Professional Documents

Culture Documents

Culvert Repair Low Res 0115

Uploaded by

zulkifliharahapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Culvert Repair Low Res 0115

Uploaded by

zulkifliharahapCopyright:

Available Formats

Choosing the right

Culvert Repair System

Rating 8: Very Good

Choosing the Right Culvert

Repair Solution

Choosing the right approach to solve your specific repair situation

is not always a simple task. The appropriate solution depends on

the type of culvert deterioration, the root cause of the problem, and

the extent to which the structure of the failing culvert allows you to

rehabilitate rather than replace. The full solution to rehabilitating

a deteriorated culvert may also depend on correcting failed

conditions on the outside of the culvert at the inlet and outlet.

Rating 6: Satisfactory

In the mid-1980s, the Federal Highway Administration (FHWA)

developed a 10 point scale (9 to 0) that is useful as a guideline for

assessing the condition of the culvert. In this scale, 9 represents

a culvert in new condition, and 0 represents one that has totally

failed.

Milliken Infrastructure offers a number of solutions to repair or

rehabilitate a variety of problems seen in corrugated metal (CMP)

and concrete pipe culverts. Our solutions may be used individually

to solve a specific issue, or together to fully rehabilitate a culvert

with a range of problems. Some examples are:

PROBLEM

CULVERT TYPE

Scour/Pitting of Invert CMP

Rating 5: Fair

SOLUTION

Milliken Concrete Cloth

Concrete Milliken GeoSpray

Shape deformations CMP

Milliken GeoSpray

Joint failures or CMP Milliken GeoPlug

Rating 4: Poor

misalignments

Concrete Milliken GeoSpray

Cracks

Concrete Milliken GeoFuse

Milliken GeoSpray

Inlet/Outlet Erosion All

Milliken Concrete Cloth

Deterioration

(rebar corrosion)

Concrete Milliken GeoSpray

Generally speaking, Concrete Cloth functions as a new wear

surface for culvert inverts and as an erosion control measure for

culvert surrounds, and is not a structural repair. Milliken products

(GeoSpray, GeoPlug and GeoFuse) can provide structural

repair options for more severe culvert failure conditions.

This guide is intended to help guide maintenance professionals with

the selection of appropriate Milliken Infrastructure culvert repair

solutions.

Rating 3: Very Poor

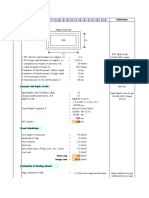

CMP Culvert Rating and Decision Guide

CONDITION

RATING

CONDITION DESCRIPTION

New Condition

Shape: good, smooth curvature in barrel

Horizontal: within 10 percent of design

Seams and Joints: tight, no openings

Aluminum: superficial corrosion, slight pitting

Steel: superficial rust, no pitting

MILLIKEN INFRASTRUCTURE SOLUTION

Concrete Cloth

GeoPolymers

Shape: generally good, top half of pipe smooth but minor flattening of bottom

Horizontal Diameter: within 10 percent of design

Seams or Joints: minor cracking at a few bolt holes, minor joint or seam

openings, potential for backfill infiltration

Aluminum: moderate corrosion, no attack of core alloy

Steel: moderate rust, slight pitting

Shape: fair, top half has smooth curvature but bottom half has flattened significantly

Horizontal Diameter: within 10 percent of design

Seams or Joints: minor cracking at bolts is prevalent in one seam in lower half of

pipe. Evidence of backfill infiltration through seams or joints

Aluminum: significant corrosion, minor attack of core alloy

Steel: fairly heavy rust, moderate pitting

Shape: generally fair, significant distortion at isolated locations in top half and

extreme flattening of invert

Horizontal Diameter: 10 percent to 15 percent greater than design

Seams or Joints: moderate cracking at bolt holes along one seam near bottom of

pipe, deflection of pipe caused by backfill infiltration through seams or joints

Aluminum: significant corrosion, moderate attack of core alloy

Steel: scattered heavy rust, deep pitting

Shape: marginal significant distortion throughout length of pipe, lower third may be kinked

