Professional Documents

Culture Documents

Camber Guideline

Uploaded by

Shamsul IslamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Camber Guideline

Uploaded by

Shamsul IslamCopyright:

Available Formats

5

SOLVING THE CAMBER PROBLEM

E

ven the simplest of buildings will consist of a

number of small components

working together to form a

suitably strong and stiff frame

on which to place cladding

material to protect occupants

from the elements of weather,

and for appearance.

In a typical brick veneer

house these smaller components

include roof battens, roof

trusses, wall frames and

possibly floor joists and bearers.

Cladding material is typically

brick, tiles, plaster, windows

and doors.

The performance of these

cladding materials is very much

dependant on the strength and

stiffness of frame elements such

as trusses. Failure in the frame

element may lead to failure in

the cladding material resulting

in an unsightly or unserviceable

building.

To fail, a member does not

necessarily have to break or fall

down. Serviceability failures

due to excessive movement in

the frame, or frame element,

may not be as spectacular as

strength failures, but can still be

very costly to repair as they are

generally not noticed until the

building has been finished and

requires not only repair to the

frame or trusses, but also to the

cladding, cornice, flashings and

paintwork.

Most serviceability problems

with roof trusses can be avoided

by designing and manufacturing

trusses with suitable camber.

TRUSSES WITH LARGE

CAMBERS

Large cambers in standard

trusses may result in significant

height differences between

truss and internal walls creating

problems for plasterers when

fixing plasterboard sheets and

cornice. Note that the slotted

holes on the Gang-Nail Internal

Wall Bracket are 30mm long to

allow for up to 25mm

movement after installation.

They are not suitable for use on

trusses with cambers greater

than 25mm.

Large relative cambers

between adjacent trusses in a

roof structure may also create

problems for both tilers and

plasterers. For example, where

camber in the Truncated Girder

of a hip end is significantly

larger than camber in an

adjacent Truncated Standard,

the extension to the Jack truss

top chord will be higher than

the Truncated Standard truss as

shown in Figure 2. This may

tempt the builder to either pack

between the extended Jack top

chord and Truncated Standard,

or birdsmouth the Jack top

chord at the Truncated Girder.

Either option may result in an

unsatisfactory roof after loading

Conversely, Cut-Off trusses span

less and will generally have less

camber than the adjacent

standard truss.

Some Cantilever trusses may

require negative camber, i.e.

some panels of the truss may

deflect upwards on loading,

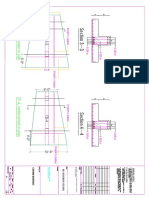

FIGURE 2 Section Through Hip End

Truncated Girder

With Large Camber

Extended Jack Top Chord

Above TS Truss

Truncated

Standard

Trusses

Standard

Trusses

Difference In Height

Of Bottom Chords

by Roger Hutton

Victorian Manager

Gang-Nail Australia Limited

Therefore the design should

be modified so that the

calculated camber is 20mm

or less.

b) RELATIVE TRUSSES

Difference in

Camber = Truss Spacing

100

with tiles or sheet. In addition

the height difference between

bottom chords on the Truncated

Girder and Truncated Standard

may create difficulties for the

plasterer.

Similar problems would be

encountered with large camber

in a Standard Girder truss

relative to the adjacent Standard

as shown in Figure 3. Large

cambers in this case would

make it difficult for the plasterer

to achieve a level ceiling under

long term loading.

while other panels will deflect

down. Trusses with internal

supports will have zero camber

at the support with positive

camber at other panel points in

the bottom chord. In both cases

the camber should be compared

with adjacent trusses to

determine camber difference

before quoting or manufacturing

trusses.

LIMITS ON CAMBER

Most of the above problems

can be avoided by limiting truss

camber as follows:

FIGURE 3 Section through girder carrying standard trusses.

Height Difference In Top Chords

Standard Truss Camber

Height Difference In Bottom Chords

SPECIAL CASES

Relative camber between

Standard trusses and Scissor,

Cut-Off, Cantilever or

internally supported trusses

may also provide problems for

following trades.

