Professional Documents

Culture Documents

Guidelines for the Installation, Inspection, Maintenance and Repair of Structural Supports for Highway Signs, Luminaries, and Traffic Signals - Inspection and Evaluation - Bridge - Structures - Federal Highway Administration.pdf

Uploaded by

varam1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines for the Installation, Inspection, Maintenance and Repair of Structural Supports for Highway Signs, Luminaries, and Traffic Signals - Inspection and Evaluation - Bridge - Structures - Federal Highway Administration.pdf

Uploaded by

varam1Copyright:

Available Formats

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Bridges&Structures

GuidelinesfortheInstallation,Inspection,MaintenanceandRepairof

StructuralSupportsforHighwaySigns,Luminaries,andTrafficSignals

6.0BoltedConnections

Sign,signal,andlightingstructuresutilizeavarietyofboltedfastenersintheirconstruction.Theserangefrom

largeanchorrodsandhighstrengthboltedstructuralconnectionsto"secondary"fastenersforsigns,wind

beams,saddles,andthelike.FastenersalsoincludeUbolts,boltedclips,andsimilaritems.While

proceduresforinstallinghighstrengthboltsareestablishedinAASHTO,andrecommendedproceduresfor

anchorrodnutinstallationareprovidedherein,installationpracticesforothertypesofboltedfastenersvaries.

Ancillarystructuresaresubjecttovibrationduetofluctuatingwindloads.Unlessproperlytensioned,thiscan

causefastenerstobecomeloseandcontributetotheirfailure.Thoughtheimplicationoffailureofananchor

rodorboltinastructuralconnectionmayseemapparent,evensecondaryfastenersthatfailcanleadtosign

breakageandsmallitemsfallingintotraffic.Connectionsshouldbedesignedwithdueconsiderationofthe

fatiguestressesinducedbyvariationsinwindloads.

6.1HighStrengthBolts

Thedesign,specification,handling,installation,andinspectionofboltedjointsinsteelsupportstructures

shouldbeinaccordancewiththeSpecificationforStructuralJointsUsingASTMA325orA490Boltsdated

June,2000bytheResearchCouncilonStructuralConnections(RCSC).Onlyafewpointsespecially

importantforsupportstructuresarementionedintheseGuidelines.TheFederalHighwayAdministration

ReportNo.FHWASA91031,"HighStrengthBoltsforBridges"providesanindepthtreatmentofboltsupply,

installation,andtesting(thismanualisavailablefordownloadatfhwa.dot.gov/bridge).TheUboltsandother

detailsforconnectingluminaries,signs,andsignalheadstothestructurearenotdiscussed.The

manufacturersdesignthesedetails,andtherehavebeenfewproblemswiththesedetailsinthepast.

Structuraljointsforgalvanizedsteelsign,signal,andlightsupportstructuresshouldonlyutilizegalvanized

ASTMA325highstrengthboltsorgalvanizedASTMF1852twistofftype,tensioncontrolboltassemblies.

Thejointsshouldbebetweensteelmembers,anditisessentialthatthejointsbeproperlypretensionedto

resistvibration.Theseboltshaveaveryhighstrengthsothattheycansupplyhighforcestocompressthe

jointwhentheyaretightenedtotheirprescribedpretension.Thesejointsactuallycarryloadthrough

compressiongeneratedfrictiononthefayingsurfacesratherthanthroughthebolt.Thejoboftheboltisto

maintainthepretensionandtheassociatedprecompressionofthefayingsurfaces.

Whenapretensionedjointissubjecttocyclicfatigueloads,itactsasifthepiecespressedtogetherwere

actuallymonolithic(i.e.,theboltsthemselvesfeelonlyabout20percentoftheloadrange),withthemajority

oftheloadrangetransferredthroughthefayingsurfaces.Whenaboltedjointisnotproperlypretensioned,all

theloadrangeistransferredthroughtheboltsandtheymayquicklyfailbyfatigue.

GalvanizedASTMA325boltsandrelatedwashersandnutsareavailableeitherhotdipgalvanizedor

mechanicallygalvanized.Hotdipgalvanizingisrecommendedasitprovidesaheaviercoatingwith

correspondingincreasedlife.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

1/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

HeavyhexnutsshouldmeettherequirementsofASTMA563(GradeDHgalvanizedandlubricated)or

ASTMA194(Grade2Hgalvanizedandlubricated).Heavyhexnutdimensionsshouldmeettherequirements

ofANSI/ASMEB18.2.6.FlatgalvanizedcircularwashersshouldmeettherequirementsofASTMF436.

Washersshouldbeusedunderthenut.Iftheboltheadistobeturnedduringthetighteningprocedure,thena

washershouldalsobeprovidedunderthehead.Lockwashersshouldneverbeusedwithhighstrengthbolts.

Foroversizedholes,platewashers8mm(5/16inch)shouldbeusedratherthanflatwashers.Platewashers

shouldbestructuralgradesteelandshouldbegalvanized,ifusedwithgalvanizedfasteners.

Lockwashersshouldnotbeusedwithhighstrengthbolts.Theirvariabilityofdeformationunderloaddoesnot

provideforproperboltinstallationtension.

Compressiblewashertype,directtensionindicatorsshouldmeettherequirementsofASTMF959.Whenthe

directtensionindicator(DTI)isusedunderthenut,anASTMF436washershouldbeplacedbetweenthebolt

andthedirecttensionindicator.Whenthedirecttensionindicatorisusedunderthebolthead,anASTMF436

washerisrequiredundertheDTIwhentheDTIisplacedonanoversizedholeandbetweentheboltheadand

theDTIwhentheboltheadistheturnedelement.

Theboltlengthusedinaconnectionshouldbesuchthattheendoftheboltisflushwithorprojectingbeyond

thefaceofthenutwhenproperlyinstalled.

6.2StainlessSteelFasteners

Connectionsforstainlesssteelstructures,whicharerare,andaluminumstructuresutilizestainlesssteel

boltsandrelatedfasteners.Stainlesssteeloffersexcellentcorrosionresistance.

StainlessfastenersaremostoftensuppliedfromAmericanIronandSteelInstitute(AISI)Type304or316

stainlessmaterial.Type304isthemostcommon.Nutsandwashersshouldmatchthesteeltypeofthebolt

orfastener.StainlessfastenersshouldconformtotherequirementsofASTMF593,"StandardSpecification

forStainlessSteelBolts,HexCapScrews,andStuds"andASTMF594"StandardSpecificationforStainless

SteelNuts."Stainlesssteelboltsaresuppliedeitherhotfinishedorcoldfinished.ColdfinishedType304and

316boltshaveanultimatetensilestrengthof620MPa(90ksi),versus516MPa(75ksi)forhotfinished.

However,coldfinishedboltsareonlysuppliedifspecificallyspecifiedandarenotnormally"offtheshelf"

items.

Sinceinstallationtensionforstainlessfastenersisnotashigh,oraswellcontrolled,asitisforhighstrength

steelbolts,theuseoflockwashersiscommonwithstainlessfasteners.Lockwashersareplacedunderthe

nutandhelptoreducelooseningduetostructurevibrationandloadfluctuation.

6.3AluminumFasteners

Aluminumfastenersaresometimesusedformiscellaneousapplications,suchassignconnections.

Aluminumboltsarenotgenerallyusedinstructuralconnections,evenonaluminumsignstructures,duetoa

tendencytostretchandhenceloosenundercyclictensionloadings.

AluminumboltsshouldconformtoASTMB316"StructuralSpecificationforAluminumAlloyRivetandCold

HeadingWireandRods."Boltsareavailableinseveralalloytempers,with2024T4and6061T6themost

common.Offtheshelfboltsaretypicallyalloytemper2024T4,whichhasanallowableshearstressof96

MPa(14ksi)andanallowabletensionstressof158MPa(23ksi)asgiveninthe"AluminumDesignManual"

publishedbytheAluminumAssociation.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

2/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

6.4InstallationofBoltsandFasteners

Allboltsandmiscellaneousfastenersmustbeinstalledinaccordancewithestablishedindustrypracticeor

manufacturer'srequirements.Thoughnotdesirable,someprocurementpracticesmayresultinsignstructures

beingerectedbyfirmswithlittleexperienceinproperinstallationofhighstrengthbolts.Inaddition,unlessa

contractoriserectingagroupofsignstructures,onlyafewhighstrengthboltsmaybeneeded.Wherethe

quantityoffastenersissmall,itmaynotberealistictoexpectthesameboltdocumentationandtestingas

wouldbeprovidedonasteelbridgeerectionproject.

Fastenercomponentsshouldbeprotectedfromdirtandmoistureinclosedcontainersatthesiteof

installation.Fastenercomponentsshouldnotbecleanedoflubricantthatispresentintheasdelivered

condition.Componentsthataccumulaterustordirtresultingfromplantorjobsiteconditionsshouldnotbe

incorporatedintothework.Galvanizedboltsthathavebeenfullypretensionedshallnotbereused.

