Professional Documents

Culture Documents

Table of Contents for Blacksmithing and Forging Techniques

Uploaded by

pandaprasad0 ratings0% found this document useful (0 votes)

17 views3 pagesforge

Original Title

Forge

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentforge

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views3 pagesTable of Contents for Blacksmithing and Forging Techniques

Uploaded by

pandaprasadforge

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

TABLE OF CONTENTS

CHAPTER I. TOOLS AND APPLIANCES. 1. The Forge; 2. Fire Tools

3. Fuels ; 4. The Anvil; 5. The Hammers; 6, The ball peen hammer ; 7. The cross peen hammer; 8. The straight peen hammer;

9. The Sledges; 10. The Tongs; 11. The flat jawed tongs; 12. The

hollow bit tongs; 13. The pick-up tongs ; 14. The side tongs;

15. The chisel tongs ; 16. The link tongs; 17. the tool or box

tongs ; 18. Anvil and Forging Tools; 19. The hardy ; 20. The cold

and hot cutters; 21. The hot cutter; 22. The flatter; 23. The

Square- and round-edged set hammers; 24. The punches; 26. The top

and bottom swages ; 26. The top and bottom fullers ; 27. The button head set or snap ; 28. The heading tool ; 29. The swage block ;

30. The surface plate; 31. The tapered mandrels ; 32. Bench and

Measuring Tools ; 33. The bench or box vise ; 84. The Chisels;

35. The center punch ; 26. The role ; 37. The dividers; 38. The

calipers; 39. The somber or scratch awl ; 40. The square; 41. The

bevel; 42. The hack saw; 43. The files.

CHAPTER II FORGING OPERATIONS. - 44. The Hammer Blows; 45. The

upright blow; 46. The edge-to-edge blow; 47. 1 lie over banging

blow; 48. The beveling or angle blows; 49. The leverage blows;

50. The backing-up blows; 51. The shearing blow; 62. Forging; 63. Drawing; 54. Bending ; 55. Upsetting; 58. Forming ;

57. Straightening; 58. Twisting ; 59. Welding; 60. The Material

for Welding; 61. Heating; 62. Scarfing; 63. The lap weld ; 64. The

cleft weld 65. The butt weld ; 66. The jump weld; 67. The

V weld

CHAPTER III. PRACTICE EXERCISES. - 68. Staple ; 69. Draw Spike;

70. S Hook; 71. Pipe Hook; 72. Gate Hook; 73, Door Hasp;

74. Hexagonal Head Bolt; 75. Square-cornered Angle ; 76. Fagot

Welding; 77. Round Weld ;78. Flat Right-angled Weld ;

79. T Weld; So. Chain Making; 81. Welded Ring; 82. Chain

Swivel; 83. Chain Swivel; 84 Chain Grabhook

CHAPTER IV. TREATMENT OF TOOL STEEL. -85. Selecting and Work.

ing Steel; 86. Uses of Different Grades of Steel; 87. Injuries;

88. Annealing; 89. Hardening and Tempering; 90. Casehardeming

CHAPTER V. TOOL MAKING AND STOCK CALCULATION. -91.

Tongs;

92. Heavy Flat Tongs 93. Light Chain Tongs; 94. Lathe Tools;

95. Brass Tool ; 96. Cutting-off or Parting Tool ; 97. Heavy Boring Tool ; 98. Light Boring or Threading Tool; 99. Diamond Point

Tool; 100. Right Side Tool; 101. Forging Tools; 102. Cold

Chisel; 103. Hot Cutter; 104. Cold Cutter; 105. Square-edged

Set ; 106. Hardy; 107. Flatter; 108. Small Crowbar; 109. Eye or

Ring Bolts; 110. Calipers; 111. Stock Calculation for Bending .

