Professional Documents

Culture Documents

FM05 Pitot Static Tube PDF

Uploaded by

Anonymous thaRdEcpDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM05 Pitot Static Tube PDF

Uploaded by

Anonymous thaRdEcpDCopyright:

Available Formats

IIT Gandhinagar, Dept.

of Mechanical Engineering

M313: Fluid Mechanics Laboratory

Version No. 1/VN/July 2010

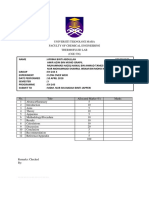

FM 05: PITOT STATIC TUBE

1. AIM

The aim of the experiment is to determine velocity of fluid at various points across the cross

section of pipe.

2. APPARATUS

The apparatus consists of a Pitot tube made of copper and fixed below a pointer gauge. The pointer

gauge is capable to measure the position of Pitot tube in transparent test section. The pipe has a

flow control valve to regulate the flow. An U-tube manometer is provided to determine the velocity

head. A pump is provided to circulate the water. The discharge is measured using a measuring tank

and a stopwatch. Relevant data pertaining to the experimental apparatus are given below:

DATA:

Cross sectional area of pipe

= 0.0006157 m2

3

Density of manometric fluid ( CCl4 )=1590 kg / m

3. RELEVANT THEORY FOR THIS EXPERIMENT

It is a device used for measuring the velocity of flow at any point in a pipe. It is based on the

principle that if the velocity of flow at a point becomes zero, there is increase in pressure due to the

conversion of the kinetic energy into pressure energy. Pitot tube measures the stagnation pressure

head (or the total head) at its dipped end. The pressure head may be determined directly by

connecting a suitable differential manometer between the Pitot tube and pressure taping at the

pipe surface.

4. EXPERIMENTAL PROCEDURE

(a) Starting Procedure:

1. Clean the apparatus and make tank free from Dust.

2. Close the drain valves provided.

3. Fill Sump tank with clean water and ensure that no foreign particles are there.

4. Close all Flow control valves given on the water line and open by-pass valve.

5. Check the level of CCl4 in all the manometer tube. It should be up to half. If it is less, then fill it.

6. Close all pressure taps of Manometer connected to manometers.

7. Ensure that On/Off switch given on the panel is at OFF position.

8. Now switch on the main power supply (220 Volts AC, 50 Hz).

9. Switch on the pump.

10. Operate the flow control valve to regulate the flow of water.

11. Open the tressure taps of the manometer of related test section very slowly to avoid the rush

of water on manometer fluidand remove the air bubbles (if any) from the manometer tube

IIT Gandhinagar, Dept. of Mechanical Engineering

M313: Fluid Mechanics Laboratory

Version No. 1/VN/July 2010

12. Record the manometer readings and measure the discharge with the help of measuring tank

and stop watch.

13. Now move the Pitot tube up and down tube for the same flow rate and note the manometer

readings to estimate the velocity at different points in pipe.

14. Take readings at sufficient number of points to plot the velocity profile across the cross

section. Repeat the same procedure for different flow rates of water by operating the control

valve, and by-pass valve.

(b) Closing Procedure:

1. When the experiment is over, close all manometer pressure taps first and switch off the pump.

2. Switch off the power supply to panel.

3. Drain the water from all the tanks using the the drain valves

5.TASKS

1. Derive the theoretical expression for the velocity profile across a pipe cross section.

2. Determine the actual (average) velocity of fluid at different points across the cross section.

3. Plot the theoretical and experimental velocity profiles for different flow rates.

4. Calculate the Reynolds number in each case.

5. Calculate the coefficient of pitot tube from actual and theoretical velocities .

6. Comment on possible sources of error in the experiment or your derivation that would change

your measurements or theoretical estimates. Indicate how these sources would affect the

results and make recommendations for improving the experiment.

REFERENCES

1. Class notes, ME 204 Fluid Mechanics, Spring semester , 2009-2010

2. Fox R.W. and McDonald A.T., Fluid Mechanics, John Wiley International, 2005.

You might also like

- Energy Losses in Pipes: Experiment # 4Document4 pagesEnergy Losses in Pipes: Experiment # 4محمد جوادNo ratings yet

- Pipe FrictionDocument4 pagesPipe FrictionShubham ChauhanNo ratings yet

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilNo ratings yet

- Validates Bernoulli's Theorem in Tapered DuctDocument29 pagesValidates Bernoulli's Theorem in Tapered DuctAnonymous NyvKBWNo ratings yet

- Orifice Jet Flow Experiment GuideDocument3 pagesOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNo ratings yet

- Exp 1-Hele ShawDocument1 pageExp 1-Hele Shawadityain2003No ratings yet

- Determine Floating Body StabilityDocument11 pagesDetermine Floating Body StabilityDember Paul100% (1)

- Bernoulli's Theorem DemonstrationDocument16 pagesBernoulli's Theorem Demonstrationamirahabidin100% (1)

- U-Tube ManometerDocument5 pagesU-Tube ManometerHarold Lee BolingetNo ratings yet

