Professional Documents

Culture Documents

Mt-I 2 Marks With Answer PDF

Uploaded by

Siva RamanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mt-I 2 Marks With Answer PDF

Uploaded by

Siva RamanCopyright:

Available Formats

www.Vidyarthiplus.

com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

Two marks question and answer

Unit I

Metal Casting Processes

1. What is draft allowance? How is it provided for patterns?

It the vertical faces of pattern are perpendicular to parting line, the edges of mould may

damaged when the pattern is removed from the sand. Hence the vertical faces are mode taper

for easy removal of pattern. This slight taper given on the vertical sides of pattern in caused

draft allowance.

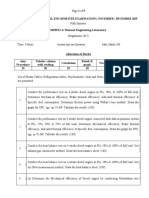

2. Enumerate the characteristics of following methods of sand ramming.

a) Hand b) Jolt c) Squeeze d) Slinger

Characteristics

Hand

Jolt

Squeeze

Slinger

Density

Ramming sand

Strength

Not

uniform

Not

Predicated

less

less

Not

uniform

less

Not

uniform

moderate

Uniform

moderate

moderate

fast

more

fast

moderate

Production rate

Accuracy

high

3. What are the common allowances provided on pattern?

The various types of pattern allowances normally given are;

1. Shrinkage allowance

2. Machining or finish allowance

3. Draft or taper allowance

4. Distortion or camber allowance

5. Rapping or shake allowance

4. What are the functions or riser?

The main function of the riser is to supply excess molten metal to the solidifying

casting it allows the escape of air.

5. How pattern differ from casting?

Pattern is slightly larger in size as compared to the casting. Pattern may be in two or

three pieces where as a casting is in one piece.

6. What are the tests carried out to determine the quality of casting?

Destructive test: Tensile, Impact, Hardness etc.

Non Destructive: Visual, sound, magnetic particles, dye penetration, ultrasonic etc.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

7. Define foundry.

A plant where the castings are made is called a foundry.

8. Define casting.

The Process of producing metal parts by pouring molten metal in to the mould cavity of

the required shape and allowing the metal to solidify. The solidified metal piece is called as

casting.

9. Define mould.

Mould is the cavity of the required casting made in wood, metal or plastics.

10. Define pattern.

The Model of the required casting made in wood, metal or plastics.

11. Name the various pattern materials.

Wood Teak wood, white pine etc.

Metal cast iron, brass, aluminium etc.

Plaster

Plastic

Wax

12. What are the different types of patterns used in foundries?

Solid or single piece pattern, match plate pattern, split pattern, sweep pattern, skeleton

Pattern, segmental pattern, loose piece pattern, shell pattern.

13. When do you made core (or) what is function of core in moulding sand?

To provide a hollow surface or recess on the casting, the core is made.

14. What is core print and what is its purpose?

A core print is an extra projection on the pattern. It supports the core.

15. What do you understand by core setting?

Caring or heating the cores to obtain enough hardness is called as core setting.

16. What are requirements of core sand?

Permeability, refractoriness, strength collapsibility, stability.

17. Mention the specific advantages of CO2 process.

Give strength and hardness to core

Process cost is less

It saves time on heating

It can be stored for long use

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

18. What is the properties good moulding sand?

Porosity or permeability, plasticity or flowability, strength or cohesiveness,

adhesiveness, Refractoriness, collapsibility.

19. What are the different types of moulding sand?

Green sand, Dry sand, Synthetic sand, Loam sand, Special sand, parting sand.

20. Write the composition of good moulding sand.

Green sand:

It contains 5 to 8% water and 15 to 20% clay.

Loam Sand:

Loam sand is a mixture of fine sands, fine refractoriness, clay, graphite fiber

and water. It contains more clay (50%)

21. List out any five moulding tools.

Shovel, Riddle, Rammer, Trowel, Slick, Strike off bar, lifter

22. What are the uses of runner and riser?

Runner:

It is used to make a sprue a hole in the cope.

It receives the molten metal from the pouring basin and passes to the cavity.

Riser:

It supplies excess molten metal to the solidifying casting.

It allows the escape of air.

23. What are chaplets?

Some times it is not possible to provide sufficient support for a core in the mould being

poured, if the cores are bigger in size. In such cases the core is supported with rigid metal

pieces called chaplets.