CHAPTER VI. STEAM HAMMER, TOOLS, AND EXERCISES - 112. A

Forging; 113. The Drop Hammer; 114, Presses; 115. The Steam

Hammer; 116. Steam Hammer Tools; 117. The hack or cutter ;

118. The circular cutter; 119. The trimming chisel 120. The

cold cutter; 121. The checking tool or side fuller; 122. The fuller;

123. The combined spring totters; 124. The combination fuller and

set; 125. The combined top and bottom swages; 126. The top and

bottom swages; 127. The bevel or taper tool; 128. The V block;

129. The yoke or saddle; 130. Bolsters or COURTS; 131. Punches ;

132. Steam Hammer Work; 133. Crack Shaft ; 134. Connecting

Rod; 135. Rod Strap; 136. Eccentric Jaw; 137. Hand Lever;

138. Connecting Lever ; 139. Solid Forged Ring; 140. Double and

Single Offsets

CHAPTER VII ART SMITHING AND SCROLL WORK. - 141. Art Smithlug; 142. Scroll Fastenings; 143. Scroll Former; 144. Bending or

Twisting Fork; 145. Bending or Twisting Wrench ; 146. Clip

Former ; 147. Clip Holder; 148. Clip Tightener or Clincher;

149. Jardinere Stand or Taboret; 150. Umbrella Stand; 151. Reading Lamp; 162. Andirons and Bar; 153. Fire Set; 154. Fire Set

separated

CHAPTER VIII. IRON ORE, PREPARATION AND SMELTING.-155. Iron

Ore; 156. Magnetite; 157. Red hematite; 158. Limonite or brown

hematite ; 159. Ferrous carbonate ; 160. The Value of Ores; 161.

Preparation of Ores; 162. Weathering; 163. Washing; 164. Crushing;

165. Roasting or calcination; 160. Fuels; 167, Fluxes; 168. The Blast;

109. The Reduction or Blast Furnace; 170. Classification of Pig Iron;

171. Bessemer iron; 172.Basic iron; 173. Mill iron; 174. Malleable iron;

175. Charcoal iron; 170. Foundry iron; 177. Grading Iron

CHAPTER IX. THE MANUFACTURE OF IRON AND STEEL. -178.

Refining Pig Iron ; 179. The Open-hearth or Finery Process; 180. The

Puddling Process ; 181. Steel; 182. The Crucible Process ; 183. The

Bessemer Process; 184. The Open-hearth Process .

FORMULAS AND TABLES .

197

INDEX .

207

You might also like

- 153 Ejericicios de CircuitoDocument7 pages153 Ejericicios de CircuitoAris GoldsteinNo ratings yet

- MODEL MP 221 Parts ExplosionDocument1 pageMODEL MP 221 Parts ExplosionntarylNo ratings yet

- Elementary Forge PracticeDocument152 pagesElementary Forge PracticeMarko KolarićNo ratings yet

- Forge Work - William L. IlgenDocument234 pagesForge Work - William L. IlgenHernán SalvayNo ratings yet

- Yachting Monthly's 200 Skipper's Tips: Instant Skills to Improve Your SeamanshipFrom EverandYachting Monthly's 200 Skipper's Tips: Instant Skills to Improve Your SeamanshipNo ratings yet

- Anchor and Mooring Gear OverviewDocument16 pagesAnchor and Mooring Gear OverviewhuyhanghaiNo ratings yet

- Heritage Institute of Technology: Department of Mechnical Engineering Workshop Practice (Mech1051) Work Instruction SheetDocument4 pagesHeritage Institute of Technology: Department of Mechnical Engineering Workshop Practice (Mech1051) Work Instruction Sheet014 Debayan Kumar GhoshNo ratings yet

- Anchor, Mooring GearDocument16 pagesAnchor, Mooring GearhgmNo ratings yet

- Anchor & MooringDocument20 pagesAnchor & MooringMahmud HasanNo ratings yet

- Unirig Lifting MooringDocument32 pagesUnirig Lifting MooringIgnacio SantanaNo ratings yet

- Types of SprinklersDocument9 pagesTypes of SprinklerssureshkanuboyinaNo ratings yet

