Professional Documents

Culture Documents

Rack Air Containment Application PDF

Uploaded by

mksayshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rack Air Containment Application PDF

Uploaded by

mksayshiCopyright:

Available Formats

APC

APPLICATION NOTE #90

Rack Air Containment application

guidelines and approved configurations

By Kevin Dunlap

Abstract

The Rack Air Containment System (RACS) is a modular front and rear plenum for use in isolating the supply and return air

between an APC Netshelter SX rack enclosure and an APC InRow cooling unit. The containment system is designed to

create a separate environment for air distribution in order to prevent mixing of hot and cold air streams, resulting in a more

predictable cooling pattern. The modular design and ability to retrofit to an existing Netshelter SX rack enables medium to high

density racks to be cooled in an autonomous environment without overcooling the room mixed with lower density loads.

How it works

The most common configuration for rows of racks in the data center is hot/cold aisle design for separating the supply and

return air paths. RACS takes this one step further by containing the return path of hot air exhausted from the IT equipment.

Optionally, the supply path can be contained as well to enhance the distribution path, isolate the rack or for noise attenuation.

Figures 1 and 2 show a rear only and front/rear containment configuration.

Figure 1 RACS (Rear only)

Figure 2 RACS (Front and Rear)

1

____________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

Rear containment only configurations capture the hot exhaust air in a plenum that is also connected to one or more InRow

cooling unit. InRow cooling units are designed to draw air in a back to front pattern. The warm air in the RACS plenum is

drawn to the InRow cooling unit where it is cooled and discharged out the front and back into the room at a room neutral

temperature. The discharge temperature is near, at, or slightly below, room temperature and the selected set point.

Front and rear containment configurations not only capture the hot exhaust air, but also the supply air from the InRow cooling

unit, directing it to the IT equipment inlets in the adjacent rack(s).

Rear only containment is an option because it addresses the warm air discharge from IT racks preventing it from heating up

the surrounding environment. Front only containment is not an option because of the net effect to the inlet side of surrounding

rack enclosures with open fronts. It would also not produce the same energy and capacity gain realized from the warmest

possible air return to the cooling unit.

Benefits of Rack Air Containment

Eliminating mixing of hot/cold air streams in the data center has several benefits over a flooded and mixed environment. The

main benefits from this design are:

Table 1 Rack Air Containment Benefits

Benefit

Description / Details

Warmer intake temperatures

increase unit capacity

Higher temperature differentials, between the entering air and the cooling

coil, increase the amount of heat transfer and therefore capacity of the

cooling unit. This

Predictable cooling

Removal of heat ensures that the supply temperature has little to no mixing

and can be relatively constant and within the ASHRAE recommended

guidelines for air delivery.

Isolate high density racks

Allows for mixed density racks to exist in the same environment without

overcapacity or overcooling by the perimeter cooling system.

Reduction or elimination of

moisture removal

Elevated entering and discharge temperatures almost guarantees that the

leaving air temperature from the cooling coil will be above dew point. This

saves energy on make-up humidification.

*Sound Reduction

Containing the front and/or rear of the rack muffles the noise created by

server and cooling unit fans.

*Using front rack air containment reduces the noise of the InRow unit by 10dba. Tests were conducted on four system

configurations: 1 ACSC100 and 1 SX Rack with standard doors, 1 ACSC100 and 1 SX Rack with rear RACS only, 1 ACSC100 and

1 SX Rack with front and rear RACS, and 2 ACSC100 and 1 SX Rack with front and rear RACS. Measurements were taken on all

four sides at a distance of 1m (3.28 ft) and 1.5m (4.92 ft) from the unit at a height of 1.2 m (3.94 ft).

2

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

Applications and product usage

The use of RACS is not limited to one situation or application in the data center or wiring closet/computer room. In fact, it may

be used as a general purpose cooling solution or as a targeted deployment for a single rack or group of racks. The following

are some common applications for the product.

Isolating Hot Racks

There is a large number of existing data centers, which were designed for densities below 3 kW per rack, in operation today.

Newer IT equipment has pushed well beyond the design density of 3 kW per rack. This stressing of the perimeter or central air

handling cooling system is sometimes compensated for by adding additional capacity (which doesnt solve the air distribution

problem) or by overcooling the room by running the set point at a lower temperature. Overcooling is a hope strategy the does

not address the hot spot directly but may temper the hot air by mixing in some portion of the overcooled surrounding air.