In general, Scissor trusses are

shallower than adjacent

Standard trusses and will

require more camber.

a) STANDARD TRUSSES

Maximum

Camber = Truss Span

300

(Up to a max 20mm.)

e.g. for a 12000mm span

truss the maximum camber

should be the smaller of:

12000 = 40 or 20mm.

300

e.g. for trusses at 900 crs.

The recommended

maximum difference in

camber between Girder and

Standard Truss is

900 = 9mm

100

OPTIONS FOR

DETAILERS

Where truss cambers are

excessive there are a number of

options available including:

1) Increasing the grade of

timber in the top and/or bottom

chords.

2) Increasing the timber depth

in the top and/or bottom chords.

3) Using thicker timber, e.g.

change timber width from 35 to

45mm.

4) Using double or triple

trusses.

5) Using internal supports if

available.

6) Revise truss layout if

possible.

When using the above

options it is always necessary to

redesign trusses to calculate the

truss camber using the modified

sizes. In some cases it may be

necessary to use more than one

of the above options to reduce

cambers to an acceptable limit.

Applying too much camber to

a truss during manufacture may

also create problems as the

camber may not be lost when

trusses are loaded.

Be sure to check the amount

of relative camber specified at

each change in truss type to

avoid customer dissatisfaction.

You might also like

- Reinforced Concrete Design: By: Dr. Haleem K. HussainDocument65 pagesReinforced Concrete Design: By: Dr. Haleem K. HussainNHEM KEAMNo ratings yet

- Link BeamDocument8 pagesLink BeamNeil SonNo ratings yet

- The Design of Structural Transfer WallDocument7 pagesThe Design of Structural Transfer WallDedy KristiantoNo ratings yet

- British Problem 5 PDFDocument5 pagesBritish Problem 5 PDFelixnzNo ratings yet

- Chapter 5-End ZonesDocument5 pagesChapter 5-End ZonesMohamed SalahNo ratings yet

- Seismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingDocument8 pagesSeismic Analysisof Fixed Baseand Base Isolated Buildingusing Lead Rubber BearingSherif FodaNo ratings yet

- Two Dimensional Analysis of Frame StructuresDocument54 pagesTwo Dimensional Analysis of Frame StructuresFrank PuchiNo ratings yet

- Bond Stress and Slip Modeling PDFDocument269 pagesBond Stress and Slip Modeling PDFraduga_fbNo ratings yet

- Force Method 2Document46 pagesForce Method 2shawn100% (1)

- Design of Composite Member Part 3 PDFDocument30 pagesDesign of Composite Member Part 3 PDFBaskara HutahaeanNo ratings yet

- PRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemDocument13 pagesPRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemPrabhat KumarNo ratings yet

- Single Degree of Freedom System (Sdof)Document32 pagesSingle Degree of Freedom System (Sdof)Abu Abdul Fattah100% (1)

- Design and Analysis of Pre-Engineered Buildings Using STAAD ProDocument6 pagesDesign and Analysis of Pre-Engineered Buildings Using STAAD ProHowo4DieNo ratings yet

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Document15 pagesAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Strengthening of Steep Slope by Nails, Anchors and Piles Using Geo-Studio SoftwareDocument16 pagesStrengthening of Steep Slope by Nails, Anchors and Piles Using Geo-Studio SoftwareNTK RavalNo ratings yet

- RC Practice Set 2 2016 SolutionsDocument5 pagesRC Practice Set 2 2016 SolutionsSayed YusufNo ratings yet

- Lateral-Torsional Buckling of Cold-Formed Zed-Purlins Partial-Laterally Restrained by Metal SheetingDocument11 pagesLateral-Torsional Buckling of Cold-Formed Zed-Purlins Partial-Laterally Restrained by Metal SheetingReaditReaditNo ratings yet

- Welcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeDocument29 pagesWelcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeAmit GuptaNo ratings yet

- Modeling of Asymmetric Shear Wall-Frame Building Structures PDFDocument8 pagesModeling of Asymmetric Shear Wall-Frame Building Structures PDFdenniscremaNo ratings yet

- Open Sees Command Language Manual June 2006Document465 pagesOpen Sees Command Language Manual June 2006dust84No ratings yet

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDocument9 pagesAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSNo ratings yet

