Professional Documents

Culture Documents

29.efficiency Based Propeller Shaft Drive & Brake System

Uploaded by

Chockalingam Athilingam0 ratings0% found this document useful (0 votes)

60 views2 pagespropeller shaft efficiency

Original Title

29.Efficiency Based Propeller Shaft Drive & Brake System

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpropeller shaft efficiency

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views2 pages29.efficiency Based Propeller Shaft Drive & Brake System

Uploaded by

Chockalingam Athilingampropeller shaft efficiency

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

EFFICIENCY BASED PROPELLER SHAFT

DRIVE & BRAKING SYSTEM

ABSTRACT

A turbo-electric transmission uses electric generators to convert the mechanical energy

of a turbine into electric energy and electric motors to convert it back into mechanical

energy to power the drive shafts.

Turbo-electric drives are used in some locomotives (gas turbines, e.g. with the first TGV)

and ships (steam and sometimes gas turbines). The advantage of the turbo-electric

transmission is that it allows the adaptation of high-speed turning turbines to the slow

turning propellers or wheels without the need of a heavy and complex gearbox. It also has

the second advantage of being able to provide electricity for the ship or train's other

electrical systems, such as lighting, computers, radar, and communications equipment.

A disadvantage shared with the more common diesel-electric powertrain is that because

of the double conversion of mechanical energy to electricity and back more energy gets

lost than with a mechanical transmission. Gas turbines are much more energy efficient

than equally sized diesel engines. Efficiency usually ranges from 30% to 38% for Diesel

engines and from 40% to 60% in a gas turbine engine.

Turboelectric drive & Brake power also permitted more rapid development of

accelerating and decelerating power on the propeller shafts. It made the last ditch

maneuver of twisting a shaft out of path by backing down shafts while running the

opposite side full ahead and applying full rudder toward the backing side more effective.

It also permitted extended periods of backing.

Rotating shaft produce electric power from automotive engine source system. So, vehicle

propeller shaft also transmit the power from gear box to differential wheel drive.

There the similarity ends. There is only a single turbine, and rather than driving the

propeller shaft, it turns one or two electric generators. The electricity created is then

routed via a bus bar system to electric motors mounted to the propeller shaft heads. The

turbine spins at a single constant, highly efficient rotation rate, while the electric motors,

mechanically divorced from the turbines, turn at the rate most efficient for the propellers.

To achieve full backing power, the electric motors are simply reversed, there being no

physical need for a separate reverse stage. This eliminates several redundant pieces of

equipment and much steam piping.

Turboelectric drive offers several advantages:

1. There is no mechanical connection between the turbogenerator system and the

propeller shaft, allowing both to turn at their disparate efficient speeds. This increases

propeller rotation speeds and increases fuel efficiency.

2. The motor is more power need to lead the propeller shafts farther forward in the speed

rotation.

3. The turbo-electric drive consumes less energy, allowing more power to the system.

4. During braking the propeller shafts can be immediately reversed by simply switching

the direction of the magnetic electric motors without the need to reroute system.

5. More power is available at power turbo generators, making more power available for

ancillary systems (including main battery elevation and training) and electronics.

You might also like

- Mixer GrinderDocument29 pagesMixer GrinderChockalingam AthilingamNo ratings yet

- Box Shift Conveyor 2018Document2 pagesBox Shift Conveyor 2018Chockalingam AthilingamNo ratings yet

- Scotch Yoke Hacksaw Sriram Engg ReportDocument67 pagesScotch Yoke Hacksaw Sriram Engg ReportChockalingam Athilingam100% (1)

- Safety For Motorised Sheet Forming 2018Document3 pagesSafety For Motorised Sheet Forming 2018Chockalingam AthilingamNo ratings yet

- 11 Foldable Bridge 2017 PrintDocument48 pages11 Foldable Bridge 2017 PrintChockalingam AthilingamNo ratings yet

