Professional Documents

Culture Documents

Existing Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3

Uploaded by

MitchellgranyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Existing Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3

Uploaded by

MitchellgranyCopyright:

Available Formats

Company

The Shell Petroleum Development Company

Of Nigeria Limited (SPDC)

Contractor:

NEMBE CREEK-CAWTHORNE CHANNEL TRUNKLINE

REPLACEMENT PROJECT

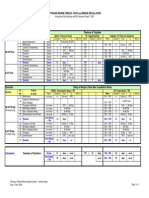

Company Contract No.:

Type of document:

PROCEDURE

Company document No.

Revision :

NCT-PRO-D03-00003

COMPANY

DOCUMENT TYPE:

D03

AO1

Document title:

EXISTING PIPELINE & CABLE UNDERCROSSING

ADDENDUM TO PROCEDURE

STATUS CODE

ACCEPTED

A

Do not resubmit unless document is modified

Operation May proceed

ACCEPTED AS NOTED

B

Revise to incorporate comments and resubmit

Operation must not proceed

NOT ACCEPTED

C

Revise to incorporate comments and resubmit

Operation must not proceed

INFORMATION ONLY

D

No impact on construction programme

AO1

02/10/08

AFU

Approved for Use / Design

RO1

27/09/08

IFR

Issued for Client Review /

Comment

Issued for

Rev.

Date

Status

CONTRACTORS DOCUMENT IDENTIFICATION:

JOB CODE:

COMPANY CODE:

TICK

Michael

Nnanna

Michael

Nnanna

Originator

SIGNATURE

M. N.

Graham

Cushion

Checked

V. Lori

Approved

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

AO1

CHANGE RECORD PAGE

REV. N

Status

Description of Revision

R01

IFR

Issued for Client Review / Comment

A01

AFU

Incorporated SPDC comments

This Document is controlled and when printed is uncontrolled

Page 2 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

AO1

CONTENTS

1.0

Introduction

2.0

Purpose

3.0

Scope

4.0

References, Standards and Specifications

5.0

Definition and Abbreviations

6.0

Organisation / Responsibilities

7.0

Flowline Undercrossing Method

7.1

Scenario 1 - Undercrossing during string production from lay barge.

7.2

Scenario 2 - Undercrossing during string pulling / Laying.

8.0

Additional Safety Precautions / Considerations

9.0

Appendices

This Document is controlled and when printed is uncontrolled

Page 3 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

1.0

AO1

Introduction

During the installation of the Trunkline and delivery lines for the NCTL Package A, a

number of existing Pipeline undercrossings shall be performed. While the main

procedure for Existing pipeline and cables undercrossing detailed the general procedure

that shall be followed in executing the pipeline undercrossings, flowlines being more

flexible than the more rigid concrete coated trunklines and often of shallow burial, thus

may require an additional consideration or modified undercrossing methodology and

Safety considerations.

Two scenarios of undercrossing of existing flowlines shall be considered thus:

Scenario 1 - Undercrossing during string production from lay barge

Scenario 2 - Undercrossing during pipe pulling and or laying.

The two scenarios appear similar but the processes differ significantly in time (process

duration). This difference can cause very costly consequences if not properly

considered.

While scenario 2 can be timed, as to the period of operation (Low tide or high tide),

scenario 1 can transcend both tidal ranges thus requires consideration for both tidal

ranges during the string production and undercrossing operation.

This addendum thus serves to augment the main procedure for existing pipeline and

cables undercrossing in the area of flowline undercrossings.

2.0

Purpose

This document is for the purpose of supplementing the main procedure for existing

pipelines and cable undercrossing in the area of undercrossing of flowlines.

3.0

Scope

This document shall apply to all the flowline undercrossings that shall be carried out for

the NCTL Package A scope. It must be appreciated, that the methods as detailed herein, may be subject to revision or modification depending upon prevailing conditions and

circumstances encountered on site, however major changes shall be approved by SPDC

prior to implementation.

4.0

References, Standards and Specifications

1)

2)

3)

4)

5.0

NCT-NST-PRO-D03-00003 Existing Pipeline and cables undercrossing

SCS Section 35 Contractor Safety

SCS Section 25 Pipeline Construction

DEP 31.40.00.15-Gen. Pipeline Engineering

Definition and Abbreviation

This Document is controlled and when printed is uncontrolled

Page 4 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

6.0

HSE

NCTL

JHA

Over bend

AO1

Health, Safety, Security & Environment

Nembe Creek Trunk Line

Job Hazards Analysis

A curved section of the pipeline allowing it to conform to the dredged

ditch.

