Professional Documents

Culture Documents

Reinforced Concrete Slab Design Examples

Uploaded by

Ghaffar LaghariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reinforced Concrete Slab Design Examples

Uploaded by

Ghaffar LaghariCopyright:

Available Formats

11/16/2014

Slabs

One Way Slabs

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Introduction

Reinforced concrete building construction

commonly has floor slabs, beams, girders and

columns continuously placed to form a

monolithic system.

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Introduction

B1,B2, and B3 are supported on the Girders

B4,B5, and B6 are supported on the Columns

G1,G2, and G3 are supported on the Columns

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Types of Slabs

One-Way Slabs

Solid Slabs

Ribbed Slabs (Ribbed Joist floor)

Long Span

>2

Short Span

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Types of Slabs

Two-Way Slabs

Solid Slabs

Ribbed Slabs (Ribbed Joist floor)

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Types of Slabs

Flat Slabs

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Example S1

A one-way single span reinforced concrete

slab has a simple span of 5.0 m. The service

live load is 15 kN/m2, the dead load is 10

kN/m2 (including self weight) and 28 MPa

concrete is specified for use with steel with a

yield stress equal to 420 MPa. Design the slab,

following the provisions of the ACI code.

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Example S1

First determine the thickness of the slab:

From Table 9.5a of the ACI code

h=

l

5

=

= 0.250 m

20 20

Assume a 1.0 m thickness strip (b=1.0 m)

wu = 1.2 *10 + 1.6 *15 = 36 kN/m

wu l 2

= 112.5 kN - m

8

0.6 max = 0.0123857

Mu =

0.0123857 * 420

112 *106 = 0.9 * 0.0123857 * 420 *1000d 2 1 0.588

28

d = 163.88 mm < 250 thus use h = 250 mm and d = 217.5 mm

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Example S1

As = 0.0123857 *1000 * 217.5 = 2693.89 mm 2

Use 525

d = 250 20 12.5 = 217.5 mm

2454.37 * 420

= 43.31 mm c = 50.96 mm

0.85 * 28 *1000

217.5 50.96

t = 0.003

= 0.00980 = .90

50.96

3694.51

=

= 0.0113 > min

186 *1000

M u = 181.70 kN - m

a=

Using formula As=1451.88 mm2 3 25

Mu=113.84 kN-m

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Example S2

A reinforced concrete slab is built integrally

with its supports and consists of two equal

spans, each with clear span of 4.5 m. The

service live load is 5 kN/m2, and 28 MPa

concrete (Density =23.5 kN/m3) is specified for

use with steel with a yield stress equal to 420

MPa. Design the slab, following the provisions

of the ACI code.

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Example S2

First determine the thickness of the slab:

From Table 9.5a of the ACI code

4.5

l

h=

=

= 0.161 m

28 28

Use h=165 mm, thus

DL = 23.5 * .165 = 3.88 kN/m 2

wu = 1.2 * 3.88 + 1.6 * 5 = 12.656 kN/m 2

Calculate the moments using the ACI coefficients

listed in section 8.3.3 of the ACI code

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Example S2

8.3.3 As an alternate to frame analysis, the following approximate

moments and shears shall be permitted for design of continuous

beams and one-way slabs (slabs reinforced to resist flexural stresses

in only one direction), provided (a) through (e) are satisfied:

(a) There are two or more spans;

(b) Spans are approximately equal, with the larger of two

adjacent spans not greater than the shorter by more than 20

percent;

(c) Loads are uniformly distributed;

(d) Un-factored live load, L, does not exceed three times unfactored dead load, D; and

(e) Members are prismatic.