Acommonboltedconnectioninancillarystructuresconsistsofboltedflangeorfaceplatesthatmatchface

toface.Suchconnectionsoccurattrusschordsplices,longmastarmsplices,armtopoleconnections,and

similarlocations.Accordingtofabricators,itisalmostimpossibletoachieveaperfectlyflatfayingsurfaceon

theflangedconnectionthatmatesattheexactanglewithaperfectlyflatfayingsurfaceontheopposing

flange.Thefabricatorshouldselectaweldtypeandprocedurefortheplatetotube(ormember)connection

thatminimizesmisalignmentanddistortionofthefayingsurfaces.Asstatedabove,theslopeofthesurfaces

ofpartsincontactwiththeboltheadornut,andthefayingsurfaces,shouldbeequaltoorlessthan1:20with

respecttoaplanethatisnormaltotheboltaxis,but100percentmatingbetweenthetwoflangeswillusually

notbeachieved.Compressiblematerials(suchasgaskets,insulation,orsheetsofothermetals)shouldnot

beplacedbetweentheseflanges,eventotrytoachievebettercontact.Tighteningofboltsshouldbe

performedinamannerthatbringsthefayingsurfacesup"evenly."Forflangetypeconnections,astar

tighteningpatternasshowninFigure8isrecommended.

Figure8.StarPatternTighteningSequence.

Forhighstrengthboltedjoints,accordingtotheRCSC,thesurfacesneedtobebroughtintofirmcontact,but

itisacceptabletohaveisolatedareaswherethereisnocontact.Thefactthatgapsmayexistinthefaying

surfacesdoesnotpreventtheboltpreloadfrombeingdeveloped.Theendplatethicknessisenoughtobridge

thegapsanddevelopthedesiredbolttension.ThesnugtightenedconditionisdefinedbytheRCSCasthe

tightnessthatisattainedwithafewimpactsofanimpactwrenchorthefulleffortofanironworkerusingan

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

3/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

ordinaryspudwrenchtobringthepliesintofirmcontact.Thestructureshouldberejectedifthereismorethan

25percentofthesurfacevisiblynotincontactaftersnuggingthebolts.TheEngineerofRecordmayapprove

theuseofsteelshimsorrepairstothestructuretocorrectthisproblem.

ForhighstrengthboltedjointsusingASTMA325galvanizedbolts,allowablemethodsofinstallation,to

developtherequiredpretension,includetheturnofnutmethod,calibratedwrenchmethod,twistofftype

tensioncontrolboltmethod,ordirecttensionindicatormethod.ThesearedescribedinSection8oftheRCSC

Specification.ProceduresforeachinstallationmethodaredetailedinreportFHWASA91031,HighStrength

BoltsforBridges,AppendicesA2throughA6.Adetailedcoverageofhighstrengthboltingmayalsobefound

intheSteelStructuresTechnologyCouncil(SSTC)StructuralBoltingHandbook.

PreinstallationverificationtestingshouldbeperformedusingaSkidmoreWilhelmdeviceasindicatedin

Section7oftheRCSCSpecification.However,sinceancillarystructuresmaycontainonlyafewhigh

strengthbolts,thistestingisoftennotperformed.Highstrengthboltsshouldbeinspectedforproperbolt

tighteningasrequiredbytheRSCSSpecificationforthechosenmethodofboltinstallation.Theinspection

verificationdatashouldbeprovidedtotheowner'srepresentative.Whereconnectionsaremadeupoverhead

withonepiecesuspendedfromacrane,pretensioningandinspectionshouldbeperformedpriortoreleasing

theloadthusminimizinginducedstressesintothejoint.

Installationmethodsforfastenersotherthanhighstrengthstructuralboltsarenotstandardized.Aswithhigh

strengthbolts,properjointfitupthatdoesnotinducebendingintothebolts,selectionofproperboltlengthto

allowfullnutengagement,anduseofwashersmustbeadheredto.Itisrecommendedthatstainlessandmild

steelboltsbeinstalledtominimumtorquevalues.Thisatleastassuresaminimumbolttensionand

consistencybetweenmultipleboltsinaconnection.Itshouldbenotedthatitcouldbebeneficialtotheowner

toperformtorque/tensiontestingonnonstructuralboltstoestablishthetensionbeingprovidedforspecified

torques.Thiswouldallowformorecompletejointevaluation.

TheSpecialtySteelIndustryoftheUnitedStates(SSIUS)recommendsthatstainlessboltsbetightenedto

aninstallationtorquevaluethatvarieswithboltsizeasshowninTable3.

Table3StainlessSteelBolts

SizeDia,mm(in)

InstallationTorque

Type304KNmm(ftlb) Type316KNmm(ftlb)

12(1/2")

59(43)

62(45)

16(5/8")

127(93)

133(97)

20(3/4")

175(128)

181(132)

24(1")

393(287)

410(300)

GalvanizedmildsteelboltsandthreadedfastenerssuchasUboltsarealsousedinancillarystructures.

TheseincludetreadedfastenersconformingtoASTMA307aswellastotheSocietyofAutomotive

Engineers(SAE)Grades1and2.Typicalultimatetensilestrengthsarefrom420MPa(60ksi)to440MPa

(64ksi).ThesefastenersshouldbeinstalledtothetorquevaluesshowninTable4,andverifiedusinga

properlycalibratedtorquewrench.

Table4InstallationTorqueforMildSteelFasteners

BoltSize,Dia.mm(in) MinimumTorqueKNmm(ftLb)

10(3/8)

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

20(15)

4/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

12(1/2)

50(37)

16(5/8)

101(74)

20(3/4)

164(120)

22(7/8)

260(190)

Aluminumfastenersarenotrecommendedforstructuralconnections.Miscellaneousorsecondaryfasteners

ofaluminumshouldbeinstalledtotorquevalvessuppliedbythemanufacturer.

6.5AnchorRods

6.5.1General

Anchorrodsprovideattachmentofthestructuretoitsfoundation.Theycancarrylargeforces,particularlyfor

cantileverstructureswhereoverturningisresistedbyamomentatthebasewhichiscarriedthroughthe

anchorrodgroup.Thedesignandproperinstallationofanchorrodshastraditionallyreceivedlittletechnical

guidanceasitfellwhollyinneithertherealmofsteelstructuresnorconcretestructures.

The"SpecificationforSteeltoConcreteJointsUsingASTMF1554Grades36,55,and05SmoothAnchor

Rods,ASTMA615andA706Grade60DeformedBars,andAWSD1.1TypeBStuds"iscurrentlybeing

developedbytheResearchCouncilonStructuralConnectionsandmayeventuallybepublishedbythe

RCSC.Forthedesignstrengthoftheconcreteanchorage,thisspecificationreferstocurrentAmerican

ConcreteInstituteACI318criteria.Foruseinhighwayancillarystructures,theACIloadfactorsand

resistancefactorsmaybemodifiedbytheStatetobeconsistentwithAASHTOdesignprovisions.NCHRP

Report469alsoprovidesguidance.

6.5.2Materials

AnchorrodsaresuppliedinconformancewithASTMF1554"StandardSpecificationforAnchorBolts,Steel,

36,55and105KsiYieldStrength."ASTMF1554providesforthreedifferentgradesofanchorrods:Grade36

(paintedblueontheprojectingend),Grade55(paintedyellowontheprojectingend),andGrade105(painted

redontheprojectingend).Thespecifiedminimumyieldstrength(Fy)andspecifiedminimumtensilestrength

(Fu )foreachGradearegiveninTable5.

Table5TensilePropertiesforAnchorRods

TensileProperty

MinimumYieldStrengthFy,

ASTMF1554 ASTMF1554

ASTMF1554

ASTMA706

RodGrade36 RodGrade55 RodGrade105 BarsGrade60

248(36)

380(55)

720(105)

415(60)

400(58)

516(75)

860(125)

550(80)

MPa(ksi)

MinimumtensileStrengthFu ,

MPa(ksi)

ASTMF1554waspassedin1994,andisessentiallythesameasAASHTOM31490,althoughthereare

somedifferences.ASTMF1554Grade36isessentiallythesameasASTMA36orASTMA307GradeC,

andASTMF1554Grade105isequivalenttoASTMA193GradeB7.ASTM1554supercedesthese

specifications,andtheolderspecificationsshouldnolongerbereferencedforanchorrods.TheASTMA325

orA490specificationsshouldnotbespecifiedforanchorrods.TheA325andA490boltsareintendedforuse

instructuralconnections.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

5/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Sincethefatiguestrengthofthesevariousgradesofanchorboltsisthesame,itisusuallynotworthwhileto

usetheGrade105anchorrods.Ifanexistingsupportstructure(notdesignedforfatigueinaccordancewith

the2001Specifications)hasGrade105anchorrodsthatweredesignedforstrengthonly,thesizeofthe

anchorrodsmaybemuchlessthanwouldbethecaseifGrade55orGrade36anchorrodswereused.

Consequently,thestressrangesintheseGrade105anchorrodsmaybemuchgreater,makingthem

particularlylikelytoexperiencefatiguecracking.Grade105anchorrodsshouldbeespeciallyevaluatedto

seeifstressrangescalculatedusingthe2001Specificationsarelargeenoughthatfatiguewouldbeexpected

tooccurquickly.Ifso,aninspectionoftherodsusingultrasonictestingmethodsmaybewarranted.

Forsimilarreasons,theuseofanchorrodsconformingtoASTMA722withminimumtensilestrengthof150

ksishouldbediscouraged,butmayoccurinsomeexistingstructures.Wheresuchrodshavebeenused,an

inspectionusingultrasonicsshouldbeperformed.

Anchorrodsarenormallysuppliedinoneofthefollowingshapes:

Bentanchorrods.TheserodsareF1554smoothanchorrodswiththeembeddedendbentastoform

ahook(Figure9).Theanchoragetotheconcreteisbymeansofthehook.Theadherencebetweenthe

shankandtheconcreteisnotreliableandshouldnotbecountedindesign.Grade105bentrods

shouldbeavoidedbecausetheyhavebeenshownbyJirsa,et.al.tostraightenbeforetheyreachany

othermorepredictablesteelorconcretemodeoffailure.

