Professional Documents

Culture Documents

TFP815 04 2006

Uploaded by

jkhgvdj mnhsnjkhgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TFP815 04 2006

Uploaded by

jkhgvdj mnhsnjkhgCopyright:

Available Formats

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Type HV

Directional Spray Nozzles, Open,

High Velocity

General

Description

The Type HV Nozzles are open (nonautomatic) directional spray nozzles

with individual inlet strainers. They are

designed for use in water spray fixed

systems for fire protection applications

where a high velocity water application

may be required, such as for the protection of flammable liquids.

The Type HV Nozzles feature an integral strainer for use when the Authority

Having Jurisdiction (other than NFPA

applications) requires the use of individual strainers in addition to main

pipeline strainers for nozzles having

an orifice diameter of 3/8 inch (9,5 mm)

or less.

Available in brass or stainless steel,

the six patterns of the Type HV Nozzles provide a wide variety of orifice

sizes and distribution characteristics.

As water passes through the internal

swirl plate, a swirling action is produced, prior to the water being discharged through the orifice tip of the

body, resulting in a solid conical spray

pattern of water droplets being discharged over a defined area.

High velocity type nozzles are principally used in water spray systems for

the protection of fixed hazards such as

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the INSTALLER

WARNING that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and installation can permanently damage

a sprinkler system or its components and cause the nozzle to fail to

operate in a fire situation.

Page 1 of 6

transformers, circuit breakers, diesel

engines and diesel storage tanks,

turbo alternators, lube oil systems, oil

fire boilers, and similar hazards. They

are capable of rapidly extinguishing oil

fires by emulsification, cooling, and

smothering. The surface cooling effects of high velocity type nozzles also

minimizes the possibility of reignition

after a fire extinguishment.

It is recommended that the end user be

consulted with respect to the suitability

of the materials of construction for any

given corrosive environment. The effects of ambient temperature, concentration of chemicals, and gas/chemical

velocity, should be considered, at a

minimum, along with the corrosive nature to which the nozzles may be exposed.

The Type HV Nozzles are a redesignation for the Gem Type HV.

vices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

WARNINGS

The Type HV Nozzles described

herein must be installed and maintained in compliance with this document, as well as with the applicable

standards of the National Fire Protection Association, in addition to the

standards of any other authorities having jurisdiction. Failure to do so may

impair the performance of these devices.

The design of individual water spray

fixed systems can vary considerably,

depending on the characteristics and

nature of the hazard, the basic purpose of the spraying system, the configuration of the hazard, and wind/draft

conditions. Because of these variations as well as the wide range of

available nozzle spray characteristics,

the design of water spray fixed systems for fire protection must only be

performed by experienced designers

who thoroughly understand the limitations as well as capabilities of such

systems.

The owner is responsible for maintaining their fire protection system and de-

APRIL, 2006

TFP815

Page 2 of 6

TFP815

Technical

Data

Approvals

The Type HV Nozzles are UL and ULC

Listed, as well as FM Approved.

Maximum Working Pressure

175 psi (12,1 bar).

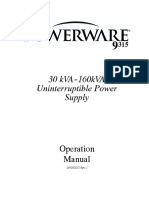

Also refer to Figure 2, Note 2.

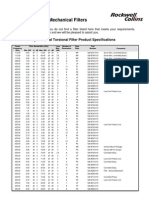

Discharge Coefficient

Refer to Figure 1.

Water Distribution

Refer to Figure 2 and 3. Optimum flowing pressure is 30 to 80 psi (2,1 to 5,5

bar).

NFPA

(GPM psi)

ISO/SI

(LPM bar)

E-NPT *

HV-14

1.6

23,0

2.83

(71,9)

1.87

(47,1)

1.50

(38,1)

1.30

(33,0)

HV-17

1.8

25,9

2.83

(71,9)

1.87

(47,1)

1.50

(38,1)

1.30

(33,0)

HV-26

2.8

40,3

2.83

(71,9)

1.87

(47,1)

1.50

(38,1)

1.30

(33,0)

HV-37

4.6

66,2

3.00

(76,2)

2.03

(51,6)

1.50

(38,1)

1.30

(33,0)

HV-45

5.5

79,2

3.00

(76,2)

2.03

(51,6)

1.50

(38,1)

1.30

(33,0)

HV-60

6.4

92,2

4.56

(115,8)

3.41

(86,6)

1.90

(48,3)

1.65

(41,9)

1-1/4

* Pipe thread connections per ISO 7/1 can be provided on special request.

