Professional Documents

Culture Documents

Brackets & Connections

Uploaded by

Kory EstesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brackets & Connections

Uploaded by

Kory EstesCopyright:

Available Formats

BRACKETS

1 Stiffened Seat Bracket design

There are two analyses:

(A) in which the seat stiffener is at right angles to the web of the beam.

(B) in which the seat stiffener is in line with the web of the beam.

1.1 Seat stiffener is at right angles to the web of the beam

For analysis, the stiffener of Type (A) is considered an eccentrically loaded column

with the reaction load applied at a fixed point.

The maximum stress is the sum of the direct load and bending effects.

The line of action of the compressive load is approximately parallel to the outer edge

of the stiffener.

The critical cross-section of the stiffener (to be used for the area and section

modulus) is at right angles to the line of action of the load.

Area and section modulus are

Minimum thickness:

Thus, Min Thickness

The eccentrically loaded column formula

( # 1) is seldom used in this case

because it will result in an excessively

thick bracket \web or stiffener.

This is because the formula is based

upon stress only and does not take into

consideration some yielding of the

bracket

which will cause the point of application

of the load to shift in toward the support,

thus reducing the moment arm and

bending stress.

treq can also be determined using nomograms

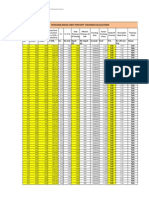

FIGURE 2-Thickness of Stiffened Seat For A36 Steel - NOMOGRAPH NO. 4

BRACKETS

1.1.1.1

seat stiffener is in line with the web of the beam

lf the beam rests in line with the bracket stiffener, Type B, Figure 3, the bearing

length ( N) of the beam ( AISC See 1.10.10) is-

The eccentricity ( e") of the reaction

load is

Lv = column length

AISC Manual, page 4-39 recommends for A36 bracket material that the bracket web's

thickness be at least equal to 1.33 times the required fillet weld size ( E70 welds).

Also it should not be less than the supported beam web thickness for A7, A373 and

A36 beams, and not less than 1.4 times the beam web thickness for A242 and A441

beams.

BRACKETS

For stiffened seats in line on opposite sides of the column web, the fillet weld size

should not exceed 3/4 the column web thickness when determining its length(Lv).

2 BS APPROACH

The outside edge of the welded column bracket, shown in Fig. 25.4, is in compression

and provided that a reasonably conservative approach is used in calculating the

extreme fibre stress, semi-Compact criteria for the outstand are appropriate (i.e.

).

With relatively light loads, this may require an unnecessarily thick stiffener. To

overcome the problem, the simple design approach of substituting fa for P y in the

formula for E, so that

,

where

fa = 1.5 X the extreme fibre compressive stress (at factored loading) can be

used.

You might also like

- Section & Steel PropertiesDocument5 pagesSection & Steel PropertiesKory EstesNo ratings yet

- Bending Strength of Steel Bracket and Splice PlatesDocument10 pagesBending Strength of Steel Bracket and Splice PlatesgorgonoidemarcoNo ratings yet

- Question 1: Thermal Energy and Heat Transfer (4 Points)Document10 pagesQuestion 1: Thermal Energy and Heat Transfer (4 Points)Sid MathurNo ratings yet

- Seismic-Detailing (Aci 318-05) 9Document1 pageSeismic-Detailing (Aci 318-05) 9Rakibul SakibNo ratings yet

- Concept Preliminary DesignDocument11 pagesConcept Preliminary Designricosanojuan100% (2)

- Risa Base Examples PDFDocument7 pagesRisa Base Examples PDFAamirShabbirNo ratings yet

- Design of Beam Based On ACI 318-99Document5 pagesDesign of Beam Based On ACI 318-99Haris AlamNo ratings yet

- Base PlateDocument2 pagesBase PlateEosNo ratings yet

- Overview Waffle SlabDocument34 pagesOverview Waffle Slabusman javedNo ratings yet

- ACI 318-08 Load CombinationsDocument12 pagesACI 318-08 Load Combinationsamanpreet_ahujaNo ratings yet

- Two Way Slab Design Analysis (8m x 7mDocument6 pagesTwo Way Slab Design Analysis (8m x 7mMuhammad Azeem KhanNo ratings yet