Headedanchorrods.TheserodsareF1554smoothanchorrodswithaheadintheembeddedend

(Figure10).Theanchoragetotheconcreteisobtainedbythehead.Typically,the"head"consistsof

oneormorenuts,witheitherheavywashersoraplatewasher.Forlightlyloadedanchorages,headed

studscouldalsobeutilized.

Deformedbars.Concretereinforcingbars(ASTMA70696,StandardSpecificationforLowAlloySteel

DeformedandPlainBarsforConcreteReinforcementmaybethreadedandusedforanchorrods.

OrdinaryreinforcingbarsconformingtoASTMA61596,StandardSpecificationforDeformedandPlain

BilletSteelBarsforConcreteReinforcementhavebeenusedinthepast.However,becauseof

possiblelowtoughness,ordinaryreinforcingbarsshouldnotbeusedfornonredundant,fatigue

susceptiblesupportstructuressuchascantileversandhighmastluminaries.Reinforcingbarsmay

relyonthedeformationsalongthebarforanchoragetotheconcrete,mayincludeanACIstandard

hook,ormaybethreadedontheembeddedendandutilizenutsandawasherforanchorage.The

tensilepropertiesofcommonGrade60reinforcingbarsarealsogiveninTable5.TheA706

specificationshouldbeusediftheanchorrodistobeweldedorusedinseismicapplications.

L=lengthofrod

Lh=lengthofhook

t=lengthofthreads

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

6/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Figure9.BentAnchorRod.

L=lengthofrod

H=heightofnutorhead

F=widthacrossflatsofheaddiameter

t1 =lengthofthreads(exposedend)

t2 =lengthofthreads(embeddedend)

Figure10.HeadedAnchorRod.

TheuseofUniformNationalCoarse(UNC)threadsarerecommended,especiallyforgalvanizedanchorrods,

althoughASTMF1554alsopermitsthelesscommon8UNseriesthreads.Thefullrangeofdiameters(1/4to

4inches)ofanchorrodswithUNCthreadscantheoreticallysustaintheovertappingofcorrespondingnuts

(requiredtoallowforzinccoatingfromgalvanizing)withoutstripping,whilethismaynotbetruefor8UN

threads.Itshouldbenotedhowever,thattheMichiganDepartmentofTransportationfeelsthattheuseof8

UNthreadsisadvantageous.Theyhavenotexperiencedanyproblemswiththreadstripping.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

7/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Thethreadclass(tolerances)oftheanchorrodsshouldalsobespecified,andtypicallyClass2Ais

satisfactory.Class2Awillbeprovidedbydefaultifclassisnotspecified.

NutsontheembeddedorprojectedendoftheanchorrodshouldconformtoASTMA563nuts.The

recommendednutstyle,gradeandfinishareshowninTable6.Thistableisbasedontheappendixofthe

ASTMA563specification.

Table6AcceptableASTMA563Nut,Grade,FinishandStyleAndASTMF436WasherTypeandFinish

forThreadedAnchorRods

Anchor

Rod

AnchorRod

Sizemm(in.)*

F1554

Grade36

638

(1/411/2)

Finish

ASTMA563NutStyle,GradeandFinish

Plain

Hex:A,B,D,DHplainHeavyHex:A,B,

(uncoated)

DC,C3,DC,DHd ,Dh4:plain

Galvanized

Hex:A,B,DC,DHd Galvanizedand

ASTMF436Washer

TypeandFinishb

1plain

1galvanized

lubricated

HeavyHex:A,B,CC,C3,DC,DHd ,Dh4

galvanizedandLubricated

Over38100

(11/24)

Plain

(uncoated)

HeavyHex:A,B,CC,C3,DC,

Galvanized

HeavyHex:A,B,CC,C3,DC,

1plain

DHd ,Dh4plain

1galvanized

DHd ,Dh4galvanizedand

Lubricated

F1554

Grade55

638

(1/411/2)

Plain

Hex:A,B,DC,DHd plainHeavyHex:A,

(uncoated)

B,CC,C3,DC,DHd ,Dh4plain

1plain

Galvanized HeavyHex:A,B,CC,C3,DC,DHd ,Dh4

1galvanized

galvanizedandLubricated

A706

Grade60

Over38100(1

1/24)

Plain

HeavyHex:A,B,CC,C3,DC,DHd ,Dh4

(uncoated)

plain

1plain

Galvanized HeavyHex:A,B,CC,C3,DC,DHd ,Dh4

1galvanized

galvanizedandLubricated

F1554

Grade

105

638

(1/411/2)

Plain

(uncoated)

Hex:DC,DHd plainHeavyHex:CC,C3,

Galvanized

HeavyHex:DHd ,Dh4galvanizedand

1plain

DC,DHd ,Dh4plain

1galvanized

lubricated

Over38100

11/24

Plain

(uncoated)

HeavyHex:DHd ,Dh4plain

1plain

Galvanized

HeavyHex:DHd ,Dh4galvanizedand

1galvanized

lubricated

a ApplicableonlytoF1554Grade55anchorrods.

b Applicableonlyifwasherisrequired.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

8/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

cASTMA194nutsGrade2or2HareacceptableequivalentsforGradesCandDnuts.

d ASTMA194nutsGrade2HareacceptableequivalentsforGradesDHnuts.

*Note:Metricboltsizesandthreadsaredifferent,forsoftconversion1inch=25mm

Corrosionprotectionisparticularlyimportantforfatiguecriticalanchorrods,sincecorrosionpittingcan

degradethefatigueresistance.Anchorrods,nuts,andwashersthatareusedoutdoorsaretypically

galvanized.ASTMF1554permitshotdipgalvanizingbyASTMA153ClassCormechanicallydepositedby

ASTMB695,Class50.Thepurchasershouldspecifywhichoftheseprocessesshouldbeusedorstate"no

preference."Thehotdipprocessprovidesaheavierzinccoatingandlongerlife.Galvanizeddeformedbars

maybeusedandshouldbespecifiedbyreferencingASTMA767.Galvanizedanchorrodsshouldalwaysbe

shippedwiththenutspreassembledtotheanchorrodstoensuregoodfitandabilitytorunthenutdownthe

threadseasily.ThisshouldbespecifiedinthepurchaseorderbecauseitisnotrequiredintheASTM

specifications.

Therearetwotypesofwashersforanchorrods:standardwashersandplatewashers.Standardwashersare

ASTMF436washers.When"NormalHoles"areused,platewashersatleast5/16inchthickshouldbeused.

Platewashersshouldbestructuralgradesteelandbegalvanizedtomatchtheanchorrods.Beveledstandard

washersshouldbeusedwhentheouterfaceofthebaseplatehasaslopethatisgreaterthan1:20with

respecttoaplanethatisnormaltotheanchoraxis.Ifananchorboltisincorrectlyinstalledresultinginlarger

outofplumbness,speciallyfabricatedwashersmaybeneededtoallowproperbearingoftheconnected

parts.

6.6BasePlateandHoles

ResearchdescribedinNCHRPReport412hasshownthatthebaseplateshouldbeatleastasthickasthe

anchorroddiametertoprovideforevendistributionoftheloadandtominimizepryingforces.Theminimum

distancefromthecenteroftheanchorrodholetotheedgeofthebaseplateshouldbetwotimesthenominal

diameteroftheanchorrod.

Baseplatesarenormallysuppliedshopweldedtothepostsorpole.Themostcommonpoletobaseplate

connectionisaweldsocketjoint,wherethecentralportionofthebaseplateiscutoutsothepolecanslip

intotheopening.Asaresult,particularlyforlargediameterpolessuchashighmastlights,thebaseplateis

inrealityabaseringwitharesultingdecreaseinplatebendingstiffness.Fieldinspectorshavereported

observingthebaseplatesactuallyflexbetweenanchorrodsforhighmastlightsduetonormalwindloads.

Thistendencycanbereducedbyuseofalargernumberofanchorrodsorathickerbaseplate.

Holesmaybethermallycutinthebaseplates.Inmostcases,theanchorrodholesinthebaseplateshould

be"ShearHoles"withthedimensionsshowninTable7,asrecommendedinNCHRPReport469.Research

byCookhasshownthatthissizeofholeisadequateforacorrecttransferofshearforcesfromthebaseplate

totheanchorrodsandtoallowplasticredistributionofshearforces.Ontheotherhand,ifanchorrodsarenot

requiredtotransfershear,onlyholeslabeledas"NormalHoles"inTable7areneeded.Thesenormalholes

arethesameholesrecommendedintheAISCManualofSteelConstructionforbaseplates.Theyare

oversizedtoallowforaneasyplacementofthebaseplateduringerection.

Table7NominalAnchorRodHoleDimensions

AnchorRodDiameterIn.* NominalAnchorRodHoleDimensionsa,b,in.*

ShearHoles

(diameter)

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

NormalHoles

(diameter)

9/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

1/2

5/8

11/16

5/8

13/16

13/16

3/4

15/16

15/16

7/8

11/16

19/16

11/4

113/16

11/4

19/16

21/16

11/2

113/16

25/16

13/4

21/16

23/4

>2

db +5/16

db +11/4

a Theuppertoleranceonthetabulatednominaldimensionsshallnotexceed1/16in.

b Theslightlyconicalholethatnaturallyresultsfrompunchingoperationswithproperlymatched

punchesanddiesinacceptable.

*Note:Metricboltsizesandthreadsaredifferent,forsoftconversion1inch=25mm

6.7AnchorRodJoints

Thereareseveraltypesofjointsforthebaseplatetofoundationconnection.Thesehaveevolvedwithin

particularindustries,withthesocalledthreadedshearandupliftjointanddoublenutmomentjointusedfor

nearlyallancillarystructures.Thesearecosteffectiveandprovidegoodperformancewhenproperlydesigned

andinstalled.

