Professional Documents

Culture Documents

Construction Schedule

Uploaded by

nasiramzanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Schedule

Uploaded by

nasiramzanCopyright:

Available Formats

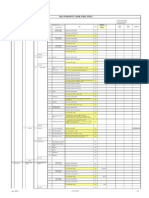

Activity

ID

Activity

Description

Orig Rem

Dur Dur

Predecessors

Early

Start

Early

Finish

17DEC10

01:00

23DEC10

07:59

17

18

0 6 12 18 0 6 12 18 0

DEC

19

20

21

6 12 18 0 6 12 18 0 6 12 18 0

22

6 12 18 0

23

24

6 12 18 0 6 12

Hot Tap Work

Subtotal

151

151

0 HT020*

17DEC10

01:00

17DEC10

08:59

48

48

0 HT010*

17DEC10

09:00

19DEC10

08:59

0 HT030*

19DEC10

09:00

19DEC10

16:59

HT040 Erect Spark Containment Habitat

18DEC10

02:00*

18DEC10

03:59

HT050 Perform lamination check/UT test

0 HT040*

18DEC10

04:00

18DEC10

05:59

HT060 Perform Ovality on hot tap location

0 HT050*

18DEC10

06:00

18DEC10

13:59

HT070 Submit UT Test/MPI result to consultant/client

0 HT060*

18DEC10

14:00

18DEC10

21:59

65

65

0 HT070*

18DEC10

22:00

21DEC10

14:59

0 HT080*

HT110 Crane and welding machine into position

0 HT320*

21DEC10

01:00

21DEC10

02:59

HT100 Operation line check/gas test

0 HT090*

21DEC10

15:00

21DEC10

15:59

Operation line check/gas test

HT120 Clamp split tee for 6" hot tap

0 HT100*,

HT110

21DEC10

16:00

21DEC10

16:59

Clamp split tee for 6" hot tap

HT130 Check with operation on flow parameter

0 HT120*

21DEC10

17:00

21DEC10

17:59

Check with operation on flow parameter

HT140 Fit-up/tack weld split tee on existing pipe

0 HT130*

21DEC10

18:00

21DEC10

18:59

Fit-up/tack weld split tee on existing pipe

HT150 Fit-up inspection(contractor/consultant/client)

0 HT140*

21DEC10

19:00

21DEC10

19:59

Fit-up inspection(contractor/consultant/client)

HT160 Welding(root run on branch section)

0 HT150*

21DEC10

20:00

21DEC10

20:59

HT170 Welding(root run on longitudinal section)

0 HT160*

21DEC10

21:00

21DEC10

21:59

HT180 NDT for both roots (MPI)

0 HT170*

21DEC10

22:00

21DEC10

23:59

HT190 Full fillet welding on circumstance existing pip

0 HT180*

22DEC10

00:00

22DEC10

03:59

HT200 Cap butt welds

0 HT190*

22DEC10

04:00

22DEC10

09:59

HT210 Pneumatic test on comp pad

0 HT200*

22DEC10

10:00

22DEC10

10:59

HT220 Install hot tap valve/blind for hydrotest

0 HT210*

22DEC10

11:00

22DEC10

11:59

HT230 Hydrotest split tee/valve

0 HT220*

22DEC10

12:00

22DEC10

13:59

HT240 Inspect hot tap machine prior to drilling

0 HT230*

22DEC10

14:00

22DEC10

14:59

Inspect hot tap machine prior to drilling

HT250 Hot tap drilling by tapping contractor

0 HT240*

22DEC10

15:00

22DEC10

16:59

Hot tap drilling by tapping contractor

HT260 Close HT valve/Depressurise/drain the tapping

0 HT250*

22DEC10

17:00

22DEC10

17:59

HT270 Remove hot tap cutter

0 HT260*

22DEC10

18:00

22DEC10

18:59

HT280 Install vent blind

0 HT270*

22DEC10

19:00

22DEC10

19:59

HT290 1st PSSR-Contractor/Consult/Client clear punches

0 HT280*

22DEC10

20:00

22DEC10

23:59

HT300 Touch-up paint on hot tap nozzle

0 HT290*

23DEC10

00:00

23DEC10

03:59

HT310 House keeping

0 HT300*

23DEC10

04:00

23DEC10

07:59

Work Pack 010

Tie-in 200

Procurement

HT020 Hot tap material received

17DEC10

00:59*

Hot tap material received

Off Site Fabrication

HT010 Fabriate Hot tap split tee

HT030 Blast & Paing Hot tap split tee

HT320 Delivery to site

Fabriate Hot tap split tee

Blast & Paing Hot tap split tee

Delivery to site

Preliminary Activities

HT080 Approve to weld on hot tap location

HT090 Hot work permit received

Erect Spark Containment Habitat

Perform lamination check/UT test

Perform Ovality on hot tap location

Submit UT Test/MPI result to consultant/client

Approve to weld on hot tap location

21DEC10

14:59

Hot work permit received

Execution

Crane and welding machine into position

Welding(root run on branch section)

