Professional Documents

Culture Documents

Excel Anchor Bolt Calculator

Uploaded by

ラディチャ ドハルマワングサOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excel Anchor Bolt Calculator

Uploaded by

ラディチャ ドハルマワングサCopyright:

Available Formats

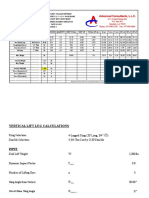

ANCHOR BOLT CALCULATIONS metal buildings

PROJECT

SAMPLE METAL BUILDING

a FREE DOWNLOAD from griffithplans.com (other calculators FREE at griffithplans.com)

MAKE ENTRIES IN YELLOW BLANKS ONLY

Read additional instructions before using (available at griffithplans.com)

BOLD ENTRIES ARE FORMULAS

DEADLOADS

version 4-10-07

WINDLOADS 15% safety factor

page 1 of 2

15% safety factor

used for footing and column pad calcs only

used for footing and column pad calcs only

WALL SEGMENTS

ROOF SEGMENTS

LATERAL WINDLOAD

ROOF WINDLOAD

WALL 1

ROOF 1

WALL 1

ROOF 1

HEIGHT

21

HEIGHT

21

HEIGHT

21

HEIGHT

21

WIDTH

20

WIDTH

20

WIDTH

20

WIDTH

20

WT PSF

25

WT PSF

25

WLOAD PSF

35.65

WLOAD PSF

17.28

SF

420

SF

420

SF

420

SF

420

TOTAL LBS.

10500

TOTAL LBS.

10500

TOTAL LBS.

14973

TOTAL LBS.

7257.6

WALL 2

HEIGHT

WIDTH

WT PSF

SF

TOTAL LBS.

0

0

0

0

0

COLUMN PAD

DEPTH ft

WIDTH ft

LENGTH ft

WT per cf

totalCF conc

TOTAL WT

3.66

4

4

150

58.56

8784

ROOF 2

HEIGHT

WIDTH

WT PSF

SF

TOTAL LBS.

FOOTING

DEPTH ft

WIDTH ft

LENGTH ft

WT per cf

totalCF conc

TOTAL WT

WALL 2

HEIGHT

WIDTH

WLOAD PSF

SF

TOTAL LBS.

0

0

0

0

0

0

0

0

0

0

ROOF 2

HEIGHT

WIDTH

WLOAD PSF

SF

TOTAL LBS.

0

0

0

0

0

TOTAL LATERAL WINDLOAD

TOTAL ROOF WINDLOAD

1.33

1.66

20

150

44.16

6623.40

14973

-7257.6

FOOTING SOIL BEARING

1050.0

wall roof PSF

199.5

footing PSF

1249.5

TOTAL LBS PSF

equals a safety margin of

750.5 PSF

2000 PSF

enter soil bearing above

7 inches

min.ftg width required

19.9

inches

footing design given

COLUMN PAD (SOIL BEARING)

18.2

16

(ASTM A 307 Bolt Tightening Criteria)

diameter

torque initially tighten bolts to achieve mating.

3/8

15

Final Tighten Bolts measuring Torque

1/2

37

Conc strength achieved in 28 days

5/8

74

3/4

120

7/8

190

1

275

9/ 8

375

5/ 4

525

SF MIN COL PAD for 2000psf soil bearing.

SF DESIGNED PAD SIZE

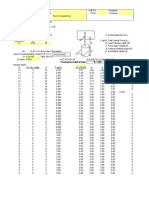

WALL WEIGHT LBS

ROOF WEIGHT LBS

COLUMN PAD WEIGHT LBS

FOOTING WEIGHT LBS

TOTAL DEADLOAD WEIGHT LBS

10500

10500

8784

6623

36407

DEADLOAD LESS UPLIFT LBS

29,150

result must be positive to prevent lifting

LOWEST amount is tension & shear allowance per bolt

embedded bolt allowance

NUMBER OF COLUMNS IN CALCS

BOLT COUNT PER COLUMN

tension LOAD NEEDED PER BOLT

SHEAR NEEDED PER BOLT

1

4

1,814

3,743

LBS

LBS

Tension + Shear safety amt

15,904 max bolt strength

10,347 bolt strength

18,910 anchor load

13,353 anchor load

30,375 conc strength

24,817 conc strength

22,500 edge dist

16,942 edge dist

values above must be positive to prevent failure

BOLTS SELECTED EXCEED REQUIREMENTS OF FBC 1912 AND 1913.

ANCHOR BOLT INFORMATION for footing bolts

Bolts shall conform to ASTM A 307 or an approved equivalent.

