Professional Documents

Culture Documents

WSA02 2002 Part0 2 3

Uploaded by

abhijithavalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSA02 2002 Part0 2 3

Uploaded by

abhijithavalCopyright:

Available Formats

Sewerage Code of Australia

WSA 022002

Second Edition

Version 2.3

Previous edition WSA 021999

WSA 022002-2.3

ACKNOWLEDGMENTS

The WSAA Board would like to express its appreciation to WSAA Members, Associates

and staff for their contributions to the revision of the first edition of the Code. Contributions

from other industry organisations and individuals are also gratefully acknowledged. In

particular the following contributors deserve special mention for their productive work and

commitment to the revision of this Code:

John Bond

Water Corporation

Kevin Dawson

Yarra Valley Water Limited

Mike Hordern

Sydney Water Corporation

Greg Moore

South Australia Water Corporation

Barry Nelson

Sydney Water Corporation

Rick Rizzi

Sydney Water Corporation

Greg Rosser

South Australia Water Corporation

Sara Saranathan

South East Water Limited

Ian Wight

Power and Water Corporation

Front Cover Graphics by Nuttshell Graphics, North Melbourne.

Standard drawings by Loburn Pty Ltd, West Lakes, South Australia.

Printing by Standards Australia, National Publishing.

DISCLAIMER

WSAA Codes are published by the Water Services Association of Australia Inc. on the

understanding that:

The Water Services Association of Australia Inc. and individual contributors are not

responsible for the results of any action taken on the basis of information in the

Sewerage Code of Australia, nor any errors or omissions.

The Water Services Association of Australia Inc. and individual contributors disclaim

all and any liability to any person in respect of anything, and the consequences of

anything, done or omitted to be done by a person in reliance upon the whole or any

part of the Sewerage Code of Australia.

The Sewerage Code of Australia does not purport to be a comprehensive statement

and analysis of its subjective matter, and if further advice is required, the services of

a competent professional should be sought.

PUBLICATION DETAILS

Published by:

Water Services Association of Australia Inc.

469 Latrobe Street

Melbourne Victoria 3000 Australia

ISBN 1 8760 8866 4

COPYRIGHT

Water Services Association of Australia will permit up to 10 percent of Parts 1 and 2 of this

Code to be copied for use exclusively in house by purchasers of this Code without payment

of a royalty or giving advice to Water Services Association of Australia Inc. Water Services

Association of Australia will also permit some or all of Parts 3 and 4 of the Code to be

copied for use in contract documentation.

Copyright 2002 by WATER SERVICES ASSOCIATION of Australia Inc. ALL RIGHTS

RESERVED.

WSA 022002-2.3

FOREWORD

It gives me great pleasure to present the second edition of the Sewerage Code of

Australia. An initiative of the Water Services Association of Australia (WSAA), this revised

edition brings together my members and associates collective experiences of adoption of

the first edition into their asset creation processes. This revised edition also now

addresses the design and construction of trunk and branch sewers, as distinct from

reticulation only. However, the clear benefits of this initiative extend beyond my members

to the wider Australian community. The performance of network infrastructure is

fundamental to achieving excellence in community health, customer service, environmental

sustainability, and delivering cost effective water and sewerage services. This revised

Code will make a practical contribution to better achieving those goals.

Cost savings in design and construction can deliver major benefits. Currently, water supply

networks accounts for 65% of the $26 billion current replacement costs of the total water

supply infrastructure in Australias major cities. Sewage collection systems account for

82% of the $28 billion current replacement cost of the total sewerage infrastructure. Water

utilities and the urban development industry are investing some $500 million annually in

water and sewerage networks.

Water supply and sewerage networks are made up of a multitude of components including

pipes, fittings, valves, connectors, access chambers and so on. Historically, Australias

urban water utilities have developed local standards and codes for the design and

construction of these networks. The wide variety of requirements for pipeline systems,

designed to achieve essentially the same objectives, has created small fragmented

markets for those components leading to higher costs. Standards have also focussed more

on prescription than the performance required. Costs are high, innovation is stifled and

export opportunities lost.

The Water Services Association of Australia is ideally positioned to provide national

leadership in actively prosecuting its National Codes Initiative. As an industry association

of the major urban water utilities in Australia, WSAAs 22 members supply some 14 million

Australians with water and sewerage services. In developing Codes of practice, WSAA is

working to provide a complete asset management framework to support the total life cycle

of our network infrastructure.

Best practice and strategic standardisation are the principal drivers to delivering living

codes and ensuring that water and sewerage assets are fit for purpose and cost effective.

Materials and product specifications, quality assurance policies, certification programs,

design and construction codes, research and development initiatives and competencybased training schemes will support and form a total package of industry practices that can

deliver the outcomes for an internationally competitive Australian water industry.

Dr John Langford BE (Ag) PhD FTSE FIE Aust

Executive Director of the Water Services Association of Australia

WSA 022002-2.3

CONTENTS

PREFACE

INTRODUCTION

PART 0: GLOSSARY OF TERMS AND ABBREVIATIONS

I Glossary of Terms

12

II Abbreviations

22

III Referenced Documents

25

IV Other References

29

PART 1: PLANNING AND DESIGN

Contents

32

1 General

38

2 System Planning

45

3 Flow Estimation

52

4 Detail Design

54

5 Property Connection

77

6 Maintenance Structures

80

7 Ancillary Structures

87

8 Structural Design

95

9 Design Review and Drawings

100

Appendix A Estimation of Equivalent Population (EP)

104

Appendix B Flow Estimation for Undeveloped Areas

110

Appendix C Gauging of Sewer Overflows, Flows, Levels and Velocities

116

Appendix D Computer Flow Modelling

119

Appendix E Analysis of Flow Gauging Results from Existing Systems

120

PART 2: PRODUCTS AND MATERIALS

Contents

122

10 Products and Materials Overview

123

Appendix F Quality Assurance of Products and Materials

140

PART 3: CONSTRUCTION

Contents

148

11 General

153

12 Quality

155

13 General Construction

158

14 Products and Materials

164

15 Excavation

169

WSA 022002-2.3

16 Bedding for Pipes and Maintenance Structures

171

17 Pipe Laying and Jointing

172

18 Maintenance Holes (MHs)

179

19 Maintenance Shafts (MS and TMS) and Inspection Shafts (IS)

182

20 Pipe Embedment and Support

183

21 Fill

186

22 Acceptance Testing

188

23 Tolerances on As-Constructed Work

202

24 Connections to Existing Sewers

204

25 Restoration

205

26 Work As Constructed Details

207

Appendix G Ovality Testing of PVC and GRP Gravity Sewers

Default Prover Diameters

208

PART 4: STANDARD DRAWINGS

Contents

210

27 Introduction

212

28 Listing of Standard Drawings

213

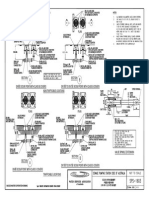

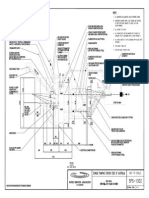

29 Commentary on SEW 1100 Series Pipeline Layout

215

30 Commentary on SEW 1200 Series Embedment and Trench Fill

219

31 Commentary on SEW 1300 Series Maintenance Structures

227

32 Commentary on SEW 1400 Series Special Crossings / Structures Arrangements

231

32 Commentary on SEW 1500 Series Insertion and Repair Systems

234

STANDARD DRAWINGS

237

SEW-1100 Series Drawings Pipeline Layout

SEW-1200 Series Drawings Embedment, Trench Fill and Support Systems

SEW-1300 Series Drawings Access Structures

SEW-1400 Series Drawings Special Crossings / Structures Arrangements

SEW1500 Series Drawings Connections to Existing Systems

WSA 022002-2.3

PREFACE

THE NEED FOR TECHNICAL DOCUMENTATION

The Sewerage Code of Australia, together with a Water Agency supplement and other

referenced documents, sets an Agencys requirements for:

Minimum acceptable technical criteria for design and construction of sewer networks;

and

Manufacture and supply of associated products and materials.