Welding(root run on longitudinal section)

NDT for both roots (MPI)

Full fillet welding on circumstance existing pip

Cap butt welds

Pneumatic test on comp pad

Install hot tap valve/blind for hydrotest

Hydrotest split tee/valve

Close HT valve/Depressurise/drain the tapping

Remove hot tap cutter

Install vent blind

Post Activities

Start Date

Finish Date

Data Date

Run Date

17DEC10 00:00

23DEC10 07:59

17DEC10 00:00

04JAN11 07:28

Early Bar

HTAP

Critical Activity

House keeping

Date

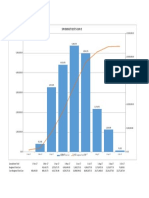

Hot Tapping Work

Classic Schedule Layout

Primavera Systems, Inc.

Touch-up paint on hot tap nozzle

Sheet 1 of 1

Float Bar

Progress Bar

1st PSSR-Contractor/Consult/Client clear punches

Revision

Checked

Approved

You might also like

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFJose R Birmighan S100% (1)

- CFLHD Production RatesDocument5 pagesCFLHD Production RatesroldskiNo ratings yet

- KLPE Steel Bill of QuantityDocument3 pagesKLPE Steel Bill of QuantityCY LeeNo ratings yet

- Excavation: Item No. Description of Work Qty Unit Manhour Hour/Day Manpower DurationDocument34 pagesExcavation: Item No. Description of Work Qty Unit Manhour Hour/Day Manpower DurationvanessaNo ratings yet

- Pipe Line S-Curve (30-Sep-2012)Document1 pagePipe Line S-Curve (30-Sep-2012)burereyNo ratings yet

- Sample Project Activities (Excel)Document3 pagesSample Project Activities (Excel)arielicawatNo ratings yet

- KUL Comml Project - Bandra (E) - Exc Qtty + Soil DetailsDocument2 pagesKUL Comml Project - Bandra (E) - Exc Qtty + Soil DetailsJnanamNo ratings yet

- Construction of Batinah Expressway Package.5 Revised Programme of Works - DD: 30 October 2016Document3 pagesConstruction of Batinah Expressway Package.5 Revised Programme of Works - DD: 30 October 2016Tahir YousafzaiNo ratings yet

- Progress S-Curve 15-21 July 2019Document27 pagesProgress S-Curve 15-21 July 2019Smith SongkhlaNo ratings yet

- Assessment New Billing Module 4 (5.02.15)Document10 pagesAssessment New Billing Module 4 (5.02.15)Aris R. AlcantaraNo ratings yet

- APO Productivity Database 2017v1Document1,109 pagesAPO Productivity Database 2017v1rahul nagareNo ratings yet

- Transportation Project Scheduling Worksheet: Mobilization and Traffic ControlDocument8 pagesTransportation Project Scheduling Worksheet: Mobilization and Traffic Controlsadaaammm sadaaammmNo ratings yet

- Daily Report in Revised Formats 310120Document3 pagesDaily Report in Revised Formats 310120Aashish MIshraNo ratings yet

- Productivity ListDocument31 pagesProductivity ListAnthony AgnerNo ratings yet

- Productivity Cum Manpower Allocation ChartDocument6 pagesProductivity Cum Manpower Allocation ChartHarneet Singh100% (1)

- Baseline S CurveDocument6 pagesBaseline S CurveGodfrey EmilioNo ratings yet

- Calculation of Duration of Activities Based On Standard ManhoursDocument20 pagesCalculation of Duration of Activities Based On Standard ManhoursMubashirNo ratings yet

- Cost S-Curve (Rev.1)Document1 pageCost S-Curve (Rev.1)xchannel28No ratings yet

- MANPOWER PLANNINGDocument271 pagesMANPOWER PLANNINGedla3710100% (2)

- National Water Supply Project UpdateDocument31 pagesNational Water Supply Project UpdateGamitha LakshanNo ratings yet

- SM014 Elemental Costing DatabaseDocument41 pagesSM014 Elemental Costing DatabasewanfaroukNo ratings yet

- Productivity Rate (Piping Works)Document21 pagesProductivity Rate (Piping Works)Ahmed Essam TimonNo ratings yet