- Designing Tall BuildingsDocument30 pagesDesigning Tall BuildingsMREFAATNo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection CheckEko Bayu AjiNo ratings yet

- Doseme Egilme ACI (2 Sira-EN)Document1 pageDoseme Egilme ACI (2 Sira-EN)OktayNo ratings yet

- SAP2000 Range Add Combo for pattern loadingDocument8 pagesSAP2000 Range Add Combo for pattern loadingcurvedbrainNo ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- Desiner 88.6Document28 pagesDesiner 88.6ramin005No ratings yet

- Waffle Slab DesignDocument12 pagesWaffle Slab DesigndrajkumarceNo ratings yet

- ACI 318-08 Beam DesignDocument10 pagesACI 318-08 Beam DesignSimit MehtaNo ratings yet

- Footing Sliding Pressure21Document452 pagesFooting Sliding Pressure21ersinNo ratings yet

- Reinforcement design for end beamDocument4 pagesReinforcement design for end beamprabhuNo ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- 1) ATRIUM-CAL-002 - Connection Calculations (23!09!2015 Updated)Document39 pages1) ATRIUM-CAL-002 - Connection Calculations (23!09!2015 Updated)Suresh DNo ratings yet

- Ductile Beam Design PDFDocument72 pagesDuctile Beam Design PDFanirban nayekNo ratings yet

- Waffle SlabDocument3 pagesWaffle Slabnarotham_medi4108100% (2)

- Tugas 02 - Beton LanjutDocument2 pagesTugas 02 - Beton LanjutsalmanNo ratings yet

- Connections I V2 1 0 A 1Document49 pagesConnections I V2 1 0 A 1ALPHYL BALASABASNo ratings yet

- BOEFDocument6 pagesBOEFmetroroadNo ratings yet

- XX X XXXX XX XXXX 1rev XX Tank Farm Sleeper DesignDocument44 pagesXX X XXXX XX XXXX 1rev XX Tank Farm Sleeper Designg4gohar0% (1)

- Design of Steel Beams To Aisc LRFD - 02Document52 pagesDesign of Steel Beams To Aisc LRFD - 02ArchIEF Form (JASA ARSITEK)No ratings yet

- MSRB 2Document127 pagesMSRB 2Sagar MandaleekaNo ratings yet

- Conception Analysis and Design of A 3d Steel BuildingDocument87 pagesConception Analysis and Design of A 3d Steel BuildinggunasekaranNo ratings yet

- Bolted connection design formulasDocument1 pageBolted connection design formulaspawkomNo ratings yet

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor Slabscaptnjack1No ratings yet

- Steelwork Design Chapter 2 - Steelwork Connections HKCodeDocument49 pagesSteelwork Design Chapter 2 - Steelwork Connections HKCodeMa Man KinNo ratings yet

- Single AngleDocument1 pageSingle AngleAnonymous z6qKli5noDNo ratings yet

- Earthquakemodule 13Document4 pagesEarthquakemodule 13dash1991No ratings yet

- SIDLDocument4 pagesSIDLBathrudeen IshakNo ratings yet

- 111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24Document7 pages111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24ItsmejanuNo ratings yet

- M&T Risk & AssuranceDocument39 pagesM&T Risk & Assurancejonodo89No ratings yet

- Modelling and Analysis of Jacket PlatformDocument11 pagesModelling and Analysis of Jacket PlatformDr R Panneer SelvamNo ratings yet

- Deck SlabDocument22 pagesDeck SlabFarid TataNo ratings yet

- III Storied Building Staad OutputDocument124 pagesIII Storied Building Staad OutputArindam RoyNo ratings yet

- Manhole Calculation Sheet AnalysisDocument95 pagesManhole Calculation Sheet AnalysisAmr AbdeinNo ratings yet

- Reinforced Concrete Torsion DesignDocument47 pagesReinforced Concrete Torsion DesignalaaNo ratings yet

- Design of overhead crane gantry girderDocument4 pagesDesign of overhead crane gantry girderswapnilbhosale96No ratings yet

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation AnalysisMagdy BakryNo ratings yet

- Punching Shear Check for Raft ThicknessDocument6 pagesPunching Shear Check for Raft ThicknessmanpreetkhanujaNo ratings yet