This set of documentation has a number of benefits. It:

enables ready acquisition from different suppliers of assets of a recognised acceptable

quality;

ensures assets have acceptable levels of buildability, operability and maintainability;

takes account of whole-of-life costs;

facilitates efficient design and construction i.e. it obviates the need for Water Agencies

to develop and maintain their own standards;

limits risk exposure of both the principal and suppliers;

facilitates controlled improvements to asset designs, usage of products and materials,

and construction and acceptance testing methods; and

facilitates quality assurance and inspection.

THE BENEFITS OF NATIONAL CODES

Historically, Australias urban water authorities developed and enforced their own parochial

standards for design, construction, materials and products. The wide variety of

requirements for pipeline systems created small, fragmented markets and hindered the

mobility of suppliers, leading to higher costs than necessary.

National Codes, which commenced publication 1999:

facilitate consistent national reform and regulation of the water industry;

provide a transitional mechanism for sharing water-industry specialist expertise as

internal Water Agency resources diminish;

provide a common technical reference for the development of industry training and

skills accreditation programs for private sector suppliers;

enhance the mobility of suppliers e.g. designers and constructors by reducing parochial

technical impediments to trade; and

improve the Australian water industrys interface with international water companies.

WSAA members and associate members have adopted the first editions of the Codes with

supplementary requirements and technical variations. The second editions of the Codes

address many of the supplementary requirements and variations such that the extent of the

Agency supplements is expected to decrease markedly.

The Codes are presented in performance based terms together with deemed-to-comply

solutions. Alternative solutions may be accepted provided it can be demonstrated that they

meet the performance requirements.

WSA 022002-2.3

INNOVATION

The word innovation has become a euphemism for doing anything differently, though not

necessarily better.

Dictionaries variously define innovation as to introduce novelties i.e. anything new or

strange; to make changes. On closer scrutiny, many changes may be shown to be

technically inferior and/or more costly in life cycle terms.

Standardisation and innovation are somewhat conflicting but associated concepts, some

characteristics of which are outlined below. Standardisation may generate a number of

benefits; however, without innovation, standards can lock in historical practice at the

expense of best practice.

STANDARDISATION

INNOVATION

In a changing market, standardisation may

not be practicable

Innovation is necessary in all markets and

precedes standardisation

Standardisation reduces complexity

Innovation thrives on complexity

Standardisation facilitates training

Innovation frustrates training

Standardisation requires pragmatism,

compromise and consensus

Innovation requires creativity and courage

Standardisation may lead to sub-optimisation

Innovation seeks optimisation

Standardisation aids in management of risk

and costs in a large market

Innovations risk and costs increase with the

scale of its initial implementation

Genuine innovative ideas and methods that enhance functionality and reduce life cycle

costs are to be encouraged but must be considered and adopted through an appropriate

screening process.

Designs/Construction Practices: WSAA members have agreed to inform each other of

innovative trials, to share information and to work with one another and with industry in

challenging accepted standards and practices and achieving more effective and efficient

outcomes.

Products: WSAA has developed a national product appraisal system that provides a

single point of entry into the market for strategic product manufacturers, developers and

innovators. Whilst a successfully appraised product will generally have universal appeal, it

should be clearly understood that a finding by WSAA that a product is fit for purpose and

has acceptable life expectancy does not automatically mean it is authorised for use by a

Water Agency. Other considerations may necessitate restrictions being placed on the

number or type of products accepted for use in a particular network.

HYPOTHETICAL EXAMPLE OF THE USE OF THE SEWERAGE CODE

When an agencys administrative and process requirements are contractually coupled with

this Code, the scenario outlined below illustrates a typical use of the Sewerage Code of

Australia in asset creation.

Concept Plan

The Agencys Concept Plan defines the broad sewerage management objectives and

states the available system to which the planned scheme will connect, design flows and, if

necessary, augmentation requirements. For a small development, the Plan may simply

state the point of connection for a nominally sized reticulation system.

WSA 022002-2.3

Agency/Development Agreement

The Agency, via a formal agreement or contract, instructs the Developer that all network

infrastructure shall comply with the deemed-to-comply technical requirements of the

Code. Special or alternative technical solutions would require formal approval by the

Agencys representative.

Project Manager

Accountability for the total project design, construction and connection is vested in a

Project Manager who is responsible for managing all facets of the project, including

procurement of design, construction and testing services. The Project Managers system

would include the necessary procedures, check lists etc addressing the Agencys process

and administrative requirements and technical elements of the Code. The Project Manager

is responsible for ensuring that all suppliers have the necessary technical

qualifications / accreditation.

Design

Under the control of the Project Managers management system and using the Code as the

principal design input, the Designer prepares Design Drawings in which the scheme layout,

design flows, component sizing, class and material options comply with the criteria of the

Code.

Project Specification

The Designer (or Project Manager) prepares a project Specification, to accompany the

Design Drawings, for issue to the Constructor. The project Specification may be prepared

by cutting and pasting standard elements of Part 3: Construction, and including reference

to or attachment of the relevant Standard Drawings (Part 4) and Purchase Specifications

(WSAA website).

Constructor

The Constructor is engaged by the Project Manager to build the asset in accordance with

the project Specification. The Constructor works under the control of the Project Managers

management system, including adherence to ITPs, witness and hold points etc. The

Constructor is responsible for ensuring that all procured materials and products are listed

in an Agencys authorised products schedule and/or comply with the nominated Purchase

Specifications, as well as being stored and installed without damage and in accordance

with the Specification and Design Drawings. The Constructor provides details to the

Designer for preparation of work-as-constructed drawings.

Testing

Testers (compaction, pressure, etc) work under the Project Managers control and conduct

tests in accordance with the requirements of the Code.

THE WSAA WEBSITE

The first editions of the Codes contained a wide variety of product guidance and

information. A decision has been made to transfer most of that information to the WSAA

website www.wsaa.asn.au where it can more efficiently be managed and kept current.

The following information is now available from the website. More information may be

added over the life of this edition:

Purchase Specifications

Product and Material Information and Guidance

Water Industry Product Standards

Technical Notes

Product Appraisal Reports

WSA 022002-2.3

INTRODUCTION

SCOPE OF CODE

The Sewerage Code of Australia covers the planning, design and construction of trunk,

branch, reticulation and property connection sewers up to DN 1200 and larger.

The Code does not specifically address sanitary drains used in private and community title

developments that are connected to a Water Agencys reticulation sewers. However, where

those drains are likely to be maintained by the Water Agency or its contractor, it is

recommended that the Sewerage Code be adopted as a deemed-to-comply solution for

the sanitary drains specified in the National Plumbing and Drainage Standard

AS/NZS 3500.2.1: Sanitary drainagePerformance requirements.

CODE STRUCTURE

The Sewerage Code of Australia is made up of separate parts, which address the technical

requirements of the design and construction elements of the Water Agency asset creation

and renewal processes.

Each part of the Code is divided into sections and clauses with supporting figures and

tables. Part 4 of the Code also has commentaries relevant to each series of Standard

Drawings. A glossary of terms and interpretation of abbreviations is provided in Part 0,

together with a list of referenced documents.

CODE PURPOSE

The primary purpose of the Sewerage Code of Australia is to document technical best

practice for design and construction of quality sewer networks. The Code is an element of

the overall asset management framework that WSAA is developing for its members

network infrastructure. The Code focuses on asset creation, but it could be used for some

of the intervention options such as replacement and renewal that may be necessary with

aging assets.

The Code is intended for Planners, Designers and Constructors servicing the land

development industry and for contract work done on behalf of Water Agencies for asset

management.

The Code does not provide administrative or process guidance that is specific to each

Water Agency, which will be dependent on the nature of the works, whether they are

developer or capital works employing Deed of Agreement or contract documents.

MANDATORY AND INFORMATIVE

The Code provides a mixture of mandatory and informative statements.