24. Mention any 2 difference between green sand mould and dry sand mould.

Green Sand Mould

Dry Sand Mould

Less time for making mould

More time consuming

Less surface finish

Better surface finish

Low strength

Stronger than green sand mould

Less permeability

More permeability

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

25. What are the different types of furnaces used for casting?

Cupola furnace, open hearth furnace, crucible furnace, pot furnace, Electric furnace.

26. What is need for providing chills in casting?

The chills are used to provide directional solidification or to increase the rate of

Solidification where the higher hardness required.

27. Name four different casting defects.

Shifts - Two halves mismatching or casting

Hot tear - Internal or external cracks

Fins - Thin projection of parting line

Inclusions - Foreign material present in casting

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

UNIT II

JOINING PROCESSES

28. What are the types of joints?

1. Permanent joint

2. Temporary joints

29. Give some example for permanent joints.

1. Riveted joint

2. Welded joint

30. Define Welding.

Welding may be defined as the process of joining similar metals by the application of

heat, with or without application of pressure and filler material.

31. What are the advantages of welding?

1. It produces permanent joints.

2. The overall cost of the welding equipment is very low.

3. A Large number of metals can be welded.

4. A good weld is as strong as base metal.

32. What are the types of welding process?

1. Pressure welding

2. Non-pressure welding

33. Give some example for pressure welding.

Spot welding, seam welding, lap and butt welding, projection welding.

34. Give some example for non - pressure welding.

1. Gas welding

2. Electric arc welding.

35. What is the principal of resistance welding?

The current is passes through the work pieces causes local heating and temperature

rises to fusion point. Subsequent applications of pressure result in permanent joining of work

pieces.

36. Give some example for resistance welding.

Spot welding, seam welding, butt welding, projection welding.

37. Give some example for gas welding.

1. Oxy acetylene welding

2. Oxy hydrogen welding

3. Oxy butane welding.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

38. What are the types of flame used in gas welding?

1. Neutral flame

2. Oxidizing flame

3. Reduction flame.

39. What are the equipments used in gas welding?

Acetylene cylinder, gas cylinder, trolley, hose and hose fitting, pressure regulator,

Welding torch.

40. List the technique used in gas welding.

1. Left ward welding.

2. Rightward welding.

3. Vertical welding

4. Overhead welding.

41. List the power sources used in arc welding.

1. AC machine

2. DC machine

3. Transformer

4. Transformer with DC rectifier

42. What is the use of flux?

To avoid the formation of oxide and get strong perfect weld. It takes away from the

impurities present in the surface of metal.\

43. Give some example for commonly used flux materials.

Borex, sodium chloride.

44. What is electrode?

Electrode made of metallic wire called core wire, coated uniformly protective coating

called flux.

45. What are the types of electrode?

1. Bare electrode

2. Dust coated electrode

46. What are the types of welding rods?

Low carbon steel rod, mild steel rod, vanadium steel rod.

47. List the spot welding methods.

Direct, indirect, push pulls method.

48. What is seam welding?

It is the resistance welding process. The heat is produced due to resistance against

current. It is also called stitch welding.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

49. Define - Electro slag welding.

It is the welding process in which metal fused together by molten slag which melt the

filler material and surface of the work to be welded.

50. What are the advantages of AC arc welding?

1. The transformer maintenance cost is less.

2. Efficiency is very high.

3. The power available is very less.

51. What is submerged arc welding?

The arc is produced between the electrode and the work piece. The arc, end of

electrode, the molten pool is submerged in the molten pool.

52. What is the use of inert gases in TIG welding?

It is used to avoid atmospheric contamination of the weld pool. The gases used in the

welding process are argon helium hydrogen.

53. What is the difference between TIG and MIG welding?

There is no filler material used in the MIG welding instead OF filler material some inert

gases are used.

54. What are the equipments used in the TIG welding?

1. Electrode, filler material, FLUX

2. Welding power source

3. Inert gas cylinder

4. Pressure regulator.

55. What is the use of wire feed mechanism in MIG welding?

It is used to deliver electrode to the constant or varying speed.

56. List the types of arc used in the plasma arc welding?

1. Transferred arc

2. Non transferred arc.

57. What is Thermit welding?

It is the welding process employing chemical energy is used to produce high

temperature.

58. What are the equipments used in Thermit welding?

1. Crucible

2. Mould

3. Supporting structure.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

59. What is the principal of Electron beam welding?

The heat is generated from the kinetic energy of intense beam of high velocity electron.