Thethreadedshearandupliftjointrestsdirectlyontheconcreteoronagroutpad(Figure11).Thebaseplate

ishelddownbynutsatopthebaseplate.Singlenutsaremostcommon,butdoublenutsaresometimes

used.Forproperjointperformance,thebaseplatemustbeindirectcontactwiththegroutandnotbe

supportedbylevelingnutsorshimpacts.Onetechniquetoachievefullgroutsupportistosetthebaseon

shimpactstoproperelevation,groutthebaseandthenremovetheshimsandgrouttheresultingvoids.Only

thencantheanchorrodsbefullypretensioned.Useofproprietaryprepackagedgroutmixes,socalled"non

shrinkgrout"isrecommendedandshouldbecarefullyinstalledtomanufacturers'recommendations.The

threadedshearandupliftjointscandevelopsomeresistancetobendingmomentasacouplebetween

compressivebearingforceonthegroutandtensileforcesintheanchorrods.Itmaybedifficulttoretainthe

pretensionintheanchorrodsundercyclicloadsasthebaseplatewearsthegrout.Forthesereasons,this

typeofjointisnotrecommendedbyNCHRPReport469forlargecantileveredsupportstructures,althoughit

isstillcommonlyusedformanyluminariesandsmalltrafficsignalsupports.Thistypeofjointissuitablefor

bridgesupportstructureswheretherearemultipleposts.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

10/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Figure11.ThreadedShearandUpliftJoint.

Allthreeshapesofanchorrodswillperformcorrectlyinthistypeofjoint.Theanchorrodstransmitshearand

tension,whilecompressionforcesaretransmitteddirectlybybearingofthebaseplateontheconcreteand

arenotcarriedbytheanchorrods.Asaresultofthecompressionontheconcrete,frictionwillbedeveloped

betweenthebaseplateandtheconcrete.Shearfrictionstrengthshouldbecalculatedusingthefactoredload

combinationthatgivesminimumpossiblecompressionfromdeadloadalongwiththemaximumupliftthatis

consistentwiththelateralloadthatisbeingevaluated.Theeffectofliveloadshouldnotbeincludedwhen

calculatingtheshearfrictionstrengthunlesstheliveloadcausesthelateralloadoruplift.

Ifthefrictionstrength,isgreaterthanthefactoredappliedshearortorsiononthejoint,anchorrodsarenot

neededfortransmittingshearortorsion.Infact,ifthefrictionissufficienttohandletheshear,andifthereis

nouplift,thenanchorrodsare,intheory,notneededatallforserviceloads.Inthiscase,anchorrodsmust

beprovidedforstabilityduringerectionbutneednotbedesignedfortheserviceloads.Iftheanchorrodsare

designedonlyforthefactoredloadsduringerection,NCHRPReport469recommendsincludingaminimum

lateralshearloadequalto5.0percentoftheaxialloadfromdeadloadduringerection.Theanchorrodsmust

alsoresistaminimummomenttoaccountforanironworkeronthepoleasrequiredbyOSHA.

If,ontheotherhand,thefactoredloadsexceedthefrictioncapacityofthejoint,anchorrodsshouldbe

assumedtotransmittheentireshearbecausethefrictionmaynolongerbeeffectiveatthedeformationlevels

requiredtodeveloptheshearstrengthoftheanchorrods.Theshearstrengthoftheanchorrodsmaybe

takenasthesmallerofthesumofthesteelshearstrengthsofthecontributingindividualanchorrodsorthe

concreteshearstrengthoftheanchorgroup.

Wheneveranchorrodsareneededfortransmittingshearinthistypeofjoint,thebaseplateshouldhaveshear

holes.Also,inthesamecase,bearingoftheanchorrodonthewallsoftheshearholesshouldbechecked.

Asanoption,normalholescanbeprovidedinthebaseplateandplatewashershavingshearholescanbe

placedovertheanchorrodsandfieldweldedtothebaseplateafterthebaseisset.Theplatewashersand

weldsmustbedesignedtotransmitallcalculatedshearforcesandweldingmustconformtoapplicable

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

11/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

portionsoftheAWSBridgeWeldingCode.

Indoublenutmomentjoints,thebaseplatestandsofffromtheconcretefoundationandbearsonleveling

nuts(Figure12).Thus,thebaseplateisattachedtoanchorrodsthroughdoublenuts:thelevelingnutanda

topnut(ornuts).Thistypeofjointmaybesuitableforanytypeofsupportstructureandisrequiredfor

cantileveredsupportstructuresdesignedbythe2001Specifications.Washersshouldbeusedunderboth

nuts,andbeveledwashersshouldbeusedifthemisalignmentexceeds1:40forthedoublenutmoment

joints.Doublenutmomentjointsareeasytolevelandplumbandarealsoveryreliablefortransmitting

momenttothefoundationtherefore,theyaresatisfactoryfornonredundantstructuresandseismicor

fatigueloadedstructuressuchashighwaysign,signal,andlightsupports.

Figure12.DoubleNutMomentJoint.

Doublenutjointsarepretensionedbetweenthenutsonly,andthepretensionhasnoeffectonstrength.

ResearchreportedinNCHRPReport412hasshownthatthepretensiongivesslightlybetterfatigue

resistance,buttheeffectisnotthatsignificant.Theanchorrodbelowthelevelingnutisnotpretensionedbut

willstillseethefullcycleoffatigueloads.Moreimportantly,thepretensionensuresthatthereisagoodload

distributionamongthevariousanchorrods.Therefore,therearespecialtighteningproceduresforthesejoints.

Headedrodsanddeformedbarsarebestsuitedfordoublenutmomentjoints.Indoublenutmomentjoints,

anchorrodsaredesignedtoresistalltheaxialforces,moments,andshearsappliedtothejoint,evenifthere

isgroutunderthebaseplate.

Opinionsonwhetherornotgroutshouldbeusedwithdoublenutmomentjointsdiffer.Asnotedabove,ina

properlydesignedjoint,allloadsareresistedintheanchorrods.Duetothegreaterstiffnessoftheanchor

rodscomparedtothegrout,andthetendencyofthegrout,evenforsocalled"nonshrinkgrouts",toshrink,

thoughperhapsimperceptibly,belowthebottomofthebaseplate,littleloadtransfertothegroutislikelyeven

ifassumedsoindesign.Grout,ifwellinstalled,maypickuploadsduetoveryhighorunexpectedload

cases.Propergroutinstallationisdifficultwhenbaseplatestendtoberings,aswithlargelightpoles.A

meansmustbeprovidedtorestrictgroutflowinsidethebaseringwhilefullyfillingbeneathit.Forthese

reasons,andseverallistedbelow,groutingofdoublenutmomentjointsisgenerallynotrecommended:

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

12/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Itmaycrack,retainmoisture,andthenpromotecorrosion.

Itmakesitimpossibletoinspectandretightenbottomnutsifnecessary.

Inordertoplacethegroutafterthebaseplateisinplace,thestandoffdistancebetweenthetopof

concreteandthebottomofthelevelingnutmayexceedtherecommendeddistanceequaltothe

anchorroddiameter.

Wherebaseplatesarenotgrouted,astainlesssteelwiremeshshouldbeplacedaroundthebaseplateto

eliminatedebrisfromaccumulatingbeneaththebaseplateandkeepanimalsoutandprotectelectricalwiresif

present.

Thereisanunfortunatetrendtowardusingfewerverylargeanchorrods.Itisalwaysbettertousemore,

smalleranchorrodsthanfewer,biggeranchorrods.Especiallyifthefailuremodeisfatigueandthestructure

isnonredundant,itisessentialtohaveatleasteightanchorrodsintheanchorrodgroup.Intheeventofone

anchorrodfailurefromfatigue,theincreaseintheloadontheneighboringanchorrodsistolerableforthe

caseofaneightboltgroup,andtherewillbeweeksormonthstypicallybeforeasecondanchorrodfailsand

totalcollapseoccurs.Thisgivesthejointsomemeasureofredundancy,evenifthestructureisnon

redundant.Thefatiguefailureofoneanchorrodfromasixorfourboltgroup,however,mayleadtoimmediate

collapse.

IftheembeddedheadofanASTMF1554anchorrodisanutorisfastenedwithnuts,theheadnutorthe

nutsfasteningtheheadshouldbepreventedfromrotatingwhiletheanchorrodistightened.Twomethods

havebeenshowntopreventrotation:

Tackweldthenuttotheanchorrodontheunstressed(bottom)sideofthenutiftheASTMF1554rod

isagrade36rodoragrade55rod.

JamanothernutontheheadnutforanygradeofASTMF1554rod.

Neitherthetackweldnorthejamnutwillaffecttheultimateorfatiguestrengthoftherod.

6.8InstallationofAnchorRods

Properinstallationoftheanchorrodsistheresponsibilityofthefoundationcontractor,andinspectionand

testingistobeperformedbythefoundationcontractor.Recordsshouldbekeptofthedatesandresultsof

testingandinspection,andtheserecordsshouldbeavailablefortheEngineerofRecordortheir

representativetoreview.TheEngineerofRecordmayrequirethattheirrepresentativewitnesstheinspection

andtesting.

