Professional Documents

Culture Documents

AA02128 (730E and 83OE Cracks in Drive Tube)

Uploaded by

Claudio Guin GodoyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AA02128 (730E and 83OE Cracks in Drive Tube)

Uploaded by

Claudio Guin GodoyCopyright:

Available Formats

COMPONENT CODE

PARTS & SERVICE

NEWS

47

REF NO. AA02128

DATE April 29, 2002

Page 1 of 2

SUBJECT:

FRAME CRACKING IN DRIVE TUBE

PURPOSE:

Inform the field of inspection area and repair procedure for frame cracking in

drive tube.

APPLICATION:

Komatsu Electric Drive Dump Trucks:

730E: AFE47-A thru AW, A30079 thru A30169;

830E: AFE32-A & Up, AFE50-A & Up, A30544 & Up

FAILURE CODE:

4710HB

DESCRIPTION:

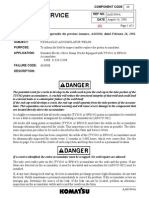

Some trucks in the field may experience frame cracking between the body guide ears on the drive tube.

Refer to Figure 1. Ensure a thorough inspection of this area is performed during normal frame inspections

at regular intervals.

If cracking is found in the specified area, the crack(s) must be gouged out and weld repairs performed.

Follow the guidelines that are outlined in Parts and Service News, "FIELD WELDING FOR ASSEMBLY OR REPAIR" (AA00046B). For additional welding guidelines, refer to Welding I (SEBF40001)

and Welding II (SEBF15002).

Always disconnect the positive and negative battery cables of the vehicle before doing any welding on

the unit. Failure to do so may seriously damage the battery and electrical equipment. Disconnect battery charging alternator lead wire and isolate electronic control components before making welding

repairs. (It is not necessary to disconnect or remove any control circuit cards on Electric Drive Dump

Trucks or any of the AID circuit control cards.)

Always fasten the welding machine ground (-) lead to the piece being welded; grounding clamp MUST

BE ATTACHED AS NEAR AS POSSIBLE to the weld area. Never allow welding current to pass

through ball bearings, roller bearings, suspensions, or hydraulic cylinders. Always avoid laying welding cables over or near the vehicle electrical harnesses. Welding voltage could be induced into the electrical harness and possibly cause damage to components.

AA02128

Page 2 of 2

Body Guide

Drive Tube

Drive Tube

THISbeen

AREA HAS

BEEN VULNERABLE

TO FIT PROBLEMS

This area has

vulnerable

to fit problems

during

DURING MANUFACTURE IN THE PAST. STEPS HAVE PREVIOUSLY

BEEN

TAKEN

TO

INSURE

A

PROPER

FIT

AND

ACCEPTABLE

WELD.

assembly of the drive tube.

GOUGING

OUT THE

AND REPAIRING

WELD

MAKING

If cracks are found,

gouge

outCRACK

the affected

areaTHE

and

weld

repair.

SURE IT IS PROPERLY TIED INTO THE EXISTING FILLET

WELD

PROBLEM.fillet

A BACKER

SHOULD BE

The repair should

beSHOULD

joinedELIMINATE

with theTHEexisting

weld.

USED TO ACHEIVE THE PROPER FIT IF NEEDED.

If necessary, a backer should be used to achieve the proper fit.

Bent Plate

Body Guides

Body Guide

Bent Plate

A

A

Fillet Weld

FILLET WELD

Drive Tube

SECTION A-A

FIGURE 1. FRAME CRACKING LOCATION

AA02128

You might also like

- AA01042A Fisura Horse CollarDocument5 pagesAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezNo ratings yet

- Repair 830E Frame CracksDocument3 pagesRepair 830E Frame CracksClaudio Guin GodoyNo ratings yet

- A A 11090Document4 pagesA A 11090Raúl Rosalino Pérez GómezNo ratings yet

- AA00046C Partes & Servicios SM930E-4Document9 pagesAA00046C Partes & Servicios SM930E-4Emmanuel Torres HerreraNo ratings yet

- Parts & Service News: Component Code Ref No. DateDocument9 pagesParts & Service News: Component Code Ref No. DateAntony Armando Huaylla QuispeNo ratings yet

- Carga SuspensionesDocument17 pagesCarga SuspensionesHeriberto ColqueNo ratings yet

