Professional Documents

Culture Documents

Rapid Steel Decking Brochure

Uploaded by

atiattiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rapid Steel Decking Brochure

Uploaded by

atiattiCopyright:

Available Formats

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 2

EFFICIENT, RELIABLE,

HONEST & PROFESSIONAL

with a Competitive Edge

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 3

We also stock:

VARIOUS SHEAR STUDS, EXPANDA FOAM ALL FIXINGS,

CLOSURE PLATES, BLOCKERS OUR OWN FLEET OF

VEHICLES FOR COST EFFECTIVE DELIVERY

Sales and Information

Please see from the following pages

examples of our work and illustrations

showing how flexible and efficient Metal

Decking is. Metal Decking is used in various

applications from high rise buildings to a

basement floor, Rapid Steel Decking have

installed the Metfloor product in a wide range

of applications. Our design team have

implemented specifications to achieve spans

of up to 7.5 mtrs and supported Structural

Engineers/ Architects in making the right

choice when it comes to a Composite Floor or

Sacrificial Formwork design.

Flexibility is key to our service and we strive

to meet client demands successfully since we

established in 2009. Rapid Steel Decking is

proud to have been established by

experienced individuals from different areas

within the Metal Decking Industry each

bringing various skills and ideas to the group

which makes for a quality recipe to our

success so far.

Not only do we supply and fix Metal Decking

and offer the full package from putting the

Metal Decking down, to laying mash, bar, to

Concrete and finish, we also Supply Only to

our clients all profiles and gauges with

associating products very efficiently from our

Stockyard in Chelmsford Essex. We also offer

support with our easy to follow install guides

or advice over the phone, our office personnel

can produce calculations swiftly to respond to

any spanning requirements or design you

may need carrying out. We can also provide

you with site specific drawings to enable your

personnel on site to identify pack locations

with tips featured on the drawings as part of

the service.

We deliver your material on various vehicles

for example our 3.5 tonne specially adapted

vehicles that can carry up to 8mtr long sheets

of deck and pay load of 1.8 tonne, which has

proved very popular in London and other City

centres due to their size to our Hi-Hab lorries

capable of 20mtr reach proving very popular

for contractors wishing to save money on

plant hire. We cover the UK at very

competitive rates and efficient service.

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 6

Our Services include . . .

Supply and Install of Metal Decking,

whatever the profile, our experienced

fully trained installation team are the

most skilled and highest certificated

install team in the country.

Studwelding services are offered as a

package or as a single service as

required, we have generators and rigs

mounted upon specially adapted

trailers to offer our clients a compact

and efficient package popular with

limited site access and space.

Safety Netting services are offered

with our package or as a dedicated

service with our FASET registered rig

teams and array of nets prepared to

net from 5m2 to thousands of m2 at

any time required, as all our services

competitively priced and efficiently

implemented.

Air Mat fall arrest systems offered as

part of our package or at individual

demands with many size cubes

available to install by our fully trained

and certificated personnel.

Many size cranes available with or

without Banksman again offered as

part of our package or a dedicated

service.

Scaffolding Services only associated

with the decking installation as edge

protection is required for personnel

fixing the system.

Concreting supply and installation to

finish only relating to the Metal

Decking area of works.

Mesh and Bar laying only or Mesh

and Bar supply only, to supply and

fixing.

www.rapidsteeldecking.co.uk

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 7

Attention to

Small Works

projects to

Projects running

into thousands

of Square

Metres . . .

Rapid Steel Decking have

successfully carried out many projects

to date with no accidents from 2009,

our health and safety record is

testament to how serious we are in

considering our environment on site

with ultimate consideration to

individuals on site or passing

pedestrians.

A small example of our Projects

completed successfully well within

time, budget and very happy clients!

Trafford Park

Arena infills.

Stepstile Meadow

Swimming Pool adaptations.

Canon Street, London

High rise offices.

Polegate Railway Station

Platform Adaptations.

Riverside Bowl, Norwich

Construction of the Riverside Bowl.

The Lounge,

Leeds Road, Leeds

4

Construction of a small Shishi

lounge floor.

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 10

54 Camden Street

Supply only decking efficiently in

phases to our client.