Horizontal Diameter: 10 percent to 15 percent greater than design

Seams or Joints: Moderate cracking at bolt holes on one seam near top of pipe, deflection

caused by loss of backfill through open joints

Aluminum: extensive corrosion, significant attack of core alloy

Steel: extensive heavy rust, deep pitting

Shape: poor with extreme deflection at isolated locations, flattening of crown, crown

radius 20 to 30 feet

Horizontal Diameter: in excess of 15 percent greater than design

Seams or Joints: 3 in. long cracks at bolt holes on one seam

Aluminum: extensive corrosion, attack of core alloy, scattered perforations

Steel: extensive heavy rust, deep pitting, scattered perforations, invert X % section loss

Shape: critical, extreme distortion and deflection throughout pipe, flattening of

crown, crown radius over 30 feet

Horizontal Diameter: more than 20 percent greater than design

Seams: plate cracked from bolt to bolt on one seam

Aluminum: extensive perforations due to corrosion

Steel: extensive perforations due to rust

Shape: partially collapsed with crown in reverse curve

Seams: failed

Road: closed to traffic

Pipe: totally failed

Road: closed to traffic

Recommended

Concrete Culvert Rating and Decision Guide

CONDITION

RATING

CONDITION DESCRIPTION

New Condition

Alignment: good, no settlement or misalignment

Joints: tight with no defects apparent

Concrete: no cracking, spalling, or scaling present; surface in good condition

MILLIKEN INFRASTRUCTURE SOLUTION

GeoPolymers

RenewWrap

Alignment: generally good; minor misalignment at joints; no settlement

Joints: minor openings, possible infiltration/exfiltration

Concrete: minor hairline cracking at isolated locations; slight spalling or scaling

present on invert

Alignment: fair, minor misalignment and settlement at isolated locations

Joints: minor backfill infiltration due to slight opening at joints; minor cracking or

spalling at joints allowing exfiltration

Concrete: extensive hairline cracks, some with minor delaminations or spalling; invert

scaling less than 0.25 in. deep or small spalls present

Alignment: generally fair; minor misalignment or settlement throughout pipe; possible

piping

Joints: open and allowing backfill to infiltrate; significant cracking or joint spalling

Concrete: cracking open greater than 0.12 in. with moderate delamination and moderate

spalling exposing reinforcing steel at isolated locations; large areas of invert with surface

scaling or spalls greater than 0.25 in. deep

Alignment: marginal; significant settlement and misalignment of pipe; evidence of piping;

end sections dislocated, about to drop off

Joints: differential movement and separation of joints; significant infiltration or exfiltration

at joints

Concrete: cracks open more than 0.12 in. with efflorescence and spalling at numerous

locations; spalls have exposed rebars which are heavily corroded; extensive surface scaling

on invert greater than 0.5 in

Alignment: poor with significant ponding of water due to sagging or misalignment pipes;

end section drop off has occurred

Joints: significant openings, dislocated joints in several locations exposing fill materials;

infiltration or exfiltration causing misalignment of pipe and settlement or depressions in

roadway

Concrete: extensive cracking, spalling, and minor slabbing; invert scaling has exposed

reinforcing steel

Alignment: critical; culvert not functioning due to alignment problems throughout

Concrete: severe slabbing has occurred in culvert wall, invert concrete completely

deteriorated in isolated locations

Culvert: partially collapsed

Road: closed to traffic

Culvert: total failure of culvert and fill

Road: closed to traffic

Recommended

infrastructure.milliken.com 855-655-6750

Milliken Infrastructure Solutions, LLC is a subsidiary of Milliken & Company.

The Milliken logo is used under license by Milliken Infrastructure Solutions, LLC, all rights reserved.

Concrete Cloth is a trademark of Concrete Canvas, Ltd.

GeoSpray, GeoPlug, and GeoFuse are trademarks of Milliken Infrastructure Solutions, LLC.