- Project Title: Box Culvert Owner: Seaoil Location: San Juan, Mabini Batangas Contractor K&F Construction Development CorporationDocument9 pagesProject Title: Box Culvert Owner: Seaoil Location: San Juan, Mabini Batangas Contractor K&F Construction Development CorporationDarius Frane MarasiganNo ratings yet

- Training Course Planning in Primavera P6Document36 pagesTraining Course Planning in Primavera P6yhzNo ratings yet

- Production Rate PPDocument26 pagesProduction Rate PPpvpallasigui31260% (1)

- Earned Value Quadrant ChartDocument2 pagesEarned Value Quadrant ChartAbhishek Pandey100% (1)

- Construction Schedule For Batla House Project: Unit QuantityDocument4 pagesConstruction Schedule For Batla House Project: Unit QuantityAnbuNo ratings yet

- Project Task EffortTracker TemplateDocument15 pagesProject Task EffortTracker TemplateSayedAsgarAliNo ratings yet

- Cost Estimate TemplateDocument61 pagesCost Estimate TemplateCorbyFrielNo ratings yet

- Project TrackerDocument7 pagesProject TrackerRandu VivaldiNo ratings yet

- Royal Saudi Land Force Artillery Corps Construction ProjectDocument70 pagesRoyal Saudi Land Force Artillery Corps Construction ProjectSajin SajiNo ratings yet

- Discipline Weight Discipline Weight CP6CC 六建施工权重 Bugdet 概算权重 VarianceDocument4 pagesDiscipline Weight Discipline Weight CP6CC 六建施工权重 Bugdet 概算权重 VarianceBoinboin HadratNo ratings yet

- Cost Breakdown StructureDocument90 pagesCost Breakdown StructureRiFTzCuTLeR -YTNo ratings yet

- Construction ProgramDocument9 pagesConstruction ProgramLakshan PriyankaraNo ratings yet

- Sr. No. Beldars Mazdoors Bhisti Mason Labour (Mazdoor) Required For Different Works ItemDocument3 pagesSr. No. Beldars Mazdoors Bhisti Mason Labour (Mazdoor) Required For Different Works ItemiGp2013No ratings yet

- Gantt Chart With Layout TableDocument3 pagesGantt Chart With Layout TableAbenezer Tesfaye100% (1)

- Productivity RateDocument10 pagesProductivity RateRodelNo ratings yet

- Real Estate vs Shares Investment ComparisonDocument19 pagesReal Estate vs Shares Investment Comparisonamit1234No ratings yet

- Progress Update As of 30-Sep-2012: From TO LineDocument9 pagesProgress Update As of 30-Sep-2012: From TO LineburereyNo ratings yet

- Plan of Piping 3 Week Plan PDFDocument1 pagePlan of Piping 3 Week Plan PDFebsmsartNo ratings yet

- ProductivityDocument18 pagesProductivityRanjith EkanayakeNo ratings yet

- Planned / Actual & Forecast Quantities: Major Boq ItemsDocument1 pagePlanned / Actual & Forecast Quantities: Major Boq ItemsburereyNo ratings yet

- 13-Discipline Progress - by PCWBS L2 - FWBS L1Document266 pages13-Discipline Progress - by PCWBS L2 - FWBS L1Jun Urbano100% (1)

- OKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYDocument1 pageOKI PULP & PAPER MILL PROJECT SUMMARY WEEKLYKusnadi AnginNo ratings yet

- Estimate Line Detail for Process Plant ProjectDocument35 pagesEstimate Line Detail for Process Plant Projectstefax2010No ratings yet

- WPM PF PJW 0089 0 Baseline Construction Programme TemplateDocument1 pageWPM PF PJW 0089 0 Baseline Construction Programme TemplateYhel HensonNo ratings yet

- S CURVE (117) (AutoRecovered)Document35 pagesS CURVE (117) (AutoRecovered)DaNiel AUreusNo ratings yet

- Ufford Street, London: Prelim Programme Nr.10Document1 pageUfford Street, London: Prelim Programme Nr.10HARISH VERMANo ratings yet

- Project Management Process Groups and Knowledge AreasDocument3 pagesProject Management Process Groups and Knowledge Areasdipendra tiwariNo ratings yet

- Sheetrock Bid Sheet for Home Renovation ProjectDocument26 pagesSheetrock Bid Sheet for Home Renovation ProjectAngelee BivinsNo ratings yet

- Structural Steel Works Man-HoursDocument2 pagesStructural Steel Works Man-HoursRenny DevassyNo ratings yet