Thread Connection

Refer to Figure 1.

Physical Characteristics

(Brass Assemblies)

Body . . . . . . . . . . .

Swirl Plate . . . . . . . .

Strainer . . . . . . . . . .

Strainer . . . . . . . . . .

Nominal Dimensions in Inches and (mm)

K-FACTOR

TYPE

A

B

.

.

.

.

.

.

.

.

. Brass

. Brass

. Brass

Copper

E-NPT *

D

WRENCH

HEX

BODY

Physical Characteristics

(Stainless Steel Assemblies)

Body . . . . . . . . . . . . Type 316

Swirl Plate . . . . . . . . . Type 316

Strainer . . . . . . . . . . . Type 316

Strainer . . . . . . . . . . Type 316L

STRAINER WITH

NOMINAL 1/8" DIA.

(3,2 mm) HOLES

SWIRL

PLATE

TYPE HV-14, HV-17, AND HV-26

A

D

B

E-NPT *

WRENCH

HEX

BODY

STRAINER WITH

NOMINAL 1/8" DIA.

(3,2 mm) HOLES

RETAINER

SWIRL

PLATE

TYPE HV-37, HV-45, AND HV-60

FIGURE 1

TYPE HV NOZZLES

NOMINAL DIMENSIONS

TFP815

Page 3 of 6

DATA KEY

1,0

4

6

2,0

8

3,0

10

METERS

1,0

FEET

4

1,0

4

6

2,0

8

3,0

10

12

4,0

AXIAL DISTANCE FROM NOZZLE, FEET

HV-17

14

METERS

1,0

FEET

4

1,0

4

2,0

6

8

3,0

10

12

4,0

14

1,0

4

6

2,0

8

3,0

10

METERS

1,0

FEET

4

HV-60

1,0

4

6

2,0

8

3,0

10

12

4,0

14

2,0

METERS

1,0

FEET

4

8

0

AXIAL DISTANCE FROMNOZZLE, METERS

HV-37

FEET

4

HV-26

8

0

2,0

0

METERS

1,0

AXIAL DISTANCE FROM NOZZLE, FEET

HV-14

2,0

HV-45

1,0

4

2,0

6

8

3,0

10

12

4,0

16

FIGURE 2 PART 1 of 2

WATER DISTRIBUTION DESIGN DATA

14

16

AXIAL DISTANCE FROM NOZZLE, FEET

AXIAL DISTANCE FROMNOZZLE, METERS

AXIAL DISTANCE FROMNOZZLE, METERS

FEET

4

AXIAL DISTANCE FROM NOZZLE, FEET

2,0

AXIAL DISTANCE FROMNOZZLE, METERS

2,0

AXIAL DISTANCE FROMNOZZLE, METERS

METERS

1,0

AXIAL DISTANCE FROM NOZZLE, FEET

AXIAL DISTANCE FROMNOZZLE, METERS

2,0

AXIAL DISTANCE FROM NOZZLE, FEET

DESIGN SPRAY PROFILE (S/2)

OVERALL SPRAY PATTERN (RADIAL DISTANCE)

Page 4 of 6

TFP815

AXIAL DISTANCE

S

S/2

S/2

NOTES (Figures C-1 and C-2):

1. Design data applies to a maximum wind

condition of 15 MPH (24 km/h).

NOZZLE

2. Unless otherwise noted, design data

applies to a residual (flowing) pressure

range at the nozzle inlet of 30 to 80 psi

(2,1 to 5,5 bar). For pressures up to 175

psi (12,1 bar) consult Tyco Fire &

Building Products Technical Services.

3. The shapes of the Overall Spray

Patterns and Design Spray Profiles

remain essentially unchanged over the

maximum recommended axial distances.