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Example S2

wln2 1

At interior support : M =

= *12.656 * 4.52 = 28.476 kN.m

9

9

wl 2 1

At midspan : + M = n = *12.656 * 4.52 = 18.306 kN.m

14 14

wl 2 1

At exterior support : M = n = *12.656 * 4.52 = 10.679 kN.m

24 24

1

24

1

9

1

14

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Example S2

0.005 = 0.0181

d=

M u _ Interior

f yb(1 0.59

fy

f c'

= 70.40 mm

)

Use h = 165 mm thus d = 115 mm

2 '

0.85 f c'

f c' (bd f c 2.36M u )

=

0.85

df y

fy

b

As = bd = 693.733 mm 2

Use 514 Each m

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Example S2

d = 165 50 7 = 108 mm

1 769.69 * 420

c=

= 15.98 mm

0.85 0.85 * 28 *1000

108 15.98

t = 0.003

= 0.0173 = .90

15.98

769.69

=

= 0.0071 > min

108 *1000

M u _ Interior = 29.44 kN - m

Similarly

As _ midspan = 437 mm 2 (Use 314 per m)

As _ Exteroir = 360 mm 2 (Use 314 per m)

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Example S2

Shear Consideration

wu ln

wu d

2

12.656 * 4.5

1

= 1.15 *

12.656 * .108 = 31.38 kN < Vc

2

2

Vu = 1.15

Shrinkage bars=0.0018bh=297 mm2 use 120

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Reinforcement Details

Straight bars

L1/5

Bent bars

L /5

L1/3

L2/3

L1

L2

L1/3

L1/7

L2/3

L1/5

L2/3

L2/3

L2/4

L1

L2/4

L2

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Ribbed Slab

2.5 cm

3.5 cm

9 cm

7 cm

14, 18 ,24 , 32 cm

2 cm

20 cm

36 cm

20 cm

12-15 cm

Shrinkage and

Temperature

Main

Reinforcement

40 cm

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11/16/2014

Ribbed Slab

Design as T-beam

52 cm

7 cm

14,18, 24,32 cm

12 cm

Review ACI provisions 8.13

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

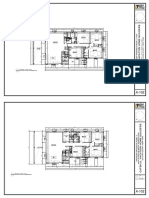

Design the Ribbed slab below according

to the ACI code provisions fy=420 MPa and fc=21 MPa

B2

0.5 m

6.5 m

B4

B3

0.5 m

B1

0.5 m

3.0 m

0.5 m

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

10

11/16/2014

Ribbed Slab

2.5 cm

3.5 cm

9 cm

7 cm

18cm

2 cm

20 cm

15 cm

20 cm

To estimate bw assume:

Cover =25 mm,

Stirrups 8,

Main reinforcement 2 20,

distance between reinforcement=30mm

h=

l

3

= = 18.75 cm

16 16

bw = 2 * (25 + 8 + 20) + 30

= 136mm Use 150mm

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Ribbed Slab

2.5 cm

3.5 cm

9 cm

7 cm

18cm

2 cm

20 cm

15 cm

20 cm

To estimate DL:

1

0.73

= 1.34 kN/m 2

Rib : (0.15 + 0.19) * 0.18 * 24 = 0.73 kN/m =

2

: 0.025 * 25 = 0.625 kN/m 2

: 0.035 * 22 = 0.77 kN/m 2

: 0.09 * 20 = 1.8 kN/m 2

0.55

: 0.020 * 22 = 0.44 kN/m 2

1

1

Block: 0.55* 0.2 *.15 = 1.36 kN/m 2

hf: 0.07* 24 = 1.68 kN/m 2

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

11

11/16/2014

Ribbed Slab

DLSlab=1.8+.625+.77+.44+1.36+1.68=8.02 kN/m2

Assume Partitions DL=2.35 kN/m2

DLTotal=10.37 kN/m2

LL=2.0 kN/m2

wu = 1.2 *10.37 + 1.6 * 2.0 = 15.64 kN/m 2

Thus load per rib is

wu = 0.55*15.64 = 8.60 kN/m

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Ribbed Slab

Design as T-beam

Mu =

wu l 2 8.81 * 3.52

=

= 13.17 kN.m

8

8

Assume stress block depth equal to flange thickness

As =

13.17 * 10 6

70

0.9 * 420 * ( 215 )