Priortoplacingtheanchorrodsintheconcrete,ananchorrodrotationcapacitytestshouldberunwithat

leastoneanchorrodfromeverylot.ThistestmayberuninaSkidmoreWilhelmdeviceorinamockupofthe

baseplateusingasmallpieceofplatewithoneholeofequivalentgrade,thickness,andfinish.Thetest

consistsofSteps2through14ofthetighteningprocedure(presentedlater),adaptedasnecessarybecause

thereisnopostorcrane,andthereisonlyoneanchorrod.NCHRPReport469recommendsthatthenutbe

rotatedatleasttotherequiredrotationgiveninTable8.Afterthetest,thenutsshouldberemovedand

inspectedfordamagetotheirthreads.

Thentheanchorrodisremovedfromthetestplateandrestrainedwhilethenutsareturnedontotheboltswell

pastthelocationofthelevelingnutandtopnutinthetestandbackedoffbyoneworkerusinganordinary

wrench(withoutacheaterbar).Thethreadsareconsidereddamagedifmorethanminimaleffortisrequiredto

turnthenut.Ifthereisnodamagetotheanchorrodornutduringthistest,theymaybeusedinthe

foundation.Ifthereisdamagetothethreadsoraninabilitytoattainatleasttheverificationtorque,thelotof

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

13/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

anchorrodsshouldberejected.

Thoughthistestingmaynotbepracticalonsmallprojects,itisrecommendedwhereeconomicallyjustifiable

onlargerprojects.

Table8NutRotationforTurnOfNutPretensioning

AnchorRodDiameter,in*. NutRotationfromSnugTightConditiona,b,c

F1554Grade36

F1554Grades55and105

A615andA706Grade60

<11/2

1/6Turn

1/3Turn

>11/2

1/12Turn

1/6Turn

a.Nutrotationisrelativetoanchorrod.Thetoleranceisplus20degrees.

b.Applicableonlytodoublenutmomentjoints.

c.Beveledwashershouldbeusedif:a)thenutisnotinfirmcontactwiththebaseplateorb)

theouterfaceofthebaseplateisslopedmorethan1:40.

Therecommendedprocedureforinstallinganchorrodsinthefoundationisasfollows:

1. Anchorrodsshouldbeinstalledasagroupandshouldbesecuredagainstrelativemovementand

misalignment,suchaswithatemplatesetcomposedofringswithnutsonbothsidesattwolocations

alongthelengthoftheanchorrods.Oneoftheplatesorringsisusuallyabovethetopofconcreteand

isreusedasatemplate,seeFigures13and14.

2. Thetemplateset(orotherdevice)withanchorrodsshouldbesecuredinitscorrectpositionin

accordancewiththedrawings.

3. Theconcreteshouldbeplacedandcured.

Figure13.FourAnchorRodGroupinaTemplate.NoteTopisGalvanized.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

14/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Figure14.TemplateSecuredtotheFormstoEnsureProperAlignment.NoteAnchorRod

ThreadsTapedtoPreventContaminationbyConcrete.

4. Ifatoptemplateisabovetheconcretesurface,itmayberemoved24hoursafterplacingtheconcrete.

5. Theexposedpartoftheanchorrodsshouldbecleanedwithawirebrushorequivalentandlubricated

withbeeswaxortoiletringwax.

6. Afteratleast24hours,theanchorrodsshouldbeinspectedvisuallytoverifythatthereisnovisible

damagetothethreadsandthattheirposition,elevation,andprojectedlengthiswithinthetolerancesof

theAISCCodeofStandardPracticeforSteelBuildingsandBridgesandthatthemisalignmentfrom

verticalisnomorethan1:40.Itisgoodpracticetouseasteelorwoodtemplatewiththeholepattern

tocheckthebaseofthepostandtheanchorrods.Thenutsshouldbeturnedontotherodswellpast

theelevationofthebottomofthelevelingnutandbackedoffbyoneworkerusinganordinarywrench

withoutacheaterbar.

7. Oncetheconcretehasreachedsufficientstrength,anchorrodsarereadytobesubjectedtoerection

loads.

6.9ProcedureforAnchorRodTighteningandFollowUpRetightening

Anchorrodjointsrequiresomelevelofpretensioning.Onlyinstallationofdoublenutmomentjointsiscovered

inthissectionsincesinglenutjointsaregenerallynotrecommendedforlargecantileveredstructures.

Requirementsforfatigueloaded,threadedshearandupliftjointsmaybederivedfromtheinstallation

requirementsofdoublenutmomentjoints.

The"turnofthenut"methodisprimarilyreliedupontoachieveacertainpretensionbetweenthedoublenuts

oftheanchorrods.Althoughtorqueisapoorwaytoinstallboltsandanchorrods,itistheonlyalternativefor

definingsnugtightconditions,inspection,andretightening.Lubricationofthethreadsoftheanchorrod,the

threadsofthenut,andthebearingsurfaceofthenutisrequiredforproperinstallation.Beeswaxandtoilet

ringwaxhavebeenshowntoprovidegoodlubrication.Inthisdocument,thesnugtightconditionforanchor

rodsisdefinedasnutstightenedtoatorquebetween20and30percentoftheverificationtorquecomputed

usingthefollowingequation:

Tv=0.12db FI

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

15/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Where

Tv=verificationtorque(inchkipsorkNmm)

db =nominalbodydiameteroftheanchorrod(inchesormm)

FI=installationpretension(kipsorkN)equalto50percentofthespecifiedminimumtensile

strengthofF1554Grade36rods,and60percentfortherestofthreadedfasteners.

ResearchbyTillandLefkehasshownthatavalueof0.12inthisrelationshipisadequateforcommonsizes

andcoatingsofanchorrods.(Note:thetorquein"inkips"canbemultipliedby83.3togetftlbandthetorque

inkNmmcanbemultipliedby0.73togetftlb).

Verylargetorquemayberequiredtoproperlytightenanchorrodsgreaterthan24mm(1inch)indiameter.A

"cheaterbar"suchasapipeorextensionhandleasmuchas3meters(10feet)longmayberequiredforthe

torquewrench.Forsnuggingthelevelingnuts,anopenendwrenchwitha3meter(10feet)longpipeor

extensionhandlewilltypicallysuffice.Tighteningthetopnutsforanchorrodsgreaterthan1inchindiameter

mayrequireeitherofthefollowing:

Ahydraulictorquewrench(Figure15)or

Aboxend"slug"or"knocker"wrenchwitha3meter(10ft),longpipeorextensionhandle.

Figure15.AHydraulicTorqueWrenchTighteningAnchorRodNutstoAchieveNeededRotation.

Theboxendwrenchmaybemovedbyimpactwithasledgehammerorbytheeffortsofseveralworkers.

Inadequatelytightenedboltscanleadtofatiguefailuresandfurtherlooseningofthenutsundercyclicloading.

Alesslikelyoutcomeoffailuretofollowthetighteningprocedureisovertightenedrodsandassociated

plasticdeformationandstrippingofthethreads,whichmayrequireremovalandreplacement.

Thefollowingstepsprovidearecommendedanchorboltinstallationandtighteningprocedure:

1. Theproperpositionoftheanchorrodsandtheproperholepatternonthepostareverified(preferably

withatemplate).

2. Itshouldbeverifiedthatthenutscanbeturnedontotherodswellpasttheelevationofthebottomof

thelevelingnutandbackedoffbyoneworkerusinganordinarywrenchwithoutacheaterbar.

3. Ifthreadsofanchorrodswerelubricatedmorethan24hoursbeforeplacingthelevelingnutorhave

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

16/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

beenwetsincetheywerelubricated,theexposedthreadsoftheanchorrodshouldberelubricated.

Levelingnutsshouldbecleaned,threadsandbearingsurfaceslubricated.

4. Thelevelingnutsareplacedontheanchorrodsandmadelevel.

5. Levelingnutwashersshouldbeplaced.

6. Next,thepostorendframeisbroughtinandpositionedwithacrane.

7. Thepostorendframeisplumbedorthebaseplateleveled(asshownontheerectiondrawings)and

theanchorrodsaretightened.Thefollowingistheinstallationsequencefordoublenutmomentjoints

usingthe"turnofthenut"methodofpretensioning.

8. Topnutwashersshouldbeplaced.

9. Threadsandbearingsurfacesofthetopnutsshouldbelubricated,placed,andtightenedtothesnug

tightconditioninastarpattern.

10. Levelingnutsshouldbetightenedtothesnugtightconditioninastarpattern.

11. Atthispoint,theinstallationcrewshouldverifyifbeveledwashersarenecessary.Beveledwashers

maybenecessaryunderthelevelingortopnutifanyfaceofthebaseplatehasaslopegreaterthan

1:20and/oranynutcouldnotbebroughtintofirmcontactwiththebaseplate.Ifanybeveledwasheris

required,theinstallationcrewshoulddisassemblethejointasnecessary,addthebeveledwasher(s)

andretighten(inastarpattern)tothesnugconditiontopandlevelingnuts.

12. Beforeturning,thereferencepositionofthetopnutinthesnugtightconditionshouldbemarkedwitha

suitablemarkingononeflatwithacorrespondingreferencemarkonthebaseplateateachbolt.Top

nutsshouldbeturnedinincrementsinastarpattern(atleasttwofulltighteningcycles)tothenut

rotationspecifiedinTable8.Aftertightening,thenutrotationshouldbeverified.

13. Theloadmaybereleasedfromthecrane.

14. Atorquewrenchshouldbeusedtoverifythatatorqueatleastequaltothecomputedverification

torque,Tv,isrequiredtoadditionallytightenthelevelingnutsandthetopnuts.Aninabilitytoachieve

thistorqueshouldbeinterpretedtoindicatethatthethreadshavestrippedandshouldbereportedto

theEngineerofRecord.