DESIGN

SPRAY

PROFILE

PLANE OF

PROTECTION

ORIENTATION

ANGLE

(90 SHOWN)

AXIS

DESIGN

SPRAY

AREA

OVERALL

SPRAY

AREA

0 (GRAVITY)

5,0

16

5,0

16

Minimum 50 psi (3,4 bar)

Minimum 30 psi (2,1 bar)

4,5

4,5

14

14

10

3,0

HV

-37

2,5

&H

V-4

5

HV-

HV-17

2,0

60

HV-2

1,5

1,0

HV-14

0,5

0

30

60

(GRAVITY) 45

90

120 150 180

135

MAXIMUM RECOMMENDED AXIAL DISTANCE

TO PLANE OF PROTECTION, FEET

3,5

MAXIMUM RECOMMENDED AXIAL DISTANCE

TO PLANE OF PROTECTION, METERS

MAXIMUM RECOMMENDED AXIAL DISTANCE

TO PLANE OF PROTECTION, FEET

12

12

3,5

10

3,0

HV

-3

7&

HV

-4

HV

-60

HV

-17

HV

-26

HV-1

2,5

2,0

1,5

1,0

0,5

0

30

60

(GRAVITY) 45

90

120 150 180

135

ORIENTATION ANGLE

ORIENTATION ANGLE

FIGURE 2 PART 2 of 2

WATER DISTRIBUTION DESIGN DATA

MAXIMUM RECOMMENDED AXIAL DISTANCE

TO PLANE OF PROTECTION, METERS

4,0

4,0

TFP815

Page 5 of 6

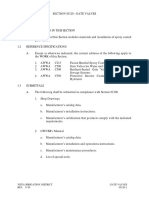

NOTES:

1. Reference dta applies to still air.

2. The Overall Spray Patterns in the plan view are the same as those in Figure C-1.

14

12

10

4,8 4,5

1,8

6

4

45

37

14

2

2

17

2

17

14

12

10

45

37

4

16

14

8

60

4

2

HORIZONTAL DISTANCE, FEET

ELEVATION, METERS

26

3,5

3,0

2,5

2,0

1,5

1,0

0,5

0

1,8

60

1,5

26

ELEVATION, FEET

60

4,0

1,5

26

45

1,0

1,0

14

37

0,5

0,5

17

0,5

1,0

1,2

4,8 4,5

0,5

14

17

37

4,0

3,5

3,0

2,5

2,0

45

1,5

1,0

1,2

26

16

6

60

1,0

0,5

HORIZONTAL DISTANCE, METERS

FIGURE 3

REFERENCE GUIDE SHOWING THE OVERALL VERTICAL SPRAY PATTERNS

WHEN PROJECTING WATER HORIZONTALLY BEYOND THE DESIGN PARAMETERS GIVEN IN FIGURE 2

30 to 80 PSI (2,1 to 5,5 bar)

Design

Criteria

jecting horizontally. As shown in Figure 3, the spray patterns become nonconcentric, beyond a certain point, due

to the affects of gravity.

Nozzle Placement. The nominal overall spray patterns, spacing, and maximum recommended axial distances

for six patterns of the Type HV Nozzles

are given in Figure 2 for residual (flowing) pressures of 30 to 80 psi (2,1 to

5,5 bar). A minimum residual pressure

of 30 psi (2,1 bar) can typically be used

for most applications; however, a minimum residual pressure of 50 psi (3,4

bar) is recommended for applications

requiring higher velocity water delivery, such as those specifying rapid extinguishment of oil fires by emulsification.

Main Pipeline Strainers. Even

though individual strainers have been

provided, main pipeline strainers are

required for systems utilizing Type HV

Nozzles, since their waterways are

less than 3/8 inch (9,5 mm) diameter.

With reference to Figure 2, use of the

Design Spray Profile for the Design

Spray Area will help assure that direct

impingement on all surfaces will occur.

The Design Spray Area shown at the

top Figure 2 - Part 2 of 2 on Page 4

consists of the square of length S

within the circular Overall Spray

Area.

The maximum recommended axial

distances given in Figure 2 are based

on maintaining the specified spray patterns under a maximum wind condition

of 15 MPH (24 km/h).