The Pits, Coventry

& Telford Manufacturers

Pit infills at Stadco Ltd.

Primark, Yeovil

Supply only typically within 3 days

from order.

Harris City Academy,

Crystal Palace

First Floor and Roof Decking.

Homebase, Aylesford

Construction of first floor.

Orbis Consumer Products

Supply of decking.

Sainsburys Nantwich

Loading dock floor.

307-309 Kentish Road,

London

Construction of first floor.

Yoga Centre, Riverpoint, Bath

Construction of a first floor studio.

St Marys Church, Wendover

Supply only delivery on specialist

vehicle as access was a challenge.

Co-op Development,

Wickham Market

Construction of first floor and

plant room.

Medix Centre, Isle of Wight

Complete floor solution for the

entire building and construction of

new medical centre floor and

atrium.

Factory Floor, Leicester

Achieved typical spans of 7.2mtrs

working closely with the structural

engineer.

www.rapidsteeldecking.co.uk

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 11

Typical end cantilever

Edge Trim

You should use edge trim to main maintain the

wet concrete at the correct level at the decking

perimeters.

Metfloor 80

Fix it to the supports in the same manner as

the deck and restrain the top by straps at 600m

centres fixed to the top of the deck profile with

steel pop rivets or self drilling screws.

Typical side detail

Unsupported edge detail

Metfloor 80

Typical side detail

Metfloor 80

Rapid Steel

Decking

Cut, Packed

Cut,

Packed &

& Delivered

DeliveredFast

Fast

Please browse the next few pages for further examples

of edge trim installation, deck fixing and propping.

For supply or technical information please call 01245 861490

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:35 Page 14

Below and Right you can see typical examples of side details incorporating trim or not as the case maybe.

Edge trim can be fabricated to any dimension required to suit individual requirements.

We do stock a large range of sizes off the shelf to accommodate urgent supply and popular slab depths.

Beam at perimeter wall

Typical wall end detail

Metfloor 80

Metfloor 55

Typical wall side detail

Typical side detail

Metfloor 80

Metfloor 80

www.rapidsteeldecking.co.uk

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:35 Page 15

End detail alternative 2

End detail alternative 1

Metfloor 55

Metfloor 55

Typical edge with plate

Side cantilever with stub bracket

Metfloor 80

Metfloor 80

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:35 Page 16

Sitework openings for shallow composite floor decks

Where openings are greater than 300mm, the engineer

must design them and provide extra reinforcement around

the opening. Openings can be accommodated up to 700mm

in composite slabs by boxing out before pouring concrete

and cutting out the deck after the concrete has cured.

Larger openings require support-trimming steel and there

must be installed prior to the decking.

Cut the decking away immediately and treat the opening

edges like any other perimeter with edge trim.

Timber Shutter

Do not cut the opening in the steel deck before concreting

or before the concrete has cured.

Temporary supports

The contractor or designated sub-contractor is responsible

for the safe design and installation of temporary props.

Where the design calls for temporary supports, these must

provide continuous support to the profiled sheeting.

Spreader beams (timbers) should be used and supported by

temporary props at one metre centres.

Dense polystyrene block

The props should be stable without relying on friction

with the deck for laterial stability. The end props in a

row should be self supporting, and braced to the

internal props.

Temporary Props

The timbers and props must be of adequate strength and

construction.

The temporary supports are placed at midspan or at other

suitable centres if more supports per span are required.

The spreaders beams or timbers should provide a minimum

bearing width of 100mm the spreaders must not deflect more

than 10mm and should be placed narrow edge up,

see diagram.

The propping structure is not to be removed until the

concrete has reached at least 70% of its characteristic

strength. The horizontal bearer timbers must be at least

100mm wide and should be propped at no more than 1m

centres. Sometimes the specification may call for 150mm

wide bearers, as determined by the structural engineers

or concreting contractor.

Percussive Drilling

We do not recommend percussive drilling into

composite concrete slabs although small-scale

rotaty hammer drills are fine.

Please see in Bearing illustrations Below

the minimum required for a continuous and shared

bearing scenario. Note the different requirements for

Masonary and Steel Sections.