- Comparative Analysis of Lateral Loads Resisting System For RCC StructureDocument9 pagesComparative Analysis of Lateral Loads Resisting System For RCC StructureIJRASETPublicationsNo ratings yet

- Steel Design - LRFD AISC Steel Manual 13th Edition Bolted ConnectionsDocument4 pagesSteel Design - LRFD AISC Steel Manual 13th Edition Bolted ConnectionsRangga SatriaNo ratings yet

- Simple Bridges NicholsonDocument94 pagesSimple Bridges Nicholsonfarhaad shaikNo ratings yet

- Slope Deflection Method ExplainedDocument33 pagesSlope Deflection Method ExplainedBari FayzulNo ratings yet

- Comparison Between R.C.C and Steel Structures by Seismic AnalysisDocument10 pagesComparison Between R.C.C and Steel Structures by Seismic AnalysisVikramNo ratings yet

- Design of RCC ColumnsDocument8 pagesDesign of RCC Columnshitendra_gkNo ratings yet

- A Fresh Look at Bolted End Plate Behaviour and DesignDocument11 pagesA Fresh Look at Bolted End Plate Behaviour and DesignSulaim Al KautsarNo ratings yet

- Advanced Steel Composite BeamsDocument68 pagesAdvanced Steel Composite BeamsMert SarıNo ratings yet

- Design of Doubly Reinforced BeamDocument7 pagesDesign of Doubly Reinforced BeamAmrutha SivaramanNo ratings yet

- Sambungan Apx-Wf150Document5 pagesSambungan Apx-Wf150Puji KurniawanNo ratings yet

- Lpile Group ModuleDocument2 pagesLpile Group ModuleMUHAMMAD ALINo ratings yet

- Philosophies of Design by Limit State MethodDocument16 pagesPhilosophies of Design by Limit State Methodganesh_2514No ratings yet

- Design Spectrum According To Eurocode 8Document6 pagesDesign Spectrum According To Eurocode 8BN NGNo ratings yet

- Analysis & Design of Reinforced Concrete StructuresDocument14 pagesAnalysis & Design of Reinforced Concrete StructuresSyazaa SalimNo ratings yet

- Slab Design Sandhi KholaDocument15 pagesSlab Design Sandhi Kholasakar shresthaNo ratings yet

- Deep BeamDocument7 pagesDeep BeamasdNo ratings yet

- Cold Formed Steel DesignDocument9 pagesCold Formed Steel DesignMNo ratings yet

- BM Kani Method TEMPDocument2 pagesBM Kani Method TEMPSana Ullah50% (2)

- Basic Concepts Rectangular and T Beams PDFDocument49 pagesBasic Concepts Rectangular and T Beams PDFBookienowNo ratings yet

- Prilaku Balok Kastela Dengan Elemen HinggaDocument7 pagesPrilaku Balok Kastela Dengan Elemen HinggaFiqri AnraNo ratings yet

- Initial Width and Depth of BeamDocument3 pagesInitial Width and Depth of BeamsssdadaNo ratings yet

- Axial capacity of circular concrete-filled tube columnsDocument20 pagesAxial capacity of circular concrete-filled tube columnsMona MahmoudNo ratings yet

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringDocument10 pagesRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpNo ratings yet

- M.Tech Project Presentation (Stage I) : College of Engineering Pune (COEP)Document31 pagesM.Tech Project Presentation (Stage I) : College of Engineering Pune (COEP)kajal jadhavNo ratings yet

- SlabDocument6 pagesSlabskumarsr0% (1)

- Designed and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameDocument3 pagesDesigned and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameAnonymous Gye18jNo ratings yet

- Minimum & Maximum SteelDocument3 pagesMinimum & Maximum SteelSathishNo ratings yet

- Development length and Lap length explained in 38 charactersDocument3 pagesDevelopment length and Lap length explained in 38 charactersmcadsri100% (1)

- Paper On Floating ColumnDocument8 pagesPaper On Floating Columnমোঃ হাসান ইমামNo ratings yet

- Effect of Backstay on RC BuildingDocument5 pagesEffect of Backstay on RC Buildingdharashah28No ratings yet