Figure 3 provided a reference guide

showing the overall still air spray patterns beyond the maximum 15 MPH

(24 km/h) axial distances, when pro-

Installation

Type HV Nozzles must be installed in

accordance with the following instructions:

NOTE

A leak tight 1 inch NPT nozzle joint

should be obtained with a torque of 20

to 30 ft.lbs. (26,8 to 40,2 Nm). A leak

tight 1-1/4 inch NPT nozzle joint

should be obtained with a torque of 30

to 40 ft.lbs. (40,2 to 53,6 Nm). Higher

levels of torque may distort the nozzle

inlet and cause impairment of the nozzle.

Step 1. With pipe thread sealant applied to the pipe threads, hand tighten

the nozzle into the nozzle fitting.

Step 2. Tighten the nozzle into the

nozzle fitting using an adjustable crescent wrench. With reference to Figure

1 the adjustable crescent wrench is to

be applied to the wrench hex.

Page 6 of 6

TFP815

Care and

Maintenance

Limited

Warranty

Ordering

Procedure

The Type HV Nozzles must be maintained and serviced in accordance

with the following instructions:

Products manufactured by Tyco Fire &

Building Products (TFBP) are warranted solely to the original Buyer for

ten (10) years against defects in material and workmanship when paid for

and properly installed and maintained

under normal use and service. This

warranty will expire ten (10) years

from date of shipment by TFBP. No

warranty is given for products or components manufactured by companies

not affiliated by ownership with TFBP

or for products and components which

have been subject to misuse, improper

installation, corrosion, or which have

not been installed, maintained, modified or repaired in accordance with applicable Standards of the National Fire

Protection Association, and/or the

standards of any other Authorities

Having Jurisdiction. Materials found

by TFBP to be defective shall be either

repaired or replaced, at TFBPs sole

option. TFBP neither assumes, nor

authorizes any person to assume for it,

any other obligation in connection with

the sale of products or parts of products. TFBP shall not be responsible for

sprinkler system design errors or inaccurate or incomplete information supplied by Buyer or Buyers representatives.

When placing an order, indicate the

full product name and P/N.

In no event shall TFBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential damages, including but not limited to labor

charges, regardless of whether TFBP

was informed about the possibility of

such damages, and in no event shall

TFBPs liability exceed an amount

equal to the sales price.

HV-14

HV-17

HV-26

HV-37

HV-45

HV-60

NOTE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Type HV Nozzles must never be

painted, plated, coated or altered in

any way after leaving the factory; otherwise, the spray performance may be

impaired.

Care must be exercised to avoid damage to the nozzles - before, during, and

after installation. Nozzles damaged by

dropping, striking, wrench twist/slippage, or the like, must be replaced.

Frequent visual inspections are recommended to be initially performed for

nozzles installed in potentially corrosive atmospheres to verify the integrity

of the materials of construction as they

may be affected by the corrosive conditions present for a given installation.

Thereafter, annual inspections per

NFPA 25 are required.

Water spray fixed systems for fire protection service require regularly

scheduled care and maintenance by

trained personnel. In addition to inspecting nozzles for proper spray performance during water flow trip tests of

the system, it is recommended that

nozzles be periodically inspected for

broken or missing parts or evidence of

impaired protection. The inspections

should be scheduled weekly or as frequently as may be necessary, and corrective action must be taken to ensure

that the nozzles will perform as intended in the event of a fire.

The owner is responsible for the inspection, testing, and maintenance of

their fire protection system and devices in compliance with this document, as well as with the applicable

standards of the National Fire Protection Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The installing contractor or sprinkler manufacturer should be contacted relative

to any questions.

It is recommended that water spray

fixed systems be inspected, tested,

and maintained by a qualified Inspection Service in accordance with local

requirements and/or national codes.

Contact your local distributor for availability.

HV Nozzles:

Specify: Type (number), (specify

brass or stainless steel) Nozzle with

(specify NPT or ISO 7/1) thread connection, P/N (specify).

Brass Assemblies, NPT

HV-14

HV-17

HV-26

HV-37

HV-45

HV-60

...................

...................

...................

...................

...................

...................