Organization / Responsibilities

The organization that shall be responsible for the execution of this document shall be as

described below:

The Project Manager shall have overall responsibility for the successful and safe

execution of all activities in the NCTL Project.

The Construction Manager shall be responsible for the successful and safe

execution of this document. He shall delegate as may be necessary, all or part of this

function to the Field Project Engineer.

The HSE Manager shall be responsible for the monitoring of the HSE aspects of this

document and shall delegate all or part of this function to the Site HSE Officer.

The Field Project Engineer shall in addition to undertaking as directed by the

Construction Manager, have direct Site Management responsibility for a safe and

successful execution of this document.

The HSE Officer shall undertake as directed by the HSE Manager and shall carry out

Site HSE surveillance and ensure HSE compliance

The Tie-in Supervisor shall have direct responsibility for the successful and safe

execution of all pipeline undercrossing operations.

The Tie-in crew shall carry out all field operations for the successful execution of all

pipeline under crossings as directed by the Tie-in Supervisor.

7.0

Flowline undercrossing method.

7.1

Scenario 1 - Undercrossing during string production from lay barge.

String production from the lay barge is a continuous process that can transcend the

2 tidal ranges (high and low tides). Thus when an undercrossing is taking place

concurrently with this operation there is a severe risk of damaging or buckling of

the existing line, due to the uplift force of the floating string under-crossing the

existing flowline. This uplift force is as a result of rising tide.

Thus, in order to prevent this potential hazard, two (2) options are possible.

a) Option 1 Take the existing line out of service and cold cut the crossing

portion to allow for push pull string production to continue un-inhibited, and

thereafter re-instate the cut flowline.

b) Option 2 Suspend the existing flowline at height above HHWS to allow for

un-inhibited push pull string production, and thereafter lower and re-instate the

This Document is controlled and when printed is uncontrolled

Page 5 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

AO1

exposed portions of the existing flow line.

c) Preferred Option

In order to prevent or minimise extended production shut-in as shall be required in

Option 1 above, Option 2 is chosen as the preferred option with limited impact on

production.

7.1.1

Detail methodology for Scenario 1 - Option 1

The methodology to be adopted for this scenario shall be as follows:

7.2

Carry out manual excavation to expose the existing flowline.

Establish the depth of existing flowline.

Establish the required lift height sufficient for undercrossing pipeline with

attached floaters (to be determined on site)

Determine the minimum required length of existing pipe ditch to expose

(refer to attached Pipe lifting analysis chart Appendix 2) to ensure no

restraint during lifting.

Expose the existing pipe as determined above and check the remaining

wall thickness using ultrasonic thickness measuring instrument.

Position the lifting equipment (buggies) at designated intervals

Wrap the lift belt (2 loops) round the pipe and hook to the lifting equipment.

Note that 2lift points shall be utilised at each lift zone in order to distribute

stress and avoid point loading (See Appendix 3).

Lift segment of exposed flowline to designated height and suspend with

timber and or sand bags ensuring that profile of lifted flowline conforms to

the minimum designated profile.

Continue pipe string push-pull from lay barge until all required string makeup is completed.

Pull string to position; lower produced pipe string and install barrier

protection where string is underlying existing flowline(s) as in NCT-NSTPRO-D03-00003, Procedure for Existing Pipeline and Cable Under

Crossing.

Lower suspended flowline(s) and re-instate exposed portions of existing

flowline.

Scenario 2 - Undercrossing during string pulling / Laying.

During pipe laying, a number of strings may be produced in the floatation ditch and

pulled/floated down the flotation ditch to their respective positions for laying.

Pulling of these strings to their locations may involve undercrossing of existing

This Document is controlled and when printed is uncontrolled

Page 6 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

AO1

pipelines and flowlines.

Two options are also possible thus:

a) Option 1 Bottom pull of undercrossing by means of buoyancy control as in

river crossing refer to undercrossing of trunk lines in document NCT-NST-PROD03-00003.

b) Option 2 Slight lifting and suspension of existing line with sand bags and / or

timber, in order to allow for pulling/floating of undercrossing pipe strings into their

respective ditches for laying (most preferably for shallow buried flowlines).

c) Preferred Option

For the undercrossing of rigid concrete coated pipelines (trunklines), which are

often of deeper burial, Option 1 above is chosen as the preferred option; refer to

document NCT-NST-PRO-D03-00003.