In this application, in conjunction with InRow cooling unit, RACS provides a targeted cooling solution to higher density racks

without changes to the existing system that was cooling lower density racks sufficiently. Figure 3 shows how a single highdensity rack could be isolated using RACS.

Figure 3 Isolated high density rack with RACS

R

R/B-2

R/B-2

R/B-2

R/B-2

R/B-2

R/B-4

...

R/B-8

...

R/B-2

R/B-2

R/B-2

R/B-2

R/B-2

R/B-2

R/B-2

R/B-2

Single high

density rack

Single rows

In some cases where hot aisle containment system (HACS) is the preferred method, there may still be a single odd row. This

happens when there are an odd number of rack rows stranding a single row from the ability to use HACS. If such a scenario

occurs, RACS can be used on the odd row to continue the containment architecture using a containment system without

blocking panels to create a shared plenum for air distribution.

Figure 3 Odd or single row RACS deployment

3

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

Small Deployments

Small computer rooms and wiring closets are typically not designed for cooling around the clock and through each seasonal

change. Most of the time, these spaces are designed for comfort cooling and may have evening and weekend set backs on

the thermostat to save money. In addition, these environments change from cooling to heat during the winter months.

For this reason, a dedicated cooling system that is separate from the surrounding environment may be required. This

application is ideal for any of the InRow cooling products with RACS and a small number of racks.

Rack Air Containment Components

There are a number of components with the RACS system that allow it to be both retrofitted in the field and modular in nature.

First, since the front containment components are optional, these must be chosen separately. Both rear and front containment

components have the option for separator panels (end caps) to isolate airflow from racks to specific InRow cooling units. While

these are optional, there are specific rules that must be followed to ensure proper air distribution that are discussed later in the

application note.

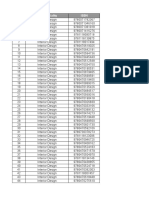

Table 2 SKUs and descriptions

SKU

Description

ACCS1000

Rear Assembly for InRow RC100, SC,

RD100/200

ACCS1001

Rear Assembly for Netshelter SX 42U

600mm Wide

ACCS1002

End Caps

ACCS1003

Front Assembly for InRow RC100, SC,

RD100/200

ACCS1004

Front Assembly for InRow RP, RC500 and

RD500

ACCS1005

Front Assembly for Netshelter SX 42U

600mm Wide

ACCS1006

Rear Assembly for NetShelter SX 42U

750mm wide

ACCS1007

Front Assembly for NetShelter SX 42U

750mm wide

4

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

Each SKU is designed to be either installed at the same time as the rack and cooling units, or be retrofitted to an existing rowbased cooling environment. Rear and front (optional) rack doors are reconfigured with plexiglass and re-mounted on the new

frame extensions. Figure 4 illustrates the different components and how they are assembled to make the final solution.

Figure 4 RACS exploded view with InRow RC and Netshelter SX rack

Rear doors

from rack

Rack plenum

assembly rear

and front

Rear door from

cooling unit

SX

Rack

Plenum end

cap

Clear insert

installed on the

inside of all

doors to block

airflow

Front door

from rack

InRow

cooling

unit

Cooling plenum

assembly front

and rear

Front door

from cooling

Product and Component Configuration Options

The ability of the RACS to work with multiple InRow cooling products and the modularity of the parts enables many different

configuration possibilities. However, since each cooling unit has different performance capabilities, there are pre-tested

configurations that have been tested for performance to ensure the proper air distribution within the RACS system. In addition,

while the number of racks is not limited in RACS, the ratio of racks to cooling units and spacing must adhere to approved

configuration layouts and application rules.

Figure 5 represents the tested and approved modules for RACS. Modules are defined as a set of racks and cooling units

paired together in a configuration. Each module has end caps to close off the rear plenum from the surrounding space. End

caps can be removed to join multiple modules together as long as the rules for common plenum are adhered to. These rules

are:

5

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APC

1.

APPLICATION NOTE

The InRow SC may not be used in combination to create a common plenum between modules without consulting

the factory.

2.

Any combination of InRow 300mm wide or InRow 600mm wide units may be used in combination without end

caps.

3.

InRow SC units may not be mixed within the same aisle on a common return plenum with any other types of

units.

4.

InRow RD100 and RD200 units may be mixed on the same common return plenum.

5.

InRow RC500 and RP500 Units may be mixed within the same aisle on a common return plenum.