- The Seaman's Friend Containing a treatise on practical seamanship, with plates, a dictinary of sea terms, customs and usages of the merchant serviceFrom EverandThe Seaman's Friend Containing a treatise on practical seamanship, with plates, a dictinary of sea terms, customs and usages of the merchant serviceNo ratings yet

- Bom MechanicalDocument104 pagesBom MechanicalTanveer Rajput EngrNo ratings yet

- Radar 1090Document8 pagesRadar 1090brpindiaNo ratings yet

- Traditional Jigs & Fixtures for Handtools: A Manual of Devices for WoodworkingFrom EverandTraditional Jigs & Fixtures for Handtools: A Manual of Devices for WoodworkingNo ratings yet

- Com T4 Drwings 3WDDocument4 pagesCom T4 Drwings 3WDMarek WyszatyckiNo ratings yet

- CPVC Ball Valves and Fittings Center of Gravity ReportDocument120 pagesCPVC Ball Valves and Fittings Center of Gravity ReportEsapermana RiyanNo ratings yet

- Metalworking Handbook Principles and Procedures 1976Document473 pagesMetalworking Handbook Principles and Procedures 1976Rob FurnaldNo ratings yet

- ARS Catalogue (Fasteners)Document140 pagesARS Catalogue (Fasteners)Chuck AnsphilNo ratings yet

- Winchester 1895 RifleDocument28 pagesWinchester 1895 RifleTactic Otd ArgNo ratings yet

- Soldering InstructionsDocument78 pagesSoldering InstructionsT-Ben EredianoNo ratings yet

- Questionnaires For Welding EngineerDocument7 pagesQuestionnaires For Welding EngineerCyril J PadiyathNo ratings yet

- Gun TypesDocument125 pagesGun Typesdewaaaaa-76100% (2)

- MultitoolsDocument4 pagesMultitoolsNikos SakellariouNo ratings yet

- Pages 54-55Document1 pagePages 54-55BobRobertsNo ratings yet

- Copian Hani Perl - TanganDocument2 pagesCopian Hani Perl - TanganPrisciliaRosdinataRosdinataNo ratings yet

- Anchor Mooring GuideDocument13 pagesAnchor Mooring GuidealsadrNo ratings yet

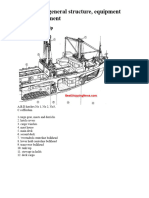

- Container Ship General Structure Equipment and ArrangementDocument15 pagesContainer Ship General Structure Equipment and ArrangementRachel Erica Guillero BuesingNo ratings yet

- Overview of Anchor and Mooring GearDocument8 pagesOverview of Anchor and Mooring GearYannick PakaNo ratings yet

- Walleye, the Moving Target: Stories and Information for the Aspiring AnglerFrom EverandWalleye, the Moving Target: Stories and Information for the Aspiring AnglerNo ratings yet

- Cargo ShipDocument20 pagesCargo Shipthaiphuoc1234567890100% (4)

- Cargo ShipDocument20 pagesCargo ShipgeorgetacaprarescuNo ratings yet

- Heat Exchanger Parts Identification GuideDocument10 pagesHeat Exchanger Parts Identification Guidesimpanan hitamNo ratings yet

- En Verde Los Horarios de Coches Con Rampa de Acceso para Personas Con Movilidad ReducidaDocument1 pageEn Verde Los Horarios de Coches Con Rampa de Acceso para Personas Con Movilidad ReducidaDNK2012No ratings yet

- Model 1897 Pump Shotgun: Instruction ManualDocument5 pagesModel 1897 Pump Shotgun: Instruction ManualGhiles OucherifNo ratings yet

- Schedule H: International Standard Syllabus for Ballroom and Latin DancesDocument1 pageSchedule H: International Standard Syllabus for Ballroom and Latin DancesAvi BrennerNo ratings yet