However for flowlines, which are more flexible and often of shallow burial, Option 2

above is chosen as the preferred option aside from its advantage of good timeefficiency, thus reduced exposure of existing facility.

7.2.1

Detail Methodology for Scenario 2 - Option 2

Unlike scenario 1 above, this activity can be timed in order to exploit the favourable

tide level (low tide).

The detail methodology shall be as follows:

Carry out manual excavation to expose the existing flowline.

Carry out manual excavation to expose the existing flowline.

Establish the depth of existing pipe wrt. LLWS

Establish the required lift height sufficient for undercrossing pipeline with

attached floaters (to be determined on site)

Determine the minimum required length of existing pipe ditch to expose

((refer to attached Pipe lifting analysis chart Appendix 2), to ensure no

restraint during lifting.

Expose the existing pipe as determined above and check the remaining

wall thickness using ultrasonic thickness measuring instrument.

Position the lifting equipment (buggies) at designated intervals

Wrap the lift belt (2 loops) round the pipe and hook to the lifting equipment.

Note that 2lift points shall be utilised at each lift location in order to

distribute stress and avoid point loading. See attachment 3.

Lift segment of exposed flowline to designated height and suspend with

This Document is controlled and when printed is uncontrolled

Page 7 of 8

NEMBE CREEK-CAWTHORN CHANNEL

TRUNKLINE REPLACEMENT PROJECT

EXISTING PIPELINE & CABLE UNDERCROSSINGS

NCT-PRO-D03-00003

AO1

timber and or sand bags ensuring that profile of lifted flowline conforms to

the minimum designated profile.

8.0

Continue pipe string pulling to float pipe string under the existing flowline.

Pull pipe string to its position and lower string.

Where string is to be pulled and laid directly below suspended

undercrossed flowline, lower produced pipe string and install barrier

protection as in NCT-NST-PRO-D03-00003, Procedure for Existing Pipeline

and Cable Under Crossing.

Lower suspended flowline(s) and re-instate exposed portions of existing

flowline.

Additional Safety Precautions / Considerations.

In order to ensure a safe and successful execution of this document, additional safety

considerations were made in the area of possible corrosion or reduced pipeline integrity as

follows:

1) Integrity checks will be performed on the exposed pipeline in the form of wall thickness

measurements (probes), to confirm the integrity of the pipeline prior to carrying out any

lifting. Where the measured thickness is less by more than 25% of the original pipe

wall thickness, then the lifting shall be suspended to allow for further considerations.

2) An additional factor of safety of 2.5 was considered in calculating the minimum elastic

bend radius for the respective pipe sizes to augment for possible reduction in integrity

due to corrosion.

3) 2point lifting was adopted to minimise point loading and enhance stress distribution

around the lift area (stress zone).

4) All pipe lifting shall be by appropriate rated and certified belts. On no account should

sling wire or shackle be used on pipe.

5) PTW shall be ensured prior to commencement of works.

9.0

Appendices

9.1

Appendix 1 Flowlines undercrossing procedure drawings

9.2

Appendix 1 Pipe lifting analysis chart

9.3

Appendix 1 2-point lifting diagram

This Document is controlled and when printed is uncontrolled

Page 8 of 8

You might also like

- 125 LayingDocument5 pages125 LayingmondelNo ratings yet

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabDocument19 pagesMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaNo ratings yet

- PEW 107.02 Insp Existing PipelineDocument71 pagesPEW 107.02 Insp Existing PipelineRamanujan IyerNo ratings yet

- Spool Deployment and Laying ProcedureDocument86 pagesSpool Deployment and Laying ProcedurePhani Kumar G SNo ratings yet

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocument92 pagesFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O OkolotuNo ratings yet

- PLEM Design Methodology: StructureDocument4 pagesPLEM Design Methodology: StructureErik AlfiandyNo ratings yet

- Method Statement For Pipeline Cleaning: Kurdistan Crude Oil PipelineDocument38 pagesMethod Statement For Pipeline Cleaning: Kurdistan Crude Oil Pipelineanon_894950656No ratings yet

- Underwater Submarine Pipe LineDocument30 pagesUnderwater Submarine Pipe LinevillanuevamarkdNo ratings yet

- Pig Handling System Brochure PDFDocument6 pagesPig Handling System Brochure PDFKRUNAL SHAHNo ratings yet

