Professional Documents

Culture Documents

Brosura KT DESWED105025EN 6pag (EN) PDF

Uploaded by

brancoveanu_justinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brosura KT DESWED105025EN 6pag (EN) PDF

Uploaded by

brancoveanu_justinCopyright:

Available Formats

Busbar Trunking

Canalis KT

A comprehensive offer

Canalis KT : rising mains

Transport and Distribution from 800 to 5000A

A new path for achieving your electrical installations

Canalis is part of a comprehensive offer of products that are perfectly

coordinated to meet all medium and low voltage electrical distribution

requirements. All of these products have been designed to work

together: electrical, mechanical and communication compatibility.

The electrical installation is thus both optimised and has improved

performance:

b better service continuity,

b increased personnel and equipment safety,

b guaranteed upgradeability,

b efficient monitoring and control.

You therefore have all the advantages at hand in terms of knowhow and creativity for achieving optimised, safe, upgradeable and

compliant installations.

Canalis KT distributes power to all floors

of a multi-storey building

(office buildings, hotels, hospitals, etc).

An electrifying

new repertoire

Canalis busbar trunking

Easy installation in a small space

In ducts, where there is generally little space,

Canalis provides a substantial space

saving compared to cables.

Lighting distribution

Canalis KBA/KBB (supports light fittings)

Rated service current: 25 and 40 A

Protection index: IP 55

Canalis KBX (lighting duct)

Rated service current: 25 A

Protection index: IP 20

Canalis KDP (flexible busbar trunking)

Rated service current: 20 A

Protection index: IP 55

Guaranteed safety in the event of a fire

No risk in the event of a fire. The busbar trunking has

a low combustible load. Its construction uses very little

consumable material and is halogen free. In the event

of a fire, the busbar trunking does not emit any gas or

toxic smoke.

An inherent fire barrier, the busbar trunking helps delay

the propagation of a fire through partition walls and

floors for a duration of 2 hours.

Power distribution

Canalis KN for low power

DESWED105025EN - 2006 Schneider Electric Industries SAS All right reserved.

Rated service current: from 40 to 160 A

Protection index: IP 55

Canalis KS for medium power

Rated service current: from 100 to 1000 A

Protection index: IP 55

Current transmission

Canalis KT for high power

High level of flexibility

The rising main sections have 3 tap-off

points per floor, thus providing spare

tap-off points for future evolutions.

Rated service current: from 800 to 5000 A

Protection index: IP 55

Schneider Electric Industries SAS

89 boulevard F. Roosevelt

F - 92500 Rueil Malmaison

France

Tl. : +33 (0)1 41 29 85 00

Fax : +33 (0) 1 41 29 89 01

http://www.schneider-electric.com

As standards, specifications and designs change from time to time,

always ask for confirmation of the information given in this publication.

.

Design: Schneider Electric

Photos: Schneider Electric

Printing:

09/2006

Building a New Electric World

Canalis

Canalis

KT

A comprehensive offer

Canalis KS tap-off units are fully compatible with Canalis KT.

b They cover all your requirements

v 25 to 400A Canalis KS plug-on tap-off units

v 400 to 1000A Canalis KT fixed tap-off units

b They offer circuit-breaker or fuse protection.

Some tap-off units can be fitted with the Transparent Ready system:

b They monitor your installation to avoid overloads, thus ensuring

service continuity

b They meter consumed power to allow precise management

of your electrical distribution

Electrical power available at all points

Canalis KT is for transporting and distributing electrical

power, from 800 to 5000A.

Canalis KTs high protection degree (IP55) protects

it against water projections, sprinklers and dust. Its

compact design and robustness (IK08) mean it can

be used in industrial applications, shopping centres,

tertiary buildings and infrastructures.

Office buildings and hospitals

An adaptable offer

Adding, moving or replacing loads can be done quickly, whilst live and

without the need for a shutdown.

The cost of these modifications is low:

b line proximity,

b tap-off point always available,

b moving, replacing or adding a tap-off unit is very quick.

Mastered safety

Busbar trunking temperature rise and

short-circuit withstand are known

and independent of the installation.

Coordination of the Schneider Electric

system results in complete mastery of

the electrical network.

Operating continuity

The busbar trunking provides immediate readability of the electrical

circuit and enables quick intervention on the zones concerned.

Work can be carried out without the need for a shutdown.

Technical characteristics

Busbar trunking rated current:

Tap-off unit rated current:

Rated insulation voltage:

No. of conductors:

A team and tools to back you up

Our teams are available to provide you with technical assistance

throughout the installation period of your project.

Our experts and our distribution and production centres

guarantee you a quick and high quality installation.

Shopping centres, airports

and exhibition centres

Project

launch

Protection degree:

Insulation type:

Enclosure type:

Dimensions:

Run sections:

Compliance with standards:

800 to 4000A, aluminium conductors

1000 to 5000A, copper conductors

25 to 1000A

1000V

3L+PE, 3L+N+PE, 3L+N+PER

(PER = reinforced PE)

IP 55, IPxxD, sprinkler resistant

Polyester class B (130C withstand),

halogen free

RAL 9001 pre-lacquered sheet steel

140x74 mm to 140x404 mm

4m and 2m or made-to-measure: 0.5 to 3m

IEC 60439-1 & 2

Technical

support

CanBrass

drawing

After-sales

service

Autocad

drawing

On-site

instruction and

installation

Production

Project

management

Recyclable equipment

The principle of a prefabricated solution and the service life of our

products mean they can be easily dismantled, cleaned and re-used.