- Benchmark cases for advanced design of structural steel connectionsDocument26 pagesBenchmark cases for advanced design of structural steel connectionswendydy6No ratings yet

- STAAD - Foundation Users Manual PDFDocument487 pagesSTAAD - Foundation Users Manual PDFTravis PaulNo ratings yet

- Latihan 1 - Perilaku Struktur Rangka Baja - Firstka Safira - 25019325Document17 pagesLatihan 1 - Perilaku Struktur Rangka Baja - Firstka Safira - 25019325Firstka SafiraNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Annual Report 2017-2018-00Document167 pagesAnnual Report 2017-2018-00Shamsul IslamNo ratings yet

- CF3 DetailDocument1 pageCF3 DetailShamsul IslamNo ratings yet

- Material Rate PWD 2014...........Document70 pagesMaterial Rate PWD 2014...........Shamsul IslamNo ratings yet

- Preparation of Papers - Paper Title: First A. Author, Second B. Author, JR., Third C. AuthorDocument1 pagePreparation of Papers - Paper Title: First A. Author, Second B. Author, JR., Third C. AuthorRalph CastinoNo ratings yet

- Energy Method For EQ DesignDocument1 pageEnergy Method For EQ DesignShamsul IslamNo ratings yet

- Angle Capacity v1Document25 pagesAngle Capacity v1Shamsul IslamNo ratings yet

- CV Jobdatul ArefinDocument3 pagesCV Jobdatul ArefinShamsul IslamNo ratings yet

- The Design Report Format: General RequirementsDocument3 pagesThe Design Report Format: General RequirementsShamsul IslamNo ratings yet

- 8.T-ProofCrete 709 13-03-28Document2 pages8.T-ProofCrete 709 13-03-28Shamsul IslamNo ratings yet

- Offer Steel Building FormatDocument16 pagesOffer Steel Building FormatShamsul IslamNo ratings yet

- Cladding Dsign For Earthquake and WindDocument32 pagesCladding Dsign For Earthquake and WindShamsul IslamNo ratings yet

- Green 2008Document95 pagesGreen 2008Shamsul IslamNo ratings yet

- '13 IiseeDocument31 pages'13 IiseeShamsul IslamNo ratings yet

- Bangladesh EarthquakeDocument31 pagesBangladesh EarthquakeShamsul IslamNo ratings yet

- Questionnaire To 2013-2014 E-Course Participants #2: X X X X X X X X X X X X X X X X X X XDocument2 pagesQuestionnaire To 2013-2014 E-Course Participants #2: X X X X X X X X X X X X X X X X X X XShamsul IslamNo ratings yet

- BRI LecsfsftureDocument1 pageBRI LecsfsftureShamsul IslamNo ratings yet

- Seismic HazardDocument20 pagesSeismic HazardShamsul IslamNo ratings yet

- The Accord InspectionDocument7 pagesThe Accord InspectionShamsul IslamNo ratings yet

- Settlement Analysis of FoundationDocument1 pageSettlement Analysis of FoundationShamsul IslamNo ratings yet

- 13 Time Predictable Fault Modeling of BDDocument91 pages13 Time Predictable Fault Modeling of BDShamsul IslamNo ratings yet

- NewBNBC - Part 6-Chap 2Document133 pagesNewBNBC - Part 6-Chap 2Shamsul IslamNo ratings yet

- Know BangladeshDocument12 pagesKnow BangladeshShamsul IslamNo ratings yet

- Calculate liquefaction potential and safety factor FLDocument4 pagesCalculate liquefaction potential and safety factor FLShamsul IslamNo ratings yet

- NewBNBC - Part 6-Chap 2Document133 pagesNewBNBC - Part 6-Chap 2Shamsul IslamNo ratings yet

- Class EvaluationDocument6 pagesClass EvaluationShamsul IslamNo ratings yet

- Settlement Analysis of FoundationDocument1 pageSettlement Analysis of FoundationShamsul IslamNo ratings yet

- StudyTrip - Tohuku AreaDocument8 pagesStudyTrip - Tohuku AreaShamsul IslamNo ratings yet

- Tech Bulletin 2Document7 pagesTech Bulletin 2Shamsul IslamNo ratings yet

- New Microsoft Office Word DocumentDocument21 pagesNew Microsoft Office Word DocumentShamsul IslamNo ratings yet