2

= 193 .563 mm 2

193.563

= 0.006 > min

150 * 215

193 .563 420

a=

= 8.28 mm < h f

0.85 21 550

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

12

11/16/2014

Ribbed Slab

Use 214

307.88 * 420

= 13.17 mm

0.85 * 21* 550

a 13.17

c= =

= 15.49 mm

1 0.85

a=

215 15.49

= 0.0386 > 0.005

15.49

307.88

w =

= 0.00955

150 * 215

13.17

M u = 0.9 307.88 420 (215

)

2

= 24.26 kN.m > Mu

t = 0.003

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

Ribbed Slab

2.5 cm

3.5 cm

9 cm

7 cm

18 cm

2 cm

20 cm

15 cm

20 cm

214

18

Design for Shear as before

Design B3 & B4 using wu=15.63*1.5=23.4 kN/m

Design Columns with axial Compression load of

23.4*7/2=81.9 kN/m

CE 432 1st Semester 14/15

Dr. Nadim Shbeeb

13

You might also like

- CSS Beginners Guide (2017-18) PDFDocument66 pagesCSS Beginners Guide (2017-18) PDFSaad Ahsan100% (1)

- Boundary Wall DesignDocument26 pagesBoundary Wall DesignAtanu Bhattacharya50% (2)

- ONE-WAY SLABS DESIGNDocument26 pagesONE-WAY SLABS DESIGNJohn Mejia50% (4)

- Design of Piping SupportsDocument15 pagesDesign of Piping SupportsWaleed EzzatNo ratings yet

- 12 Design of Hordy Slab 23052014Document1 page12 Design of Hordy Slab 23052014Ahmad Badsha QuadriNo ratings yet

- ETABS design checks for a 4-story RC buildingDocument76 pagesETABS design checks for a 4-story RC buildingMaram M HaseebaNo ratings yet

- Beam DesignDocument84 pagesBeam DesignFoo He XuanNo ratings yet

- Design of Steel Truss MembersDocument6 pagesDesign of Steel Truss MembersSaim WaqarNo ratings yet

- Faculty of Applied Engineering and Urban PlanningDocument22 pagesFaculty of Applied Engineering and Urban PlanningHazem Almasry100% (1)

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Example: Design The Beams in The Figure Below. The Imposed Load Is 2.5 KN/MDocument32 pagesExample: Design The Beams in The Figure Below. The Imposed Load Is 2.5 KN/MSarah HaiderNo ratings yet

- Philosophy of Limit State Design and Classification of SectionsDocument96 pagesPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- George Van TasselDocument2 pagesGeorge Van TasselManea SilviuNo ratings yet

- University of Salahaddin-Hewler College of Engineering Department of Civil Eng. Multistorey Design ProjectDocument36 pagesUniversity of Salahaddin-Hewler College of Engineering Department of Civil Eng. Multistorey Design Projectdev6483% (12)

- DESIGN OF CIRCULAR WATER TANK USING GFRP BARSDocument35 pagesDESIGN OF CIRCULAR WATER TANK USING GFRP BARSmohammed samiNo ratings yet

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Designing, Planning and Analysis of VillaDocument34 pagesDesigning, Planning and Analysis of VillaMohamed FarweezNo ratings yet

- HW5Document2 pagesHW5Mohammad Iqbal Mahamad Amir100% (1)

- Lecture 5 FoundationsDocument30 pagesLecture 5 FoundationsCarel De JagerNo ratings yet

- Method Statement for Treating Building Expansion JointsDocument4 pagesMethod Statement for Treating Building Expansion JointsGhaffar Laghari100% (2)

- Shear DesignDocument17 pagesShear DesignAyez Sassin100% (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Most Repeated Question Current Affairs - 2000 To 2017 Ver1Document24 pagesMost Repeated Question Current Affairs - 2000 To 2017 Ver1Ghaffar Laghari100% (1)