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Fluid Mechanics Lab ReportDocument14 pagesFluid Mechanics Lab ReportEdwin Jesu DassNo ratings yet

- Jet ReactionDocument4 pagesJet ReactionSelva RajNo ratings yet

- CavitationDocument3 pagesCavitationTara JenkinsNo ratings yet

- Energy Losses in BendsDocument10 pagesEnergy Losses in BendsAngelica Joyce BenitoNo ratings yet

- Flow Through an Orifice - Calculating Discharge, Velocity & Contraction CoefficientsDocument6 pagesFlow Through an Orifice - Calculating Discharge, Velocity & Contraction Coefficientshozipek559950% (2)

- Practical Verification of Bernoulli'S Theorem: StructureDocument3 pagesPractical Verification of Bernoulli'S Theorem: StructureVívék SâíNo ratings yet

- Flow Experiment Determines Discharge CoefficientsDocument15 pagesFlow Experiment Determines Discharge CoefficientsLai YenNo ratings yet

- Abstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesDocument18 pagesAbstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesHariz MiorNo ratings yet

- Fluid Mechanics Lab 3.1Document13 pagesFluid Mechanics Lab 3.1mahmoudNo ratings yet

- Free VortexDocument3 pagesFree VortexVrushiket Patil67% (3)

- Impact of JetDocument5 pagesImpact of Jetميسرة33% (3)

- Calibration of VenturimeterDocument2 pagesCalibration of VenturimeterAhmedElsayedNo ratings yet

- Fluid Mechanics Lab Manual for Civil Engineering StudentsDocument29 pagesFluid Mechanics Lab Manual for Civil Engineering Studentsvihangam yoga chandauli100% (1)

- Fluid and Hydrostatic BenchDocument1 pageFluid and Hydrostatic BenchBalRam DhimanNo ratings yet

- Calibrate Venturimeter Flow MeterDocument4 pagesCalibrate Venturimeter Flow Meterabhishekpatil21No ratings yet

- Revised LabDocument18 pagesRevised LabAbu AyemanNo ratings yet

- Venturi meter experiment proceduresDocument2 pagesVenturi meter experiment proceduresAnonymous mRBbdopMKf100% (1)

- EXPERIMENT 1 HYDROSTATIC FORCEDocument6 pagesEXPERIMENT 1 HYDROSTATIC FORCENor Farah AlwaniNo ratings yet

- Fluids Mechanics Lab ManualDocument30 pagesFluids Mechanics Lab ManualHaseen KaurNo ratings yet

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarNo ratings yet

- Exp 2 Friction LossesDocument15 pagesExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Flow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical StudyDocument6 pagesFlow Over A Broad-Crested Weir in Subcritical Flow Conditions, Physical Studyho_afsharNo ratings yet

- Flow Through OrificesDocument9 pagesFlow Through OrificesShida Shidot100% (1)

- Report Hydraulic JumpsDocument11 pagesReport Hydraulic JumpsMayLeongNo ratings yet

- Lab 2 Mini FLow ChannelDocument16 pagesLab 2 Mini FLow ChannelIr Fik TNo ratings yet

- Specific Energy Hydraulic Jumps WeirsDocument23 pagesSpecific Energy Hydraulic Jumps WeirsHaris jugnooNo ratings yet

- Energy Losses in Bends and FittingsDocument11 pagesEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- FULL REPORT Flow Over WeirDocument18 pagesFULL REPORT Flow Over WeirShahrul Ikram0% (1)

- Lab 4-Friction Losses and Minor LossesDocument7 pagesLab 4-Friction Losses and Minor LossesJJ Sean CruzNo ratings yet

- Verify Bernoulli's Theorem LabDocument5 pagesVerify Bernoulli's Theorem LabismailNo ratings yet

- Experiment 7 DiagramDocument7 pagesExperiment 7 Diagramartemio john claveNo ratings yet

- Lab2FREE AND FORCE VORTEXDocument32 pagesLab2FREE AND FORCE VORTEXjuaxxo50% (2)

- Orifice MeterDocument11 pagesOrifice MeterSumit JhaNo ratings yet

- Fluid Exam 2016Document20 pagesFluid Exam 2016hthaier4062No ratings yet

- CE 2020 - Fluid Mechanics LaboratoryDocument67 pagesCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamNo ratings yet

- Venturimeter and Orifice MeterDocument5 pagesVenturimeter and Orifice MeterVrushiket Patil100% (1)

- Bernaulli's Theorem FullDocument17 pagesBernaulli's Theorem FullBart KwanNo ratings yet

- Measuring Air Flow Rate Using a Venturi TubeDocument5 pagesMeasuring Air Flow Rate Using a Venturi TubeDinesh Bala KrishnanNo ratings yet

- Fluid Mechanics PDFDocument65 pagesFluid Mechanics PDFSiddharth GargNo ratings yet

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanNo ratings yet

- CE142P Exercise No. 02Document2 pagesCE142P Exercise No. 02streetranpuNo ratings yet

- Flow Demonstration ExperimentDocument5 pagesFlow Demonstration ExperimentVictoria SooknananNo ratings yet