The mandatory requirements are a mixture of both prescriptive and performance

requirements. Overall, the Code provides deemed-to-comply solutions to the planning,

design and construction of trunk, branch, reticulation and property connection sewers. The

development of a fully performance-based code underpinned by a standard deemed-tocomply solution document is high on WSAAs agenda.

The information and guidance (informative text) contained in the Code has been

deliberately interspersed throughout the mandatory requirements to provide some context

and enable better understanding of the mandatory requirements. Informative text has been

italicised to enable clearer differentiation.

However, it is emphasised that the exact approach taken to all aspects of a particular

sewerage project is the decision of the Water Agency and Planners, Designers and

WSA 022002-2.3

10

Constructors involved in each project. This Code provides technical information to aid in

that process.

PURCHASE SPECIFICATIONS

The WSAA materials network, in conjunction with product suppliers, has developed a suite

of default Purchase Specifications to assist with preparation of contract documentation.

The Purchase Specifications have been kept as clear and simple as possible and do not

repeat the need for requirements that are already covered by the relevant product

standard.

A range of quality assurance options based on international practice and commensurate

with the risk of failure have been adopted.

The Purchase Specifications have been placed on the WSAA website for ease of access

and to enable regular updating and improvements. Each Purchase Specification is freely

downloadable.

It is anticipated that Purchase Specifications will be revised over the life of this edition to

reflect changes in Standards and advice from users. Similarly, additional Purchase

Specifications may be published.

PROPOSED AMENDMENTS

WSAA invites users of this Code and its supporting documentation to propose

amendments. An amendment proforma can be downloaded from www.wsaa.asn.au.

To increase the likelihood of suggested amendments being adopted, it is recommended

that users of the Code seek preliminary review by and support of a WSAA Member or

Associate or other relevant organisation, for example, CSIRO, Civil Contractors Federation

or PIPA for inclusion with the submission.

Amendments will be published from time to time on the WSAA website. Users may register

their interest so that published amendments can be emailed directly. To register, please

submit your name, position, company and contact details, together with the WSAA Code

titles in which you have an interest, to david.cox@wsaa.asn.au.

Sewerage Code of Australia

Part 0: Glossary of Terms,

Abbreviations and References

WSA 022002-2.3

12

I GLOSSARY OF TERMS

The purpose of this glossary is to assist you to interpret terminology used in the various

parts of the Sewerage Code of Australia.

The terms and definitions are adopted from various sources including:

Australian/New Zealand Standard AS/NZS 2566.1, Buried flexible pipelines Part 1:

Structural design

British Standard BS 8005.1, Guide to new sewerage construction

European Standard EN 752-1, Drain and sewer systems outside buildings, Part 1:

Generalities and definitions

Glossary of Building Terms published jointly by National Committee on Rationalised

Building (NCRB), Standards Australia and Suppliers Index Pty Ltd

Australian/New Zealand Standard AS/NZS 3500 National Plumbing and Drainage

Code Part 0: Glossary of terms

Water Agency documentation

Term

Definition

access chamber

See maintenance hole and gas check maintenance hole

access chamber

offset

See maintenance hole offset

access cover

A removable cover that is installed at or above finished surface

level to allow access to a maintenance hole or a maintenance

shaft

aggressive soil

Soil which could have a corrosive or other adverse effect on a

pipeline component and which requires special consideration with

respect to protective measures. See also contaminated soil

allotment

See lot

allotment control

See lot control

Australian Height

Datum, AHD

A level datum, uniform throughout Australia, derived from mean

sea level observations at 30 tide gauge locations located along

the Australian coastline and used as a base reference for

derived datum levels throughout Australia; replaces Australian

Levelling Survey

Authorised

Acceptable to, authorised by or approved by the Water Agency or

Owner or Regulator

average dry

weather flow

(ADWF)

The combined average daily sanitary flow into a sewer from

domestic, commercial and industrial sources. Based on empirical

evidence, AWDF is deemed to be 180 L/d/EP or 0.0021 L/s/EP

backfill

Material (including embedment and trench fill) and procedure

used to fill an excavation. See also engineered fill

bedding

Zone between the foundation and the bottom of a pipeline. See

also embedment

boring

A method of machine excavation working from a shaft or pit and

creating a cylindrical tunnel slightly larger than the pipeline

boundary

Survey line separating adjoining properties for the purposes of

defining ownership/title

13

Term

WSA 022002-2.3

Definition

boundary trap

An inverted siphon trap installed in a customer sanitary drain to

prevent sewer gas passing and entering the building through the

drain. See also water seal

boundary trap area

An area within which properties connected to a sewer are

potentially at risk of back-vented gases and where boundary traps

are usually required to be installed as a preventive measure

branch sewer

A network of pipes nominally DN 375 to DN 600 that connects

reticulation sewers. See also reticulation sewer, main sewer,

trunk sewer

bulkhead

A structural partition across a pipeline trench, built to minimise

longitudinal and lateral movement of the pipeline, to minimise

ground movement in the trench, and to restrict movement of fines

within and along the trench caused by infiltration and ground

water flow through the embedment and trench fill materials

cathodic protection

Partial or complete protection of a metal from corrosion by

making it the cathode, using either galvanic or impressed current.

It is usually applied to mitigate external corrosion of electrically

continuous welded steel buried pipelines and internal corrosion of

welded steel service reservoirs

carriageway

Portion of a road or bridge assigned to the movement of vehicles,

inclusive of any shoulders and auxiliary lanes. It is designated as

that part of a public road(way) between kerbs. See also local

road, major road, road, road reserve

catchment area

That area (watershed) made up of properties that discharge or

have potential to discharge to a sewerage system

coating

Additional organic or inorganic material applied to the internal

and/or external surface of a pipeline component at a specified

film thickness, which is intended to provide long-term protection

from corrosion, mechanical damage and/or chemical attack. Such

coatings require special surface preparation and application

techniques. See also lining

Concept Plan

A package of information provided to the Designer by the Water

Agency to enable the appropriate planning / design of major

sewerage system components to be performed

connection point

Point of connection between the property connection sewer and

the customer sanitary drain. Also called property connection point

conical access

chamber

See conical maintenance hole

conical

maintenance hole

A maintenance hole with a conical tapered section to convert

from shaft diameter to neck diameter, and a neck where fine

adjustment in level is made

Constructor

An individual, corporation or legal entity including any contractors

and sub-contractors that is accountable at law for delivery of

Works under a specific contract or development agreement

contaminated soil

Soil that has been affected by previous land use or by direct or

indirect infiltration of chemicals or other substances such that it

requires special consideration. See also aggressive soil

WSA 022002-2.3

Term

14

Definition

controlled fill

See engineered fill

corrosion

Deterioration of a material and alteration of its properties due to

chemical or electrochemical reaction between the material and its

environment

customer sanitary

drain

A pipeline installed by a licensed plumber within the property

boundary and operated by a property owner to convey sewage

from buildings to the connection point; constructed to plumbing

code standards; also called house drain, house service line,

house sewer, sanitary connection, property drain, sanitary drain

cylindrical access

chamber

See cylindrical maintenance hole

cylindrical

maintenance hole

A maintenance hole with constant shaft diameter

Design Drawings

Plans, elevations and drawings required for the construction of

the sewer systems and showing the locality including roads and

sewer details, the site plan including lots, boundaries, roads,

proposed and existing sewers, proposed property connection

sewers, pumping stations, pressure mains, water mains, drains,

watercourses, site contours, proposed aqueducts, proposed

boreholes, a longitudinal section, construction details and a

connection to existing sewer schedule. Supplementary

information may include proposed buildings, existing services,

and groundwater and watercourse levels

design flow

The estimated maximum flow into a sewer comprising the sum of

peak dry weather flow (PDWF), ground water infiltration (GWI)

and stormwater inflow and infiltration (IIF). See also peak dry

weather flow, groundwater, infiltration, inflow, stormwater

Designer

Person(s) or firm responsible for a design output. Such person or

firm may be accountable to a Project Manager or other person

having responsibility under a contract or otherwise

Developer

A person, organisation, local government authority or government

authority (other than the Water Agency) responsible for provision

of a sewerage

drop

Difference in level between the inlet and outlet pipes at a

maintenance hole

drop junction

A fitting, usually of a tee configuration, used in the pipework of

drop structures and vertical risers. See vertical riser and drop

structure

drop structure

A vertical section of pipe inside or just outside a maintenance

hole to connect a sewer that is at a considerably higher level than

the outlet

easement

A right held by one party to make use of the land of another for

certain purposes

embankment fill

Fill material placed over the overlay for the purpose of creating an

embankment

15

Term

WSA 022002-2.3

Definition

embedment

Zones around a pipe between the foundation, the trench or

embankment fill and the trench walls. See bedding, haunch

support, side support and overlay

emergency relief

structure (ERS)