- Gas Cutting DeviceDocument3 pagesGas Cutting DeviceChockalingam AthilingamNo ratings yet

- Project Titles NC 2018 Cs Fea RDDocument9 pagesProject Titles NC 2018 Cs Fea RDChockalingam AthilingamNo ratings yet

- Bottling Plant PLC 2019Document4 pagesBottling Plant PLC 2019Chockalingam AthilingamNo ratings yet

- Project List With Cost Details 2018 2019 Panimalar PolyDocument8 pagesProject List With Cost Details 2018 2019 Panimalar PolyChockalingam AthilingamNo ratings yet

- Shock Absorber Failure 2018Document3 pagesShock Absorber Failure 2018Chockalingam AthilingamNo ratings yet

- Block Diagram of Carbon Level IndicatorDocument1 pageBlock Diagram of Carbon Level IndicatorChockalingam AthilingamNo ratings yet

- 6.design and Fabrication of Length Adjustable Belt Conveyor-1Document3 pages6.design and Fabrication of Length Adjustable Belt Conveyor-1Chockalingam AthilingamNo ratings yet

- Scotck Yoke PPT Veltech 2016Document29 pagesScotck Yoke PPT Veltech 2016Chockalingam Athilingam50% (2)

- Manual Bi Folding Gate PRINTCOPY SBDDocument50 pagesManual Bi Folding Gate PRINTCOPY SBDChockalingam AthilingamNo ratings yet

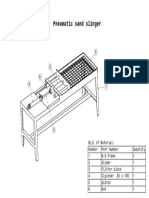

- Pneumatic Sand SlingerDocument1 pagePneumatic Sand SlingerChockalingam AthilingamNo ratings yet

- Sand Slinger MC Pneumatic 2016 VeltechDocument47 pagesSand Slinger MC Pneumatic 2016 VeltechChockalingam AthilingamNo ratings yet

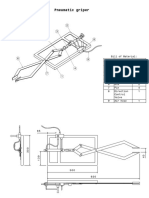

- Pneumatic GriperDocument2 pagesPneumatic GriperChockalingam AthilingamNo ratings yet

- Plastic Injection Manual 2016 Amk PolyDocument43 pagesPlastic Injection Manual 2016 Amk PolyChockalingam AthilingamNo ratings yet

- Abs 127two - Axes - Drill 2016 ReviewDocument3 pagesAbs 127two - Axes - Drill 2016 ReviewChockalingam AthilingamNo ratings yet

- HTTP FOR ENGINEERINGDocument1 pageHTTP FOR ENGINEERINGChockalingam AthilingamNo ratings yet

- HonningDocument1 pageHonningChockalingam AthilingamNo ratings yet

- MOTORISED Press Durga Poly 2016Document76 pagesMOTORISED Press Durga Poly 2016Chockalingam AthilingamNo ratings yet

- Pneumatic Elevator Abs 20124Document3 pagesPneumatic Elevator Abs 20124Chockalingam AthilingamNo ratings yet

- Air Brake PROJECT REPORTDocument52 pagesAir Brake PROJECT REPORTChockalingam Athilingam72% (18)

- Lorry Trailor Lifter CostDocument1 pageLorry Trailor Lifter CostChockalingam AthilingamNo ratings yet

- Electronic ComparatorDocument1 pageElectronic ComparatorChockalingam AthilingamNo ratings yet

- Shell and Tube Heat Exchanger Design Using CFD ToolsDocument4 pagesShell and Tube Heat Exchanger Design Using CFD ToolsChockalingam AthilingamNo ratings yet

- F T ZL 6L: 4 - RLT TTJ R5 !.1Document1 pageF T ZL 6L: 4 - RLT TTJ R5 !.1Chockalingam AthilingamNo ratings yet

- IR Sensor UnitDocument1 pageIR Sensor UnitChockalingam AthilingamNo ratings yet