60. What are the types of weld defects?

1. Dimensional defects Warpage, incorrect joint preparation, size and profile.

2. Structural defects porosity, non metallic inclusion, incomplete fusion, inadequate

penetration.

3. Defective properties low strength, toughness.

61. What is slag inclusion?

It is a defect in the welding process in which failure to remove the slag after each layer

in a multilayer in the welding operation lead to slag inclusion.

62. What is the principle crack in the welding?

1. Hot cracking It occurs at high temperature just below freezing point. Excessive

sulpher and carbon content in promotes the cracking.

2. Cold cracking It occurs at room temperature. It occurs due to change in volume at

weld cool.

63. List the method involve in soldering.

1. Torch method

2. Furnace and hot plate method

3. Soldering iron method

4. Induction method.

64. What is soldering?

Soldering is the metal joining process with the help of the low melting point metal by

the use of filler material and heat. The melting point of filler metal is below 427C.

65. What is brazing?

Brazing may be defined as the technique of joining two similar or dissimilar materials

by the addition of filler material whose melting point is above 427C.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

66. What is the difference between soldering and brazing?

Soldering

Brazing

Joints require finishing

Soldering joints are very week and

are used for electrical contact fluid

toughness or sealing characteristics.

Used for joining metal and alloy

below 427C

It is very weak shearing strength

Little finishing is required

Joints are strong with good

resistance to fatigue and corrosion

Used for joining metal and alloy

above 427C

It is very high shearing strength

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

UNIT III

BULK DEFORMATION PROCESSES

67. What are the general advantages of forging as a manufacturing process?

Porosity in the materials largely eliminated

Better mechanical properties

Ability of forging to withstand unpredictable loads

Rapid duplication of the components

Wide range of forgeable metals is available

68. Define cold working of metals.

Those processes, which are working below the recrystallisation temperature, are called

cold working of metals.

69. Define hot working of metals.

Those processes which are working above the recrystallisation temperature is called hot

working of metals.

70. What are the advantages of hot working over cold working?

Hot working requires less to get necessary deformation

Brittle materials can also be hot worked.

71. Define extrusion ratio.

It is defined as the ratio of the cross sectional area of the billet to the cross section area

of the product.

72. Define degree of drawing.

The ratios of the difference in cross sectional area before and after drawing to the initial

Cross sectional area.

RA=1- (Do)2 /Di

73. What are the methods used for producing seam less tube?

Extrusion, piercing

74. What is the formula for percentage reduction in redrawing?

% reduction= D-d/Dx100

75. What is the difference between a bloom and a billet?

Bloom fast break down of ingot into the size of 150mm x 150 mm to 250 mm x

300mm

Billet a reduction of bloom of 50mm x 50mm to 125mm x 125mm by hot rolling.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

76. Define slab, plate, sheet, and strip.

Slab - obtained from bloom by rolling

Plate - the thickness, which is having minimum 6.35 mm

Sheet - thin partner of plate

Strip - a narrow sheet having maximum with of 6.00mm

77. Define foil, bar wire.

Foil strip with maximum width of 300mm and maximum thickness of 1.5m.

78. Define hobbing.

It is the process of forming a very smooth, accurate polished shape on punch.

79. What is the difference between coining and embossing process?

Coining - pressing operation

Embossing - forging operations

80. What is meant by spring back?

During the bending operations, when the pressure on the metal release the bend angle

may slightly change this is called spring back.

81. What do you understand by recrystallisation and recrystallization temperature?

The approximate minimum temperature at which complete recrystallisation of a cold

worked metals take place within a specified time.

Recrystallization: Formation of new grain when the metal undergoes working.

82. List the different types of forging machines.

1. Forging presses

2. Forging hammers

3. Forging machine or up setter

83. What is tube piercing?

It is used to produce the seamless tube by using mandrel. It is used to produce the

pierce at the center of the ballet.

84. List the different types of rolling mills.

1. Two high rolling mills

2. Three high rolling mills

3. Three high rolling mills

4. Cluster rolling mills

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

85. What are the defects in rolled parts?

1. Pitting

2. Cold shut and laps

3. Dents

4. Cracks

86. What are the types of extrusion?

1. Direct or forward extrusions

2. Indirect or backward extrusion.

87. What is wire drawing?

Wire drawing is carried out by pulling a rod through the die which causes the reduction

in cross section area of the rod.