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBNo ratings yet

- Orifice and Jet Flow (HB 019)Document12 pagesOrifice and Jet Flow (HB 019)Usman AliNo ratings yet

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- Mech. Engg. DepartmentDocument37 pagesMech. Engg. DepartmentHamza AhmadNo ratings yet

- FM & HM Lab Lab ManualDocument75 pagesFM & HM Lab Lab ManualRajib DasNo ratings yet

- Pitot Static TubeDocument4 pagesPitot Static TubeVrushiket PatilNo ratings yet

- Venturi and OrificemeterDocument10 pagesVenturi and OrificemeterVikrant KumarNo ratings yet

- 2018 01 30 p3fh Ms 4000 PRC 1005 RC Hydrostatic Test ProcedureDocument7 pages2018 01 30 p3fh Ms 4000 PRC 1005 RC Hydrostatic Test ProcedureavriamandaNo ratings yet

- Fluid Mechanics & HydraulicsDocument4 pagesFluid Mechanics & HydraulicsFreezeNo ratings yet

- Offshore - Introduction LayoutDocument131 pagesOffshore - Introduction LayoutgeorgiadisgNo ratings yet

- Basic Control ValveDocument59 pagesBasic Control ValveChiheb KaanicheNo ratings yet

- KTA - TB-PAC03-M07-007.Rev0 - OVERHEAD SYSTEM PIDDocument2 pagesKTA - TB-PAC03-M07-007.Rev0 - OVERHEAD SYSTEM PIDlamNo ratings yet

- Yee Wan Yin: University of Birmingham, UKDocument4 pagesYee Wan Yin: University of Birmingham, UKYou JaicNo ratings yet

- 123Document13 pages123Cheska FernandezNo ratings yet

- Von Karman Institute For Fluid Dynamics: Arts@vki - Ac.beDocument4 pagesVon Karman Institute For Fluid Dynamics: Arts@vki - Ac.beMarcos A SantosNo ratings yet

- Multiple Choice Practice Questions/Answers For Online/Omr AITT-2020 2 Year Mech. Ref & Ac. Trade TheoryDocument62 pagesMultiple Choice Practice Questions/Answers For Online/Omr AITT-2020 2 Year Mech. Ref & Ac. Trade TheoryPhi losNo ratings yet

- Drilling Exam Answers SummaryDocument6 pagesDrilling Exam Answers SummaryMohab Ayman100% (3)

- Shell Middle Distillate Synthesis: The Process, The Plant, The ProductsDocument5 pagesShell Middle Distillate Synthesis: The Process, The Plant, The ProductsEan7731451No ratings yet

- 11 Fluids 1Document13 pages11 Fluids 1Thaya GanapathyNo ratings yet

- Leybold FundamentalsDocument199 pagesLeybold FundamentalsvelmuruganNo ratings yet

- Pompe GasoilDocument2 pagesPompe Gasoilday rachidNo ratings yet

- Industrial 501 KDocument8 pagesIndustrial 501 K'Izzad AfifNo ratings yet

- DistillationDocument109 pagesDistillationAmna AnjumNo ratings yet

- Calculating Compressor Efficiency and Isentropic WorkDocument20 pagesCalculating Compressor Efficiency and Isentropic WorkJJNo ratings yet

- Kimre Aiche 2008Document12 pagesKimre Aiche 2008Marcelo PerettiNo ratings yet

- Turbine Meter Reference MaterialDocument8 pagesTurbine Meter Reference MaterialjsmargateNo ratings yet

- Empirical DeliverabilityDocument199 pagesEmpirical Deliverabilitymath62210No ratings yet

- BFW Pump Sizing CalculationsDocument2 pagesBFW Pump Sizing Calculationsgopiiitkgp100% (2)

- Dryness Fraction of Steam ExpDocument5 pagesDryness Fraction of Steam ExpAthinaNo ratings yet

- 2420 Pressure Reducing PilotDocument14 pages2420 Pressure Reducing PilotRyan VelezNo ratings yet

- Manual 67c Series Instrument Supply Regulators en 125112Document12 pagesManual 67c Series Instrument Supply Regulators en 125112walter johnn pinzon trianaNo ratings yet

- Pro2 Check Elite User ManualDocument10 pagesPro2 Check Elite User ManuallakshmivillegasNo ratings yet

- Formation Multi-Tester (FMT) Principles, Theory, and InterpretationDocument61 pagesFormation Multi-Tester (FMT) Principles, Theory, and InterpretationMannbeard0% (1)

- 400 Series Regulators for High Flow PurgingDocument3 pages400 Series Regulators for High Flow PurgingmiguesobeNo ratings yet

- Absorbers - Separations - Chemical - MEL Equipment Encyclopedia 4 PDFDocument10 pagesAbsorbers - Separations - Chemical - MEL Equipment Encyclopedia 4 PDFTeo Pui KuanNo ratings yet

- Energetica ExaminationDocument11 pagesEnergetica ExaminationDwi NicHeNo ratings yet

- BSS Guide Chap7Document38 pagesBSS Guide Chap7handoyo_eko20017573No ratings yet