Car industry and industrial buildings

A safe offer

The busbar trunking and tap-off units are

designed to guarantee the safety of personnel

and equipment.

A foolproof system prevents dismantling errors

and the fitting or removing of an on-load

connector. Live parts remain inaccessible.

Contact excellence

The silver-plated electrical contacts guarantee

life long performance levels.

Installation

A modular system for a simple and modifiable installation

1 Sections joined together

using single-unit junction

blocks

2 Problems encountered during

installation can be resolved

using adjustable sections

3 Quick connection to Prisma

Plus and Okken switchboards

4 Direct connection to

transformers

5 Addition of tap-off units

whilst live

6 Vertical fixing

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Document23 pagesQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Mutual Fund Insight Nov 2022Document214 pagesMutual Fund Insight Nov 2022Sonic LabelsNo ratings yet

- Is 778 - Copper Alloy ValvesDocument27 pagesIs 778 - Copper Alloy ValvesMuthu KumaranNo ratings yet

- Summary - A Short Course On Swing TradingDocument2 pagesSummary - A Short Course On Swing TradingsumonNo ratings yet

- Ss1169 - Telecom Frameworx l1TMFDocument65 pagesSs1169 - Telecom Frameworx l1TMFPrince SinghNo ratings yet

- OOPS Notes For 3rd Sem ALL ChaptersDocument62 pagesOOPS Notes For 3rd Sem ALL Chaptersabhishek singh83% (6)

- Brosura Panorama DESWED105028EN 6pag (EN) PDFDocument2 pagesBrosura Panorama DESWED105028EN 6pag (EN) PDFbrancoveanu_justinNo ratings yet

- Brosura KN KS DESWED105024EN 6pag (EN) PDFDocument6 pagesBrosura KN KS DESWED105024EN 6pag (EN) PDFbrancoveanu_justinNo ratings yet

- Brosura KDP DESWED105026EN 4pag (EN) PDFDocument4 pagesBrosura KDP DESWED105026EN 4pag (EN) PDFbrancoveanu_justinNo ratings yet

- Brosura KBX DESWED105027EN 4pag (EN) PDFDocument4 pagesBrosura KBX DESWED105027EN 4pag (EN) PDFbrancoveanu_justinNo ratings yet

- Brosura Kba KBB Deswed105023en 4pag (En)Document4 pagesBrosura Kba KBB Deswed105023en 4pag (En)brancoveanu_justinNo ratings yet

- Common Base AmplifierDocument6 pagesCommon Base AmplifierMuhammad SohailNo ratings yet

- 1.6 Program AdministrationDocument56 pages1.6 Program Administration'JeoffreyLaycoNo ratings yet

- Study of Means End Value Chain ModelDocument19 pagesStudy of Means End Value Chain ModelPiyush Padgil100% (1)

- MNO Manuale Centrifughe IngleseDocument52 pagesMNO Manuale Centrifughe IngleseChrist Rodney MAKANANo ratings yet

- Questionnaire: ON Measures For Employee Welfare in HCL InfosystemsDocument3 pagesQuestionnaire: ON Measures For Employee Welfare in HCL Infosystemsseelam manoj sai kumarNo ratings yet

- Government of India Act 1858Document3 pagesGovernment of India Act 1858AlexitoNo ratings yet

- Nasoya FoodsDocument2 pagesNasoya Foodsanamta100% (1)

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportDocument6 pagesConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworNo ratings yet

- Province of Camarines Sur vs. CADocument8 pagesProvince of Camarines Sur vs. CACrisDBNo ratings yet

- Jainithesh - Docx CorrectedDocument54 pagesJainithesh - Docx CorrectedBala MuruganNo ratings yet

- VoIP Testing With TEMS InvestigationDocument20 pagesVoIP Testing With TEMS Investigationquantum3510No ratings yet

- CNS Manual Vol III Version 2.0Document54 pagesCNS Manual Vol III Version 2.0rono9796No ratings yet

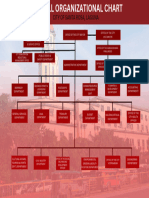

- Org ChartDocument1 pageOrg Chart2021-101781No ratings yet

- ADS Chapter 303 Grants and Cooperative Agreements Non USDocument81 pagesADS Chapter 303 Grants and Cooperative Agreements Non USMartin JcNo ratings yet

- Shares and Share CapitalDocument50 pagesShares and Share CapitalSteve Nteful100% (1)

- GSMDocument11 pagesGSMLinduxNo ratings yet

- Pharaoh TextDocument143 pagesPharaoh Textanon_31362848No ratings yet

- Journalism Cover Letter TemplateDocument6 pagesJournalism Cover Letter Templateafaydebwo100% (2)

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDocument7 pagesA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiNo ratings yet

- 11 TR DSU - CarrierDocument1 page11 TR DSU - Carriercalvin.bloodaxe4478100% (1)

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Document7 pagesINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeNo ratings yet

- Oops in PythonDocument64 pagesOops in PythonSyed SalmanNo ratings yet

- QuestionDocument7 pagesQuestionNgọc LuânNo ratings yet

- G JaxDocument4 pagesG Jaxlevin696No ratings yet