- Truck Body and Canopy - RemoveDocument5 pagesTruck Body and Canopy - RemoveBelimar CostaNo ratings yet

- Wheel Motor Inspection GuidelinesDocument29 pagesWheel Motor Inspection GuidelinesRimbertNo ratings yet

- Analisis Motor de Traccion (Ingles) PDFDocument28 pagesAnalisis Motor de Traccion (Ingles) PDFVictorDjChiqueCastillo100% (1)

- 930 Frame Weld Reference Example BookDocument39 pages930 Frame Weld Reference Example Booklarry50% (2)

- Shipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671ADocument4 pagesShipping Instructions For Ge787 and Ge788 Motorized Wheel: GEK-91671Aait mimouneNo ratings yet

- Handle-End Bottom Plate RemovalDocument4 pagesHandle-End Bottom Plate Removalraul contrerasNo ratings yet

- Parts & Service News: Component Code Ref No. DateDocument3 pagesParts & Service News: Component Code Ref No. DateLodyNo ratings yet

- Documento CatDocument133 pagesDocumento Catchechar10No ratings yet

- Mine Specialty Bodies PDFDocument11 pagesMine Specialty Bodies PDFRodolfoMarínNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- KOmatsu P&H-trc-series-dipperDocument2 pagesKOmatsu P&H-trc-series-dipperhidrastar123No ratings yet

- 793D Off-Highway Truck FDB00001-UP MACHINE POWERED BY 3516B EngineSEBP3976 - 13Document23 pages793D Off-Highway Truck FDB00001-UP MACHINE POWERED BY 3516B EngineSEBP3976 - 13carlosNo ratings yet

- Komatsu Field Assembly InstructionDocument33 pagesKomatsu Field Assembly InstructionEbrahim SabouriNo ratings yet

- Armado 793d InglésDocument289 pagesArmado 793d InglésFelipeNicolasSilvaNo ratings yet

- OHT Wheel Stud Removal ToolDocument4 pagesOHT Wheel Stud Removal Toolwhmidi7331No ratings yet

- AA02083G Approved GE LubesDocument4 pagesAA02083G Approved GE LubesSebastiao Duarte100% (1)

- Locking Assembly Crowd 7495HR CATERPILLARDocument4 pagesLocking Assembly Crowd 7495HR CATERPILLARFrancisco GonzalezNo ratings yet

- LUBRICACIONDocument6 pagesLUBRICACIONOrlando LaraNo ratings yet

- Assembly Procedure For The 785B and 785C Dual Slope Truck Body (7258, 7960)Document69 pagesAssembly Procedure For The 785B and 785C Dual Slope Truck Body (7258, 7960)Carlos Lobo100% (1)

- Bucyrus DetailsDocument15 pagesBucyrus Detailscharanpalsingh95100% (2)

- AH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonDocument12 pagesAH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonfernandojNo ratings yet

- Komatsu's 400t 980E-4 Electrical Dump TruckDocument6 pagesKomatsu's 400t 980E-4 Electrical Dump Trucksamsularief03100% (1)

- Parts & Service News: Component Code Ref No. DateDocument2 pagesParts & Service News: Component Code Ref No. DateAndree Ayma NuñezNo ratings yet

- Reusable Gear Guide HTT - GG1 - 0711Document18 pagesReusable Gear Guide HTT - GG1 - 0711sphiri600100% (1)

- Comisionado - 793fDocument157 pagesComisionado - 793fPercy Herrera ZeballosNo ratings yet

- Maximum Operating Weight: 390 t / 860,000 lbsDocument8 pagesMaximum Operating Weight: 390 t / 860,000 lbsJulioNo ratings yet

- Maleta de Tapones 2767018Document4 pagesMaleta de Tapones 2767018Orlando HuillcaNo ratings yet

- Wheel Motor Oil Drain Hole ModificationDocument3 pagesWheel Motor Oil Drain Hole ModificationSebastiao DuarteNo ratings yet

- PH-Electric-Rope-Shovel-Components (Splited)Document3 pagesPH-Electric-Rope-Shovel-Components (Splited)Oscar JimenezNo ratings yet

- Welding InstructionsDocument12 pagesWelding Instructionsrahman asadiNo ratings yet