- Machines in Workshop GuideDocument5 pagesMachines in Workshop Guideমুশফিক আকাশNo ratings yet

- Electrical Tools and Equipment Identification GuideDocument48 pagesElectrical Tools and Equipment Identification GuideGeorge DalivaNo ratings yet

- 06 Soldering 101 (PPTmin)Document65 pages06 Soldering 101 (PPTmin)Emman BositoNo ratings yet

- The Ultimate Shooting Skills Manual: 212 Essential Range and Field SkillsFrom EverandThe Ultimate Shooting Skills Manual: 212 Essential Range and Field SkillsRating: 3 out of 5 stars3/5 (1)

- Gravely 800 Series Riding Tractor Illustrated Parts ListDocument36 pagesGravely 800 Series Riding Tractor Illustrated Parts ListMike StevensNo ratings yet

- Studio Srp60n Ribber ManualDocument78 pagesStudio Srp60n Ribber ManualAlejandro MonroyNo ratings yet

- Watchmaking ExcerpDocument21 pagesWatchmaking Excerpharyantosumanto100% (4)

- Matri 420 Sewing Machine Instruction ManualDocument64 pagesMatri 420 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Equipments and Machines Required For Following Labs:-1. Hydraulics LabDocument2 pagesEquipments and Machines Required For Following Labs:-1. Hydraulics LabNishaNo ratings yet

- Robinson M96 Expeditionary Rifle User ManualDocument23 pagesRobinson M96 Expeditionary Rifle User ManualGasMaskBobNo ratings yet

- DXD - Fire FightingDocument71 pagesDXD - Fire FightinganhNo ratings yet

- Chipmunk 22Document6 pagesChipmunk 22rleblanc1No ratings yet

- Forcec 2Document16 pagesForcec 2Leon BertossiNo ratings yet

- Oil Tanker Transverse MembersDocument1 pageOil Tanker Transverse MembersKyaw OoNo ratings yet

- The Breech Loader and How To Use ItDocument436 pagesThe Breech Loader and How To Use Itsjw981No ratings yet

- Container ShipDocument14 pagesContainer Shipthaiphuoc1234567890No ratings yet

- Shipbuilding Picture DictionaryDocument22 pagesShipbuilding Picture DictionaryRajiv RanjanNo ratings yet

- SCT CarbideDocument56 pagesSCT CarbidedadoNo ratings yet

- Dictionary ListDocument8 pagesDictionary ListHector CidNo ratings yet

- 286 - 40 Rev.01Document14 pages286 - 40 Rev.01dantopan117No ratings yet

- Amateur Gunsmithing PDFDocument176 pagesAmateur Gunsmithing PDFBri BroooNo ratings yet

- Winchester Model 1885Document0 pagesWinchester Model 1885carlosfanjul1No ratings yet

- 45 Post Office RD Interest CalculatorDocument4 pages45 Post Office RD Interest CalculatorpandaprasadNo ratings yet

- 54 EmiDocument6 pages54 EmipandaprasadNo ratings yet

- 0 Loan Interest CalculationDocument24 pages0 Loan Interest CalculationpandaprasadNo ratings yet

- Binomialprobabilitydistribution 120218130430 Phpapp01Document17 pagesBinomialprobabilitydistribution 120218130430 Phpapp01pandaprasad100% (1)

- D OptimalDocument12 pagesD OptimalpandaprasadNo ratings yet

- 22 Tax Calculator Excel SheetDocument23 pages22 Tax Calculator Excel SheetpandaprasadNo ratings yet

- 47 Depreciation CalculatorDocument1 page47 Depreciation CalculatorpandaprasadNo ratings yet

- 4 Discrete Probability Distribution PDFDocument44 pages4 Discrete Probability Distribution PDFpandaprasadNo ratings yet

- Chapter 8Document8 pagesChapter 8pandaprasadNo ratings yet

- Correlation Regression Relationship Analysis 1233772232553257 1Document8 pagesCorrelation Regression Relationship Analysis 1233772232553257 1pandaprasadNo ratings yet