End bearing and shared bearing (min)

Continuous bearing (min)

Temporary support using and Acrow type prop

www.rapidsteeldecking.co.uk

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 13

10

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 12

Special Spanning Conditions

0.9 55 130mm slab, C35 concrete 4.5 span

Single Span One prop A252 8mm bar Imposed Loading 3kn/m2

60 mins Fire rating

0.9 55 150 slab C35 concrete 5.45 span

Single Span One prop A252 10mm bar Imosed Loading 3kn/m2

60 mins fire rating

0.9 55 175 slab C35 Concrete 6.2 span

Single Span Two props A393 16mm bar imposed loading 3kn/m2

60 mins fire rating

1.2 55 130 slab C30 Concrete 5.0 span

Single Span One prop A252 10mm bar Imposed loading 3kn/m2

60 mins fire rating

1.2 55 150 slab C30 Concrete 5.850 span

Single Span One prop A252 12mm bar Imposed loading 3kn/m2

60 mins fire rating

1.2 55 175 slab C30 Concrete 6.300 span

Single Span two props A252 12mm bar Imposed loading 3kn/m2

60 mins fire rating

These are examples of the most common deck type in design using additional

reinforcement and various slab thicknesses.

We can assist with any special requirements you have. These examples are ideal for our

small work clients perfoming infills or renovations in tight spaces as the deck is readily

available and easy to amend at short notice with Rapid Steel Decking.

www.rapidsteeldecking.co.uk

11

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 9

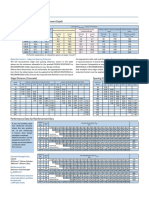

MetFloor 55 Design Information www.rapidsteeldecking.co.uk

Contact tel: 01223 654549

MetFloor 55 - span table - Normal weight concrete using mesh

Props @

Mid-Span only

No Temporary

props

Props

Span**

Single Span

Double Span

Single Span

Double Span

Fire

Rating

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

1 hr

Slab

Depth

(mm)

1.5 hr

2 hr

3.5

5.0

Total Applied Load (kN/m )

10.0

2.8a

2.8a

2.8a

140

A193

2.5m

2.2m

1.8m

A142

3.3a

130

120

130

200

200

1 hr

0.9

A142

130

2 hr

Mesh

120

120

1.5hr

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

120

130

200

A142

A142

A393

2.8a

3.4a

3.2m

1.9m

2.9m

2.6m

2m

3a

2.3m

3.3a

3.3a

2.6m

3.5a

3.5a

3m

4a

4a

3.2m

2.8a

2.8a

2.8a

3a

3a

3a

3.4a

3.4a

3.4a

2.8m

A393

10.0

3.4a

3a

2.4m

5.0

2.9m

2.3m

2.7m

3.5

2.9m

A393

A393

3a

10.0

3.4a

3.7m

A252

3a

5.0

1.2

3.4a

A252

A393

2.8a

3.5

3.5m

4.2m

4.5m

4.4m

3.3a

3.4m

3.1m

2.6m

4m

4.1m

4.1m

2.6m

2.7m

2.5m

2.2m

3.2m

3.2m

3.3m

3.4a

3.7m

3.5m

2.8m

4.4m

4.5m

4.4m

3.4a

3.4m

3.1m

2.6m

2.6m

2.7m

2.5m

2.2m

3.7a

4m

3.7a

3.7m

2.8m

2.9m

3.6m

3.3m

2.6m

3m

2.8m

2.3m

4m

3.2m

4.6m

4.2m

3.4m

4.1m

3.3m

4.5m

4.1m

3.4m

4.1m

3.3m

4.5m

4.1m

3.3m

MetFloor 55 - span table - Lightweight concrete using mesh

No Temporary

props

Props

Span**

Single Span

Double Span

Props @

Mid-Span only

Single Span

Single Span

Double Span

Double Span

Fire

Rating

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

2 hr

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

Slab

Depth

(mm)

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

Mesh

0.9

3.5

5.0

Total Applied Load (kN/m )

