Professional Documents

Culture Documents

Fuel Pump Replacement Kit: Caution

Uploaded by

Antonio MonteiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Pump Replacement Kit: Caution

Uploaded by

Antonio MonteiroCopyright:

Available Formats

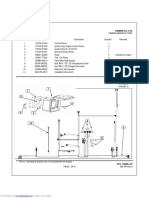

Fuel Pump Replacement Kit

Form No. 3358320 Rev A

Kubota Engines

Part No. 1128400

Installation Instructions

Caution

If you leave the key in the ignition switch, someone

could start the engine. Accidental starting of the

engine could seriously injure you or other

bystanders.

2

1

Remove the key from the ignition switch before

you do any maintenance.

1. Disengage the PTO and set the parking brake.

Figure 2

2. Stop the engine and remove the key from the ignition

switch. wait for all moving parts to stop before leaving

the operators position.

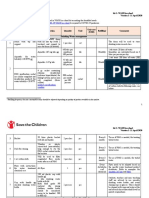

1. Fuel pump (Part No.

993464)

3. Disconnect the battery.

2. Ring terminal

3. Bullet connector

A. Cut the supplied jumper wire at the location shown

in figure 3.

4. Remove the existing fuel pump and plug the fuel hoses

to prevent leakage. Retain all hardware for future use

5. Insert the supplied bracket over the pump as shown

figure 1.

6. Connect the electrical jumper wire to the new fuel

pump wire harness (Fig. 1).

3

Figure 3

B. Strip each wire 1/4 inch (Fig. 4).

Figure 1

1. Fuel pump

2. Electrical jumper wire

3. Fuel pump wire harness

4. Bracket

Figure 4

Note: This jumper connects the new fuel pump to the

existing vehicle wire harness for most applications. If

replacing a fuel pump, part number 993464 with a ring

and bullet electrical connection, as shown in figure 2,

continue to step A. Otherwise, proceed to step 7.

W 2006 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

Note: It is not necessary to use the other bolt hole on the

clamp. If desired, the second bolt hole may be used with

one of the original mounting bolts. It may be necessary to

drill a new mounting hole in order to use the second bolt.

C. Place the supplied splice terminal on the red wire

and the supplied ring terminal on the black wire

(Fig. 5). Crimp the terminals in place and heat

shrink the crimped side of the splice terminal.

2

1

Figure 5

1. Splice terminal

2. Ring terminal

D. Cut the bullet connector off of the machine wire

harness (Fig. 6). Strip 1/4 inch off the end and crimp

on new splice terminal connector installed in step C.

Heat shrink the newly crimped side of the splice

terminal.

Figure 7

1. Use this clamp mounting hole

8. Install the fuel hoses to the pump. Make sure the fuel

hose attached to the Out connector (stamped on the

flanged end of the pump) goes to the fuel/water

separator. Secure the fuel hose at both ends of the fuel

pump, using the original hose clamps.

9. Connect the electrical wires from the fuel pump to

machines wiring harness.

10. Test the new pump by turning the ignition switch to the

On position and bleeding air and fuel out of the fuel

filter bleed screw.

Note: On Groundsmaster 328 traction units with serial

numbers prior to 269999999, it is possible that the 7.5 amp.

fuse which powers the electric fuel pump and the engine

run solenoid could be over stressed do to the higher current

draw of the new fuel pump and fail after some period of

time. If this 7.5 amp. fuse (located in the #4 position of the

fuse block) fails, replace it with a 10 amp. fuse to resolve

the problem.

Figure 6

1. Bullet connector

E. Using the enclosed bolt, secure the black wire ring

terminal and the fuel pump bracket to the machine

(Fig. 7). Use the bracket mounting holes closest to

the fuel pump. Torque the bolt to 100 inchpounds.

7. Using the enclosed bolt, secure the fuel pump bracket to

the machine (Fig. 7). Use the bracket mounting holes

closest to the fuel pump. Torque the bolt to 100

inchpounds.

Note: When mounting the fuel pump on Groundsmaster

3500D and Reelmaster 3100D traction units, use the

longer spacer and screw supplied in the kit.

