagesSelection of Equivalent Steel Materials To European Steel Materials SpecificationsJean-Noël LerouxNo ratings yet

- 16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionDocument89 pages16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionHimanshu SainiNo ratings yet

- Application of Second-Order Elastic Analysis in LRDocument17 pagesApplication of Second-Order Elastic Analysis in LRboyzesNo ratings yet

- Hilti - Example Calculation - 2014-09Document3 pagesHilti - Example Calculation - 2014-09boyzesNo ratings yet

- Dowel BarsDocument70 pagesDowel Barsesprindia100% (1)

- Eot Crane During SeismicDocument12 pagesEot Crane During SeismicboyzesNo ratings yet

- Hilti - Hvu Has (-E) - 2014-09Document10 pagesHilti - Hvu Has (-E) - 2014-09boyzesNo ratings yet

- Dynamics of a mathematical pendulum suspended from a moving massDocument6 pagesDynamics of a mathematical pendulum suspended from a moving massEduardo Caldas da RochaNo ratings yet

- EOTA TR29 Design of Bonded AnchorsDocument36 pagesEOTA TR29 Design of Bonded Anchorsl282No ratings yet

- 16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionDocument89 pages16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionHimanshu SainiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TXP TrainingDocument88 pagesTXP Trainingsina20795100% (1)

- Indigenous Microorganisms Production and The Effect On Composting ProcessDocument5 pagesIndigenous Microorganisms Production and The Effect On Composting ProcessAldrin Baquilid FernandezNo ratings yet

- Pure Unit 1 Topic Test FINALDocument8 pagesPure Unit 1 Topic Test FINALHNo ratings yet

- Trafo 40 Mva PDFDocument719 pagesTrafo 40 Mva PDFeug_manu8No ratings yet

- Dev - Mag - 09Document26 pagesDev - Mag - 09georgpiorczynskiNo ratings yet

- Manual EAP1.5-2kg 040Document21 pagesManual EAP1.5-2kg 040mykeenzo5658No ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- Staad FoundationDocument25 pagesStaad FoundationAnonymous nwByj9L100% (2)

- Laing Electric Heater-CirculatorDocument20 pagesLaing Electric Heater-Circulatorkamilawehbe100% (1)

- Vorplex - MST - Airblowing and Water FlushingDocument14 pagesVorplex - MST - Airblowing and Water FlushingAmirHakimRusliNo ratings yet

- Angle Facts Powerpoint ExcellentDocument10 pagesAngle Facts Powerpoint ExcellentNina100% (1)

- Components of A BarrageDocument21 pagesComponents of A BarrageEngr.Hamid Ismail CheemaNo ratings yet

- Brahma 152 192sm CM MMDocument6 pagesBrahma 152 192sm CM MMThiago FernandesNo ratings yet

- Vitamins With Minerals Oral PowderDocument8 pagesVitamins With Minerals Oral PowderWH PANDWNo ratings yet

- CN Lab ManualDocument49 pagesCN Lab ManualKN DEEPSHI100% (1)

- POWER Nav1 - MIDTERM - Topic 1 & 2Document31 pagesPOWER Nav1 - MIDTERM - Topic 1 & 2CLIJOHN PABLO FORD100% (1)

- Efectele Pe Termen Lung Ale Alaptatului OMSDocument74 pagesEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiNo ratings yet

- Movie Recommender System: Shekhar 20BCS9911 Sanya Pawar 20BCS9879 Tushar Mishra 20BCS9962Document27 pagesMovie Recommender System: Shekhar 20BCS9911 Sanya Pawar 20BCS9879 Tushar Mishra 20BCS9962Amrit SinghNo ratings yet

- EE - Revision Through Question - GATE - 2020 PDFDocument138 pagesEE - Revision Through Question - GATE - 2020 PDFRamesh KumarNo ratings yet

- Cube Nets Non-Verbal Reasoning IntroductionDocument6 pagesCube Nets Non-Verbal Reasoning Introductionmirali74No ratings yet

- Homework ClassDocument11 pagesHomework ClassHossain100% (1)

- Sky Telescope 201304Document90 pagesSky Telescope 201304Haydn BassarathNo ratings yet

- Cs8080 - Irt - Notes AllDocument281 pagesCs8080 - Irt - Notes Allmukeshmsd2No ratings yet

- C34 January 2014 (IAL)Document44 pagesC34 January 2014 (IAL)SandyDavidNo ratings yet

- Hacking TechniquesDocument84 pagesHacking Techniquesgourmetcomidas4No ratings yet

- Alili M S PDFDocument20 pagesAlili M S PDFStatsitika ITNo ratings yet

- Grade 7 Spa ReviewerDocument1 pageGrade 7 Spa ReviewerLanie De la Torre100% (1)

- Deep Glow v1.4.6 ManualDocument6 pagesDeep Glow v1.4.6 ManualWARRIOR FF100% (1)

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Document52 pagesSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNo ratings yet

- Web Intelligence XI 3.0 Parameter GuideDocument10 pagesWeb Intelligence XI 3.0 Parameter GuideJaime Andrés Triviño Sánchez0% (1)