- Reinforced Concrete Design: By: Dr. Haleem K. HussainDocument65 pagesReinforced Concrete Design: By: Dr. Haleem K. HussainNHEM KEAMNo ratings yet

- Bulk and Suspenshion Polynerization of MMA Into PMMADocument5 pagesBulk and Suspenshion Polynerization of MMA Into PMMADavid Meza CarbajalNo ratings yet

- Slab Design To BS 8110Document11 pagesSlab Design To BS 8110Samuel Antobam100% (2)

- Sol 4Document10 pagesSol 4Stian BilekNo ratings yet

- Steps in Designing A Rectangular BeamDocument8 pagesSteps in Designing A Rectangular BeamIvan GonzalesNo ratings yet

- Design of Staircase Slab and ReinforcementDocument16 pagesDesign of Staircase Slab and ReinforcementOscarKonzultNo ratings yet

- Beam Design for 5m Simply Supported BeamDocument28 pagesBeam Design for 5m Simply Supported BeamSarah HaiderNo ratings yet

- Bridge Beam DesignDocument8 pagesBridge Beam DesignAnonymous KQtFm3No ratings yet

- Calculation SheetDocument21 pagesCalculation SheetEngAmr ElmohndesNo ratings yet

- NCC Developer Undertaking LetterDocument2 pagesNCC Developer Undertaking LetterGhaffar LaghariNo ratings yet

- Significant Figures WorksheetDocument2 pagesSignificant Figures WorksheetKevin BakerNo ratings yet

- Manual Fundamental Hydraulic SystmsDocument131 pagesManual Fundamental Hydraulic Systmssawmag123100% (3)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Prepared By: Ms. Ethel D. Nabor, LPTDocument29 pagesPrepared By: Ms. Ethel D. Nabor, LPTJohn Ralf T. TorrejosNo ratings yet

- Coal Carbonization: Current and Future ApplicationsDocument9 pagesCoal Carbonization: Current and Future ApplicationsVenkata Krishnan RamanujamNo ratings yet

- Flexure Beam Analysis and Design Continuous BeamDocument31 pagesFlexure Beam Analysis and Design Continuous Beamsaleh34534rf34No ratings yet

- WE Slabs Sep07Document31 pagesWE Slabs Sep07Kristina OraNo ratings yet

- 7 Design of One Way Slabs5b16145dDocument7 pages7 Design of One Way Slabs5b16145dClarisse DoriaNo ratings yet

- Shear Design Continuous BeamDocument18 pagesShear Design Continuous Beamsaleh34534rf34No ratings yet

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IIIDocument32 pagesProf (1) - Zahid Ahmad Siddiqi Formwork Design-IIIasdasNo ratings yet

- CONTINUOUS ONE WAY SLAB DESIGNDocument12 pagesCONTINUOUS ONE WAY SLAB DESIGNMuhammad Farhan Gul86% (7)

- 2020 Solution Module 4 Two-Way SlabsDocument5 pages2020 Solution Module 4 Two-Way SlabsAli HassanNo ratings yet

- 3.0 Learning Outcome: Principles of Reinforced Concrete/PrestressedDocument6 pages3.0 Learning Outcome: Principles of Reinforced Concrete/PrestressedAllysa Joy MoralesNo ratings yet

- أنواع البلاطاتDocument71 pagesأنواع البلاطاتحسام قطينيNo ratings yet

- CE 71 DRB Internal-2-Answer Key (Student Copy)Document22 pagesCE 71 DRB Internal-2-Answer Key (Student Copy)PaulNo ratings yet

- Mod 4Document35 pagesMod 4Eesha NairNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- Design of Flat SlabDocument44 pagesDesign of Flat SlabRaveendra Babu CherukuriNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Reinforced Concrete ProjectDocument22 pagesReinforced Concrete ProjectRon Oliver LonzagaNo ratings yet