Griffithplans.com has stock plans, custom plans, free const calculators and const references

inches

3/ 4

in

MINIMUM EMBEDMENT in inches (12 dia)

in

IDEAL MIN DIST FROM CONC EDGE 1.5xshank

NOTE: Locate all anchor bolts with templates before pouring concrete

use ASTM A 307 bolts or approved equiv. The use of lower rated bolts

could result in building collapse in high wind conditions.

TOTAL BOLT LENGTH REQUIRED inches

12

conc cover from bolt bottom to COLUMN PAD bottom

35

REQUIRED BOLT DIAMETER

THREADED PORTION ABOVE CONC

9

14.0

ANCHOR BOLT CALCULATIONS

MAKE ENTRIES IN YELLOW BLANKS ONLY BOLD ENTRIES ARE FORMULAS

page 2 of 2

3,000

36,000

12

3/ 4

9

13.5

12.73

359.87

254.47

CONC STRENGTH PSI

ANCHOR YIELD STRENGTH PSI

81 cone cross section area in sq in

TOTAL BOLT LENGTH REQUIRED inches

BOLT DIA

0.375 bolt radius

0.4418 bolt sq in

EMBED LENGTH

FREE EDGE DIST use 1.5 times embed

3.141592654 =pi

SLANT HEIGHT of cone

162 hyp=SQ RT OF side1+side2

CONE SURFACE AREA

area of cone=PI*R*SLANT HT

CIRCLE AREA

pi=3.141592654ratio of the circumf to the dia (C/d)=3.14 of circle.22 / 7 =pi

ALLOWABLE TENSILE LOAD

18,910 1.ALLOWABLE LOAD psi (based on anchor)

formula=.5*(cone surface area)*sq rt(bolt dia*anchr yield strength psi.)

result above /

30,375 2.ALLOWABLE LOAD psi (based on conc psi)

for close spacing

pull-out factor

formula=bolt dia times .02 *(cone cross sec*conc strength psi)

result above /

12 inches ACTUAL DIST TO CONC EDGE

value below cannot exceed allowable load 2 above

22,500 ADJUSTED LOAD psf ( based on conc psi & edge distance)

1.2

1.2

for close spacing

pull-out factor

formula=PSF load*(actual edge dist divided by free edge dist.)

result above /

value below cannot exceed allowable load 1 above

15,904 actual bolt strength based on size = (bolt sq in*anchor yield psi)

a FREE DOWNLOAD from griffithplans.com (other calculators FREE at griffithplans.com)

Griffithplans.com has stock plans, custom plans, free const calculators and const references

1.2

for close spacing

pull-out factor

You might also like

- Excel Anchor Bolt CalculatorDocument2 pagesExcel Anchor Bolt CalculatorPrantik Adhar Samanta100% (1)

- 16 PoleDocument2 pages16 PoleMario Sajulga Dela CuadraNo ratings yet

- 2 PDFDocument1 page2 PDFSujit RasailyNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- 1th SectionDocument10 pages1th SectionfaridullahNo ratings yet

- 10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDocument3 pages10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDesign explorer olomizanaNo ratings yet

- Seismic CalculationsDocument21 pagesSeismic CalculationsMoganna GowdaNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- EqualAngle PDFDocument2 pagesEqualAngle PDFGalih PutraNo ratings yet

- Annexure 3 Anchor Bolt and BaseplateDocument8 pagesAnnexure 3 Anchor Bolt and BaseplateDarshan PanchalNo ratings yet

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- Combined FootingDocument7 pagesCombined FootingMohammed ElemamNo ratings yet

- Plate DesignDocument6 pagesPlate DesignUmesh ChamaraNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Analysis of Rate For Providing/Fixing of Single Lights: Amount of 44 Pole 3% ContigencyDocument2 pagesAnalysis of Rate For Providing/Fixing of Single Lights: Amount of 44 Pole 3% Contigencymuhammad iqbalNo ratings yet

- Wind Loading Based On EC 1991-4Document4 pagesWind Loading Based On EC 1991-4janethNo ratings yet

- Client Comment Response - DG FoundationDocument7 pagesClient Comment Response - DG FoundationAnnelzNo ratings yet

- RCC One Way SlabDocument2 pagesRCC One Way SlabAniket GunjalNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- Design of Non Composite Beams With Large OpeningsDocument73 pagesDesign of Non Composite Beams With Large OpeningsbalaNo ratings yet

- Anchor Bolt - BiAxialDocument10 pagesAnchor Bolt - BiAxialArivoli JayaramanNo ratings yet

- PropertY Calculation 75CS40X10X1.2Document15 pagesPropertY Calculation 75CS40X10X1.2kingsuk1980No ratings yet

- 8224 Grating No HeaderDocument69 pages8224 Grating No HeadervishalnalwarNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- Final BeamDocument18 pagesFinal BeamNikhilNo ratings yet