- Design of I-Shape Column Base Plate With Moment and Axial CompressionDocument2 pagesDesign of I-Shape Column Base Plate With Moment and Axial CompressionAndro RebuyasNo ratings yet

- Link BeamDocument8 pagesLink BeamNeil SonNo ratings yet

- Column PMM EnvelopeDocument23 pagesColumn PMM EnvelopeKutty MansoorNo ratings yet

- Building Structure Design - Graduation ProjectDocument185 pagesBuilding Structure Design - Graduation ProjectKalomenniNo ratings yet

- Structural Engineering Report: Project: Location: Client: Code: SGE Job NoDocument31 pagesStructural Engineering Report: Project: Location: Client: Code: SGE Job NoWalid Abou HassanNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- Column design details for rectangular columnDocument27 pagesColumn design details for rectangular columnnsureshbabu0% (1)

- TEnsion MembersDocument24 pagesTEnsion MembersJade CarilloNo ratings yet

- Deep Beam Design ExampleDocument7 pagesDeep Beam Design Examplebasum matNo ratings yet

- Fundamentals of Beam BracingDocument16 pagesFundamentals of Beam Bracingofingjbrm100% (1)

- Fundamentals of Beam Bracing 1Document16 pagesFundamentals of Beam Bracing 1sunny171083_90123592No ratings yet

- An Analysis of Shear Stress in Beams of Various Cross SectionsDocument10 pagesAn Analysis of Shear Stress in Beams of Various Cross SectionsGaurav KumarNo ratings yet

- 5beams2 PDFDocument84 pages5beams2 PDFAlexa BuquirNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Balcony AnalysysDocument4 pagesBalcony AnalysysKory EstesNo ratings yet

- Floating RoadsDocument6 pagesFloating RoadsKory EstesNo ratings yet

- 00 FormulasDocument86 pages00 FormulasKory EstesNo ratings yet

- Landscaping For Energy EfficiencyDocument8 pagesLandscaping For Energy EfficiencyKory EstesNo ratings yet

- 1.1 Fatigue: Check This - Welded - Connections PDFDocument4 pages1.1 Fatigue: Check This - Welded - Connections PDFKory EstesNo ratings yet

- Torsional StressesDocument48 pagesTorsional StressesKory EstesNo ratings yet

- DavitsDocument1 pageDavitsKory EstesNo ratings yet

- Beam - Design ProcessDocument2 pagesBeam - Design ProcessKory EstesNo ratings yet

- Yield StressDocument2 pagesYield StressKory EstesNo ratings yet

- Column Axial Strength Aisc 360-05Document42 pagesColumn Axial Strength Aisc 360-05Kory Estes0% (1)

- Blast Effects of High Explosive Charges Detonating in Cylindrical Steel TubesDocument5 pagesBlast Effects of High Explosive Charges Detonating in Cylindrical Steel TubesKory EstesNo ratings yet

- Beam Bending Strenght Aisc 9th EditionDocument17 pagesBeam Bending Strenght Aisc 9th EditionKory Estes100% (1)

- Formulae: Two-Way Shear With Negligible Moment TransferDocument7 pagesFormulae: Two-Way Shear With Negligible Moment TransferKory EstesNo ratings yet

- Structural Design Optimization of Wind Turbine TowersDocument18 pagesStructural Design Optimization of Wind Turbine TowersAnonymous tW1zTL2ltNo ratings yet

- Steel GuitarDocument5 pagesSteel GuitarangelroninNo ratings yet

- Dictionary Civil EngineeringDocument1 pageDictionary Civil EngineeringKory EstesNo ratings yet

- FractureDocument29 pagesFracturemshameliNo ratings yet

- As Clean As A New PinDocument1 pageAs Clean As A New PinKory EstesNo ratings yet

- Fatigue and Fracture Mechanics of Offshore StructuresDocument189 pagesFatigue and Fracture Mechanics of Offshore StructuresXianju Yiang Li100% (5)

- Thermodynamic Properties of SteamDocument10 pagesThermodynamic Properties of SteamMohammed AlSalehNo ratings yet

- Pushover Analysis of Reinforced Concrete Frame Structure Using SAP 2000Document8 pagesPushover Analysis of Reinforced Concrete Frame Structure Using SAP 2000Rishi RamakrishnanNo ratings yet