- Design of Small BuildingDocument28 pagesDesign of Small BuildingJaime CoronellNo ratings yet

- Examples 1 CVG314Document5 pagesExamples 1 CVG314Ahmed ShakerNo ratings yet

- R.C Continuous Beam Design and AnalysisDocument12 pagesR.C Continuous Beam Design and Analysisعبدالعزيز حازم صباحNo ratings yet

- Chapter 4 STR 3 One Way Slab ServiDocument8 pagesChapter 4 STR 3 One Way Slab ServidaniNo ratings yet

- Reinforcement Concrete Design ProjectDocument20 pagesReinforcement Concrete Design ProjectShahram SalimNo ratings yet

- One Way Solid SlabDocument26 pagesOne Way Solid SlabalaajabbarNo ratings yet

- Design cross girder and calculate reinforcement for prestressed I-girder bridgeDocument3 pagesDesign cross girder and calculate reinforcement for prestressed I-girder bridgeSudip NeupaneNo ratings yet

- CIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringDocument52 pagesCIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringHakuna MatataNo ratings yet

- Tutorial 2 - Axially Loaded Members-TensionDocument27 pagesTutorial 2 - Axially Loaded Members-TensionChan Keng ChunNo ratings yet

- ##FNuj Slab NotesDocument36 pages##FNuj Slab NotesthembalethuNo ratings yet

- Steel and Concrete Beam DesignDocument12 pagesSteel and Concrete Beam DesignTalha tahirNo ratings yet

- Typical Slab DesignDocument3 pagesTypical Slab DesignArpan SahaNo ratings yet

- Load Distribution Calculation by One Way SlabDocument9 pagesLoad Distribution Calculation by One Way Slabmona vermaNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Utilities EngineerDocument3 pagesUtilities EngineerGhaffar LaghariNo ratings yet

- Plot Demarcation Certificate ApplicationDocument2 pagesPlot Demarcation Certificate ApplicationGhaffar Laghari100% (2)

- Master 2Document2 pagesMaster 2Ghaffar LaghariNo ratings yet

- Trakhees Comments ReplyDocument2 pagesTrakhees Comments ReplyGhaffar LaghariNo ratings yet

- Asbuilt Jvc11dmrp200 ModelDocument1 pageAsbuilt Jvc11dmrp200 ModelGhaffar LaghariNo ratings yet

- Footing ConcreteDocument1 pageFooting ConcreteGhaffar LaghariNo ratings yet

- 15 Days Practice For IELTS WritingDocument174 pages15 Days Practice For IELTS WritingnguyenbatiepNo ratings yet

- Setting Out Plan Sport City-ModelDocument1 pageSetting Out Plan Sport City-ModelGhaffar LaghariNo ratings yet

- President Donald TrumpDocument3 pagesPresident Donald TrumpGhaffar LaghariNo ratings yet

- 500 EAST: 423 W 800 S Suite A316 Salt Lake City, UT 84101Document2 pages500 EAST: 423 W 800 S Suite A316 Salt Lake City, UT 84101Ghaffar LaghariNo ratings yet

- Emmcs Scholarship 2014Document4 pagesEmmcs Scholarship 2014sajeelaqdasNo ratings yet

- Road User CodeDocument73 pagesRoad User Codeadma1No ratings yet

- Sample of How I Want The To LookDocument5 pagesSample of How I Want The To LookGhaffar LaghariNo ratings yet

- Civil Engineering Objective Questions Part 12Document52 pagesCivil Engineering Objective Questions Part 12Ghaffar LaghariNo ratings yet

- 2017 04 07 14 52 50 PDFDocument4 pages2017 04 07 14 52 50 PDFGhaffar LaghariNo ratings yet

- For CollectionDocument1 pageFor CollectionGhaffar LaghariNo ratings yet

- Payment ReceiptDocument1 pagePayment ReceiptGhaffar LaghariNo ratings yet

- Dewatering LetterDocument1 pageDewatering LetterGhaffar LaghariNo ratings yet

- Layout With Gen DimensionsDocument1 pageLayout With Gen DimensionsGhaffar LaghariNo ratings yet