(1) A structure designed to permit controlled discharge of

stormflows that exceed downstream system capacity. Also called

an overflow

(2) The location to which the sewage will overflow in case of

system failure

end of pipe

A termination of a pipeline with no provision for access from the

surface

engineered fill

Fill that has been selected, placed and compacted to meet

specified performance criteria

Equivalent

Population (EP)

The equivalent hypothetical residential population that would

produce the same peak dry weather flow as that contributed by

the area under consideration i.e. all zonings including residential,

commercial and industrial

exfiltration

Escape of sewage from a sewer into the surrounding ground

existing surface

level

Undisturbed ground surface

finished surface

Paved or unpaved surface of a filled trench or an embankment

finished surface

level, FSL

Ground level at the completion of construction and landscaping

fitting

A component of a pipeline, other than a pipe, which allows

pipeline deviation, change of direction or bore. In addition, valves,

flanged-socketed pieces, flanged-spigot pieces, junctions,

inspection openings, collars and couplings are also defined as

fittings

fixture

A receptacle with necessary appurtenances designed for a

specific purpose, the use or operation of which results in

discharge into the customer sanitary drain

flat top access

chamber

See flat top maintenance hole

flat top

maintenance hole

A maintenance hole fitted with a horizontal reinforced concrete

slab (converter slab) to convert from shaft diameter to neck

diameter

flexible joint

A joint that permits significant angular deflection, both during and

after installation, and which can accept a slight offset to the

centreline

flexible pipe

A pipe that relies primarily upon side support to resist vertical

loads without excessive deformation. Flexible pipe materials

include PVC, GRP, ABS, PE, steel and ductile iron

footpath

A formed pavement for pedestrians, especially one at the side of

a road in the footway. See also footway

footway

A strip of land between the front boundary of a lot and the kerb or

carriageway. Also known as nature strip or verge in some regions

of Australia. See also carriageway

WSA 022002-2.3

Term

16

Definition

gas check

maintenance hole

A combination of two MHs separated by a water seal to prevent

migration of sewer gas

grade

Ratio between the vertical and horizontal projections of a pipe

length; may also be expressed as a percentage

gravity sewer

system

A system wherein flow and/or pressure are caused by the force of

gravity. There are two kinds of such systems:

Pressurised gravity system, where the pipeline operates full;

and

Non-pressurised gravity

operates partially full

system,

where

the

pipeline

groundwater

Water present in the sub-surface strata

haunch support

That part of the side support below the spring line of a pipeline

head, H

Pressure expressed in terms of the height of a column of water

(in metres). The head is a factor of 9.81 (nominally 10) lower than

the equivalent value in kPa, e.g. 800 kPa 80 m

head loss

A reduction in head in a hydraulic system. Head loss is:

a measure of the resistance of a system to the flow of

sewage through it

the amount of energy used by sewage in moving from one

location to another

See also head

hold point

A point beyond which an activity may not proceed without the

approval of a designated organisation or authority

hydraulic grade

line, HGL

A line (hydraulic profile) indicating the piezometric level of flow at

all points along a conduit, open channel or stream. In pipes under

pressure, each point on the hydraulic profile is an elevation

expressed as the sum of the height associated with the pipe

elevation and the pipe pressure (head)

infiltration

Ingress of groundwater into a sewer system

inflow

Ingress of stormwater into a sewer system

inspection opening

(IO)