UNIT IV SHEET METAL PROCESSES

88. Enumerate the various typical applications of electro magnetic forming process.

Compression and expansion of circular bar was carried out it is used for instrument

gear assembly, embossing and sizing of cups etc.

89. Name any 4 four high power explosive used in explosive forming?

Dynamite

Amatol

TNT (Tri-hitrolnene)

RDX (Cyclotrimelthylene trinitramine)

90. List out major functions which affect the performance in electromagnetic forming?

High intensity between the coils

Eddy current

Coil compression

Flux concentration

91. List out and 2 advantages of explosive forming?

Forming process occurs in

Small interval of time

Very high compact densities can be obtained

Mixtures of metal can be easily compacted

92. Give the applications of electro hydraulic forming?

Bulging, bending, drawing, blanking and piercing

93. What is high energy rate forming process?

It includes a number of process in which part are formed at a rapid rate by extremely

high pressure. The energy needed for processing the material is released in a very short time.

It is called high-energy rate forming process.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

94. Mention the few applications of HERF

It is used for compacting metal powder

It is used for forging and cold welding

It is also used for bending and extruding

Metal cutting process is also possible

95. Classify the high energy rate forming process?

Explosive forming, Electro hydraulic forming, Electromagnetic forming, Dynapak high

speed forming process.

96. What are materials used for making dies in explosive forming?

The commonly used die materials are concrete, world, epoxy, plastics, plaster of paris

and CI, stud etc.

97. What is the principle of magnetic pulse forming?

The basic principle is that discharging of a capacitor through coil over a period of micro

seconds, the magnetic flux densities of the order of hundreds of kilogauss can be produced.

98. What is the basic principle of dynapak machine?

There are simple in construction

Better surface finished in achieved

Better control of gain and size forging capability

99. Define blanking.

It is used to produce the outer contour of the work piece by using presses.

100. What are the types of sheet metal joining tools?

1. Seaming tools

2. Grooving punch

3. Rivet set

101. What are the types characteristics of sheet metals?

1. Plasticity

2. Malleability

3. Stretch ability

UNIT V MANUFACTURING OF PLASTIC COMPONENTS

102. Classify the types of plastics.

1. Thermoplastics

2. Thermosetting plastics.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

103. Classify thermoplastics.

1. Amorphous Methacrylate, polyvinyl chloride, cellulose, fluorinated polymer

2. Crystalline polyethylene, polyamide, polypropylene

104. List the application of blow moulding.

It is used to produce hollow components like containers, drink bottles etc.

105. What are the characteristics of thermosetting plastics?

1. It cannot soften once it moulded even at high temperature.

2. These plastics have cross linked molecules

3. These links are broken at high temperature but important properties are destroyed.

106. Give some example for thermosetting plastics.

Phenol formaldehyde, urea formaldehyde, phenolic, polyester, epoxide.

107. Distinguish between thermo and thermosetting plastics.

1. They can be repeadly softened 1. Once hardened and set, they do by heat an

hardened by cooling. not soften with the application of heat.

2. They are comparatively softer 2. They are more stronger and and less strong harder

than thermoplastics

3. They are produced by the 3. They are produced by the Polymerization condensation

Polymerization

4. They are usually supplied as 4. They are usually supplied in granular material

polymerized form.

108. What are the types of injection mouldings?

1. Straight plunger type

2. Single stage reciprocating screw type

3. Two stage plunger or screw plasticizer type.

109. What is extrusion?

It is the term applied to the Process OF shaping plastics through die orifice. It is a

continuous process.

110. List the parts used in the transfer moulding.

1. Plunger

2. Sprue.

3. Knockout pins

4. Cooling systems

5. Transfer chamber.

www.Vidyarthiplus.com

www.Vidyarthiplus.com

SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL

03 Ph: 9942099122

DEPARTMENT OF MECHANICAL ENGG.| MANUFACTURING TECHNOLOGY I

Sem/Year III/ II

111. What is the use of torpedo and hopper?

Hopper It is used to feed the granular form of material in to the heated cylinder.

Torpedo It helps in spreading the moulding material uniform around the wall of the heated

cylinder.

112. What is the use of rotational moulding?

It is used to produce the hollow component like toys. Normally it is used for polyvinyl

chloride, polyethylene.