- Amk SymbolDocument6 pagesAmk SymbolChockalingam AthilingamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DANZIG, Richard, A Comment On The Jurisprudence of The Uniform Commercial Code, 1975 PDFDocument17 pagesDANZIG, Richard, A Comment On The Jurisprudence of The Uniform Commercial Code, 1975 PDFandresabelrNo ratings yet

- Daughters of The Storm by Kim Wilkins - Chapter SamplerDocument32 pagesDaughters of The Storm by Kim Wilkins - Chapter SamplerHarlequinAustraliaNo ratings yet

- Estwani ISO CodesDocument9 pagesEstwani ISO Codesनिपुण कुमारNo ratings yet

- HU675FE ManualDocument44 pagesHU675FE ManualMar VeroNo ratings yet

- Understand Azure Event HubsDocument12 pagesUnderstand Azure Event HubselisaNo ratings yet

- Class 9th Chemistry Unit#4 Structure of MoleculesDocument8 pagesClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahNo ratings yet

- Donny UfoaksesDocument27 pagesDonny UfoaksesKang Bowo D'wizardNo ratings yet

- Marksmanship: Subject: III. Definition of TermsDocument16 pagesMarksmanship: Subject: III. Definition of TermsAmber EbayaNo ratings yet

- Panasonic TC-P42X5 Service ManualDocument74 pagesPanasonic TC-P42X5 Service ManualManager iDClaimNo ratings yet

- Malaysia Year 2011 Calendar: Translate This PageDocument3 pagesMalaysia Year 2011 Calendar: Translate This PageStorgas FendiNo ratings yet

- Chetan Bhagat's "Half GirlfriendDocument4 pagesChetan Bhagat's "Half GirlfriendDR Sultan Ali AhmedNo ratings yet

- Grade 10Document39 pagesGrade 10amareNo ratings yet

- LGFL Service GuideDocument24 pagesLGFL Service GuideThe Return of the NoiristaNo ratings yet

- The Invisible Hero Final TNDocument8 pagesThe Invisible Hero Final TNKatherine ShenNo ratings yet

- Addition and Subtraction of PolynomialsDocument8 pagesAddition and Subtraction of PolynomialsPearl AdamosNo ratings yet

- Brooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFDocument36 pagesBrooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFlois.guzman538100% (12)

- Ne 01 20 09 2018Document436 pagesNe 01 20 09 2018VaradrajNo ratings yet

- StsDocument10 pagesStsSamonte, KimNo ratings yet

- 256267a1Document5,083 pages256267a1Елизавета ШепелеваNo ratings yet

- Notes On The Life and Works of Jose Rizal - IncompleteDocument15 pagesNotes On The Life and Works of Jose Rizal - Incompleteblock_me_please50% (2)

- Hencher - Interpretation of Direct Shear Tests On Rock JointsDocument8 pagesHencher - Interpretation of Direct Shear Tests On Rock JointsMark2123100% (1)

- LLoyd's Register Marine - Global Marine Safety TrendsDocument23 pagesLLoyd's Register Marine - Global Marine Safety Trendssuvabrata_das01100% (1)

- Mama Leone's Profitability AnalysisDocument6 pagesMama Leone's Profitability AnalysisLuc TranNo ratings yet

- The Slave Trade and The British Empire An Audit of Commemoration in WalesDocument133 pagesThe Slave Trade and The British Empire An Audit of Commemoration in WaleslegoarkeologNo ratings yet

- OLA CAB MARKET ANALYSIS AND TRENDSDocument55 pagesOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariNo ratings yet

- Startups Helping - India Go GreenDocument13 pagesStartups Helping - India Go Greensimran kNo ratings yet

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- WA Beretta M92FS Parts ListDocument2 pagesWA Beretta M92FS Parts ListDenis Deki NehezNo ratings yet

- Av1 OnDocument7 pagesAv1 OnLê Hà Thanh TrúcNo ratings yet

- Mechanical Questions & AnswersDocument161 pagesMechanical Questions & AnswersTobaNo ratings yet