- How To Import WBS From Excel To Primavera P6 Using The SDKDocument20 pagesHow To Import WBS From Excel To Primavera P6 Using The SDKsajjadNo ratings yet

- Construction An Construction and Renovation Works: Key Dates Key DatesDocument1 pageConstruction An Construction and Renovation Works: Key Dates Key DatesAhmad Ramin Abasy100% (1)

- Lusail Plaza Tower - Value Engineering ReportDocument15 pagesLusail Plaza Tower - Value Engineering Reportsamir rabiaNo ratings yet

- Creating Filters in PrimaveraDocument14 pagesCreating Filters in PrimaveraARP MEILNo ratings yet

- March Look Ahed PlanningDocument4 pagesMarch Look Ahed PlanningErMelvinDiasNo ratings yet

- Brief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion DateDocument4 pagesBrief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion Datesidiq7No ratings yet

- Sample Hot Tap Construction Schedule PDFDocument1 pageSample Hot Tap Construction Schedule PDFrajkamal eshwarNo ratings yet

- Heatpro: Heat Pump Replacement PartsDocument6 pagesHeatpro: Heat Pump Replacement PartsDavid TerronNo ratings yet

- Continental Disc Corporation Rupture Disc Selection GuideDocument20 pagesContinental Disc Corporation Rupture Disc Selection GuidenasiramzanNo ratings yet

- Lifting EquipmnetsDocument118 pagesLifting EquipmnetsnasiramzanNo ratings yet

- Witholding TaxDocument1 pageWitholding TaxnasiramzanNo ratings yet

- 217light EngineeringFeasibilityDocument30 pages217light EngineeringFeasibilitysomeonestupid1969100% (1)

- STS Transfer Operations Plan: Ship Name: Imo NumberDocument183 pagesSTS Transfer Operations Plan: Ship Name: Imo NumbernasiramzanNo ratings yet

- Galaxy Sanitary CatalogueDocument1 pageGalaxy Sanitary CataloguenasiramzanNo ratings yet

- Engine Room Ventilation: Application and Installation GuideDocument36 pagesEngine Room Ventilation: Application and Installation Guidesunder81100% (3)

- Valves Test & Inspection Seminar - by H. Sinaei PourDocument67 pagesValves Test & Inspection Seminar - by H. Sinaei PournasiramzanNo ratings yet

- Acceptance 2Document1 pageAcceptance 2nasiramzanNo ratings yet

- Sehs 7654 CM20160713 53120 62927 PDFDocument28 pagesSehs 7654 CM20160713 53120 62927 PDFnasiramzanNo ratings yet

- Sanitary FittingDocument1 pageSanitary FittingnasiramzanNo ratings yet

- GETP - 31 - Piping PresentationDocument18 pagesGETP - 31 - Piping PresentationnasiramzanNo ratings yet

- Grace Sanitary CatalogueDocument1 pageGrace Sanitary CataloguenasiramzanNo ratings yet

- Grace Sanitary CatalogueDocument1 pageGrace Sanitary CataloguenasiramzanNo ratings yet

- Retailer'S Statement U/S 115 (4) of The Income Tax Ordinance, 2001 But Not Having Any Other Taxable Source of Income)Document1 pageRetailer'S Statement U/S 115 (4) of The Income Tax Ordinance, 2001 But Not Having Any Other Taxable Source of Income)nasiramzanNo ratings yet

- Effective CommunicationDocument138 pagesEffective CommunicationEngr Muhammad SohailNo ratings yet

- 201410111510360228ReturnFormIT 1BforTaxYear2014forIndividualsderivingIncomeundertheHeadsotherthanBusinessDocument9 pages201410111510360228ReturnFormIT 1BforTaxYear2014forIndividualsderivingIncomeundertheHeadsotherthanBusinessnasiramzanNo ratings yet

- CPD Guideline ManualDocument59 pagesCPD Guideline ManualAhmad CheemaNo ratings yet

- Vlookupweekvideo06 StartDocument1 pageVlookupweekvideo06 Starttrick8No ratings yet

- What Is Project ControlsDocument5 pagesWhat Is Project ControlsnasiramzanNo ratings yet

- AOA Project Algeria - Ammonia Urea Fertilizer ComplexDocument2 pagesAOA Project Algeria - Ammonia Urea Fertilizer Complexnasiramzan0% (1)

- (Job Title #1) / (Job Title #2) : (NAME)Document3 pages(Job Title #1) / (Job Title #2) : (NAME)nasiramzanNo ratings yet

- 10 Q Whizables PMP PrepDocument7 pages10 Q Whizables PMP PrepnasiramzanNo ratings yet