- NCh2369-2003 Seismic Design of Industrial Facilities and StructuresDocument75 pagesNCh2369-2003 Seismic Design of Industrial Facilities and StructuresypuifoongNo ratings yet

- Jabatan Pengairan Dan Saliran Malaysia: Lampiran DDocument6 pagesJabatan Pengairan Dan Saliran Malaysia: Lampiran DAfiqah NorshamNo ratings yet

- Ce 442Document107 pagesCe 442MasudNo ratings yet

- Burj Al Arab 120378682233445 4Document79 pagesBurj Al Arab 120378682233445 4api-385146393% (14)

- Saic L 1004Document2 pagesSaic L 1004Hussain Nasser Al- NowiesserNo ratings yet

- 4 Classification of SoilDocument8 pages4 Classification of SoilPRAJWAL srNo ratings yet

- Unit 6 P1 ExampleDocument13 pagesUnit 6 P1 ExampleYI HEN ONGNo ratings yet

- OJT Narrative Report FormatDocument31 pagesOJT Narrative Report FormatLyjen MendizNo ratings yet

- ACI 562 16 The ACI Concrete Repair CodeDocument7 pagesACI 562 16 The ACI Concrete Repair CodeDonny. B TampubolonNo ratings yet

- An Investigative Approach To Design of Trussless Roof by Indian Codes & FEMDocument8 pagesAn Investigative Approach To Design of Trussless Roof by Indian Codes & FEMSurya PrakashNo ratings yet

- Chapter 4 Seismic Design GuideDocument96 pagesChapter 4 Seismic Design Guidemustafurade1No ratings yet

- Price Summary for Construction ProjectDocument22 pagesPrice Summary for Construction ProjectAbreham WorkuNo ratings yet

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 pageStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilNo ratings yet

- Homework 03Document2 pagesHomework 03HesapNo ratings yet

- Kalzip - Vapour Layer FR 0822 PDFDocument2 pagesKalzip - Vapour Layer FR 0822 PDFBerat CakmakliNo ratings yet

- PSC HandbookDocument40 pagesPSC HandbookVivekNo ratings yet

- Rain Loads 1611 From IBCDocument9 pagesRain Loads 1611 From IBCJim GregsonNo ratings yet

- HILTI Technical Guide Volume 1Document175 pagesHILTI Technical Guide Volume 1xpertsteelNo ratings yet

- Arbaminch University: Panel 4Document1 pageArbaminch University: Panel 4dilnessa azanaw0% (1)

- Geotechnical Engg. I: ProblemsDocument3 pagesGeotechnical Engg. I: ProblemsShraddha BuradkarNo ratings yet

- Seismic Design of Tunnels: Wang', MunfakhzDocument10 pagesSeismic Design of Tunnels: Wang', MunfakhzGabriel SanchezNo ratings yet

- Factors Affecting PSU CE Graduates' Board Exam PerformanceDocument14 pagesFactors Affecting PSU CE Graduates' Board Exam PerformanceKennethNo ratings yet

- Flood and Debris Loads On Bridges PHD Thesis Mark Jempson PDFDocument457 pagesFlood and Debris Loads On Bridges PHD Thesis Mark Jempson PDFThong NguyenNo ratings yet

- Perlifoc HP - Data SheetDocument1 pagePerlifoc HP - Data SheetAndreiNo ratings yet

- Construction of Two Storied Mosque TenderDocument24 pagesConstruction of Two Storied Mosque TenderSanjay AcharjeeNo ratings yet

- Tubewells and DesignDocument60 pagesTubewells and Designاشتیاق حسینNo ratings yet

- Calculating Wind Loads on a Steel Mill BuildingDocument135 pagesCalculating Wind Loads on a Steel Mill BuildingKaraline MarcesNo ratings yet

- Design ManualDocument138 pagesDesign Manualtags7991% (11)

- Pre Stressed BeamsDocument127 pagesPre Stressed BeamsjaffnaNo ratings yet

- 74 Toyohashi Tech EngDocument21 pages74 Toyohashi Tech EngKip YegoNo ratings yet