- Etame Pipeline Fabrication PlanDocument25 pagesEtame Pipeline Fabrication PlanWilliam O OkolotuNo ratings yet

- BSPL-1540-LCL1-CM-MS-0003 (A2) Method Statement For Anchor Chain Pre TensioningDocument16 pagesBSPL-1540-LCL1-CM-MS-0003 (A2) Method Statement For Anchor Chain Pre TensioningPhani Kumar G SNo ratings yet

- Specification For Offshore Pipeline InstDocument28 pagesSpecification For Offshore Pipeline InstChandra WisnuNo ratings yet

- 05) Offshore Marine Spread Duration (Topsides & Bridges)Document1 page05) Offshore Marine Spread Duration (Topsides & Bridges)YusufNo ratings yet

- 23792turret Buoy BookDocument32 pages23792turret Buoy BookTeck Tiong Huan100% (1)

- Cable On-Bottom Stability Analysis for Zakum Oil Lines Replacement ProjectDocument12 pagesCable On-Bottom Stability Analysis for Zakum Oil Lines Replacement ProjectSourabhNo ratings yet

- Lowering Pipe SafelyDocument5 pagesLowering Pipe SafelyLarry Ubu100% (1)

- Above Water Tie inDocument2 pagesAbove Water Tie inZadeh NormanNo ratings yet

- Offshore Pipeline Sparing PhilosophyDocument4 pagesOffshore Pipeline Sparing Philosophysurfin_bumpkinNo ratings yet

- QCS 2010 Section 8 Part 4 Pipeline InstallationDocument29 pagesQCS 2010 Section 8 Part 4 Pipeline Installationahmed abdohNo ratings yet

- Flexible Jumper Design PremiseDocument12 pagesFlexible Jumper Design PremiseAgus BudionoNo ratings yet

- Seabed PreparationDocument16 pagesSeabed PreparationPhani Kumar G SNo ratings yet

- SSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsDocument8 pagesSSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsDaniel DamboNo ratings yet

- 4subsea - PSA-Norway - Flexibles-Rev5 - Un-Bonded Flexible Risers - Recent Field Experience and Actions For Increased RobustnessDocument78 pages4subsea - PSA-Norway - Flexibles-Rev5 - Un-Bonded Flexible Risers - Recent Field Experience and Actions For Increased RobustnessyuniariwibowoNo ratings yet

- 2632 PL DS 001 Line PipeDocument3 pages2632 PL DS 001 Line PipeAdvisNo ratings yet

- TOTAL Ikike Field Development ProjectDocument15 pagesTOTAL Ikike Field Development Projectemodeye kenneth100% (1)

- Spool and Riser Flooding & HydrotestDocument30 pagesSpool and Riser Flooding & HydrotestPhani Kumar G SNo ratings yet

- 9170 A04 SubseaDocument16 pages9170 A04 SubseaTina PhilipNo ratings yet

- Offshore Pipelaying DynamicsDocument150 pagesOffshore Pipelaying DynamicsfredisterikNo ratings yet

- 14 - NRG - Pipe Installation - Davit LiftDocument16 pages14 - NRG - Pipe Installation - Davit LiftBalanNo ratings yet

- Offshore Pipeline Design Course ChaptersDocument6 pagesOffshore Pipeline Design Course ChaptersDonald.K100% (1)

- BTC004-B010-CM-PRO-00031 C01 - Pipeline Cleaning and GaugingDocument29 pagesBTC004-B010-CM-PRO-00031 C01 - Pipeline Cleaning and GaugingAbdulkadir Berk Malkoç100% (2)

- Open Drain Caisson RFQ SummaryDocument29 pagesOpen Drain Caisson RFQ SummaryWilliam Smith100% (1)

- Pre Trenching ProsedurDocument19 pagesPre Trenching Prosedurmaniacs14No ratings yet

- Jangkrik Complex - Mto Piping Bulk (Bidding)Document13 pagesJangkrik Complex - Mto Piping Bulk (Bidding)shoghi wisesaNo ratings yet

- Flexible Pipe StudyDocument52 pagesFlexible Pipe StudycardozoedmNo ratings yet

- Offshore Pipe Line and RisersDocument27 pagesOffshore Pipe Line and Riserssaeed ghafooriNo ratings yet

- Attachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water WaysDocument16 pagesAttachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water Wayshasan shahriar0% (1)

- BGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationDocument26 pagesBGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationMitchel Fernandes100% (1)