15. Afteratleast48hours,thetorquewrenchshouldbeusedtoverifythatatorqueatleastequalto110

percentoftheverificationtorque,Tv,isrequiredtoadditionallytightenthelevelingnutsandthetop

nutsontheanchorrods.Aninabilitytoachievethistorqueshallbeinterpretedtoindicatethatthe

threadshavestrippedandshouldbereportedtotheEngineerofRecord.

16. Thenutsontheanchorrodsshouldbepreventedfromlooseningunlessamaintenanceplanisinplace

toverifyatleastevery4yearsthatatorqueequaltoatleast110percentoftheverificationtorque,Tv,

isrequiredtoadditionallytightenthelevelingnutsandthetopnuts.Jamnutsorotherlockingdevices

maybeusedtopreventnutloosening.

Tackweldingthenuttotheanchorrodontheunstressed(top)sideofthetopnuthasbeenusedsuccessfully

topreventlooseningortopreventtheftofthenuts,althoughthiswouldnotbeallowedunderAWSD1.1and

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

17/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

thereforecannotberecommended.Ifitisused,onlyASTMFl554Grade36orGrade55rod,orGradeA706

reinforcingbarshouldbetackwelded.Undernocircumstanceshouldanynutbetackweldedtothewasheror

thebaseplatenorshouldthelevelingnutbetackwelded.

7.0ManagementofInventory

Collectionofinventoryinformationandtheabilitytoorganizeandcategorizetheinventoryisparamountforan

ancillarystructureinspectionprogram.Thissectiondetailscollectionofsuchinformationanddevelopmentof

ausefuldatabase.

7.1CollectionofInventoryInformation

Oneofthebiggestproblemsininspectionofancillarystructuresisthelackofinformation.Rarelyarethe

structuresnumberedforeasyidentification.Historicalrecordssuchasasbuiltplans,maintenancerepairs,

andinstallationofnewsignpanelsarehardtofind.Onlynowaremanystatesbeginningtoassignstructures

numbersduringdesignand/orfabricationsimilartobridgestructures.Suchrecordsareveryimportantdueto

themanychangestothedesignspecificationsofsignstructuresovertheyears.Anotherproblemisthat

fabricatorshavesubstituteddesigndrawingswiththeirownshopdrawings.Whilethisisanacceptable

practice,itaddsanotherlayerofdocumentationthatismanytimeslost.

Forthesereasonstheinitialcollectionofinventoryinformationonancillarystructuresiscritical.Keypiecesof

informationincluderoute,milepost,GPScoordinates,routeassociation(ifnotonmainline),county,town,etc.

Photosandsignmeasurementsareimportanttohelpidentifystructures,asseeninFigure16.Thefollowing

sectionondatabasedevelopmentgivesacompletelistingthathasbeenusedinNewJerseyforinventory

purposes.

Figure16.InspectorMeasuresSignPanelDuringInventory/InspectionOperation.

7.2DatabaseDevelopment

Thelargeamountofdatacollectedtoproperlyinventoryasignstructurewarrantsasophisticateddatabase

thatcansortandprioritizeaccordingtostructuretype,age,location,material,ratingsandrepairpriorities.

Thegoalistohaveadatabaseusefultothefieldinspector,programmanager,andmaintenanceandrepair

personnel.Eachcanthendrawontheirdesiredinformation.Thedatabasecanbeasimplespreadsheetbut

usuallyinvolvesamoresophisticatedprogramlikeMicrosoftAccessorOracle.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

18/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

7.3ExampleInventoryChecklist

ThechecklistbelowisreferencedfromtheNewJerseyDepartmentofTransportationOverheadSign

DatabaseProgram.Theseareitemsdeemedimportanttothatparticularagency,andwillofcoursevary

somewhatwithindividualStateneeds.Manyitemsinvolvethephysicallocationofthestructure,the

personnelinvolvedwiththeinventory/inspection,specificsaboutthestructureitself,importantdimensions

andattachments.

NJDOTRequiredInventory/InspectionInformation

DateInspected

PreviousInspectionDate

InspectionType

CycleNumber

RecommendedInspectionFrequency

CountyCode

MunicipalityCode

Latitude/Longitude

Route

Milepost

LocationDescription

TrafficControlRequirements

ContractNumber

ConsultantFirmName

ConsultantProjectManager

ConsultantTeamLeader

ConfirmingRegisteredPE

StructureName

StructureConfiguration

NumberofTrussSections

MaterialType

InServiceStatusandDate

OverallSpanLength

MinimumVerticalClearance

LeftandRightLateralClearance

NumberofTraveledLanes

NumberofSigns

AreaofeachSign

InstallationYear

PlansAvailable?

Walkway?

Lighting?

Modificationsinceconstruction

DamageReports

ElementRatings

ElementRepairs

7.4InventoryNumbering

Aninventorynumberingschemeisrequiredforallancillarystructures.Theinventorynumberisusuallythe

keypieceofdatathatanydatabaserelatesto.Itcanbesequentialalongaroute,andcontaininformation

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

19/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

relevanttolocationsuchasCountyandTownCoding.Itishighlyrecommendedthatafteranancillary

structurenumberisassignedthenumberbeimmediatelystenciledontotheexistingsign.Documentation

shouldflowfromthefieldtothesigndesignersothatanynewstructureswouldnotbeassignedthatspecific

inventorynumber.

Oneproblemwithsignstencilingisthatmanystructuralsupportsareonshouldersthataretargetsfor

roadwaygrime,saltsprayandsnowplows.Properpositioningofthesignnumbershouldconsiderthese

effects.Thestencilcanbeplacedabovethesprayofsaltoronthebacksideofthestructure.Anotheroption

mightbetostencilthesignbridgeinsteadofthesupportingtowermembers,ortostampthenumberinwith

metalstamps.

8.0InspectionVariables

8.1TypesofInspections

Thereareseveralinspectiontypesdependingonthecircumstancesofthesignstructure.Theseinspection

typesfollowthosetypicallyperformedforbridgeinspections.

8.1.1InitialInspection

Thisinspectionshouldtakeplaceshortlyafterthesignstructureisconstructed.Itiscommonforboltson

signstructures,shortlyafterinstallation,tobecomelooseandshouldberecheckedwithin60daysafter

constructioniscomplete.

8.1.2Routine

Thiscansimplyconsistofagroundlevelinspectionwithnoattempttoclosetrafficlanes.Thistypeof

inspectionisrecommendedduringthefirstphasesofasignstructureinspectionprogramtoobtaininventory

informationandquicklylookfordeficiencies.However,sincemanystructuraldeficienciessuchasweld

cracksintheoverheadtrusscannotbeidentifiedfromagroundlevelinspection,thistypeofinspectionisnot

recommendedtooccurnormallyinsubsequentinspectioncycles.However,asstatedinthe'TrafficControl'

portionoftheseguidelinescyclicgroundlevelinspectionsmaysupplementanInDepthinspectiondueto

severetrafficrestrictions.

8.1.3InDepth

Thistypeofinspectionisrecommendedasatypicalinspectionofasignstructure.Theinspectionwillbe

'HandsOn'asdiscussedinthefollowingsection.

8.1.4InterimInspection

ThiswouldberecommendedbytheInspectorifasignstructureisfoundtohavedeficienciesorother

problemsthatrequiremorefrequentinspectionthanthetypicalinspectionfrequency.AnInterimInspection

mightalsoberequiredaftertemporaryrepairsaremadetothesignstructure.Forexample,somemeasures

areimmediatelytakenwhencracksarefoundintheoverheadsigntruss.Thismaybesimplyremovingthe

signpanelstoreducewindload,installationofadampener,oractuallycompletingrepairssuchastheuseof

fibercompositematerialtotemporarilyrestrainthecrackedconnection.

8.1.5DamageInspection

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

20/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Thisinspectionisprovidedafterasignisdamaged.Thiscouldincludetrafficimpactonthepost,anover

heighthitofthetrussorsignpanels,etc.

9.0InspectionFrequency

Determiningthefrequencyforancillarystructureinspectionisdependentonseveralfactors.Oneismaterial

type.Forexample,aluminumtrusstypespanstructureshaveshownincreasedproblemsduetofatigue

deficiencies.Highstrengthanchorrodshavebeenmoreproblematicthanmildsteel.Frequencycanalsobe

basedonstructuralredundancy.Cantileversignstructuresupportsonlyhaveonemainsupportinsteadoftwo

ormorewithspantypestructures.Signstructuresassociatedwithanotherstructuresuchasabridge

mountedsignmaybeinspectedasthebridgeisinspectedduringanormaltwoyearfrequency.Manyowners

areinitiatingsignstructureprogramsanddeterminingfrequencyafterthefirstcycleiscompleteand

deficienciescanbecategorized.Anotherpreviouslydiscussedfactoristrafficcontrolandtheproblems

associatedwithaccess.

Someguidelinesforinspectionfrequenciesareasfollows:

MaterialIssues:Sinceithasbeendeterminedthataluminumsignbridgesareproblematic,itis

recommendedthatatwoyearfrequencyofindepthinspectionsbeconducted.Todetermineif

materialissuesarerelevantpriortoafullscaleinspectionprogramissetinmotionasample

projectthatinspects10%ofthestructureinventorymaybeprudent.

RedundancyIssues:Forcantileverandothernonredundantstructuresafouryearfrequencyis

recommended.

TypicalSignBridges:Atypicaltwotower,twoorfourpostsignbridgewithasteelsuperstructureneedonly

beinspectedhandsoneverysixyears.Routineorgroundinspectionscanbeconductedmorefrequentlyto

checkcorrosionofpostsorconnectionproblems.