- Letter To Kumara For JVC GreenDocument1 pageLetter To Kumara For JVC GreenGhaffar LaghariNo ratings yet

- Application FormDocument2 pagesApplication FormGhaffar LaghariNo ratings yet

- Labour Productivity Chart in UaeDocument9 pagesLabour Productivity Chart in UaeGhaffar LaghariNo ratings yet

- Ground Floor Plan: Dubai Sports City - L.L.CDocument1 pageGround Floor Plan: Dubai Sports City - L.L.CGhaffar LaghariNo ratings yet

- Compliance LetterDocument2 pagesCompliance LetterGhaffar LaghariNo ratings yet

- Gunite and Shotcrete BrochureDocument2 pagesGunite and Shotcrete BrochureGhaffar LaghariNo ratings yet

- Advanced Excel TipsDocument34 pagesAdvanced Excel TipsSatish NamballaNo ratings yet

- Chapter 3 - Vectors and Coordinate Systems - SolutionsDocument7 pagesChapter 3 - Vectors and Coordinate Systems - SolutionsJeff BEzosNo ratings yet

- Introduction To Chemical Engineering Thermodynamics - 7th Ed - Smith, Van Ness & Abbot PDFDocument709 pagesIntroduction To Chemical Engineering Thermodynamics - 7th Ed - Smith, Van Ness & Abbot PDFmangelmp78% (18)

- Contrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesDocument5 pagesContrasts Between Finite and Infinite Dimensional Spaces and Between Normed and Inner Product SpacesQuinton WestrichNo ratings yet

- ETEN4001 Tute1 2017Document3 pagesETEN4001 Tute1 2017Orlando CalderasNo ratings yet

- ACI - Measurement of Properties of Fiber Reinforced ConcreteDocument12 pagesACI - Measurement of Properties of Fiber Reinforced ConcreteTran Tuan Kiet100% (1)

- Lyft Pec FootprintsDocument1 pageLyft Pec FootprintsZoran TripunovskiNo ratings yet

- 2A The Structure of The Atom-AnswerDocument6 pages2A The Structure of The Atom-AnswerSiti Nursahidah0% (1)

- b3 g1 Gummy Bear Launcher Written UpDocument6 pagesb3 g1 Gummy Bear Launcher Written Upapi-462982749No ratings yet

- Lucas TuningDocument12 pagesLucas TuningMichael RohrNo ratings yet

- Molecular Shapes and BondingDocument24 pagesMolecular Shapes and BondingSandunil JayasingheNo ratings yet

- PDU Assignment 3 TitleDocument15 pagesPDU Assignment 3 Titleaqib rizwanNo ratings yet

- Acp2011 Final LR NewDocument72 pagesAcp2011 Final LR NewExodus Kwaku OforiNo ratings yet

- Definition of Elements 1-20Document2 pagesDefinition of Elements 1-20War ThunderNo ratings yet

- Physics QuestionsDocument25 pagesPhysics QuestionsCarlos KasambiraNo ratings yet

- The Thermal Expansion of The Fireclay BricksDocument38 pagesThe Thermal Expansion of The Fireclay BricksanuarsgNo ratings yet

- Structural Analysis & Design QuizDocument5 pagesStructural Analysis & Design QuizBongA.SalinasNo ratings yet

- Aceros PoscoDocument35 pagesAceros PoscoregistrosegNo ratings yet

- 0053 Dynamics of Commodity Forward CurvesDocument25 pages0053 Dynamics of Commodity Forward Curvesamitnp7373No ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- B 21 - B 21M - 14Document8 pagesB 21 - B 21M - 14Ahmed BilalNo ratings yet

- Module 1 RTS PDFDocument48 pagesModule 1 RTS PDFPràmêyá HëgdēNo ratings yet