- SPECIALISED DREDGING SERVICES FOR OFFSHORE PROJECTSDocument5 pagesSPECIALISED DREDGING SERVICES FOR OFFSHORE PROJECTSUyavie ObonnaNo ratings yet

- 2005-6031-2L-0009 Rev.C Specification For Pipeline TestingDocument13 pages2005-6031-2L-0009 Rev.C Specification For Pipeline Testinghavuta100% (1)

- Pipeline Stabilisation Using Pre-Trenching and Sand BackfillDocument8 pagesPipeline Stabilisation Using Pre-Trenching and Sand BackfillDonny HarmokoNo ratings yet

- A1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1Document20 pagesA1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1khabiranNo ratings yet

- Swamp DredgingDocument19 pagesSwamp Dredgingmaniacs14No ratings yet

- Shore ApproachDocument5 pagesShore Approachvpandya1981No ratings yet

- For Pipeline Route SelectionDocument11 pagesFor Pipeline Route SelectionGalymzhan Botabayev100% (1)

- Skarv Marine Operations HandbookDocument75 pagesSkarv Marine Operations Handbook고병석No ratings yet

- 10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112Document5 pages10.0000@Www - Onepetro.org@conference Paper@ISOPE I 14 112FelipeNo ratings yet

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDocument29 pagesNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidNo ratings yet

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDocument94 pagesFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O Okolotu100% (1)

- Manage pipeline maintenance & corrosion activitiesDocument24 pagesManage pipeline maintenance & corrosion activitiesRoshin9980% (5)

- 0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationDocument54 pages0029 - ND Rev - 0 22-Jun-13 Guidelines For Submarine Pipeline InstallationGiray Çıvak100% (1)

- 18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsDocument28 pages18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsAJAY PatilNo ratings yet

- Static Analysis Report Rev-A PDFDocument16 pagesStatic Analysis Report Rev-A PDFbee4manuNo ratings yet

- Mechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestFrom EverandMechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestNo ratings yet

- Pipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Document7 pagesPipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Mitchellgrany80% (5)

- Specification - Tunnel Waterproofing and Drainage SpecificationDocument33 pagesSpecification - Tunnel Waterproofing and Drainage SpecificationAlhad Panwalkar100% (1)

- 3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Document16 pages3281-RP124-2!19!0001 (Method S... Ment Cable Installation) 1Pradeep Kumar MaraptlaNo ratings yet

- Pigging in Pipeline Pre-Commissioning PDFDocument8 pagesPigging in Pipeline Pre-Commissioning PDFAbhiyan Anala Arvind100% (1)

- Entergy Estimate - New 230 KV SubstationDocument8 pagesEntergy Estimate - New 230 KV SubstationSam WinstromNo ratings yet

- Trenchless Construction TechniquesDocument26 pagesTrenchless Construction TechniquesSimranjitSinghNo ratings yet

- Review of Water Resources Management in NigeriaDocument2 pagesReview of Water Resources Management in NigeriaMitchellgranyNo ratings yet

- Review of Water Resources Management in NigeriaDocument6 pagesReview of Water Resources Management in NigeriaMitchellgranyNo ratings yet

- Review of Water Resources Management in NigeriaDocument6 pagesReview of Water Resources Management in NigeriaMitchellgranyNo ratings yet

- Project Execution Plan For Offshore Maintenance Coating OperationDocument13 pagesProject Execution Plan For Offshore Maintenance Coating OperationMitchellgrany100% (3)

- Heat Shrink Sleeve Material RequrementDocument1 pageHeat Shrink Sleeve Material RequrementMitchellgranyNo ratings yet

- Oral Presentation On Student's Industrial Work Experience Scheme - SiwesDocument11 pagesOral Presentation On Student's Industrial Work Experience Scheme - SiwesMitchellgrany60% (5)

- Pipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Document7 pagesPipeline Systems Dewatering Method Statement and Work Procedure - Rev - A01Mitchellgrany80% (5)

- Project Technical Plan For Heavy Lifts and PipelinesDocument14 pagesProject Technical Plan For Heavy Lifts and PipelinesMitchellgrany100% (1)

- Incident - Accident Reporting ProcedureDocument26 pagesIncident - Accident Reporting ProcedureMitchellgrany100% (2)

- Business Plan, Paper Recycling PlantDocument22 pagesBusiness Plan, Paper Recycling PlantSucesor66650% (4)