6.

InRow RD500 and RP100 Units may be mixed within the same aisle on a common return plenum.

7.

Any unit type combinations not specifically allowed in Rules 5, 6, and 7 may not be mixed within the same aisle

8.

InRow RC100 and RD100 configurations highlighted as Type D may not be combined with another module

on a common return plenum.

when three InRow RC100 or RD100 units would then be adjacent.

9.

Containment systems using InRow RP should never mix heat of rejection methods (chilled water and air-cooled).

6

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

InRow RP, RC500, and RD500

(Chilled Water and Air-Cooled)

InRow RC100 and RD100

(Chilled Water, Air-Cooled, or

Glycol-cooled)

InRow SC

(Air cooled self-contained)

Figure 5 RACS Modules and Module Combination Rules

SC

SC

SX Rack

SC

SC

SX Rack

2+1

SX Rack

2+1

SX Rack

2+1

SX Rack

SX Rack

SC

SX Rack

RC

RC

SX Rack

RC

RC

SX Rack

RC

RC RC

SX Rack

RC RC

Type

SX Rack

SX Rack

RP

SX Rack

RP

SX Rack

RP

RP

SX Rack

SX Rack

RP

SX Rack

Blue dashed lines indicate

optional front containment

System Controls

InRow products have multiple modes of operation for system control. When placed in a rack air containment system, the

InRow unit must be set to RACS/HACS to ensure that the system is operating properly.

7

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APPLICATION NOTE

APC

In addition, the RACS mode has two set points that must be configured. These set points are supply air temperature and

fan speed preference. In this mode, the cooling set point will have no effect on the operation of the unit. The reason is, the

cooling set point looks at a remote temperature probe in an open-row configuration in order to maintain the inlet temperature to

the adjacent racks. In a RACS configuration, the temperature of the supply air (discharge from the unit) will be the same as

the inlet to the IT equipment because it will not have a chance to mix with the surrounding environment. In addition, the inRow

unit must respond much quicker in RACS mode to ensure that spikes in rack exhaust temperature that occurs over a time

scale of a few seconds is properly neutralized.

While most IT equipment is designed for approximately a 20F (11.1C) temperature rise from the inlet to the exhaust (deltaT),

some equipment will require more or less airflow. In cases where the deltaT is known, the fan speed preference setting can be

configured for the desired cfm/kW (l/s per kW).

Figure 5 Fan speed preference selection

Fan Speed

Preference

DeltaT

F

CFM per

kW

DeltaT

C

L/s per

kW

High

10

325

5.5

2.56

Medium-High

15

215

8.3

1.69

Medium

20

160

11.1

1.26

Medium-Low

25

130

13.9

1.02

Low

30

105

16.6

.83

Selection of the fan speed preference should be done by the user using the chart above if the deltaT or CFM/kW (L/s per kW)

is a known. If neither of these two values is known, then a setting of medium is recommended. If it is later determined that the

fan speed is to low or high, it can be easily adjusted.

Choosing a fan speed preference that is too low (higher delta T and lower CFM/kW) could result in the airflow from the servers

to the greater than that of the cooling unit. In this case hot air would be exhausted out the top and bottom of the racks

resulting in an increase in heat load to the rest of the room. Operating with the fan speed preference set higher than

necessary does not have a negative effect on cooling capability, but in general the fans will run faster and the unit will use

more energy. For more information on the controls of the InRow RP, RD, or RC, refer to APC application note #119.

8

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

APC

APPLICATION NOTE

Conclusions

The rack air containment system is a modular plenum system for improving the predictable architecture of InRow cooling.

Following the guidelines for mating the containment system, system control settings, rack placement and cooling units will

ensure proper air distribution throughout the system.

About the Author:

Kevin Dunlap is Director of Business Strategy for Cooling Solutions at APC. Involved with the power management industry

since 1994, Kevin previously worked for Systems Enhancement Corp., a provider of power management hardware and

software, which APC acquired in 1997. Following the acquisition, Kevin joined APC as a Product Manager for management

cards and then precision cooling solutions following the acquisition of Airflow Company in 2000. Kevin has participated on

numerous power management and cooling panels, as well as on industry consortiums and ASHRAE committees.