MIS1002 0115

You might also like

- Pipe Rack CalculationDocument51 pagesPipe Rack Calculationbalumagesh1979100% (2)

- Hydro Permit ProposalDocument2 pagesHydro Permit ProposalzulkifliharahapNo ratings yet

- LIST OF DPT PLN 2019 Rev1Document2 pagesLIST OF DPT PLN 2019 Rev1zulkifliharahap100% (1)

- Rev - Initial Design T 33mmDocument6 pagesRev - Initial Design T 33mmzulkifliharahapNo ratings yet

- Presented By: Sonam Choden, A.E S.E.D, M.H.P.ADocument22 pagesPresented By: Sonam Choden, A.E S.E.D, M.H.P.AzulkifliharahapNo ratings yet

- 227 PortraitDocument2 pages227 Portraitc1190222No ratings yet

- Tor Indonesia PDFDocument44 pagesTor Indonesia PDFzulkifliharahapNo ratings yet

- Rec - Design 53 MMDocument6 pagesRec - Design 53 MMzulkifliharahapNo ratings yet

- Preparing For A Job InterviewDocument24 pagesPreparing For A Job InterviewComen MateNo ratings yet

- Daftar Besi BajaDocument38 pagesDaftar Besi BajaArdi Putra HarsonoNo ratings yet

- Pressure Relief ValveDocument4 pagesPressure Relief ValvezulkifliharahapNo ratings yet

- HydroHelp 1.6 ProtectedDocument72 pagesHydroHelp 1.6 ProtectedzulkifliharahapNo ratings yet

- Arc Hydro Tools 2.0 - OverviewDocument18 pagesArc Hydro Tools 2.0 - OverviewPiara Guadalupe Arroyo CastilloNo ratings yet

- Soil Investigation Work Quotation in NatalDocument1 pageSoil Investigation Work Quotation in NatalzulkifliharahapNo ratings yet

- Packwood Lake Hydro DiagramDocument1 pagePackwood Lake Hydro DiagramzulkifliharahapNo ratings yet

- Lampiran 01. Koordinat Hasil Pengamatan GPS & Base LineDocument2 pagesLampiran 01. Koordinat Hasil Pengamatan GPS & Base LinezulkifliharahapNo ratings yet

- Determination of The Friction Factor in Small PipesDocument6 pagesDetermination of The Friction Factor in Small PipesLTE002No ratings yet

- Tabel Distribusi Chi SquaredDocument1 pageTabel Distribusi Chi SquaredAlfredAbidondifuNo ratings yet

- 2015 04 20 16 14 00sbda2014 3Document100 pages2015 04 20 16 14 00sbda2014 3zulkifliharahapNo ratings yet

- Dokter Mata Di Lam Wah EeDocument1 pageDokter Mata Di Lam Wah EezulkifliharahapNo ratings yet

- Cromc 6205 enDocument5 pagesCromc 6205 enMijin28No ratings yet

- Unsur Ekonomi Rekayasa 0311Document14 pagesUnsur Ekonomi Rekayasa 0311Prety HundsomeNo ratings yet

- Abstract of CostDocument4 pagesAbstract of CostzulkifliharahapNo ratings yet

- WIN10 Commands PDFDocument3 pagesWIN10 Commands PDFemil2809No ratings yet

- Eticket Itinerary / Receipt: Booking DetailsDocument3 pagesEticket Itinerary / Receipt: Booking DetailszulkifliharahapNo ratings yet

- Example NPV, NBC, Irr 02062010Document3 pagesExample NPV, NBC, Irr 02062010zulkifliharahapNo ratings yet

- Diversion & Spillway Tunnel Bab Ii. Data Teknis: Tunneling CirataDocument2 pagesDiversion & Spillway Tunnel Bab Ii. Data Teknis: Tunneling CiratazulkifliharahapNo ratings yet

- Pressure Relief Valve & Air Valve Rev.0 (20.12.2015)Document2 pagesPressure Relief Valve & Air Valve Rev.0 (20.12.2015)zulkifliharahapNo ratings yet

- WIN10 Commands PDFDocument3 pagesWIN10 Commands PDFemil2809No ratings yet

- Review Penawaran Log Slide & Blank PlateDocument1 pageReview Penawaran Log Slide & Blank PlatezulkifliharahapNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Case StudyDocument11 pagesCase StudyJesusa Nambio Sapungan100% (1)