A fitting with provision for visual inspection and limited access to

facilitate inspection and testing and/or clearing of obstructions,

but not human access; generally requiring excavation for use

inspection shafts

See terminal maintenance shafts

invert

Lowest point of the internal surface of a pipe or channel at any

cross-section

inverted syphon

A pipe where the soffit drops below the hydraulic gradient and in

which the sewage flows under pressure of gravity

joint

A connection between the ends of two pipeline components

including the means of sealing

jump-up

See vertical riser

lamphole

See maintenance shaft and inspection opening

17

Term

WSA 022002-2.3

Definition

legally parked

Street side parking in road carriageways (but not freeways) and in

public car parks giving due regard to parking signs and the

minimum legally required distances from intersections, corners,

bends etc

lining

Additional organic or inorganic material applied to the internal

surface of a pipeline component at a specified thickness, which is

intended to provide long-term protection from corrosion,

mechanical damage and/or chemical attack. Such linings require

special surface preparation and application techniques. See also

coating

local planning

authority

Local municipal council or local government body or appeals

board authorised to administer or arbitrate government town

planning legislation

local road

A road, under the control of the local government or council, with

load restriction, or one that carries less than 200 commercial

vehicles per day in each direction. See road, major road

lot

A property for which a separate title may be held or issued to be

serviced by the sewerage system

lot control

Highest level at which a reticulation sewer may be constructed to

ensure a gravity service is possible for development on the

serviced area of the lot

main sewer

Principal reticulation sewers excluding the last upstream section

of end-of-line sewers and property connection sewers. See also

branch sewer, reticulation sewer, property connection sewer,

trunk sewer

maintenance hole,

MH

A chamber with a removable cover which allows human and

machine access to a (typically buried) sewer; abbreviation MH

retains the traditional abbreviation for manhole

maintenance hole

offset

A situation where the centre of an MH is displaced from the point

of intersection of two or more sewers, to allow better use of space

within the MH

maintenance shaft,

MS

A structure on a sewer between MHs, larger than an inspection

opening, which provides equipment access but not person access

to the sewer and which allows limited change of grade and/or

direction; used where appropriate as an alternative to MHs

major road

A collective term for any freeway, expressway, arterial road or

distributor road; See also road, local road

manhole, MH

See maintenance hole

minor road

See local road

nominal size, DN

An alphanumeric designation of size for components of a pipeline

system, which is used for reference purposes; it comprises the

letters DN followed by a dimensionless whole number which is

indirectly related to the physical size, in millimetres, of the bore or

outside diameter of the end connections

obvert

See soffit

offset

Distance specifying the location of the centreline of a pipeline,

generally measured perpendicular from a title boundary

WSA 022002-2.3

Term

overflow

18

Definition

(1) Condition where sewage overflows from a sewerage system

due to blockage, choke or hydraulic overloading and either

discharges to the environment or enters buildings. See surcharge

(2) See Emergency Relief Structure

overlay

Zone between the side support and either the trench fill or the

embankment fill

Owner

Agency, Authority, Board, Company, Controlling Authority,

Corporation, Council, Department, Individual, Regulator, Utility or

other legal entity who is the owner of the asset and/or who has

responsibility for the asset

partial service

A condition where the sewer is not sufficiently deep to provide

gravity service if certain portions of a lot are developed. See also

lot control

peak dry weather

flow

The most likely peak sanitary flow in the sewer during a normal

day. It exhibits a regular pattern of usage with morning and

evening peaks related to water usage for toilets, showers, baths,

washing and other household activities

pipe

A pipeline component of uniform bore, normally straight in axis,

having socket, spigot or flanged ends

precast access

chamber

See precast MH

precast access

chamber top

See precast MH top

precast MH

An MH constructed

components

precast MH top

A precast concrete MH top incorporating an access cover and

frame with factory-formed concrete surround and, if applicable,

cover infilling

preformed MH

An MH constructed

components

property

connection fitting

Most upstream fitting of a property connection sewer; the

upstream end of the fitting is the connection point

property

connection sewer

A short sewer, owned and operated by the Water Agency, which

connects the main sewer and the customer sanitary drain; it

includes a junction on the main sewer, a property connection

fitting, in some cases a vertical riser, and sufficient straight pipes

to ensure the property connection fitting is within the lot to be

serviced

Regulator

Entity that has the power to enforce Regulations related to the

activities and responsibilities of a Commonwealth, State, Territory

or Local government. It applies to environmental management

and protection, occupational health and safety and the like

reticulation sewer

A sewer operated by the Water Agency, generally DN 100 to

DN 300, for the collection of wastewater from individual

properties and conveyance to branch and trunk sewers or to a

point of treatment. See also branch sewer, main sewer, trunk

sewer

from

from

manufactured

manufactured

precast

preformed

concrete

plastic

19

Term

WSA 022002-2.3

Definition

rigid pipe

A pipe that supports vertical loads primarily by virtue of its

inherent resistance to bending or deformation as a ring; when

rigid pipes are used, flexible joints must be used to ensure that

the pipeline installation is flexible. Pipe material types include VC

and RC

road

A surface devoted to public travel and movement of goods by

vehicles; a road covers the entire width between opposite

property boundaries in a road reserve including the road

pavement, footways, cycleways (where appropriate) and verges

road reserve

Land set aside for the road pavement, footway(s) and verge(s)

roadway

See road

rodding point

See terminal maintenance shaft

roughness

coefficient, n

A measure of the resistance of the surface of a pipe or channel

under turbulent flow which is expressed as a dimensionless

constant; it is used in the Manning formula

roughness value, k s

A measure of the resistance of the surface of a pipe or channel

under turbulent flow which is expressed in millimetres; it is used

in the Colebrook White formula

sanitary drain

See customer sanitary drain

SCADA

An electronic supervisory control and data acquisition system for

compiling water system operations data and enabling automatic

and remote control/operation of specific facilities

self cleansing

Ability of the flow in a sewer to carry away solid particles, which

would otherwise be deposited in the pipe

sewage

Water polluted by use and discharged to a sewer system

sewer

Pipeline or other construction, usually buried, designed to carry

sewage from more than one source; See also reticulation sewer,

branch sewer, customer sanitary drain, main sewer, property

connection sewer, trunk sewer

sewer system

Network of pipelines and ancillary works that conveys sewage to

a treatment works or other place of disposal

side support

Embedment zone between the bottom and top of a pipe

sideline

See property connection sewer

soffit

Inside top of a pipeline

Specification

The document detailing the work involved in the particular project

in hand

specifications

Precise standards of performance for construction work, materials

and manufactured products. Specifications make it possible to

express expected values when work or items are purchased or

contracted for, and they provide means of determining

conformance with expectations after purchase or construction

spring line

Projection of the horizontal centreline to the walls of a pipe

WSA 022002-2.3

Term

standards

20

Definition

(1) Documents that specify the minimum acceptable

characteristics of a product or material, a test procedure, an

installation method etc, issued by an organisation that develops

such documents e.g. Standards Australia. Such standards may or

may not be used as (or called) specifications

(2) A set numerical limit e.g. a contaminant limit set by a

regulatory agency

stormwater

Runoff due to rainfall from roofed areas and paved and unpaved

areas, which has not seeped into the ground. Also termed surface

water. See also groundwater

street alignment

Horizontal shape of the boundary between a road reserve and

adjoining lots. See also road

sub-critical flow

State of flow when the water velocity is less than the velocity of

the small surface wave, water levels tending to be stable

super-critical flow

State of flow when the water velocity is greater than the velocity

of the small surface wave, violent fluctuations in water level being

possible

Superintendent

The individual appointed by the contract principal as an

independent arbiter of contract directions, issues, claims and

variations

support type

A mode of pipe embedment

surcharge

Condition in which sewage is held under pressure within a gravity

sewerage system, but does not overflow. See overflow

system planning

A process of examining the present, recognising trends, making

projections and developing plans to ensure sewerage systems

have the capability to achieve agreed customer, stakeholder and

regulator outcomes

terminal

maintenance shaft,

TMS

A structure at the end of a reticulation sewer to allow insertion

into the sewer of equipment for inspection and maintenance. See

maintenance shaft

Tester

An individual, corporation or legal entity registered by the

National Association of Testing Authorities for the relevant

classes of tests and that is accountable at law for delivery of

testing services under a specific contract with the Constructor

tie

Distance specifying the location of a property connection sewer,

MH or MS, generally from a subdivision peg or physical structure

trench fill

Fill material placed over the overlay for the purpose of refilling a

trench

trenchstop

A non-structural partition across a pipeline trench built to restrict

movement of fines within and along the trench caused by

infiltration and ground water flow through the embedment and

trench fill materials

trunk sewer

Principal sewer of a catchment system that drains to the point of

treatment. See also reticulation sewer, branch sewer, main sewer

21

Term

WSA 022002-2.3

Definition

vent shaft

A structure provided to limit pressure fluctuations within the

sewerage system, for air to enter the system and for sewer gases

to escape from the system

verge

Areas between the boundaries of a road reserve and the

carriageway. This term is usually applied where there are no

formed footways

vertical riser

Vertical section of a property connection sewer used where the

customer sanitary drain is at a considerably higher level than the

sewer

Water Agency

An authority, board, business, corporation, council, local

government body with the responsibility for planning or defining

planning requirements, for defining and authorising design

requirements, for defining and authorising construction

requirements and for operating and maintaining or defining

operation and maintenance requirements for a water supply

and/or sewer system or systems

water seal

An arrangement that traps water and prevents passage of gas

and controls odours; may be installed in a double MH, in a sewer

adjacent to an MH, or in a customer sanitary drain; water seals in

MHs are also known as gas check chambers; water seals in

customer sanitary drains are also known as boundary traps

witness point

A point in the work process at which an activity may be observed

Work As

Constructed (WAC)

Documentation showing details of work as actually constructed

(in contrast to Design Drawings). Also called Work As Executed

Works

All those Works being sewers, maintenance structures, pumping

stations, pressure mains and accessories and shall include valve

chambers and storage facilities as shown on the Design Drawings

and includes any part or parts of the Works

y connection

A fitting (junction) used on a property connection sewer that

allows the sewer to serve two lots

zone of influence

An area likely to be influenced by building loads, the extent of

which depends on the nature of the ground on which the structure

is to be located

WSA 022002-2.3

22

II ABBREVIATIONS

ABBREVIATION

INTERPRETATION

percentage

ABS

acrylonitrile butadiene styrene

ADWF

average dry weather flow

AHD

Australian Height Datum

AMG

Australian Map Grid

ANSI

American National Standards Institute

ARI

average recurrence interval

AS

Australian Standard

AS/NZS

Australian/New Zealand Standard

ASTM

American Society for Testing Materials

AWWA

American Water Works Association

BSP

British standard pipe

dispersion factor

CB

certification body

CBD

central business district

CCF

Civil Contractors Federation

CCTV

closed-circuit colour television

CEN

European Committee for Standardisation

CLSM

controlled low strength material

day

di

internal diameter

DF

design flow

DI

ductile iron

DICL

ductile iron cement (mortar) lined

DN

nominal size

DP

design pressure

EF

electrofusion

EIA

environmental impact assessment

EP

equivalent population

ERS

emergency relief structure

ESL

existing surface level

FF

full face

FRP

fibre reinforced plastic

FSL

finished surface level

gravitational acceleration

23

ABBREVIATION

INTERPRETATION

GDA

Geocentric Datum of Australia

GIS

geographical information system

GRP

glass reinforced polyester

GWI

ground water infiltration

hour

head (in metres)