- 797BDocument19 pages797Barfa ujiantoNo ratings yet

- Dipper Door Assembly Part No R72209F1 PDFDocument3 pagesDipper Door Assembly Part No R72209F1 PDFFrancisco Gonzalez0% (1)

- PH 2800xpc DC Bro PDFDocument5 pagesPH 2800xpc DC Bro PDFMario Zurita CamachoNo ratings yet

- Bucket Control Pins and BearingDocument13 pagesBucket Control Pins and BearingGeovanny Sanjuan100% (1)

- 930e 2 PDFDocument16 pages930e 2 PDFMatyOyarzoAlvaradoNo ratings yet

- 830E Frame FormDocument5 pages830E Frame FormClaudio Guin GodoyNo ratings yet

- Defau lt/QTY STOCK/DESCRIPTION PART NUMBER Material WEIGHT PcMRPDocument1 pageDefau lt/QTY STOCK/DESCRIPTION PART NUMBER Material WEIGHT PcMRPKumganbayev NurbolatNo ratings yet

- BI011852-00-00-EN CMPL - Parts ER601508Document1,303 pagesBI011852-00-00-EN CMPL - Parts ER601508EdwarthMaza100% (1)

- Procedure To Inspect and Repair The Center Section Frame On Certain 793F Off-Highway Trucks (0679, 7051) Caterpillar - Spare PartsDocument107 pagesProcedure To Inspect and Repair The Center Section Frame On Certain 793F Off-Highway Trucks (0679, 7051) Caterpillar - Spare PartsBrendanNo ratings yet

- Custom Configuration Liners 793HPDocument1 pageCustom Configuration Liners 793HPAndree Ayma NuñezNo ratings yet

- Manual Dipper 7495 - Inspeccion en Campo OEM PDFDocument147 pagesManual Dipper 7495 - Inspeccion en Campo OEM PDFjhonatanNo ratings yet

- M20015607902 Rep 1906061300Document122 pagesM20015607902 Rep 1906061300KOMATSU SHOVEL100% (1)

- MT6300Document4 pagesMT6300ForomaquinasNo ratings yet

- 980E-4 Hoist System Components, Operation, AdjustmentDocument30 pages980E-4 Hoist System Components, Operation, AdjustmentRonny Leido Rodriguez Bernabe100% (1)

- Copy of 9.24船EPA申請リスト-2Document54 pagesCopy of 9.24船EPA申請リスト-2RiotaNo ratings yet

- SEBF 8737 головка С-9Document6 pagesSEBF 8737 головка С-9Евгений АбрамовNo ratings yet

- Bucyrus: Technical ManualDocument7 pagesBucyrus: Technical ManualJohn GrayNo ratings yet

- Special Instruction 797fDocument600 pagesSpecial Instruction 797fLuisNo ratings yet

- Comparative ScheduleDocument6 pagesComparative ScheduleGustavo Adolfo De Haro GonzálezNo ratings yet

- 730E (AC) Spec Sheet PDFDocument16 pages730E (AC) Spec Sheet PDFsoufiane OkNo ratings yet

- Service Letter: Single EngineDocument8 pagesService Letter: Single EngineElmer VillegasNo ratings yet

- Installation and Service Instructions For 180-210 C-Face MotorsDocument4 pagesInstallation and Service Instructions For 180-210 C-Face MotorsAnonymous gMMbTAQlNo ratings yet

- AA08122 (830E Front Suspension Instalation)Document5 pagesAA08122 (830E Front Suspension Instalation)Claudio Guin GodoyNo ratings yet

- AA02024 (830E Reinforcing Dump Bodies On 830E Dump Trucks)Document3 pagesAA02024 (830E Reinforcing Dump Bodies On 830E Dump Trucks)Claudio Guin GodoyNo ratings yet

- AA01044A (830E Hydraulic Acumulator Welds)Document3 pagesAA01044A (830E Hydraulic Acumulator Welds)Claudio Guin GodoyNo ratings yet

- 830E Frame FormDocument5 pages830E Frame FormClaudio Guin GodoyNo ratings yet

- Pathfinder Manual 2012Document192 pagesPathfinder Manual 2012shawqiNo ratings yet

- Summary Table of Electl Material Device and Eqpt SurveyDocument4 pagesSummary Table of Electl Material Device and Eqpt SurveyAngellica Ruth MatroNo ratings yet