- Forcados WDL Technical Presentation Rev 1Document45 pagesForcados WDL Technical Presentation Rev 1MitchellgranyNo ratings yet

- Mineral WaterDocument7 pagesMineral WatersadiboyNo ratings yet

- Century Power Work Programme DetailsDocument17 pagesCentury Power Work Programme DetailsMitchellgranyNo ratings yet

- Pipe Support SpansDocument4 pagesPipe Support SpansMitchellgranyNo ratings yet

- Ipe 100-600 en 19-57Document4 pagesIpe 100-600 en 19-57jo_rz_57No ratings yet

- Typical Joint Venture AgreementDocument9 pagesTypical Joint Venture AgreementMitchellgranyNo ratings yet

- Electrical Engineer CVDocument13 pagesElectrical Engineer CVShaikh Ahamed100% (1)

- Article - BWP HydrocoolingDocument5 pagesArticle - BWP Hydrocoolingmahmoud mohamedNo ratings yet

- Migration To HANA Made Easy With DMODocument11 pagesMigration To HANA Made Easy With DMOrajendraNo ratings yet

- Stsedac QC SRP Uf 01Document6 pagesStsedac QC SRP Uf 01mohd as shahiddin jafriNo ratings yet

- Advantages of JSPDocument4 pagesAdvantages of JSPanon_599765031No ratings yet

- Scope of Accreditation CABsDocument90 pagesScope of Accreditation CABsMidhunRameshThuvasseryNo ratings yet

- Guide to Cleaning Underground TanksDocument26 pagesGuide to Cleaning Underground TanksAhmed FodaNo ratings yet

- Sappress Change Request ManagementDocument53 pagesSappress Change Request Managementzahid948650% (2)

- Okala Ecodesign Strategy Guide 2012 PDFDocument61 pagesOkala Ecodesign Strategy Guide 2012 PDFMyriam Valladares SamaniegoNo ratings yet

- Design and Fabrication of Automatic Wall Plastering Machine 2Document6 pagesDesign and Fabrication of Automatic Wall Plastering Machine 2Zainullah ButtNo ratings yet

- Vendor Selection ProcedureDocument14 pagesVendor Selection ProceduresqalopezNo ratings yet

- Resource Kit GuideDocument44 pagesResource Kit GuideSrikanth GobburuNo ratings yet

- Testing SamplesDocument22 pagesTesting SamplesCarol Isaac Murphy100% (1)

- Sundance Supply®, LLC Framing GuideDocument15 pagesSundance Supply®, LLC Framing GuideHouariKouadriNo ratings yet

- An Application of SMED MethodologyDocument4 pagesAn Application of SMED MethodologyIng Raul OrozcoNo ratings yet

- Vestas Track Record 2019 Q2Document8 pagesVestas Track Record 2019 Q2Squall LeonhartNo ratings yet

- 91075Document408 pages91075Fido FidoNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- Activity Based CostingDocument3 pagesActivity Based Costingsumit kumarNo ratings yet

- Sap Ittoolbox Com Groups Technical Functional Sap Acct AccouDocument4 pagesSap Ittoolbox Com Groups Technical Functional Sap Acct AccouAmaranathreddy YgNo ratings yet

- McKinsey - Unlocking The Potential of The IoT PDFDocument144 pagesMcKinsey - Unlocking The Potential of The IoT PDFWillianKenzoFujimotoNo ratings yet

- July 2012Document104 pagesJuly 2012Swati AmarNo ratings yet

- Scaleform Unity - Plug-In ReadMe For PCDocument8 pagesScaleform Unity - Plug-In ReadMe For PCVictor FrancoNo ratings yet

- Hospitality Industry ProjectDocument19 pagesHospitality Industry ProjectAman BhattacharyaNo ratings yet

- Pp-Es3100c TrainingDocument6 pagesPp-Es3100c Trainingwilliam lozadaNo ratings yet

- TOCBooksDocument15 pagesTOCBooksinfaredmailmanNo ratings yet

- CarlHansenCollection BrochureDocument28 pagesCarlHansenCollection BrochureayzlimNo ratings yet

- Online Banking QuestionnaireDocument4 pagesOnline Banking QuestionnaireMukesh Arya100% (3)

- IS 2062 Rev 2011Document10 pagesIS 2062 Rev 2011Ganesh LohakareNo ratings yet

- The Dubsado Workflow ManualDocument46 pagesThe Dubsado Workflow ManualRebekah Grace100% (1)