You might also like

- AFC Sensor de Presion PDFDocument10 pagesAFC Sensor de Presion PDFCharlie BrownNo ratings yet

- Dellorto Carb Install Instructions For 13bDocument7 pagesDellorto Carb Install Instructions For 13bBrent Z. BaileyNo ratings yet

- Recall No. 970Document15 pagesRecall No. 970Johann SGNo ratings yet

- 1985 1993 Chevrolet Metro 3 Cylinders 6 1.0L TBI SOHC 32388501Document89 pages1985 1993 Chevrolet Metro 3 Cylinders 6 1.0L TBI SOHC 32388501Jaime SánchezNo ratings yet

- MSD 4151Document8 pagesMSD 4151rxhughesNo ratings yet

- C107C1 - CAT TH580B Chain Shackles - Dist PDFDocument15 pagesC107C1 - CAT TH580B Chain Shackles - Dist PDFBart JohnNo ratings yet

- 2010-09-26 200008 3126 UiDocument5 pages2010-09-26 200008 3126 UiDeny YusufNo ratings yet

- Detroit Diesel DD15 - EPA07 and EPA10 DD Platform, EGR Delta Pressure Sensor UpdateDocument6 pagesDetroit Diesel DD15 - EPA07 and EPA10 DD Platform, EGR Delta Pressure Sensor UpdateAhmetCan YüzükçüNo ratings yet

- Rehs1037 04Document10 pagesRehs1037 04Pauk HseinNo ratings yet

- DD EPA04S60 ActuatorturboDocument5 pagesDD EPA04S60 ActuatorturboCuong DinhNo ratings yet

- TD10242 Automatic Oiler 230VAC 0216A WEBDocument13 pagesTD10242 Automatic Oiler 230VAC 0216A WEBBallsNo ratings yet

- Unit Injector Synchronization - AdjustDocument5 pagesUnit Injector Synchronization - AdjustAhmed Rezk100% (1)

- Vrod Fuel Flange ReplacementDocument5 pagesVrod Fuel Flange ReplacementAubrey Lee Calhoun100% (1)

- Sum-Carb InstrDocument14 pagesSum-Carb InstrbobNo ratings yet

- 30wg IEI Conversion DirectionsDocument3 pages30wg IEI Conversion DirectionsclslaundryNo ratings yet

- 4 3 Vortec Engine Manual Powerdyne Automotive Products IncDocument6 pages4 3 Vortec Engine Manual Powerdyne Automotive Products Incgarrett86No ratings yet

- MBE4000 EGR Connector Pipe InstallationDocument6 pagesMBE4000 EGR Connector Pipe InstallationАндрейNo ratings yet

- 6.0L StandpipesDocument12 pages6.0L StandpipesElias PicazoNo ratings yet

- rp6378 MTDocument14 pagesrp6378 MTMessi EmetievNo ratings yet

- dd15 Egr PDFDocument6 pagesdd15 Egr PDFcesar100% (1)

- D533-14 InstructionsDocument23 pagesD533-14 InstructionsBojan DimitrijevicNo ratings yet

- Calibracion InyectoresDocument4 pagesCalibracion InyectoresWladimir AmaguañaNo ratings yet

- Instructions: Replacement 5 In. Electronic Speedometer KitsDocument6 pagesInstructions: Replacement 5 In. Electronic Speedometer KitsEddie SpeghettyNo ratings yet

- Carb Turbo Kit InstructionsDocument11 pagesCarb Turbo Kit InstructionsKevin ShankleNo ratings yet

- SB 10091401 2280Document14 pagesSB 10091401 2280Artur ElectroMecânicoNo ratings yet

- Installation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224Document6 pagesInstallation Instructions For Electric Choke KIT P/Ns 45-224, 45-224S, & 745-224dave pNo ratings yet

- 4inch Install Instruction Rev4Document16 pages4inch Install Instruction Rev4Anonymous 52DDvGtvNo ratings yet

- Fitting Instructions For Yamaha XS650 Micro Power IgnitionDocument2 pagesFitting Instructions For Yamaha XS650 Micro Power IgnitionDupontNo ratings yet

- Rcrit 19V813 0002Document27 pagesRcrit 19V813 0002José GonzálezNo ratings yet

- 2.4L Install InstructionsDocument13 pages2.4L Install InstructionskpepasNo ratings yet

- Caterpillar 320clDocument7 pagesCaterpillar 320clHamilton MirandaNo ratings yet

- Universal Electric Fuel Pump InstallationDocument5 pagesUniversal Electric Fuel Pump InstallationElsa Alabado-OrtegaNo ratings yet