P/N

P/N

P/N

P/N

P/N

P/N

49-014-1-001

49-016-1-001

49-026-1-001

49-037-1-001

49-045-1-001

49-060-1-001

Stainless Steel Assemblies, NPT

HV-14

HV-17

HV-26

HV-37

HV-45

HV-60

...................

...................

...................

...................

...................

...................

P/N

P/N

P/N

P/N

P/N

P/N

49-014-0-001

49-016-0-001

49-026-0-001

49-037-0-001

49-045-0-001

49-060-0-001

Brass Assemblies, ISO 7/1

HV-14

HV-17

HV-26

HV-37

HV-45

HV-60

...................

...................

...................

...................

...................

...................

P/N PBP55062

P/N PBP55071

P/N PBP55080

P/N PBP55099

P/N PBP55101

P/N AEC00236

Stainless Steel Assemblies, ISO 7/1

...................

...................

...................

...................

...................

...................

The foregoing warranty is made in lieu

of any and all other warranties, express or implied, including warranties

of merchantability and fitness for a particular purpose.

This limited warranty sets forth the exclusive remedy for claims based on

failure of or defect in products, materials or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full extent permitted by law. The invalidity, in

whole or part, of any portion of this

warranty will not affect the remainder.

TYCO FIRE & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

P/N

P/N

P/N

P/N

P/N

P/N

AEC00012

AEC00021

AEC00030

AEC00049

AEC00058

AEC00263

You might also like

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- API 608 Floating Ball ValvesDocument2 pagesAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNo ratings yet

- API 608 Floating Ball ValvesDocument2 pagesAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgNo ratings yet

- ISO 5211 Drilling Patterns Imperial SizesDocument1 pageISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgNo ratings yet

- Tip Sheet 9 Web Version DocumentDocument2 pagesTip Sheet 9 Web Version DocumentKarun NooneyNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgNo ratings yet

- ASTM Method D1945-96: Analysis of Natural GasDocument1 pageASTM Method D1945-96: Analysis of Natural GasJosep JaamNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNo ratings yet

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pages12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgNo ratings yet

- Cantilever Retaining Wall Design PDFDocument2 pagesCantilever Retaining Wall Design PDFjkhgvdj mnhsnjkhgNo ratings yet

- En 12201Document33 pagesEn 12201jkhgvdj mnhsnjkhgNo ratings yet

- BZC 14Document1 pageBZC 14jkhgvdj mnhsnjkhgNo ratings yet

- Tolerancesspecifications & DimensionsDocument1 pageTolerancesspecifications & DimensionswernhowNo ratings yet

- Handling PigBasket GADocument1 pageHandling PigBasket GAjkhgvdj mnhsnjkhgNo ratings yet

- Indian Standards For Natural Gas Pipeline SystemDocument5 pagesIndian Standards For Natural Gas Pipeline SystemNapidduNo ratings yet

- LowVoltage Feb19thDocument6 pagesLowVoltage Feb19thShreyas EsheNo ratings yet

- MSG 00018Document7 pagesMSG 00018jkhgvdj mnhsnjkhgNo ratings yet

- Carmagen 6 10Document3 pagesCarmagen 6 10ikhleifNo ratings yet

- Lawctd 603Document5 pagesLawctd 603Nguyen Anh TuanNo ratings yet

- File 1361847746Document8 pagesFile 1361847746jkhgvdj mnhsnjkhgNo ratings yet

- Audit Checklist Master-HEMSA - June2010Document6 pagesAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgNo ratings yet

- Collins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsDocument2 pagesCollins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsGdfsndh GfdvhjzdNo ratings yet

- Semiconductor DevicesDocument524 pagesSemiconductor Devicesapuinwork100% (1)

- Datasheet 1mbhDocument5 pagesDatasheet 1mbhnguanjukNo ratings yet

- 0871Document1 page0871jkhgvdj mnhsnjkhgNo ratings yet

- 164200252Document92 pages164200252jkhgvdj mnhsnjkhgNo ratings yet

- 570 Examination Sample ItemsDocument3 pages570 Examination Sample ItemsMaria_Victoria_5742No ratings yet