113. What is calendaring?

It is used to produce sheets and films from plastics materials such as polyvinyl chloride,

polyethylene.

114. What is Parison?

The blow moulding process starts with the production of a tube made of thermoplastics

material. This is called parison.

115. List the types of joining of plastics.

1. Mechanical fastening

2. Solvent bonding

3. Hot plate welding

4. Induction welding.

116. Define - solvent welding.

It is used to join the plastics by the help of solvent. The solvent is used to soften the

plastics and joining by pressing together.

www.Vidyarthiplus.com

You might also like

- Planetary EmpiresDocument15 pagesPlanetary Empiresrodnan197886% (7)

- Robotics MCQ 1Document25 pagesRobotics MCQ 1Siva Raman100% (4)

- Robotics MCQ 1Document25 pagesRobotics MCQ 1Siva Raman100% (4)

- 27.4 MATHS Number-and-Place-Value-Workbook PDFDocument34 pages27.4 MATHS Number-and-Place-Value-Workbook PDFdddenisadNo ratings yet

- Anthony J Jakeman Et. Al. - Integrated Groundwater ManagementDocument756 pagesAnthony J Jakeman Et. Al. - Integrated Groundwater ManagementPaul Kevin Bautista PalaciosNo ratings yet

- Gate FormulaDocument121 pagesGate FormulaJosh Manohar0% (1)

- Engineering Material AssignmentDocument3 pagesEngineering Material AssignmentSharjeel Faisal100% (1)

- Intro RoboticsDocument49 pagesIntro Roboticsariff05100% (2)

- EG5096 Fatigue and Fracture Mechanics Exam PaperDocument4 pagesEG5096 Fatigue and Fracture Mechanics Exam PaperShanice McAlister-BishopNo ratings yet

- Manufacturing Technology - I Unit - I: 2 Marks Question & AnswersDocument15 pagesManufacturing Technology - I Unit - I: 2 Marks Question & AnswersSK NAGOOR VALI100% (1)

- MT-1 (English) - N SchemeDocument288 pagesMT-1 (English) - N SchemeKumar Subramanian100% (1)

- Introduction To Casting ProcessDocument11 pagesIntroduction To Casting ProcessMuraliMohan0% (1)

- Manufacturing Process 1 Question BankDocument8 pagesManufacturing Process 1 Question Bankashok PradhanNo ratings yet

- MF7203-Dec 16 THEORY-OF-METAL-FORMINGDocument3 pagesMF7203-Dec 16 THEORY-OF-METAL-FORMINGupender100% (1)

- UNIT-IV Question BankDocument3 pagesUNIT-IV Question BankParamasivam VeerappanNo ratings yet

- Ep LabDocument89 pagesEp LabkanagavelNo ratings yet

- Casting and Pattern Making ProcessesDocument11 pagesCasting and Pattern Making ProcessesAshok PradhanNo ratings yet

- ME8792 2marksDocument31 pagesME8792 2marksRajNo ratings yet

- Me8792 - Power Plant EngineeringDocument48 pagesMe8792 - Power Plant EngineeringPalanivel Rajan A RNo ratings yet

- Term Paper Inorganic PolymersDocument24 pagesTerm Paper Inorganic PolymersCasey Karua0% (1)

- ME 8682 Project work on 3-Roller Bar Bending MachineDocument14 pagesME 8682 Project work on 3-Roller Bar Bending MachineLovely Mohan0% (1)

- 18ME35A-MCF Vtu QuestionsDocument5 pages18ME35A-MCF Vtu QuestionsRakshith M100% (7)

- DMM-2 Second Mid Bit PaperDocument2 pagesDMM-2 Second Mid Bit PaperYeswanth Kumar ReddyNo ratings yet

- RP Question BankDocument4 pagesRP Question BankAkshay IyerNo ratings yet

- Pattern MaterialsDocument16 pagesPattern MaterialsMani Kandan100% (1)

- MOM OU Old Question PaperDocument2 pagesMOM OU Old Question PaperAmmineni Syam PrasadNo ratings yet

- Engineering Physics 2 Unit-5Document98 pagesEngineering Physics 2 Unit-5Sriram J0% (1)

- Machine Design Tutorial Sheet QuestionsDocument3 pagesMachine Design Tutorial Sheet Questionsabhishek chaurasiyaNo ratings yet