H2S

hydrogen sulphide

ha

hectare

HGL

hydraulic grade line

IBC

inside bolt circle

ID

Density Index

IIF

inflow and infiltration flow

IL

invert level

IO

inspection opening

IS

inspection shaft

ISG

International Survey Grid

ISO

International Standards Organisation

ITP

inspection and test plan

ks

equivalent sand roughness size

kL

kilolitre

km

kilometre

kN/m

kilonewton/metre

kPa

kilopascal

kV

kilovolt

litre

LP

pipe length

L/s

litre/second

metre

m/s

metres per second

mg/L

milligrams/litre

MH

maintenance hole

mL

millilitre

mm

millimetre

MPa

megapascal

MS

maintenance shaft

newton

NATA

National Association of Testing Authorities

WSA 022002-2.3

WSA 022002-2.3

24

ABBREVIATION

INTERPRETATION

degree

degree Celsius

OH&S

occupational health and safety

OP

operating pressure

PCS

property connection sewer

PDWF

peak dry weather flow

PE

polyethylene

PN

pressure class (number)

PIPA

Plastics Industry Pipe Association of Australia Limited

PP

polypropylene

PVC

polyvinylchloride

flow (in cubic metres/second)

RC

reinforced concrete

RD

dry density ratio

RL

reduced level

RRJ

rubber ring (seal) joint

RTU

remote terminal unit

RV

reflux valve

second

spacing

SCADA

supervisory control and data acquisition

SCJ

solvent cement joint

SCL

steel cement (mortar) lined

SDR

standard dimension ratio

SN

stiffness class (number)

SPS

sewage pumping station

SR

spigot and recess

STP

system test pressure

SWJ

solvent weld joint

TMS

terminal maintenance shaft

UV

ultraviolet

volt

VC

vitrified clay

WAC

Work As Constructed

WSAA

Water Services Association of Australia Inc.

WSA 022002-2.3

25

III REFERENCED DOCUMENTS

The following documents are referred to in this Code.

STANDARD TITLE

CLAUSE / TABLE / DRAWING

ASdownloadable from http://www.standards.com.au/catalogue/Script/search.asp

1100

Technical drawing

1100.401

Engineering survey and engineering survey

design drawing

1170

Minimum design loads on structures

1170.2

Wind loads

SEW1408

1199

Sampling procedures and tables for inspection

by attributes

G3.2

1289

Methods of

purposes

1289.5.1

Soil compaction and density tests

1289.5.1.1

Determination of the dry density/moisture

content relation of a soil using standard

compactive effort

1289.5.4

Compaction control test

1289.5.4.1

Dry density ratio,

moisture ratio

1289.5.6

Compaction control test

1289.5.6.1

Density index

material

1289.5.7

Soil compaction and density tests

1289.5.7.1

Compaction control testHilf density ratio and

Hilf moisture variation (rapid method)

22.3.4.3

1379

Specification and supply of concrete

G4.3

1579

Arc-welded steel pipes and fittings for water and

wastewater

4.8.1, 4.8.2

2124

General conditions of contract

11.1

2159

PilingDesign and installation

SEW1204

2187

Explosivesstorage, transport and use

15.5

2360

Measurement of fluid flow in closed conduits

C4

2490

Sampling procedures and charts for inspection

by variables for percent nonconforming

G3.2

2638

Gate valves for waterworks purposes

2638.2

Part 2: Metal seated valves

3500

National Plumbing and Drainage Code

Compendium

3500.1

Water supply

3500.2

Sanitary plumbing and drainage

testing

soils

for

moisture

method

for

engineering

variation

27.1

21.2, 22.3.1, Table 22.1, Table

22.2

and

22.3.1, Table 22.1, Table 22.2,

22.3.4.3

cohesionless

22.3.1, Table 22.1, Table 22.2,

22.3.4.3

10.4.1

WSA 022002-2.3

STANDARD

26

TITLE

CLAUSE / TABLE / DRAWING

3500.2.1

Sanitary plumbing and drainagePerformance

solutions

1.1

3518

Acrylonitrile butadiene styrene (ABS) pipes and

fittings for pressure applications

Table 10.1

3571

Glass filament reinforced thermosetting plastics

(GRP) pipesPolyester basedWater supply,

sewerage and drainage applications

H1, Table H1

3600

Concrete structures

14.5.4

3610

Formwork for concrete

14.5.3.1

3680

Polyethylene sleeving for ductile iron pipelines

17.10

3681

Guidelines for the application of polyethylene

sleeving to ductile iron pipelines and fittings

17.10

3725

Loads on buried concrete pipes

8.3, 8.9

3735

Suppl 1: Concrete

liquidsCommentary

3778

Measurement of water flow in open channels

3778.3

Measurement of water flow in open channels Velocity-area methods

3778.3.7

Measurement by ultrasonic (acoustic) method

(ISO 748:1979)

3894

Site testing of protective coatings

3894.1

Non-conductive coatingsContinuity testing

High voltage (brush) method

22.8.2

4041

Pressure piping

17.16.2

4058

Precast concrete pipes (pressure and nonpressure)

Table 10.2

4060

Loads on buried vitrified clay pipes

8.3

4087

Metallic flanges for waterworks purposes

4.8.4

4198

Precast

concrete

access

sewerage applications

4799

Installation of underground utility assets and

pipelines within railway boundaries

structures

for

retaining

chambers

for

4.7.3

C3.3

28.12

4.3.3, 8.1, Table 10.4, SEW

1401

AS/NZS downloadable from http://www.standards.com.au/catalogue

1260

PVC pipes and fittings for drain, waste and vent

applications

H1, Table H1, SEW1313

1477

PVC pipes and fittings for pressure applications

10.4.1

1554

Structural steel welding

1554.1

Welding of steel structures

4.8.3, 17.16.1

2280

Ductile iron pressure pipes and fittings

10.4.1

2566

Buried flexible pipelines

2566.1

Part 1: Structural design of buried flexible pipe

4.6.3, 8.3, 8.9, 28.1,

WSA 022002-2.3

27

STANDARD

TITLE

CLAUSE / TABLE / DRAWING

28.3.1, 28.3.2, 28.3.3

2566.1

Supp 1: Structural designCommentary

2566.2

Part 2: Installation

28.1

3500.1.2

Acceptable solutions

14.6

3500.2.2

Sanitary plumbing and drainageAcceptable

solutions

4.6.4.1, 4.6.4.4, 4.6.5.2,

4.6.5.3, 5.1.2, 5.1.3, 7.2.1,

27.3

3679

Structural steel

3679.1

Hot-rolled bars and sections

4327

Metal-banded flexible

pressure applications

4536

Life cycle costingAn application guide

10.6

4801

Occupational health and safety management

systems - Specification with guidance for use

12.1.1

4853

Electrical hazards on metallic pipelines

4.4.3, Table 10.4

couplings

SEW1405, SEW1406

for

low-

30.1, SEW1500

ASTMdownloadable from http://www.astm.org/cgi-bin

C1244M

Test Method for Concrete Sewer manholes by

the Negative Air Pressure (Vacuum) Test

22.4.4.2

PIPAdownloadable from http://www.pipa.com.au/Guidelines.html

POP006

Derating requirements for fittings

3.5.2.2

POP010A

Part 1 Polyethylene pressure pipes design for

dynamic stresses

3.5.1, 3.5.2.1, Table 3.2

POP010B

Part 2 Fusion fittings for use with polyethylene

pressure pipes design for dynamic stresses

3.5.2.2

BS ENdownloadable from http://bsonline.techindex.co.uk

295

Vitrified clay pipes and fittings and pipe joints

for drains and sewers

10.4.1

545

Ductile pipes, fittings, accessories and their

joints for water pipelinesRequirements and

test methods.

10.4.1

598

Ductile pipes, fittings, accessories and their

joints for sewerage applicationsRequirements

and test methods.