- PS-urdu Tutorial PartialDocument20 pagesPS-urdu Tutorial PartialnasiramzanNo ratings yet

- Words of SuccessDocument17 pagesWords of SuccessnasiramzanNo ratings yet

- Junior Green PowerBox 1KVADocument1 pageJunior Green PowerBox 1KVAnasiramzanNo ratings yet

- AOA Project Algeria - Ammonia Urea Fertilizer ComplexDocument2 pagesAOA Project Algeria - Ammonia Urea Fertilizer Complexnasiramzan0% (1)

- Industrial Zones and States in PakistanDocument3 pagesIndustrial Zones and States in PakistannasiramzanNo ratings yet

- Junior Green PowerBox 2KVADocument1 pageJunior Green PowerBox 2KVAnasiramzanNo ratings yet

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadNo ratings yet

- Teodora Sarkizova: Certificate of AchievementDocument2 pagesTeodora Sarkizova: Certificate of AchievementAbd El-RahmanNo ratings yet

- Examining Language in Romeo and Juliet - The Prologue - Mastery TestDocument5 pagesExamining Language in Romeo and Juliet - The Prologue - Mastery TestPhạm MyNo ratings yet

- Texas Final LeadsDocument36 pagesTexas Final Leadsabdullahmohammed4460No ratings yet

- The historical evolution of organizational behavior and how it shaped modern managementDocument3 pagesThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)

- Designing of 3 Phase Induction Motor Blackbook DoneDocument30 pagesDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- 1 Clock Domain CrossingDocument35 pages1 Clock Domain CrossingRamakrishnaRao SoogooriNo ratings yet

- Marginal Field Development Concepts (Compatibility Mode)Document17 pagesMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- Trends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeDocument53 pagesTrends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeNarasimhaReddy PangaNo ratings yet

- CDM 856 WheelloaderweichaiengineDocument1 pageCDM 856 WheelloaderweichaiengineRusmiyanto YantoNo ratings yet

- Drainage PDFDocument1 pageDrainage PDFSwapnil JainNo ratings yet

- Evolution of The Fire SprinklerDocument11 pagesEvolution of The Fire SprinklerPedro DudesonNo ratings yet

- CA 1 - Đề thi AV5 - CLC - Made - efDocument5 pagesCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenNo ratings yet

- The Chair As Health Hazard Part II J of PDFDocument11 pagesThe Chair As Health Hazard Part II J of PDFPablo BuniakNo ratings yet

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmDocument1 pageOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpNo ratings yet

- Adiabatic Production of Acetic AnhydrideDocument7 pagesAdiabatic Production of Acetic AnhydrideSunilParjapatiNo ratings yet

- 5e Lesson Plan s16 - MagnetsDocument6 pages5e Lesson Plan s16 - Magnetsapi-317126609No ratings yet

- MN00119 Unicom LT User ManualDocument45 pagesMN00119 Unicom LT User ManualPhilipp A IslaNo ratings yet

- Samsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingDocument47 pagesSamsung GT-I8160 Galaxy Ace 2 08 Level 3 Repair - Block-, PCB Diagrams, Flow Chart of TroubleshootingOuadghiri Badre Ddine50% (2)

- Proposal BP3IP FinalDocument3 pagesProposal BP3IP FinalGiant SeptiantoNo ratings yet

- 8.9 Basic Maths For Well PlanningDocument9 pages8.9 Basic Maths For Well PlanningKhanh Pham MinhNo ratings yet

- Strategic Investment Plan ForDocument78 pagesStrategic Investment Plan Forapi-3833112No ratings yet

- Capacitor BanksDocument49 pagesCapacitor BanksAmal P RaviNo ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- 10 ExtSpringsDocument27 pages10 ExtSpringsresh27No ratings yet

- Kerala University 2013 Admission ProspectusDocument50 pagesKerala University 2013 Admission ProspectusMuneer SainulabdeenNo ratings yet

- Delhi University SEC Exam Date Sheet March 2023Document2 pagesDelhi University SEC Exam Date Sheet March 2023aamir9ali-42No ratings yet

- Obeid Specialized Hospital - Riyadh: Inpatient DeptsDocument4 pagesObeid Specialized Hospital - Riyadh: Inpatient DeptsLovelydePerioNo ratings yet

- Keynote Proficient End-Of-Course Test BDocument7 pagesKeynote Proficient End-Of-Course Test Bana maria csalinasNo ratings yet

- HIBAH PKSM Sps 2021Document9 pagesHIBAH PKSM Sps 2021Gargazi Bin HamidNo ratings yet