TrafficIssues:If'severe'restrictionsexist,asdiscussedinthe'TrafficControl'sectionoftheseguidelines,

frequenciesstatedabovecanbeextendedbutsupplementedbyroutinegroundinspections.

10.0InspectionPrioritiesandPlanning

Theancillarystructureinspectionprocessshouldnotproceeduntilastructureinventoryhasbeencompleted.

Onlythencanproperplanningtakeplace.ManyStateDepartmentsofTransportationhavestartedtheir

structureinspectionprogramusingthefollowingstrategy:

1. Performfieldreconnaissanceandcollectinventoryinformation

2. Performarandomsamplinginspectionprojectofperhaps10%oftotalinventory

3. Basedonfindingsofsampleproject,prioritizeandcontinuefullinspectionprogram.

ExamplePriorities

Aluminumsignbridges

SignBridgeswithlongspan

NonRedundantcantileversignstructures

SignStructuresgreaterthan20yearsold

SignStructureswheresignpanelsizesexceedsthoseoriginallydesignedfor.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

21/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

11.0RequiredResources

11.1SuggestedPersonnelRequirements

InspectionofancillarystructuresisnotrequiredbyFederalRegulations,norarethereanyrequirementsfor

thosepersonwhoconductsuchinspections.

Inspectionofancillarystructureshassimilaritiestohighwaybridgesbutalsosomespecialcircumstances

thatshouldbeaddressed.ThequalificationsforbridgeinspectionpersonnelasgivenintheNationalBridge

InspectionStandards(23CFR650),aresummarizedbelowwithsuggestedspecialmodificationsforancillary

structures.

ProgramManagerTheprogrammanagerisinchargeofthescoping,scheduling,costcontrol,andquality

assurance.MinimumqualificationsshouldbeaProfessionalEngineerorhaveaminimumof10yearsof

experienceinstructuresinspectionsinaresponsiblecapacityandhavecompletedcomprehensivetraining

basedontheGuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsfor

HighwaySigns,LuminariesandTrafficSignals.

TeamLeaderHavequalificationsspecifiedforProgramManagerorhaveaminimumof5yearsof

experienceinstructureassignmentsinaresponsiblecapacityorNICETLevelIIIorIVcertificationin

StructureInspectionandhavecompletedacomprehensivetrainingprogrambasedontheGuidelinesforthe

Installation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminariesand

TrafficSignals.Inaddition,theTeamLeadershouldbetrainedinworkzonetrafficcontrolsuchastheNHI

Course38003DesignandOperationofWorkZoneTrafficControl.

AninspectionteamwillusuallyconsistofaTeamLeaderandanAssistant.AssistantTeamLeader

qualificationscanbeprojectspecific.Duetotheextentofweldedmembersfoundinmostancillary

structures,itisdesirableforatleastoneteammembertohaveexperienceinvisualweldinspectionaswell

astraininginlocatingandrecognizingfatiguecracking.

Allinspectionpersonnelshouldbeabletophysicallyperformthework.Althoughbuckettrucksaretypically

usedtoaccessthesignbridge,anadequateindepthinspectioncannotbefullyperformedfromthebucket

andsomeclimbingwillberequired.

11.2ToolsandEquipment

Eachinspectionteamshouldbefullyequippedtoperformthestructuralinspections.Additionalequipment

maybeneededsincesignstructureinspectorsroutinelymakeminorrepairs.Thereasonminorrepairsmay

beattemptedduringtheinspectionprocessistoavoidanotherworkzonesetuptoperformaminorrepair.

Suchminorrepairsmayincludebolttightening,replacementoffastenerssuchascotterpins,andpaint

touchup,alongwithreplacingmissingpolecaps,anchorrodnutcoversandhandholecovers.

Thelistbelowiswhatwouldbeconsideredas'ToolsoftheTrade'forthesignstructureinspector.

WorkZoneprotectionandtrafficcontrolequipment,includingsigns,trafficconesandflags(in

compliancewiththeMUTCDandlocalrequirements).

Personalsafetyequipment,includinghardhats,reflectivehighvisibilityvests,goggles,faceshields,

harnesses(orbelts),andlanyards.(AllOSHAapproved).

Basicaccessequipment,suchasastepladder,extensionladder,andrope

Toolsforinspection,includingchippinghammers,pocketknives,screwdriversorawls,magnifying

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

22/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

glass,magnet,flashlights,mirrors.Thehammerisanexcellenttoolfortestinganchorrods.Themirror

isforinspectingcircumferentialweldswhileclimbingthetruss.Amagnetcanconfirmwhetherthe

materialissteeloraluminum,asaluminumisnonmagnetic.

Toolsformeasuring,suchasaplumbbob,levels,foldingrulers,tapes,calipers,thicknessgauges

Wrenches,allenwrenches,screwdriversforremovingaccesspanelsandboltcovers

Torquewrenchforbolttighteningorcheckingbolttension

Digitalcamerafordocumentation

Shovelandbrushcutters

Markingutensilssuchaslumbercrayonsorkeel,paintsticks,soapstone,centerpunch

GPSrecommendedsincemanysignslooksimilar,evensignpanels,andareroutinelyreplaced

withoutcompletenotificationtoallparties.

Electronicdeviceformeasuringverticalclearancesisrecommended.

Equipmenttonumberthesigns,eitherpaintstenciling,adhesivetape,paintmarkers,etc.

NonDestructivetestequipmentsuchasultrasonictesting,dyepenetrant,ormagneticparticle.

Remotecamerasforhighmastlighting

Buckettruck,seeexplanationbelow

Whilefreeclimbingfromtheshoulderorwithladders,Figure17,canaccessmanysignstructures,themost

typicalwaythesignstructureisaccessedisbyuseofavehiclemountedaccessbucket,Figure18.These

vehiclesarecommonlyusedbycableandtelephonecompaniesandarereadilyavailableforrent.Formost

ancillarystructuresa30'boomissufficient.Accessvehiclesmustbeoperatedinaccordancewithrequired

safetyprocedures.

Figure17.InspectorClimbingStructure.

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

23/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Figure18.BucketTruckMostCommonWaytoAccessSignStructure.

11.3TrafficControl

Oneofthemostdifficultchallengesfortheinspectionandevaluationofoverheadsignstructuresisthatof

accessforinspectionpersonnel.ThischallengearisesfromtheneedtosatisfyMaintenanceandProtection

ofTraffic(MOT)safetyrequirementswhilecontrollingcostswithinacceptablelimits.Suchaccessstrategies

includenightwork,mobilelaneclosures,andotherinnovativemethodsforshorttermlaneclosures.Atthe

heartoftheabilitytogaininspectionaccessisdeterminationofwhatareasofthesestructuresaremost

criticalandhowoftenshouldtheybeinspected.

Itissuggestedthatacostbenefitratiobedevelopedforeachoverheadsigninspectionprojectthatconsiders

inspectionaccess,inspectiondetail,MOTcostandoverallsafety.Somesuggestionsforeacharepresented

belowwiththekeydeterminingfactordefinedasthelaneclosurerestrictions.Allsuggestionscomplywiththe

basicrequirementsdiscussedinthe'ManualforUniformTrafficControlDevices'(MUTCD).

Itisrecommendedthatnightworkbealastresortinplanninganinspectionprogram.Thesmallfatigue

cracksinatypicalsigntrussaredifficultenoughtospotduringdaytimeinspectionhours.Ifinspectionsare

performedatnight,adequatelightingmustbeprovided.Belowareseveralconsiderationsindevelopingasign

inspectionstrategydrivenbyclosurerestrictions.

MinimalLaneClosureRestrictionsAnexampleofminimalrestrictionswouldbetheallowanceofdouble

laneclosuresduringnormalworkhoursbetween8AMand5PM.Forthisscenarioitissuggestedthat

conventionalstationarytypeMOTbeused.Theclosure,sinceofatemporarynature,shouldbeeasily

deployedandremoved.TypicalMOTequipmentwouldbeafabricsignconformingtoNCHRP350.Fabric

signsalloweasydeploymentoverrigidmetal.Also,conesshouldbeusedoverbarrelsorbarricadesagainto

alloweasysetupandremoval.IfmoresubstantialMOTequipmentisrequiredmeansotherthanastationary

setupshouldbeinvestigated.Undertheselaneclosurerestrictionsacompletefullhandsoninspection

shouldbescheduledasrecommendedinthe'InspectionFrequency'sectionofthisdocument.

ModerateLaneClosureRestrictionsAnexampleofamoderateclosurerestrictionwouldbelimitedclosure

timesuchasa10AMto2PMwindowforadoublelaneclosure.Aconventionalstationaryclosurecouldbe

consideredifafull8hourwindowcanbescheduledusingsinglelaneclosuresduringthemorningand

afternoonhours.Anefficientinspectiondaymightallowforamorningsinglelaneclosureencompassing

severalsignstructuresthatcanbeexpandedintoadoublelaneclosureat10AM.Itisrecommendedthat

undermoderatelaneclosurerestrictionsafullhandsoninspectioncouldbecompletedperthefrequency

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

24/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

recommendedinthe'InspectionFrequency'sectionofthisdocument.