9

___________________________________________________________________________________________________

2006 American Power Conversion. All rights reserved. No part of this publication may be used, reproduced, photocopied, transmitted,

or stored in any retrieval system of any nature, without the written permission of the copyright owner. www.apc.com

Rev 2010-3

You might also like

- Chap7 Basic Cluster AnalysisDocument82 pagesChap7 Basic Cluster AnalysismksayshiNo ratings yet

- Chen 96 DataDocument41 pagesChen 96 DatamksayshiNo ratings yet

- Oracle9i Data Mining (2002) PDFDocument14 pagesOracle9i Data Mining (2002) PDFmksayshiNo ratings yet

- Lesson Plan Template (141) - Present ContinuousDocument5 pagesLesson Plan Template (141) - Present ContinuousmksayshiNo ratings yet

- Chapter6 Giachetti EnterpriseProjectMgtDocument34 pagesChapter6 Giachetti EnterpriseProjectMgtmksayshi100% (1)

- 0001-9701-NOVEC 360 Clean Agent CylindersDocument2 pages0001-9701-NOVEC 360 Clean Agent CylindersmksayshiNo ratings yet

- MDS (Fire Rated Glass) Fix Firerated GDocument1 pageMDS (Fire Rated Glass) Fix Firerated GmksayshiNo ratings yet

- Barbell Curl Standards For Men and Women (KG) - Strength LevelDocument1 pageBarbell Curl Standards For Men and Women (KG) - Strength LevelmksayshiNo ratings yet

- Romanticism Chart APDocument4 pagesRomanticism Chart APmksayshi0% (1)

- Muscular - Active Assistive Range of Motion (AAROM)Document4 pagesMuscular - Active Assistive Range of Motion (AAROM)mksayshiNo ratings yet

- Triangular Fibrocartilage Complex (TFCC) Repair and RehabilitationDocument5 pagesTriangular Fibrocartilage Complex (TFCC) Repair and RehabilitationmksayshiNo ratings yet

- Info Erp ImpDocument5 pagesInfo Erp ImpmksayshiNo ratings yet

- CP-190 - Quality Management System For Project DeliveryDocument61 pagesCP-190 - Quality Management System For Project Deliveryzhangjie100% (2)

- 3 ERP LifeCycleConcepts Rev2Document17 pages3 ERP LifeCycleConcepts Rev2mksayshiNo ratings yet

- Day 14 ERP ProjectMngtConceptsDocument11 pagesDay 14 ERP ProjectMngtConceptsmksayshiNo ratings yet

- Internal Assignment - Math StatsDocument28 pagesInternal Assignment - Math StatsmksayshiNo ratings yet

- Aim AdvantageDocument11 pagesAim AdvantagecrazycoolgeekNo ratings yet

- The Islamic Foundation of The RenaissanceDocument11 pagesThe Islamic Foundation of The RenaissancemksayshiNo ratings yet

- Seq Sub Speciality IsbnDocument8 pagesSeq Sub Speciality IsbnmksayshiNo ratings yet

- 02 Single-Wavelength - Performance - Calculator - Microsoft Excel FileDocument2 pages02 Single-Wavelength - Performance - Calculator - Microsoft Excel FilemksayshiNo ratings yet

- The Secrets of The Florentine DomeDocument23 pagesThe Secrets of The Florentine DomemksayshiNo ratings yet

- G7bclistDocument667 pagesG7bclistmksayshiNo ratings yet

- The Secrets of The Florentine DomeDocument23 pagesThe Secrets of The Florentine DomemksayshiNo ratings yet

- Chicago NarcoticsDocument1,638 pagesChicago NarcoticsPablo MorenoNo ratings yet

- In TRDocument6 pagesIn TRMAns GreedhArryNo ratings yet

- Physium Application: User's GuideDocument20 pagesPhysium Application: User's GuidemksayshiNo ratings yet

- The Elements of DesignDocument42 pagesThe Elements of DesignmksayshiNo ratings yet

- Booze Around The WorldDocument1 pageBooze Around The WorldmksayshiNo ratings yet

- Interactive Visualisation of The Cone of Vision As A Design ToolDocument8 pagesInteractive Visualisation of The Cone of Vision As A Design ToolmksayshiNo ratings yet

- Pre-Calculus Math 40s - Permutations & Combinations - Lesson 3Document9 pagesPre-Calculus Math 40s - Permutations & Combinations - Lesson 3mksayshiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Netsure 7100 Data Sheet With Esure Power Extend ConvertersDocument2 pagesNetsure 7100 Data Sheet With Esure Power Extend ConvertersCedillo Cortés SaraNo ratings yet