- Awwa - D100-96 Welded Steel Tanks For Water Storage - Awwa PDFDocument140 pagesAwwa - D100-96 Welded Steel Tanks For Water Storage - Awwa PDFكرم عمروNo ratings yet

- Chimney Calculation SheetDocument14 pagesChimney Calculation SheetSrinivasa Rao VenkumahanthiNo ratings yet

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Anx 1Document17 pagesAnx 1mecon bhilaiNo ratings yet

- SteelDesign Composite Fu NewDocument16 pagesSteelDesign Composite Fu Newpresentasi mankonNo ratings yet

- CalculationsDocument6 pagesCalculationsMichael Haise100% (1)

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- 12.5 MVA Transformer Design (Latest)Document4 pages12.5 MVA Transformer Design (Latest)Amarjit KulkarniNo ratings yet

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sNo ratings yet

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- Wind Load CalculationDocument13 pagesWind Load CalculationSonik PradhanNo ratings yet

- Space 2001Document43 pagesSpace 2001Nguyen Duc CuongNo ratings yet

- Sag Tension Claulation ZEBRA-50 Meter STGDocument10 pagesSag Tension Claulation ZEBRA-50 Meter STGRamchandar KumaresanNo ratings yet

- Standard Tech SpecDocument3 pagesStandard Tech SpecBhuvan GanesanNo ratings yet

- Nameof Work:-Design of Circular Water Tank: Narok ETPDocument27 pagesNameof Work:-Design of Circular Water Tank: Narok ETPAbhay Thakur100% (1)

- Snow Load As Weight Per MM Calculation 330Document1 pageSnow Load As Weight Per MM Calculation 330Anonymous Iev5ggSRNo ratings yet

- Flood Lighting PoleDocument8 pagesFlood Lighting PoleMayuresh KudveNo ratings yet

- Design of Connection (Rb2 With Column)Document14 pagesDesign of Connection (Rb2 With Column)adil_khan648No ratings yet

- Wind Load CalculationsDocument1 pageWind Load Calculationsfrog15No ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Rean Water Tech Pvt. LTD.: Isolated Footing DesignDocument5 pagesRean Water Tech Pvt. LTD.: Isolated Footing DesignSougata MondalNo ratings yet

- Water Tank Load CalculationDocument2 pagesWater Tank Load CalculationyarmeenaNo ratings yet

- General Purpose Worksheet: Wind LoadingDocument11 pagesGeneral Purpose Worksheet: Wind LoadingabuzahrauNo ratings yet

- STP XXXXXXX 15-Feb-19: Metro Engineering Works Sheet NoDocument1 pageSTP XXXXXXX 15-Feb-19: Metro Engineering Works Sheet NoNagender KumarNo ratings yet

- PostFoundation 1Document1 pagePostFoundation 1امين الزريقيNo ratings yet

- Calculation B14 039Document158 pagesCalculation B14 039Apichartj JusuayNo ratings yet

- Spliced ColumnsDocument5 pagesSpliced ColumnsALPHYL BALASABASNo ratings yet

- PILE LOAD TEST (Sub Beam)Document16 pagesPILE LOAD TEST (Sub Beam)A.K.M Shafiq MondolNo ratings yet

- Base Plate DesignDocument3 pagesBase Plate Designyangmeme32No ratings yet

- Fixing of Rebar in ConcreteDocument98 pagesFixing of Rebar in ConcreteChandra MouliNo ratings yet

- W01 358 7304Document29 pagesW01 358 7304MROstop.comNo ratings yet

- W01 358 7047Document29 pagesW01 358 7047MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Concrete Pavement Joints PDFDocument4 pagesConcrete Pavement Joints PDFapirakqNo ratings yet

- Contraction Joint Transverse Construction Joint: Top ViewDocument2 pagesContraction Joint Transverse Construction Joint: Top ViewMuhammad Ali BhuttoNo ratings yet

- Crypt Analysis of The Random Number Generator of The Windows Operating SystemDocument24 pagesCrypt Analysis of The Random Number Generator of The Windows Operating SystemSand SonNo ratings yet

- Addison Wesley - Rootkits - Subverting The Windows Kernel (2005) enDocument363 pagesAddison Wesley - Rootkits - Subverting The Windows Kernel (2005) enmumtazoneNo ratings yet

- C TutorialDocument285 pagesC TutorialtekellamerZ aka tekellamerNo ratings yet

- Hump Dump PDFDocument12 pagesHump Dump PDFラディチャ ドハルマワングサNo ratings yet

- Anti Unpacking TechniquesDocument30 pagesAnti Unpacking Techniques@4e4enNo ratings yet