- Op AmpDocument42 pagesOp AmpJyotiSharmaNo ratings yet

- Astm e 426Document4 pagesAstm e 426김경은No ratings yet

- Module On Electrical Circuits and Electrical SafetyDocument17 pagesModule On Electrical Circuits and Electrical SafetyJomel HerrasNo ratings yet

- ZG Final PHD ThesisDocument228 pagesZG Final PHD ThesisRafael Coats RamirezNo ratings yet

- Diesel Engine Fire Pump Controller (GPD Model)Document9 pagesDiesel Engine Fire Pump Controller (GPD Model)haryNo ratings yet

- Overview of Power Integrity Solutions On Package and PCB: Decoupling and EBG IsolationDocument39 pagesOverview of Power Integrity Solutions On Package and PCB: Decoupling and EBG IsolationIsmaiel KaladiNo ratings yet

- IEC Stdandards 1 3Document77 pagesIEC Stdandards 1 3Shanmuga Baskar0% (2)

- Electric Mining Shovel - AC Drive Product OverviewDocument5 pagesElectric Mining Shovel - AC Drive Product OverviewJuan Córdova AguileraNo ratings yet

- 1SFA896110R7000 psr37 600 70Document4 pages1SFA896110R7000 psr37 600 70BilalNo ratings yet

- 9.2 A 715G9324 PSU (For 43" 6503/6523/6703/6753 Series) : 9-2-1 AC InputDocument4 pages9.2 A 715G9324 PSU (For 43" 6503/6523/6703/6753 Series) : 9-2-1 AC InputJefferson LeiteNo ratings yet

- Lecture 02 HDL PDFDocument216 pagesLecture 02 HDL PDFijalab1No ratings yet

- Embedded Systems (IT409)Document10 pagesEmbedded Systems (IT409)mohamed elgammlNo ratings yet

- Nagaraj CV UpdatedDocument4 pagesNagaraj CV UpdatedNagaraj VjNo ratings yet

- Flexiva 10kwDocument168 pagesFlexiva 10kwMohamed Elshaaer100% (1)

- Catalogue Onkyo 2014-2015Document10 pagesCatalogue Onkyo 2014-2015Thawatchai PirapongsilNo ratings yet

- Velleman hpg1 Function Generator Frequency Generator hpg1 Hoja de DatosDocument28 pagesVelleman hpg1 Function Generator Frequency Generator hpg1 Hoja de DatosAbelNo ratings yet

- Controller With EMIDocument12 pagesController With EMIMehedi Hasan100% (1)

- Regenerate Digital Signals with Schmitt TriggersDocument75 pagesRegenerate Digital Signals with Schmitt TriggersEd JudgeNo ratings yet

- Compact motorbike security system featuresDocument4 pagesCompact motorbike security system featuresbarbastylNo ratings yet

- Brkewn 3014Document84 pagesBrkewn 3014vssreekanth_321No ratings yet

- DC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525Document1 pageDC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525NewsUPdateNo ratings yet

- 3.1 Aim: Use PLC To Test The START STOP and TEST Logic For Two Inputs and One Output. 3.2 Apparatus: PLC Software, NO and NC Switches. 3.3theoryDocument3 pages3.1 Aim: Use PLC To Test The START STOP and TEST Logic For Two Inputs and One Output. 3.2 Apparatus: PLC Software, NO and NC Switches. 3.3theoryrashmi patilNo ratings yet

- Catalogo Schneider 2019Document33 pagesCatalogo Schneider 2019vjdmNo ratings yet

- Fingur+gsm Based Locker SystemDocument48 pagesFingur+gsm Based Locker SystemGaus PatelNo ratings yet

- FactSheet CellD DPS 2900B 48 5 - enDocument2 pagesFactSheet CellD DPS 2900B 48 5 - enManuel Torrón FerreiroNo ratings yet

- Nichrome Thin Film Technology and Its ApplicationDocument7 pagesNichrome Thin Film Technology and Its ApplicationvladislavNo ratings yet

- TLP181 Datasheet en 20170512Document9 pagesTLP181 Datasheet en 20170512FranklinNo ratings yet

- Wiring Diagram: Quantium 1P1H Dispenser: L N To Pump PSU To Pump MotherboardDocument11 pagesWiring Diagram: Quantium 1P1H Dispenser: L N To Pump PSU To Pump MotherboardFilimone ThumboNo ratings yet