- Is 1200 13 1994 PDFDocument10 pagesIs 1200 13 1994 PDFSudarshan GadalkarNo ratings yet

- Bearing Failures and Root CausesDocument19 pagesBearing Failures and Root CausesMiroslav ZecNo ratings yet

- 0.1 Introduction PDFDocument14 pages0.1 Introduction PDFB VarunNo ratings yet

- Plumbing Materials and FittingsDocument14 pagesPlumbing Materials and FittingsMarc PajaritoNo ratings yet

- Spraying Tank-Hot Oil Heating (Massenza)Document2 pagesSpraying Tank-Hot Oil Heating (Massenza)jude tallyNo ratings yet

- 507 39 Solutions Instructor Manual Chapter 4Document2 pages507 39 Solutions Instructor Manual Chapter 4Arun GoyalNo ratings yet

- NSCP Chap4Document8 pagesNSCP Chap4BUILDING PERMITNo ratings yet

- Principles of Reinforced Concrete Design: Arlegui, Quiapo, ManilaDocument10 pagesPrinciples of Reinforced Concrete Design: Arlegui, Quiapo, ManilaMary Scarlette CenaNo ratings yet

- Aims03 08 007Document7 pagesAims03 08 007Jorge OrtegaNo ratings yet

- Matindok Activity Project TrackingDocument102 pagesMatindok Activity Project Trackingnailulfalah17No ratings yet

- Basic Concept Limit State Design Partial Factor of Safety Types of LoadingsDocument9 pagesBasic Concept Limit State Design Partial Factor of Safety Types of LoadingsRCdesign2012No ratings yet

- Composite Propane Cylinder Fire Safety RiskDocument19 pagesComposite Propane Cylinder Fire Safety RiskOoNo ratings yet

- Formworks Group 1 - 2Document100 pagesFormworks Group 1 - 2Patrick TulayNo ratings yet

- Services Hot Water Provisions For Commercial BuildingsDocument52 pagesServices Hot Water Provisions For Commercial Buildingsrobiged100% (1)

- Intro & Theory VentilationDocument7 pagesIntro & Theory VentilationSyahir HadziqNo ratings yet

- PPT-FINAL - Light HouseDocument46 pagesPPT-FINAL - Light Housesunitasanga0% (1)

- Type-1 - Structural Plan - 2013-02-16 PDFDocument3 pagesType-1 - Structural Plan - 2013-02-16 PDFjremptymak0% (1)

- Marine doors and windows manufacturer guideDocument40 pagesMarine doors and windows manufacturer guideBegad MohamedNo ratings yet

- Swissma: PAM Northern Chapter Half Day Seminar 20 May 2017Document117 pagesSwissma: PAM Northern Chapter Half Day Seminar 20 May 2017Shrimp HeadNo ratings yet

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Mideco Burnley - Baffles MinDocument4 pagesMideco Burnley - Baffles MinLuiz CostaNo ratings yet

- Investigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA MethodDocument15 pagesInvestigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA Methodسجى EngNo ratings yet

- The Effects of Coarse Sand On Sandcrete BlocksDocument14 pagesThe Effects of Coarse Sand On Sandcrete BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- KD Nicholson Bench Lost Art PressDocument3 pagesKD Nicholson Bench Lost Art PressIulian MihaiNo ratings yet

- Hague Fasteners - Special Fasteners & Non Standard Bolts and NutsDocument8 pagesHague Fasteners - Special Fasteners & Non Standard Bolts and Nutsn1ghtfallNo ratings yet

- Glued Laminated TimberDocument25 pagesGlued Laminated Timberpametnica21No ratings yet

- Amazing Feats of Civil Engineering (Great Achievements in Engineering)Document114 pagesAmazing Feats of Civil Engineering (Great Achievements in Engineering)Fouad Kehila100% (3)

- Prakash Acrylics Pvt. LTD.: ISO 9001: 2015 CompanyDocument21 pagesPrakash Acrylics Pvt. LTD.: ISO 9001: 2015 CompanyPradeep KumarNo ratings yet