- European Standard Norme Européenne Europäische NormDocument31 pagesEuropean Standard Norme Européenne Europäische NormMarija IvanovskaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument11 pagesDepartment of Education: Republic of The PhilippinesRAMON VENEZUELANo ratings yet

- WORKSHEET General 2 Mathematics: QuestionsDocument35 pagesWORKSHEET General 2 Mathematics: QuestionsIWAN SETIAWANNo ratings yet

- Lancer'S Convent: Prashant Vihar, Rohini, Delhi-110085 ANNUAL CURRICULUM (2023-24) Class ViiiDocument28 pagesLancer'S Convent: Prashant Vihar, Rohini, Delhi-110085 ANNUAL CURRICULUM (2023-24) Class ViiiKARANNo ratings yet

- Mathematics: Quarter 1 - Module 9: Solving Word Problems Involving Polynomial EquationsDocument20 pagesMathematics: Quarter 1 - Module 9: Solving Word Problems Involving Polynomial EquationsSherwin G SerranoNo ratings yet

- Sample PaperDocument3 pagesSample PaperPriya RavikumarNo ratings yet

- Welcome To Calculus PDFDocument329 pagesWelcome To Calculus PDFPhilippe DubostNo ratings yet

- The Practicing Estimating Method in Malaysia'sDocument9 pagesThe Practicing Estimating Method in Malaysia'sMohd Faiz FahmiNo ratings yet

- NMAT-2003: Instructions To Test TakersDocument31 pagesNMAT-2003: Instructions To Test TakersFusion HCM Knowledgebase100% (4)

- 100 Geometry Problems: Solutions: Alvin ZouDocument26 pages100 Geometry Problems: Solutions: Alvin ZouMuhammad TaufanNo ratings yet

- Essential Maths 8H Test 1 PDFDocument5 pagesEssential Maths 8H Test 1 PDFAdam SandersNo ratings yet

- GCSE Formula SheetDocument1 pageGCSE Formula SheetSara AyaNo ratings yet

- Astm A578-A578m-07Document5 pagesAstm A578-A578m-07Renato MassanoNo ratings yet

- Answers: Middle Primary Upper Primary Intermediate SeniorDocument11 pagesAnswers: Middle Primary Upper Primary Intermediate SeniorjkjigijNo ratings yet

- 廖寶珊紀念書院 06-07 f4 下學期考試 試卷一 英文版Document19 pages廖寶珊紀念書院 06-07 f4 下學期考試 試卷一 英文版KILLUASONo ratings yet

- Semester One - 2024 - Year 8 MathsDocument19 pagesSemester One - 2024 - Year 8 Mathsbp5573373No ratings yet

- Long Test in TleDocument2 pagesLong Test in Tlecharo salanda100% (1)

- Similar Shapes and Enlargement 6+Document7 pagesSimilar Shapes and Enlargement 6+EffNo ratings yet

- Mtap Reviewer Grade 5 Set 1-9 2019Document19 pagesMtap Reviewer Grade 5 Set 1-9 2019Catherine MendozaNo ratings yet

- Wiley Problems in MATHEMATICS For JEE, Volume-1Document740 pagesWiley Problems in MATHEMATICS For JEE, Volume-1Anderson Alfred100% (2)

- NVS TGT SyllabusDocument3 pagesNVS TGT SyllabusSuresh SharmaNo ratings yet

- B3 Quiz 2 Review G1-G4Document2 pagesB3 Quiz 2 Review G1-G4danNo ratings yet

- Q3 Module 11 CLMD4ASTAT&PROB 135-146Document12 pagesQ3 Module 11 CLMD4ASTAT&PROB 135-146KyotieNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary EducationAaban AijazNo ratings yet

- Math 6 DLL Q3 Week 6Document10 pagesMath 6 DLL Q3 Week 6Julie Galamay SungaNo ratings yet

- Teaching Mathematics Creatively in The Junior Secondary ClassesDocument6 pagesTeaching Mathematics Creatively in The Junior Secondary ClassesGilbert MawufemorNo ratings yet

- EM - Math - G9 - T3 - I, II PP Ans - 2018Document4 pagesEM - Math - G9 - T3 - I, II PP Ans - 2018jasekanNo ratings yet

- Unit 2 - Horizontal Distance MeasurementsDocument22 pagesUnit 2 - Horizontal Distance Measurementsabdulrahman alsarmiNo ratings yet

- Past Board Exam Problems in Integral CalculusDocument5 pagesPast Board Exam Problems in Integral CalculusRomeo Nerio CepedaNo ratings yet

- PrPs Mock AMC 8 Official SolutionsDocument9 pagesPrPs Mock AMC 8 Official SolutionsPulkit SabharwalNo ratings yet