- Experimental Design Analysis in 40 CharactersDocument31 pagesExperimental Design Analysis in 40 Characterssricharitha6702No ratings yet

- Correlation Regression Relationship Analysis 1233772232553257 1Document37 pagesCorrelation Regression Relationship Analysis 1233772232553257 1pandaprasadNo ratings yet

- Cell Biology Lecture Notes ExplainedDocument108 pagesCell Biology Lecture Notes ExplainedpandaprasadNo ratings yet

- Savitribai Phule Pune University Department of BiotechnologyDocument1 pageSavitribai Phule Pune University Department of BiotechnologypandaprasadNo ratings yet

- Simple Linear Regression Design Matrix & Optimality StepsDocument4 pagesSimple Linear Regression Design Matrix & Optimality StepspandaprasadNo ratings yet

- The Genetic MaterialDocument6 pagesThe Genetic MaterialpandaprasadNo ratings yet

- Simple Slopes For A 2-Way Interaction 2009-08-25Document6 pagesSimple Slopes For A 2-Way Interaction 2009-08-25pandaprasadNo ratings yet

- Cost JustificationDocument8 pagesCost Justificationfrancis_frpqa100% (1)

- Tell How Time Has ElapsedDocument2 pagesTell How Time Has ElapsedpandaprasadNo ratings yet

- Introduction To ChromatographyDocument25 pagesIntroduction To ChromatographyKameswara RaoNo ratings yet

- B C Vol 05 PDFDocument5 pagesB C Vol 05 PDFpandaprasadNo ratings yet

- ICT in EducationDocument34 pagesICT in EducationTarathipNo ratings yet

- Cbse Worksheet-04 Class - Ivmathematics - Word Problem - Time, Speed and DistanceDocument2 pagesCbse Worksheet-04 Class - Ivmathematics - Word Problem - Time, Speed and DistancepandaprasadNo ratings yet

- The Genetic MaterialDocument6 pagesThe Genetic MaterialpandaprasadNo ratings yet

- CBSE Worksheet-06 CLASS - IV Mathematics (Calendar)Document2 pagesCBSE Worksheet-06 CLASS - IV Mathematics (Calendar)pandaprasadNo ratings yet

- CBSE Class 4 Maths Chapter 9 Revision WorksheetDocument6 pagesCBSE Class 4 Maths Chapter 9 Revision WorksheetpandaprasadNo ratings yet

- CBSE Worksheet-09 CLASS - IV Mathematics (Time and Calendar)Document2 pagesCBSE Worksheet-09 CLASS - IV Mathematics (Time and Calendar)pandaprasadNo ratings yet

- CBSE Class 4 Maths Chapter 12 Revision WorksheetsDocument9 pagesCBSE Class 4 Maths Chapter 12 Revision WorksheetspandaprasadNo ratings yet

- CBSE Class 4 Maths Chapter 7 Revision WorksheetDocument6 pagesCBSE Class 4 Maths Chapter 7 Revision WorksheetpandaprasadNo ratings yet

- Binomialprobabilitydistribution 120218130430 Phpapp01Document17 pagesBinomialprobabilitydistribution 120218130430 Phpapp01pandaprasad100% (1)

- Zijin Mining - Material Classification System and Characteristics - V2.7 - 20200730ú¿englishúDocument891 pagesZijin Mining - Material Classification System and Characteristics - V2.7 - 20200730ú¿englishúNatasa SindjelicNo ratings yet

- Ukuran Kapal 2Document10 pagesUkuran Kapal 2Bhayu DewantoNo ratings yet

- 1.0 Dry DockingDocument200 pages1.0 Dry DockingMohd Azril Naharudin100% (9)

- Evaluasi Produktivitas Alat Gali-Muat Dan Alat Angkut Untuk PengupasanDocument8 pagesEvaluasi Produktivitas Alat Gali-Muat Dan Alat Angkut Untuk PengupasanExorcism ExoNo ratings yet