- Netlabve Real Equipment Pod Management Guide PDFDocument120 pagesNetlabve Real Equipment Pod Management Guide PDFpamukumarNo ratings yet

- Etsi en 300 119-1Document8 pagesEtsi en 300 119-1ghosh_souvikNo ratings yet

- Comtech Ut4500Document112 pagesComtech Ut4500Fernando CornejoNo ratings yet

- EST EST3 Intelligent Control For Large and Medium Sized ApplicationsDocument58 pagesEST EST3 Intelligent Control For Large and Medium Sized Applicationsjavierchapa75100% (1)

- 3BDD010023 B en Freelance 800F System DescriptionDocument44 pages3BDD010023 B en Freelance 800F System DescriptionBen ChanNo ratings yet

- Aten KVM Switch ManualDocument86 pagesAten KVM Switch ManualDiNo ratings yet

- NBRK0200 Installation Configuration ManualDocument32 pagesNBRK0200 Installation Configuration ManualGoran JovanovicNo ratings yet

- Data Center: Fiber Optic SolutionsDocument72 pagesData Center: Fiber Optic SolutionsFadi Mohd ShaherNo ratings yet

- T42S-2U/T42Sp-2U: Quantaplex SeriesDocument41 pagesT42S-2U/T42Sp-2U: Quantaplex SeriesburnslNo ratings yet

- LSU Telecommunication Notes To Designer: Telecom RoomDocument2 pagesLSU Telecommunication Notes To Designer: Telecom RoomBusinge BrunoNo ratings yet

- Replacing A Fan Tray ModuleDocument2 pagesReplacing A Fan Tray Moduletibi_fNo ratings yet

- Implementing PowerVC and CMO TechbookDocument462 pagesImplementing PowerVC and CMO Techbookihidouri100% (1)

- HP Integrity Rx1620-c01404656Document73 pagesHP Integrity Rx1620-c01404656usunomNo ratings yet

- Primergy TX300 S4 - Operating ManualsDocument127 pagesPrimergy TX300 S4 - Operating Manualsbvidov1970No ratings yet

- Catalog - 4 - Conventional-Pallet-Racking - en - UNDocument44 pagesCatalog - 4 - Conventional-Pallet-Racking - en - UNcatalinbloaje100% (1)

- Electrical Equipment LayoutDocument3 pagesElectrical Equipment LayoutMeenakshi Td100% (3)

- Smart-UPS On-Line - SRTG20KXLIDocument4 pagesSmart-UPS On-Line - SRTG20KXLIMark Vincent AlcarazNo ratings yet

- ShopNotes Issue 73Document36 pagesShopNotes Issue 73qpidoneuro100% (7)

- ACE3600 ManualDocument164 pagesACE3600 ManualAlexander Marcos TeixeiraNo ratings yet

- Safewell Basic PDU Series Model: SW-1U-8IEC13-KDocument4 pagesSafewell Basic PDU Series Model: SW-1U-8IEC13-KMahmudur RahmanNo ratings yet

- Kdm-706-706a - Install Manual - 006-00177-0006 - 6Document59 pagesKdm-706-706a - Install Manual - 006-00177-0006 - 6Marcus Drago100% (2)

- Lampiran 1Document32 pagesLampiran 1Profighter PeterNo ratings yet

- 2008 Argus DC Catalog - ReducedDocument100 pages2008 Argus DC Catalog - ReducedL IvanNo ratings yet

- Ent-Factsheet Network Security 7100 Series 01-2005.en-UsDocument7 pagesEnt-Factsheet Network Security 7100 Series 01-2005.en-UsLawrence O OgunsusiNo ratings yet

- 9 12, 24 Rack Mount LIU DatasheetDocument2 pages9 12, 24 Rack Mount LIU DatasheetBalakrishnan KrishnanNo ratings yet

- Install BC-6000 AnalyzersDocument114 pagesInstall BC-6000 AnalyzersHuy Trung GiápNo ratings yet

- Bently Nevada 3300 System DatasheetDocument11 pagesBently Nevada 3300 System DatasheetPraba YuwanaNo ratings yet

- Optimize RET 521 transformer protection terminal configurationDocument7 pagesOptimize RET 521 transformer protection terminal configurationlucasNo ratings yet

- Optimized SOP for NOx MeasurementsDocument17 pagesOptimized SOP for NOx MeasurementsDienNo ratings yet