10.4.1

1295-1

Structural design for buried pipelines under

various conditions of loading Part 1 General

requirements

8.3, 28.1, 28.3.1

ISO downloadable from http://www.standards.com.au/catalogue/Script/search.asp

9000

Quality management and quality assurance

standards

H1, H2.1, H2.2, H2.2.3,

H2.4, H4.1.2, H4.1.3, H4.1.4,

H4.2

9001

Quality systemsModel for quality assurance in

design, development, production, installation

and servicing

12.1.1, H2.1

WSA 022002-2.3

STANDARD

28

TITLE

CLAUSE / TABLE / DRAWING

9002

Quality systemsModel for quality assurance in

production, installation and servicing

H2.1

14001

Environmental management systems

Specification with guidance for use

12.1.1

TS 15769

Hydrometric determinationsLiquid flow in

open channels and partly filled pipes

Guidelines for the application of Doppler-based

flow measurements

C3.2

WSA 01

Polyethylene Pipeline Code

17.1.3

WSA 04

Sewage Pumping Station Code

WSA 05

Sewer Inspection Reporting Code of Australia

22.7, 30.4

WSA 108

Fibre reinforced plastic ladders

10.4.1

H2S

Manual

Hydrogen Sulphide Control ManualSepticity,

Corrosion and Odour Control in Sewerage

Systems, Technological Standing Committee on

Hydrogen Sulphide Corrosion in Sewerage

Works, Volumes 1 and2, Melbourne and

Metropolitan Board of Works, December 1989

(now published by WSAA)

WSAA

29

WSA 022002-2.3

IV OTHER REFERENCES

The following documents are published on the WSAA website. While not necessarily specifically

referred to in this Code, they may be used to process documentation permitting the adoption of

this Code and/or preparation of Contract documentation. The list of documents is not complete

as other documents may be published from time to time.

WSAA PURCHASE SPECIFICATIONS

WSA PS

NON PRESSURE PIPE AND FITTINGS

230

PVC-U Non-Pressure Pipe and Fittings

231

Vitrified Clay (VC) Pipe and Fittings

232

Glass Reinforced Plastic (GRP) Non-Pressure Pipe

233

Reinforced Concrete (RC) Non-Pressure Pipe

234

Ductile Iron Pipe for Gravity Sewers

235

Metal-Banded Flexible Couplings

235A

Metal-Banded Flexible Couplings (alternative specification)

236

Post-Formed PVC Variable Bend Non Pressure Fittings

237

Glass Reinforced Plastic (GRP) Non-Pressure Fittings

238

Acrylonitrile Butadiene Styrene (ABS) Non-Pressure Pipe and Fittings

SURFACE FITTINGS

290

Access Covers Sewerage

295

Vent Shaft Educt

296

Vent Shaft Induct

ANCILLARY PRODUCTS

314

Step Irons, Plastic Encapsulated

315

Ladders, Fibre Reinforced Plastic

316

Ladders, Stainless Steel

317

Ladders, Hot Dipped Galvanised

318

Marking Tape, Non-Detectable

319

Marking Tape, Detectable

320

Polyethylene Sleeve for Ductile Iron Pipe and Fittings

321

Maintenance Shafts PVC

322

Maintenance Shafts PE

323

Maintenance Holes Precast Concrete

CONSTRUCTION MATERIALS

350

Compaction Sand (For Pipe Embedment)

351

Single Size Coarse Aggregate (For Pipe Embedment)

352

Controlled Low Strength Materials (CLSM)

353

Fine Crushed Rock for Road Base

WSA 022002-2.3

30

354

Coarse Crushed Rock for Road Base

355

Geotextile Filter Fabric

356

Piles

357

Pre-mixed Concrete, Normal Class

358

Pre-mixed Concrete, Special Class

You might also like

- NSPC 2015 Sin Marca de Agua PDFDocument568 pagesNSPC 2015 Sin Marca de Agua PDFCARLOS ARMANDO MELHADO GRANADOSNo ratings yet

- Code of Practice WastewaterDocument113 pagesCode of Practice WastewaterDuong DoanNo ratings yet

- Australian Standard: Design Charts For Water Supply and SewerageDocument8 pagesAustralian Standard: Design Charts For Water Supply and Sewerageqt1125No ratings yet

- WSA 02 Sydney Water Edition Version 4 - Code Content ExtractDocument24 pagesWSA 02 Sydney Water Edition Version 4 - Code Content ExtractDmitry Pigul0% (1)

- Australian Standard: Concrete Structures For Retaining Liquids-Commentary (Supplement To AS 3735-2001)Document66 pagesAustralian Standard: Concrete Structures For Retaining Liquids-Commentary (Supplement To AS 3735-2001)Andy100% (3)

- Drainage Design ManualDocument77 pagesDrainage Design ManualcolawariNo ratings yet

- Laminated Composite Stiffened Panels Application and BehaviourDocument46 pagesLaminated Composite Stiffened Panels Application and BehaviourHemendra Jain100% (1)

- 05-5 QCS 2014Document31 pages05-5 QCS 2014Raja Ahmed Hassan100% (11)

- Australian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsDocument8 pagesAustralian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsVăn AnhNo ratings yet

- Hydraulic Services DesignDocument10 pagesHydraulic Services DesignSeenivasan GovindarajNo ratings yet

- WSA 03 AnnexuresDocument8 pagesWSA 03 AnnexuresShahabShoaeeNo ratings yet

- WSA02 2002 Part1 2 3Document90 pagesWSA02 2002 Part1 2 3abhijithavalNo ratings yet

- Australian/New Zealand Standard: Buried Flexible Pipelines Part 1: Structural DesignDocument7 pagesAustralian/New Zealand Standard: Buried Flexible Pipelines Part 1: Structural Designmailmaverick8167No ratings yet

- As NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningDocument66 pagesAs NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningdavidNo ratings yet

- Design Loads for Box Culverts under AS 5100Document13 pagesDesign Loads for Box Culverts under AS 5100bambangtirtas_984017No ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- PW 344 2017 DPW Manual Volume 2-Annexures PDFDocument266 pagesPW 344 2017 DPW Manual Volume 2-Annexures PDFMichael BenhuraNo ratings yet

- 3725 2007 PDFDocument49 pages3725 2007 PDFdhavalNo ratings yet

- Supplementary Manual To The WSAA Sewerage Pumping Station Code (WSA 04-2005:2.1)Document57 pagesSupplementary Manual To The WSAA Sewerage Pumping Station Code (WSA 04-2005:2.1)jituplanojrNo ratings yet

- 15.12 - Water Supply Design V2Document33 pages15.12 - Water Supply Design V2saifulNo ratings yet

- Chapter13 Structures2020Document199 pagesChapter13 Structures2020Frank XiuNo ratings yet

- MRWA Sewer Acceptance Testing Specification 13-01.1 PDFDocument38 pagesMRWA Sewer Acceptance Testing Specification 13-01.1 PDFbuddy1971No ratings yet

- Chapter1 General2020Document90 pagesChapter1 General2020TSHEPO DIKOTLA100% (1)

- Technical Communique Standards Covering Civil Engineering Test Methods (Sans 3001 Series)Document2 pagesTechnical Communique Standards Covering Civil Engineering Test Methods (Sans 3001 Series)AshebirNo ratings yet

- Pavement DesignDocument56 pagesPavement DesignKitibwa Gitta100% (3)

- Water Supply Design ChartsDocument6 pagesWater Supply Design ChartsIftikhar Kamran0% (1)

- D10 Handbook of Stormwater Drainage DesignDocument59 pagesD10 Handbook of Stormwater Drainage DesignAnonymous WqYvpVd100% (3)

- WSA02 - Hunter Water Version 2 - Code Contents ExtractDocument26 pagesWSA02 - Hunter Water Version 2 - Code Contents Extractxvpcfx0% (1)

- STD-SPE-G-012 WSA 03 Water Supply Code SupplementDocument36 pagesSTD-SPE-G-012 WSA 03 Water Supply Code Supplementhung0% (1)

- Chapter14 Repair2020Document108 pagesChapter14 Repair2020Frank XiuNo ratings yet

- OMEGA AIR Alternative Filter Elements English PDFDocument56 pagesOMEGA AIR Alternative Filter Elements English PDFbinhleduc36100% (1)

- Soil and gravel testing methodsDocument1 pageSoil and gravel testing methodsLindieMarriott100% (1)

- Design Guidelines For Drinking Water SystemsDocument311 pagesDesign Guidelines For Drinking Water SystemsJason LeBlancNo ratings yet