- Machine Tools LabDocument37 pagesMachine Tools LabAbdelhay Mohamed HassanNo ratings yet

- Kings: Manufacturing Technology - IiDocument5 pagesKings: Manufacturing Technology - IiSaravanan MathiNo ratings yet

- Project Report on Rack and Pinion Gear DesignDocument15 pagesProject Report on Rack and Pinion Gear DesignWaqasNo ratings yet

- Assignment For UNIT IDocument2 pagesAssignment For UNIT IParamasivam VeerappanNo ratings yet

- Machine design philosophy and procedure considerationsDocument20 pagesMachine design philosophy and procedure considerationsS VNo ratings yet

- ME8491 Engineering Metallurgy COURSE PLANDocument4 pagesME8491 Engineering Metallurgy COURSE PLANKarthick NNo ratings yet

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Machining Processes and Metrology Question PaperDocument2 pagesMachining Processes and Metrology Question PaperHarshan ArumugamNo ratings yet

- Structural Materials: Unit 3Document53 pagesStructural Materials: Unit 3Jayashree MisalNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document2 pagesQuestion Paper Code:: (10×2 20 Marks)jastraNo ratings yet

- Chapter 1 - Introduction To Hybrid Machining ProcessesDocument31 pagesChapter 1 - Introduction To Hybrid Machining ProcessesGAURAV KUMAR100% (1)

- Fitting Models: Semi Circular JointDocument2 pagesFitting Models: Semi Circular Jointsubba reddyNo ratings yet

- 2016Document896 pages2016Someshwar KoreNo ratings yet

- Introduction To UCMPDocument27 pagesIntroduction To UCMPGowtham sivateja100% (2)

- Engineering Materials and Metallurgy 2 Mark With AnswersDocument31 pagesEngineering Materials and Metallurgy 2 Mark With AnswersbrindharajasekarNo ratings yet

- Department of Chemical Engg. UET PeshawarDocument2 pagesDepartment of Chemical Engg. UET PeshawarZakaria UsafxaiNo ratings yet

- 03a Direct Stiffness Method Spring and BarDocument23 pages03a Direct Stiffness Method Spring and BarAnamolNo ratings yet

- Computer Aided Machine DrawingDocument16 pagesComputer Aided Machine DrawingAmit BhagureNo ratings yet

- KINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsDocument7 pagesKINEMATICS OF MACHINERY: UNIT 2: VELOCITY & ACCELARATION: Objective Questions From Gate With SolutionsVenkateswar Reddy MallepallyNo ratings yet

- Latest PHD TopicsDocument11 pagesLatest PHD Topicsvsreedhar80100% (2)

- LVDT Lab ManualDocument3 pagesLVDT Lab Manualguruabhay100% (2)

- IIT Roorkee Advanced Manufacturing ProcessesDocument92 pagesIIT Roorkee Advanced Manufacturing Processesvishal guptaNo ratings yet

- SheetDocument3 pagesSheetBarun BeheraNo ratings yet

- Chap 3 DieterDocument25 pagesChap 3 DieterTumelo InnocentNo ratings yet

- Mechanical Behavior of Banana Fiber Reinforced Epoxy CompositesDocument30 pagesMechanical Behavior of Banana Fiber Reinforced Epoxy Compositespramo_dassNo ratings yet

- Ucmp 2 Mark With AnswerDocument17 pagesUcmp 2 Mark With AnsweranithayesurajNo ratings yet

- Ce 8381som Lab ManualDocument31 pagesCe 8381som Lab ManualAERO JPR50% (2)

- Me6411 Manufacturing Technology-II Lab ManualDocument35 pagesMe6411 Manufacturing Technology-II Lab ManualdibyenindusNo ratings yet

- CFD Question Bank for Aerospace ApplicationsDocument3 pagesCFD Question Bank for Aerospace ApplicationsGanesh Natarajan SNo ratings yet

- Thin Wall Pressure VesselsDocument20 pagesThin Wall Pressure VesselsTare Er KshitijNo ratings yet

- Eee3352 TutorialDocument23 pagesEee3352 TutorialDesmond CheweNo ratings yet

- MFT 2 TWO Marks With AnswersDocument28 pagesMFT 2 TWO Marks With AnswersThulasi RamNo ratings yet