- Isc 300Document37 pagesIsc 300AwanNo ratings yet

- 18 SP685 Rev 2Document9 pages18 SP685 Rev 2arstjunkNo ratings yet

- International Distribution Bulletin No: CHALL 13/10 Section 10-0095 Issue: 1 Date: May 2010Document10 pagesInternational Distribution Bulletin No: CHALL 13/10 Section 10-0095 Issue: 1 Date: May 2010Messi EmetievNo ratings yet

- Pistons and Connecting Rods - Assemble: Previous ScreenDocument4 pagesPistons and Connecting Rods - Assemble: Previous ScreenqwuLzNo ratings yet

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- 2 Mbe4000 06aDocument76 pages2 Mbe4000 06azahar222100% (3)

- Ford Tempo Topaz 1984-1994 Repair GuideDocument11 pagesFord Tempo Topaz 1984-1994 Repair GuideFer VN100% (2)

- Finding Top Center Position For No. 1 Piston: Testing and AdjustingDocument6 pagesFinding Top Center Position For No. 1 Piston: Testing and AdjustingIndiNo ratings yet

- Diagnosis and Testing BlazerDocument308 pagesDiagnosis and Testing BlazerAli Castillo100% (1)

- Unit Injector - Install: Installation ProcedureDocument6 pagesUnit Injector - Install: Installation ProceduredayanaNo ratings yet

- MEGA Operating InstructionsDocument14 pagesMEGA Operating InstructionsSumit SinghaNo ratings yet

- 1984 Corvette Dealer VersionDocument1,653 pages1984 Corvette Dealer VersionKomáromi LászlóNo ratings yet

- Ford TSB 08-7-6 PDFDocument11 pagesFord TSB 08-7-6 PDFnoe dela vega100% (1)

- Engine Brakes PDFDocument18 pagesEngine Brakes PDFMitchelle GonouyaNo ratings yet

- J02798Document6 pagesJ02798Ron CordesNo ratings yet

- Final Laboratory Activity 2Document8 pagesFinal Laboratory Activity 2Angel CareNo ratings yet

- Manual BombaDocument8 pagesManual BombaLuisNo ratings yet

- Installation ManualDocument6 pagesInstallation ManualBEARNo ratings yet

- 3408E Finding TDC For No.1 PistonDocument4 pages3408E Finding TDC For No.1 Pistonmanu luvungaNo ratings yet

- REHS1037 - Fuel Priming PumpDocument13 pagesREHS1037 - Fuel Priming Pumpkman548No ratings yet

- Yosh R55 InstallDocument6 pagesYosh R55 Installsnoop43No ratings yet

- Unit Injector Synchronization - Adjust: 3114, 3116 and 3126 Industrial, Marine and Generator Set EnginesDocument6 pagesUnit Injector Synchronization - Adjust: 3114, 3116 and 3126 Industrial, Marine and Generator Set EnginesChristian Vinueza VillavicencioNo ratings yet

- Mallory Points Ignition Conversion ModuleDocument4 pagesMallory Points Ignition Conversion Modulepaul_a_rodriguezNo ratings yet

- MBE900 Injector Unit Pump PDFDocument6 pagesMBE900 Injector Unit Pump PDFJosue Alvarez VegaNo ratings yet

- Turbo Systems Installation InstructionsDocument17 pagesTurbo Systems Installation InstructionsAndrew DavisNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Caterpillar c4 4 Engine ManualDocument3 pagesCaterpillar c4 4 Engine ManualAndré58% (31)

- Cat C4.4 ACERTDocument304 pagesCat C4.4 ACERTAntonio Monteiro100% (7)

- CAT 312D-312DL 2008 LeafleatDocument28 pagesCAT 312D-312DL 2008 LeafleatLuka Borna100% (1)

- Operation Manual Komatsu Pc138uslcDocument375 pagesOperation Manual Komatsu Pc138uslcAle Cre100% (1)

- Treinamento de Mecânicos - Pesados Trouble ShootingDocument22 pagesTreinamento de Mecânicos - Pesados Trouble ShootingAntonio MonteiroNo ratings yet

- TB175 Service ManualDocument378 pagesTB175 Service ManualAnonymous DSEG94100% (1)

- Komatsu FG25T-14 Operator Manual PDFDocument166 pagesKomatsu FG25T-14 Operator Manual PDFAntonio Monteiro0% (1)