- Dry Cooling Systems1.2Document40 pagesDry Cooling Systems1.2paragmishra1986No ratings yet

- Modelling of Laser Welding of Aluminium Using COMSOL MultiphysicsDocument73 pagesModelling of Laser Welding of Aluminium Using COMSOL MultiphysicsAli NasserNo ratings yet

- Living HingeDocument2 pagesLiving HingeRavi TarunNo ratings yet

- H83RED Exam Feedback Form 2011-2012Document2 pagesH83RED Exam Feedback Form 2011-2012Devina IreneNo ratings yet

- Refrigeration CatalogDocument32 pagesRefrigeration CatalogSami ThirunavukkarasuNo ratings yet

- Specific heat values of foods and materialsDocument1 pageSpecific heat values of foods and materialslucasNo ratings yet

- Hydraulic Design of Syphon Aqueduct at CH 24.645 KM.: Canal DataDocument19 pagesHydraulic Design of Syphon Aqueduct at CH 24.645 KM.: Canal DatamiestyNo ratings yet

- One-Dimensional Site Response AnalysisDocument85 pagesOne-Dimensional Site Response AnalysisesscindiaNo ratings yet

- Grillage Analysis of Cellular Decks With Inclined WebsDocument6 pagesGrillage Analysis of Cellular Decks With Inclined WebsLama20No ratings yet

- Study On The Foaming Mechanism of Polypropylene in The Gas-Assisted Microcellular Injection MoldingDocument32 pagesStudy On The Foaming Mechanism of Polypropylene in The Gas-Assisted Microcellular Injection MoldingProton HutabaratNo ratings yet

- Mahajan DissertationDocument123 pagesMahajan DissertationhithereNo ratings yet

- Engineering Failure Analysis: Rui Yu, Jinxiang LiuDocument7 pagesEngineering Failure Analysis: Rui Yu, Jinxiang LiuPrasad GharatNo ratings yet

- Lecture 7: Convective Heat Transfer: Reynolds AnalogyDocument16 pagesLecture 7: Convective Heat Transfer: Reynolds Analogy06me395No ratings yet

- Bms SystemDocument13 pagesBms SystemgaineyskNo ratings yet

- Concrete Topping Reinforcement DesignDocument3 pagesConcrete Topping Reinforcement DesignGermar PorquerinoNo ratings yet

- Hydraulics MicroprojectDocument17 pagesHydraulics MicroprojectAkash ChourasiaNo ratings yet

- Mid Question FluidDocument1 pageMid Question FluidSubrata DebnathNo ratings yet

- Study On The Diaphragm Fracture in A Diaphragm Compressor For A Hydrogen Refueling StationDocument10 pagesStudy On The Diaphragm Fracture in A Diaphragm Compressor For A Hydrogen Refueling StationMateusNo ratings yet

- 2009-11-06 Boardwalk Partners Update W Test Results Search AbleDocument126 pages2009-11-06 Boardwalk Partners Update W Test Results Search AblepalblackburnNo ratings yet

- Non-Linear Analysis of Composite Beams by A Displacement ApproachDocument12 pagesNon-Linear Analysis of Composite Beams by A Displacement ApproachCharles WongNo ratings yet

- Wells and Pumps Course SyllabusDocument2 pagesWells and Pumps Course Syllabusyt premiumNo ratings yet

- Combustión: Análisis Termodinámico, Químico y Transferencia de MasaDocument365 pagesCombustión: Análisis Termodinámico, Químico y Transferencia de MasaPaulo Cæsar SlowNo ratings yet

- Technical Data Sheet: Recirculating Chiller F-100 / F-105Document4 pagesTechnical Data Sheet: Recirculating Chiller F-100 / F-105Palak AgarwalNo ratings yet

- Mini Project On Solar Water Heater Complete 2Document19 pagesMini Project On Solar Water Heater Complete 2jadhavakshay610No ratings yet

- fb190409125958 PDFDocument102 pagesfb190409125958 PDF潘子豪No ratings yet

- Design Detail For RCC One Way SlabDocument18 pagesDesign Detail For RCC One Way SlabWanda BeasleyNo ratings yet

- SI Heat 4e Chap12 LectureDocument43 pagesSI Heat 4e Chap12 LectureNik JaffNo ratings yet