- Manufacturing Technology-I - Department of Mechanical EngineeringDocument4 pagesManufacturing Technology-I - Department of Mechanical EngineeringSoma SundaramNo ratings yet

- Engineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)Document4 pagesEngineering Physics-Important Questions: Shorts UNIT - 1 (Units and Dimensions)psatyasankarNo ratings yet

- Question Paper 2 PDFDocument4 pagesQuestion Paper 2 PDFfotickNo ratings yet

- Types of Pattern and Its ApplicationDocument27 pagesTypes of Pattern and Its ApplicationKarthik GanesanNo ratings yet

- Material Science Course File (Coded New)Document36 pagesMaterial Science Course File (Coded New)vipulNo ratings yet

- Differential Transformation Method for Mechanical Engineering ProblemsFrom EverandDifferential Transformation Method for Mechanical Engineering ProblemsNo ratings yet

- Me8381 CadDocument20 pagesMe8381 CadSiva RamanNo ratings yet

- Thermal Lab-2 Manual CompletedDocument69 pagesThermal Lab-2 Manual CompletedSiva RamanNo ratings yet

- Vallathirakkottai Post, Pudukkottai-622305 Anna University-ChennaiDocument1 pageVallathirakkottai Post, Pudukkottai-622305 Anna University-ChennaiSiva RamanNo ratings yet

- ME8512 Thermal Engineering Laboratory: Fifth SemesterDocument5 pagesME8512 Thermal Engineering Laboratory: Fifth SemesterKARTHINo ratings yet

- FEMAP and MATLAB Simulation Lab ManualDocument90 pagesFEMAP and MATLAB Simulation Lab ManualSiva RamanNo ratings yet

- ME8511-Kinematics and Dynamics Laboratory: Fifth SemesterDocument2 pagesME8511-Kinematics and Dynamics Laboratory: Fifth SemesterSiva RamanNo ratings yet

- Me8361 - MT-1Document10 pagesMe8361 - MT-1Siva RamanNo ratings yet

- B.E/B.Tech Practical Exam on Mechatronics LabDocument2 pagesB.E/B.Tech Practical Exam on Mechatronics LabSiva RamanNo ratings yet

- Me8513 MMDocument2 pagesMe8513 MMSiva RamanNo ratings yet

- MT II LAB MANUAL NewDocument51 pagesMT II LAB MANUAL NewSiva RamanNo ratings yet

- Me8381 CadDocument20 pagesMe8381 CadSiva RamanNo ratings yet

- High Voltage Engineering: Unit 1Document9 pagesHigh Voltage Engineering: Unit 1Siva RamanNo ratings yet

- DOM Manual Only ExperimentsDocument38 pagesDOM Manual Only ExperimentsSiva RamanNo ratings yet

- Francis Xavier Engineering College Manufacturing Technology Lab ManualDocument101 pagesFrancis Xavier Engineering College Manufacturing Technology Lab ManualSiva RamanNo ratings yet

- Aucr2017 TIME TABLEDocument120 pagesAucr2017 TIME TABLESiva RamanNo ratings yet

- FM Lab Manual NewDocument73 pagesFM Lab Manual NewSiva RamanNo ratings yet

- MECH (University Examination)Document1 pageMECH (University Examination)Siva RamanNo ratings yet

- Semes Ter Subject Code Subject Name Ex Am Dat e TimingDocument7 pagesSemes Ter Subject Code Subject Name Ex Am Dat e TimingSiva RamanNo ratings yet

- Industrial Robot AnatomyDocument68 pagesIndustrial Robot AnatomyVimal KekNo ratings yet

- ME8511-Kinematics and Dynamics Laboratory: Fifth SemesterDocument2 pagesME8511-Kinematics and Dynamics Laboratory: Fifth SemesterSiva RamanNo ratings yet

- SRR CET University Exams Dec 2020-Jan 2021 ScheduleDocument2 pagesSRR CET University Exams Dec 2020-Jan 2021 ScheduleSiva RamanNo ratings yet

- Me6503 Dome QB PDFDocument65 pagesMe6503 Dome QB PDFmaniNo ratings yet

- Dme QNDocument3 pagesDme QNSiva RamanNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Dme Model KeyDocument10 pagesDme Model KeySiva RamanNo ratings yet

- Me6503 Dme Mech VST Au Unit IV PDFDocument34 pagesMe6503 Dme Mech VST Au Unit IV PDFSandeep BadinehalNo ratings yet