- WEG Alternadores Sincronos Linha Ag10 12638144 Manual Portugues BRDocument139 pagesWEG Alternadores Sincronos Linha Ag10 12638144 Manual Portugues BRAntonio Monteiro100% (1)

- Edi Ford Air To Boil Procedure Rev 0Document8 pagesEdi Ford Air To Boil Procedure Rev 0Antonio MonteiroNo ratings yet

- Cooling and Lubrication - 3Document8 pagesCooling and Lubrication - 3AbhinavTiwariNo ratings yet

- C 10704342Document134 pagesC 10704342Antonio MonteiroNo ratings yet

- Hydraulic Injection Injury LearningDocument5 pagesHydraulic Injection Injury LearningAntonio MonteiroNo ratings yet

- Hydraulic Injection Injury LearningDocument5 pagesHydraulic Injection Injury LearningAntonio MonteiroNo ratings yet

- BorgWarner TurboalimentadoresDocument108 pagesBorgWarner TurboalimentadoresAntonio Monteiro100% (1)

- Manulife Health Flex Cancer Plus Benefit IllustrationDocument2 pagesManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNo ratings yet

- Bs en 1991-1-5 2003 + 2009 Thermal Actions (Unsecured)Document52 pagesBs en 1991-1-5 2003 + 2009 Thermal Actions (Unsecured)Tan Gui SongNo ratings yet

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Document50 pagesDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RNo ratings yet

- CasesDocument4 pagesCasesNaveen Stephen LoyolaNo ratings yet

- Gogte Institute of Technology: Karnatak Law Society'SDocument33 pagesGogte Institute of Technology: Karnatak Law Society'SjagaenatorNo ratings yet

- Deshidratador Serie MDQDocument4 pagesDeshidratador Serie MDQDAIRONo ratings yet

- OOPS Notes For 3rd Sem ALL ChaptersDocument62 pagesOOPS Notes For 3rd Sem ALL Chaptersabhishek singh83% (6)

- S SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesDocument3 pagesS SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesMohan PreethNo ratings yet

- WPGPipingIndex Form 167 PDFDocument201 pagesWPGPipingIndex Form 167 PDFRaj AryanNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Coca-Cola Summer Intern ReportDocument70 pagesCoca-Cola Summer Intern ReportSourabh NagpalNo ratings yet

- Ucbackup Faq - Commvault: GeneralDocument8 pagesUcbackup Faq - Commvault: GeneralhherNo ratings yet

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 pagesKit 2: Essential COVID-19 WASH in SchooltamanimoNo ratings yet

- 0901b8038042b661 PDFDocument8 pages0901b8038042b661 PDFWaqasAhmedNo ratings yet

- MG206 Chapter 3 Slides On Marketing Principles and StrategiesDocument33 pagesMG206 Chapter 3 Slides On Marketing Principles and StrategiesIsfundiyerTaungaNo ratings yet

- Musings On A Rodin CoilDocument2 pagesMusings On A Rodin CoilWFSCAO100% (1)

- For Exam ReviewerDocument5 pagesFor Exam ReviewerGelyn Cruz67% (3)

- Elb v2 ApiDocument180 pagesElb v2 ApikhalandharNo ratings yet

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDocument9 pagesAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- Mentorship ICT at A GlanceDocument5 pagesMentorship ICT at A GlanceTeachers Without Borders0% (1)

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Document7 pagesINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeNo ratings yet

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Document23 pagesQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Medical Devices RegulationsDocument59 pagesMedical Devices RegulationsPablo CzNo ratings yet

- Study of Means End Value Chain ModelDocument19 pagesStudy of Means End Value Chain ModelPiyush Padgil100% (1)

- Comparative Analysis of Mutual Fund SchemesDocument29 pagesComparative Analysis of Mutual Fund SchemesAvinash JamiNo ratings yet

- Resources and Courses: Moocs (Massive Open Online Courses)Document8 pagesResources and Courses: Moocs (Massive Open Online Courses)Jump SkillNo ratings yet

- Cencon Atm Security Lock Installation InstructionsDocument24 pagesCencon Atm Security Lock Installation InstructionsbiggusxNo ratings yet

- 19-2 Clericis LaicosDocument3 pages19-2 Clericis LaicosC C Bờm BờmNo ratings yet

- Catalog enDocument292 pagesCatalog enSella KumarNo ratings yet

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNo ratings yet