- Wetex Middle East Exhibitors 2016Document7 pagesWetex Middle East Exhibitors 2016Dinkar JoshiNo ratings yet

- Water Supply Code of AustraliaDocument69 pagesWater Supply Code of Australiahuman2955No ratings yet

- Sewerage Code of Australia: Second EditionDocument26 pagesSewerage Code of Australia: Second Editionabhijithaval100% (1)

- WASA CodeDocument34 pagesWASA CodeJaz SinghNo ratings yet

- Design and Construction Standards ManualDocument46 pagesDesign and Construction Standards ManualLouise BlackNo ratings yet

- WSA02 2002 Part3 2 3Document62 pagesWSA02 2002 Part3 2 3abhijithavalNo ratings yet

- SAPEM Chapter 14 2nd Edition 2014Document40 pagesSAPEM Chapter 14 2nd Edition 2014Edgar Mugarura100% (1)

- Coto Chapter 20-Quality Assurance - DS Version Oct 2020Document56 pagesCoto Chapter 20-Quality Assurance - DS Version Oct 2020Spam Me here100% (1)

- MPMSAA Rainwater Tank Design and Installation Handbook 2008Document111 pagesMPMSAA Rainwater Tank Design and Installation Handbook 2008izamaiyusNo ratings yet

- TMH 6 IntroductionDocument9 pagesTMH 6 IntroductionATHOLSCHWARZ100% (1)

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDocument8 pagesC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNo ratings yet

- Subsurface Drainage TRH 15 Analyzes South African ProjectDocument158 pagesSubsurface Drainage TRH 15 Analyzes South African ProjectjihadNo ratings yet

- TRH26Document89 pagesTRH26nephembaniNo ratings yet

- Section 2 - Determination of Storm RunoffDocument37 pagesSection 2 - Determination of Storm RunoffSudharsananPRSNo ratings yet

- City of Durban Standard Engineering Specification Part C - Concrete WorkDocument33 pagesCity of Durban Standard Engineering Specification Part C - Concrete WorkLuke Jabulani ReidNo ratings yet

- TRH 14 ManualDocument22 pagesTRH 14 ManualNelson KachaliNo ratings yet

- Sans 2001-DP4 - 2010Document37 pagesSans 2001-DP4 - 2010Brendon GovaNo ratings yet

- SAPEM Chapter 1 2nd Edition 2014Document52 pagesSAPEM Chapter 1 2nd Edition 2014kjhkjh100% (1)

- Botswana Road Design Manual. - Hydrology and DrainageDocument88 pagesBotswana Road Design Manual. - Hydrology and DrainageBalarka100% (1)

- Sewerage Code of Australia GuideDocument2 pagesSewerage Code of Australia GuideabhijithavalNo ratings yet

- TRH 22 Pavement Management SystemsDocument157 pagesTRH 22 Pavement Management Systemsannaselemela100% (1)

- JRA Stormwater Design ManualDocument47 pagesJRA Stormwater Design ManualMrr KuxNo ratings yet

- Policy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009Document13 pagesPolicy Design Guideline Standards For Single Carriageway National Roads - Draft May 2009sage.electconNo ratings yet

- SATCC Chapter 8Document20 pagesSATCC Chapter 8Rui Lourenco50% (2)

- Regional Standard For Water ServicesDocument130 pagesRegional Standard For Water ServicesJames Everett AbdulNo ratings yet

- BS 6717 - 2001Document34 pagesBS 6717 - 2001Ahmad Khreisat100% (1)

- Best Practice Guidlines - A4 - Pollution Control DamsDocument34 pagesBest Practice Guidlines - A4 - Pollution Control DamsnathychidazNo ratings yet

- Rational Method Hydrologic Calculations With Excel-R1Document25 pagesRational Method Hydrologic Calculations With Excel-R1Rajkumar SagarNo ratings yet

- TN27 Australian Standard For Precast BC and HeadwallDocument8 pagesTN27 Australian Standard For Precast BC and HeadwallgemotorresNo ratings yet

- 3rd Edition New Zealand Pipe Inspection ManualDocument156 pages3rd Edition New Zealand Pipe Inspection ManualYadi KusmayadiNo ratings yet

- Wmts-006:2014 Reflux Valves - Sewerage: Watermark Technical SpecificationDocument13 pagesWmts-006:2014 Reflux Valves - Sewerage: Watermark Technical Specificationpaul greigNo ratings yet

- WMTS 014 2016 Jointing MaterialsDocument14 pagesWMTS 014 2016 Jointing Materialspaul greigNo ratings yet

- 4 WastewaterDocument74 pages4 WastewaterKyle TsengNo ratings yet

- WMTS-012:2018 In-Line Valves: For Use in Plumbing Water Supply Systems-Miscellaneous Types Metallic and Non-MetallicDocument18 pagesWMTS-012:2018 In-Line Valves: For Use in Plumbing Water Supply Systems-Miscellaneous Types Metallic and Non-Metallicpaul greigNo ratings yet

- Sewerage Code of Australia GuideDocument2 pagesSewerage Code of Australia GuideabhijithavalNo ratings yet

- SPS-1603 1 1Document1 pageSPS-1603 1 1abhijithavalNo ratings yet

- SPS-1500 1 1Document1 pageSPS-1500 1 1abhijithavalNo ratings yet

- WSA02 2002 Part4 2 3Document29 pagesWSA02 2002 Part4 2 3abhijithavalNo ratings yet

- Sydney Water scour pipe fittings standardDocument1 pageSydney Water scour pipe fittings standardabhijithavalNo ratings yet

- Stormwater Guidelines 2012 FinalDocument137 pagesStormwater Guidelines 2012 FinalJuanjo GonzalezNo ratings yet

- Quantity (Litres/Second) : Pressure Main ConfigurationDocument1 pageQuantity (Litres/Second) : Pressure Main ConfigurationabhijithavalNo ratings yet

- SPS-1603 1 1Document1 pageSPS-1603 1 1abhijithavalNo ratings yet

- Magus Rigid PavementDocument13 pagesMagus Rigid PavementabhijithavalNo ratings yet

- SPS-1604 1 1Document1 pageSPS-1604 1 1Abhijit HavalNo ratings yet

- Product Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationDocument1 pageProduct Details For Pressure Mains: For Dicl, PVC, GRP & Pe Pipes Pipe InstallationabhijithavalNo ratings yet

- SPS-1605 1 1Document1 pageSPS-1605 1 1Abhijit HavalNo ratings yet

- Typical Cover Arrangement: Valve Chamber LegendDocument1 pageTypical Cover Arrangement: Valve Chamber LegendabhijithavalNo ratings yet

- Concrete Cover Detail: NotesDocument1 pageConcrete Cover Detail: NotesabhijithavalNo ratings yet

- Plan of Top Slab ElevationDocument1 pagePlan of Top Slab ElevationabhijithavalNo ratings yet

- Mechanical wall pipe penetration sealDocument1 pageMechanical wall pipe penetration sealabhijithavalNo ratings yet

- SPS-1301 1 1Document1 pageSPS-1301 1 1abhijithavalNo ratings yet

- SPS-1300 1 1Document1 pageSPS-1300 1 1abhijithavalNo ratings yet

- SPS-1300 1 1Document1 pageSPS-1300 1 1abhijithavalNo ratings yet

- SPS-1304 1 1Document1 pageSPS-1304 1 1abhijithavalNo ratings yet

- Minor Cut Fill Fill: SO IL ILDocument1 pageMinor Cut Fill Fill: SO IL ILabhijithavalNo ratings yet

- SPS-1305 1 1Document1 pageSPS-1305 1 1abhijithavalNo ratings yet

- SPS-1305 1 1Document1 pageSPS-1305 1 1abhijithavalNo ratings yet

- SPS-1303 1 1Document1 pageSPS-1303 1 1abhijithavalNo ratings yet

- Minor Cut Fill Fill: SO IL ILDocument1 pageMinor Cut Fill Fill: SO IL ILabhijithavalNo ratings yet

- SPS-1301 1 1Document1 pageSPS-1301 1 1abhijithavalNo ratings yet