- Colosseum Code of Conduct Procedure - Chinese RevDocument4 pagesColosseum Code of Conduct Procedure - Chinese Revhrdhse. WanxindaNo ratings yet

- TERMINOLOGI HUKUM-1st LectureDocument15 pagesTERMINOLOGI HUKUM-1st LectureAal Lukmanul HakimNo ratings yet

- KSH13007 KSH13007: SEMIHOW REV.A1, Oct 2007Document6 pagesKSH13007 KSH13007: SEMIHOW REV.A1, Oct 2007Manolo DoperNo ratings yet

- Sound Propagation p.11-p.13Document2 pagesSound Propagation p.11-p.13Antonio BarónNo ratings yet

- 2 Tutorial Pressure Sept19Document7 pages2 Tutorial Pressure Sept19hairinnisaNo ratings yet

- Constructing The Roadbed: Group 4: Capangpangan, JalikaDocument56 pagesConstructing The Roadbed: Group 4: Capangpangan, JalikaKrizza Joy Lintag CaspeNo ratings yet

- DLL Handicraft - Grade 7 q2w4Document3 pagesDLL Handicraft - Grade 7 q2w4lawsinmaureenNo ratings yet

- Full Test Bank For Child and Adolescent Development An Integrated Approach 1St Edition Bjorklund PDF Docx Full Chapter ChapterDocument36 pagesFull Test Bank For Child and Adolescent Development An Integrated Approach 1St Edition Bjorklund PDF Docx Full Chapter Chapterslogmaying7y5g100% (8)

- Psych Stats CIA-2030206 Method FileDocument39 pagesPsych Stats CIA-2030206 Method FileAranya BanerjeeNo ratings yet

- Business 71 PDFDocument1 pageBusiness 71 PDFLissa Montiel0% (1)

- Network Adjustment Report: Project DetailsDocument5 pagesNetwork Adjustment Report: Project DetailsNeira Melendez MiguelNo ratings yet

- Example of Discussion in Research PaperDocument6 pagesExample of Discussion in Research Paperipkpzjbkf100% (1)

- Self ReflectionDocument2 pagesSelf Reflectionapi-575370301No ratings yet

- A Letter To BenefactorDocument2 pagesA Letter To BenefactorJeremy JM88% (8)

- Margaret Hamilton Takes Software Engineering To The Moon and BeyondDocument5 pagesMargaret Hamilton Takes Software Engineering To The Moon and BeyondAntonio TorizNo ratings yet

- 1.my Feelings ADocument2 pages1.my Feelings ACath TempestNo ratings yet

- Unit I - UV-vis Spectroscopy IDocument10 pagesUnit I - UV-vis Spectroscopy IKrishna Prasath S KNo ratings yet

- 201 EE1029 Midterm - Group1Document4 pages201 EE1029 Midterm - Group1Thao Vo VanNo ratings yet

- ActivityDocument2 pagesActivitycathy cajegas100% (1)

- TROUBLE CODE - Ma-1Document55 pagesTROUBLE CODE - Ma-1José Rojo EspinozaNo ratings yet

- Laboratory Ergonomics Checklist: (DOSH Registration)Document3 pagesLaboratory Ergonomics Checklist: (DOSH Registration)Bakhtiar DollahNo ratings yet

- Environmental and Social Impact Assessment for Tamane Gamada Exploration ProjectDocument39 pagesEnvironmental and Social Impact Assessment for Tamane Gamada Exploration ProjectFiraol GetenetNo ratings yet

- Formation Damage Cuased by A Water Blockage Chemical SPE-00073790Document12 pagesFormation Damage Cuased by A Water Blockage Chemical SPE-00073790Oscar Mauricio TellezNo ratings yet

- Lesson 1 Definition of Quantitative Research - pdf2Document8 pagesLesson 1 Definition of Quantitative Research - pdf2Funny JuanNo ratings yet

- Inked Lives - Tattoos Identity and PowerDocument88 pagesInked Lives - Tattoos Identity and Powerךו ני אלNo ratings yet

- Osman Jayasinghe Chemistry IIDocument4 pagesOsman Jayasinghe Chemistry IIyasidu rashmikaNo ratings yet

- Transcription M3S2Document21 pagesTranscription M3S2GrowUP. AINo ratings yet