- 05120Document4 pages05120jkhgvdj mnhsnjkhgNo ratings yet

- Material GradesDocument2 pagesMaterial Gradespankaj_pawar89No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bipotentiostat Installation and SetupDocument2 pagesBipotentiostat Installation and SetupwjawichNo ratings yet

- Chapter Nine Conducting The IT Audit: Lecture OutlineDocument22 pagesChapter Nine Conducting The IT Audit: Lecture OutlineKiervin ReyesNo ratings yet

- BSI Standards Publication: Natural Stone Test Methods - Determination of Geometric Characteristics On UnitsDocument7 pagesBSI Standards Publication: Natural Stone Test Methods - Determination of Geometric Characteristics On UnitsAbdul-alim BhnsawyNo ratings yet

- Slimline 04Document6 pagesSlimline 04kylegazeNo ratings yet

- Nos 700 Commandref PDFDocument2,242 pagesNos 700 Commandref PDFnanjundaNo ratings yet

- Aplicatii Client - ServerDocument9 pagesAplicatii Client - Serverdox811No ratings yet

- Automobile LayoutDocument17 pagesAutomobile LayoutAbhishek RajNo ratings yet

- Convergence and RegulationDocument248 pagesConvergence and RegulationrbustilloNo ratings yet

- Axle ShaftsDocument14 pagesAxle ShaftsAnonymous QiMB2lBCJLNo ratings yet

- Wa0007.Document50 pagesWa0007.rohitfc3105No ratings yet

- SPC CalculationsDocument7 pagesSPC CalculationsVinoth KumarNo ratings yet

- Reinsurance CasestudyDocument2 pagesReinsurance CasestudyGanesh RahulNo ratings yet

- CBT Inspector Qualification Guideline PDFDocument9 pagesCBT Inspector Qualification Guideline PDFhemant128467% (6)

- PWA CAD Standards Manual Ver. 3.0 September 2013Document73 pagesPWA CAD Standards Manual Ver. 3.0 September 2013raghebomNo ratings yet

- En Title DesignerDocument76 pagesEn Title DesignerTechne PhobosNo ratings yet

- No PlanDocument74 pagesNo PlanhenrykylawNo ratings yet

- JDBCDocument6 pagesJDBCiamnotfucchaNo ratings yet

- TranscriptDocument3 pagesTranscriptapi-370360557No ratings yet

- Health - Check - NE40E-07.05.13 08-30-00Document118 pagesHealth - Check - NE40E-07.05.13 08-30-00K.m.khizir AhmedNo ratings yet

- 2019 Standards Manual Supplement For NetworksDocument82 pages2019 Standards Manual Supplement For NetworksSmahjoobNo ratings yet

- SonicOS 5.9 SonicPoint Layer 3 Management GuideDocument37 pagesSonicOS 5.9 SonicPoint Layer 3 Management GuideaarnulfoNo ratings yet

- Srs - Ytv Mp3 PlayerDocument6 pagesSrs - Ytv Mp3 PlayerYasin KhanNo ratings yet

- ERA Energy SubsystemDocument47 pagesERA Energy SubsystemrhusmenNo ratings yet

- Enterprise Architect Version 11 Release NotesDocument291 pagesEnterprise Architect Version 11 Release NotesCordoba ClaudioNo ratings yet

- GXT3 Configuration Program User ManualDocument13 pagesGXT3 Configuration Program User ManualcaiolocoNo ratings yet

- ZTT Opgw 19-101354Document9 pagesZTT Opgw 19-101354Wilmer Andres Sanchez RinconNo ratings yet

- Brochure-Oracle 12c Introduction To SQLDocument2 pagesBrochure-Oracle 12c Introduction To SQLChew Yong SoonNo ratings yet

- Invertec V275-S: For Stick and DC TIG WeldingDocument4 pagesInvertec V275-S: For Stick and DC TIG WeldingPedro Ernesto Rodriguez RojasNo ratings yet

- Anatomy of A Radio LANDocument40 pagesAnatomy of A Radio LANamir11601100% (1)

- Techforce Control Room Operator & Monitoring Centre Operator SopsDocument6 pagesTechforce Control Room Operator & Monitoring Centre Operator SopsprabhaNo ratings yet