SevereLaneClosureRestrictionsAnexampleofaseverelaneclosurerestrictionwouldbenodaytime

doublelaneclosuresallowed.Inthiscase,thebestoptionwouldbeamobilenighttimeclosure.Toreduce

theriskofmissingdeficienciesduringthenighttimeinspectionsasmuchoftheworkaspossibleshouldbe

completedduringthedayusingsinglelaneclosures.Anexamplewouldbetheuseofsingleleftandrightlane

closuresduringthedaytoinspectthepost,base,foundationandtrusstopostconnections.Thenighttime

workwouldthereforeberestrictedonlytotheinteriortraveledlanesfocusingjustonthetrussweldsandsign

connections.Insteadofafullhandsoninspectionwithfrequenciesrecommendedinthe'Inspection

Frequency'sectionoftheseguidelines,amodifiedstrategymightbeneeded.Thismaybeanalternatecyclic

combinationofhandsonandshoulderinspectionstominimizethefulllaneclosures.

11.4Safety

Itishighlyrecommendedthateveryancillarystructureinspectionprogramhaveadetailedsafetyplan

submittedpriortoworkcommencing.Signstructureinspectionsareoneofthemosthazardoustypesof

structuralinspections.Theyusuallyoccuradjacenttolivetraffic.Thesignstructuresaremanytimeslocated

atthe'gore'orexitareasofhighspeedroadswhereworkzonesafetysetupscanbeextremelydifficultto

setup.Inaddition,itisroutinethattheinspector'climb'thestructure,whicharecomplicatedduetoangled

diagonalsandslipperystructuralmembers.

Whenclimbingasignorotherancillarystructureatwolanyardsystemoffersthebestprotectionwithone

lanyardalwayssecuredtothestructure,seeFigure19.Goodgrippingbootssimilartoonesamountain

climberwouldusearerecommended.Toperformaclimbinginspectioneverythingwornorcarriedbythe

inspectormustbesecurelyattachedtohim/hersonothingcandroporhangbelowthebottomofthe

structure.Thereportingofinspectionfindingsmaybehandledbyuseofaradioattachedtotheinspector

throughwhichfindingsarerelayedtoanotetakerontheground.Sincethetravelingpublicmaybeconcerned

whenobservingsomeoneclimbingasignstructure,somestatesplaceavariablemessagesignstating

"WorkersOverhead"asinformationalaid.

Listedbelowaretypicalcontentsofasafetyplan:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

SafetyPlanOfficerforInspectionfirm

SafetyOrganization

SafetyIncidentReportProceduresandForms

FallSafetySpecifications

OperationofBucketorlifttruckguidelines

HospitalLocations

LatestManualofUniformTrafficControlDevices(MUTCD)

Specificworkzonetrafficsetupsfor'gore'areas

Mandatorypersonalsafetyequipment

FirstAidKit

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

25/26

4/28/2015 GuidelinesfortheInstallation,Inspection,MaintenanceandRepairofStructuralSupportsforHighwaySigns,Luminaries,andTrafficSignalsInspection

Figure19.InspectorUsesDoubleLanyardSystem.

<<Previous|TableofContents|Next>>

FederalHighwayAdministration|1200NewJerseyAvenue,SE|Washington,DC20590|202

3664000

http://www.fhwa.dot.gov/bridge/signinspection02.cfm

26/26

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Same s80 EngDocument432 pagesSame s80 EngSabadsag DariusNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bolt Tightening HandbookDocument44 pagesBolt Tightening HandbookShekhar V Madhavi100% (1)

- Manual de Motor Toyota Corolla 4a-Ec 1990Document30 pagesManual de Motor Toyota Corolla 4a-Ec 1990David Emmanuel Turcios CarrilloNo ratings yet

- Inconel 718Document28 pagesInconel 718aavadepa100% (1)

- Analysis of isolated footing subjected to high biaxial momentsDocument21 pagesAnalysis of isolated footing subjected to high biaxial momentsvaram1No ratings yet

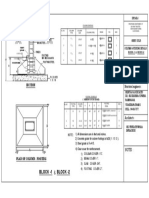

- Column & Footing Details Block-1 & Block-2Document1 pageColumn & Footing Details Block-1 & Block-2Sandeep VarmaNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument66 pagesAtlas Copco: Stationary Air CompressorsChriss Vzz100% (4)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- 2715 Top BracingDocument41 pages2715 Top BracingValentin-Madalin Voica100% (2)

- SFSP Catalogue Guide for Pipe Supports and AccessoriesDocument50 pagesSFSP Catalogue Guide for Pipe Supports and AccessoriesAnees OlasserilNo ratings yet

- How to Estimate Formworks for Columns, Beams, and GirdersDocument7 pagesHow to Estimate Formworks for Columns, Beams, and GirdersAromoc RanojNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- Titanium and Titanium AlloysDocument24 pagesTitanium and Titanium AlloysGuilherme FranzoiNo ratings yet

- List RDSO DrawingsDocument52 pagesList RDSO Drawingsprasagnihotri75% (4)

- Pipe TableDocument12 pagesPipe Tablevaram1No ratings yet

- Ejercicio de Soldadura AISC 2005Document11 pagesEjercicio de Soldadura AISC 2005APBNo ratings yet

- Worked Example 2 Concrete CantileverDocument18 pagesWorked Example 2 Concrete CantileverJaime A Gutierrez VNo ratings yet

- Seismic Retrofit PDFDocument1 pageSeismic Retrofit PDFvaram1No ratings yet

- Walls-Seismic Analysis - Lec-35 PDFDocument27 pagesWalls-Seismic Analysis - Lec-35 PDFvaram1No ratings yet

- Seismic Lateral Earth PressureDocument32 pagesSeismic Lateral Earth PressureKay CharlesNo ratings yet

- 425 Serviceability CHP 6 S11Document76 pages425 Serviceability CHP 6 S11varam1No ratings yet

- SDOF PlasticDocument19 pagesSDOF Plasticvaram1No ratings yet

- Tengs Chart PDFDocument1 pageTengs Chart PDFvaram1No ratings yet

- Shear WallDocument14 pagesShear WallSadatcharaMoorthi NNo ratings yet

- Grating Brochure PDFDocument26 pagesGrating Brochure PDFvaram1No ratings yet

- UB ProfilesDocument8 pagesUB ProfilesdevgrpNo ratings yet

- Requirements of Tower/AntennasDocument8 pagesRequirements of Tower/Antennasvaram1No ratings yet

- 3370 1Document28 pages3370 1rambinodNo ratings yet

- Properties of Soils AppendixDocument5 pagesProperties of Soils Appendixpinkuru100% (1)

- Investigation of Bixial Bending Reinforced Concrete ColumnDocument13 pagesInvestigation of Bixial Bending Reinforced Concrete ColumnJoseph Cloyd LamberteNo ratings yet

- Compression MembersDocument42 pagesCompression MembersAntonio MorenoNo ratings yet

- Beam DesignDocument17 pagesBeam Designvaram1No ratings yet

- Unit Estimate of Circular Manhole of 1800 MM Dia Size and Depth of 7.5 MDocument9 pagesUnit Estimate of Circular Manhole of 1800 MM Dia Size and Depth of 7.5 MArvind BajpaiNo ratings yet

- Guide To Low Voltage Panel SeparationDocument6 pagesGuide To Low Voltage Panel SeparationMarkNo ratings yet

- Influence of Initial Imperfection On The Behaviour of Extended Bolted by Chen 2007Document10 pagesInfluence of Initial Imperfection On The Behaviour of Extended Bolted by Chen 2007fahmi aballiNo ratings yet

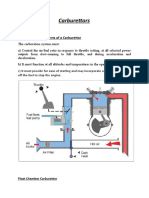

- CarburettorsDocument12 pagesCarburettorsrohitNo ratings yet

- G.F.R.C. Guide for Polymer Modified ConcreteDocument5 pagesG.F.R.C. Guide for Polymer Modified ConcreteVladoiu SorinNo ratings yet

- Vernacular ArchitectureDocument22 pagesVernacular ArchitectureSharmae Rongavilla100% (1)

- SOPs To Work Maunal 2019 20 March 2019 PDFDocument274 pagesSOPs To Work Maunal 2019 20 March 2019 PDFAbhishek Choudhary100% (5)

- WATERPROOFINGDocument14 pagesWATERPROOFINGAashi GuptaNo ratings yet

- Dezurik Awwa Butterfly Valves Baw Technical 43 - 00 - 2 PDFDocument24 pagesDezurik Awwa Butterfly Valves Baw Technical 43 - 00 - 2 PDFANILNo ratings yet

- Structural Engineering Handbooks and Codes ListDocument4 pagesStructural Engineering Handbooks and Codes ListAmey GudigarNo ratings yet

- Unconfined Compressive Strength of Cohesive SoilsDocument4 pagesUnconfined Compressive Strength of Cohesive SoilsZedrickTrinidad100% (1)

- Timber Gridshells - Design Methods and T PDFDocument9 pagesTimber Gridshells - Design Methods and T PDFTani PartnerNo ratings yet

- Urban Open SpacesDocument49 pagesUrban Open SpacesRitika RituNo ratings yet

- S He E G B: 4.5 Water Hammer Phenomenon in PipelinesDocument9 pagesS He E G B: 4.5 Water Hammer Phenomenon in PipelinesWalter Velásquez100% (1)

- Gravity Based Structure FoundationDocument8 pagesGravity Based Structure FoundationHa NgNo ratings yet

- Áfico de Correlación Del Martillo Schmidt Miller 1965 PDFDocument1 pageÁfico de Correlación Del Martillo Schmidt Miller 1965 PDFalexanderNo ratings yet

- Effect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceDocument7 pagesEffect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceChime MornNo ratings yet

- Saep 1024Document5 pagesSaep 1024balajiNo ratings yet

- Thermal Stress Composite Bars: Bibin ChidambaranathanDocument30 pagesThermal Stress Composite Bars: Bibin ChidambaranathanDr. BIBIN CHIDAMBARANATHAN100% (1)