- Block CavingDocument5 pagesBlock CavingHarry PiyoNo ratings yet

- ATT III - 12. Maintain Seaworthiness of The ShipDocument7 pagesATT III - 12. Maintain Seaworthiness of The ShipGideon Tarigan0% (1)

- Ship Stability and SubdivionDocument16 pagesShip Stability and SubdivionAnmol AgarwalNo ratings yet

- Vishv E Malhar: S. DWTRDocument5 pagesVishv E Malhar: S. DWTRavishkar guptaNo ratings yet

- Presentation Viscaria Copper Project Avalon Australia SwedenDocument29 pagesPresentation Viscaria Copper Project Avalon Australia SwedenKevin YoungNo ratings yet

- HydroFloat CPF - Cu ApplicationDocument34 pagesHydroFloat CPF - Cu ApplicationNicolas PerezNo ratings yet

- Number of Body Corporate Approved and Renewed their RegistrationDocument66 pagesNumber of Body Corporate Approved and Renewed their RegistrationsanglimNo ratings yet

- 24 Universal Measurement of Ships CridlandDocument21 pages24 Universal Measurement of Ships Cridlandc rkNo ratings yet

- COAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Document56 pagesCOAL MINING TECHNOLOGY. A Presentation by MANOJ KUMAR SINGH Manager (IE), NCL-HQ, Singrauli (MP) - 486 889 E-Mail - Mks - Ie@nclhq - Nic.Sidhartha sahu100% (1)

- Optimum Hull Distance for Danube Delta CatamaranDocument8 pagesOptimum Hull Distance for Danube Delta CatamaranSathish VidyutNo ratings yet

- Muhammad Elvan Nawawi - 2006577044 - MIDSHIP SECTIONDocument1 pageMuhammad Elvan Nawawi - 2006577044 - MIDSHIP SECTIONMuhammad Elvan NawawiNo ratings yet

- Thick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHDocument13 pagesThick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHPrabhu PrasadNo ratings yet

- Mining Methods-Part III Surface Mining-Placer Mining: February 2010Document11 pagesMining Methods-Part III Surface Mining-Placer Mining: February 2010Ferdinand SiahaanNo ratings yet

- Mineral Resources Part 2Document31 pagesMineral Resources Part 2Eji AlcorezaNo ratings yet

- Standard BOMs for 1 ton billet productionDocument8 pagesStandard BOMs for 1 ton billet productionkoolshah09No ratings yet

- Vocational Training ReportDocument32 pagesVocational Training ReportManish KujurNo ratings yet

- Laju Perkasa ship specificationsDocument4 pagesLaju Perkasa ship specificationsIhsanul RidhoNo ratings yet

- Note Oc Engbatch15Document21 pagesNote Oc Engbatch15pawitra WijayaNo ratings yet

- Annual Land Use Format SampleDocument3 pagesAnnual Land Use Format SampleMAHARLIKA CONSTRUCTION AND AGGREGATES SUPPLY, OPCNo ratings yet

- Regional Coal Reserves Summary Philippines 2013Document1 pageRegional Coal Reserves Summary Philippines 2013Anonymous ilWXWxgNo ratings yet

- Bulbous bow increases ship speed and efficiencyDocument6 pagesBulbous bow increases ship speed and efficiencySameer NarsapurNo ratings yet

- International Tonnage Certificate (Surat Ukur)Document3 pagesInternational Tonnage Certificate (Surat Ukur)Samsul Basri LubisNo ratings yet

- Kehoe 2009Document16 pagesKehoe 2009Ananth Surya TejaNo ratings yet

- VENTILATION SYSTEM MODELINGDocument10 pagesVENTILATION SYSTEM MODELINGatha angelyNo ratings yet

- 14.draft Survey MV Eurus VentureDocument15 pages14.draft Survey MV Eurus VentureHussain KaddourahNo ratings yet