10.0

3.5

5.0

10.0

3.5

1.2

5.0

10.0

120

A142

3.0a

3.0a

2.8m

3.2a

3.2a

2.9m

3.6a

3.6a

3.2m

140

A193

2.9a

2.5m

1.9m

2.9m

2.5m

1.9m

3.1m

2.7m

2.0m

130

120

130

140

200

120

130

200

120

130

200

A142

A142

A142

A193

A252

A252

3.0a

3.6a

3.5a

3.4a

3.0a

3.9m

A393

3.6m

A252

4.7m

A393

A393

A393

3.0m

4.8m

4.7m

3.0a

3.6a

3.5a

2.3m

3.0m

2.7m

3.2a

3.7a

3.7a

3.2a

3.7a

3.7m

2.4m

3.1m

2.8m

3.5a

4.2a

4.1a

3.5a

4.2a

3.3m

2.6m

3.9m

3.3m

2.5m

3.6a

3.4m

2.5m

3.9m

3.5m

3.5m

2.7m

4.0m

3.6m

2.8m

4.3m

3.9m

3.0a

3.2m

2.8m

4.2m

4.3m

4.3m

3.0a

2.5m

2.2m

3.2m

3.4m

3.5m

3.3a

3.7m

3.1m

4.7m

4.9m

4.8m

3.3a

3.3m

2.8m

4.3m

4.4m

4.4m

3.2m

2.6m

2.3m

3.3m

3.4m

3.5m

3.7a

3.9m

3.2m

5.0m

5.1m

4.9m

2.6m

2.9m

3.7a

3.3m

3.5m

2.7m

2.9m

4.5m

4.5m

4.5m

3.0m

2.4m

3.5m

3.5m

3.6m

The load span tables above are examples only, Rapid Steel Decking will provide specific calculations based on your

The load span tables above are examples only, Rapid Steel Decking will provide specific calculations based on your

requirements or specification.

requirements or specification.

The calculations will show detailed analysis and provide accurate information to enable you to make a confident

The calculations will show detailed analysis and provide accurate information to enable you to make a confident

decision on slab design.

decision on slab design.

12

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:34 Page 8

MetFloor 60 Design Information www.rapidsteeldecking.co.uk

Contact tel: 01223 654549

MetFloor 60 - span table - Normal weight concrete using mesh

Props

Span**

Props @

Mid-Span

only

No Temporary

props

Single Span

Double Span

Double Span

Fire

Rating

1 hr

1.5 hr

2 hr

1 hr

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

Slab

Depth

(mm)

Mesh

160

A252

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

0.9

3.5

5.0

Total Applied Load (kN/m )

10.0

3.5

5.0

10.0

3.5

1.2

5.0

10.0

130

A193

3.5i

3.5i

2.4m

3.6i

3.6i

2.4m

3.8i

3.8i

2.6m

180

A252

3.1i

3.1i

2.2m

3.2i

3.2i

2.1m

3.4i

3.4i

2.1m

130

150

150

180

130

160

180

3.2i

3.2i

2.4m

3.3i

3.3i

2.4m

3.5i

3.5i

2.5m

A142

3.9e

3.9e

2.8m

4.1m

3.9m

2.8m

4.4m

3.9m

3.0m

A252

3.7e

3.7e

3.1m

3.9e

3.9e

3.2m

4.4e

4.4e

3.3m

A252

A393

A393

A393

A393

3.7e

3.7e

3.5e

3.5e

5.0k

5.0m

4.7m

3.6m

3.5e

4.0e

3.7e

4.0e

3.7e

3.5m

3.7e

4.4e

4.1a

4.4e

4.1a

3.7m

3.7m

4.5m

3.5m

5.0m

4.7k

3.7m

5.1k

4.8m

3.7m

4.3m

3.4m

4.6m

4.4m

3.6m

4.7m

4.3m

3.6m

4.6m

3.6m

5.0m

4.6m

3.6m

5.1m

4.6m

3.7m

MetFloor 60 - span table - Lightweight concrete using mesh

Props

Span**

No Temporary

props

Single Span

Double Span

Slab

Depth

(mm)

Mesh

1 hr

130

A193

3.7i

3.7i

2.4m

3.8i

3.8m

2.4m

4.0i

4.0i

2.6m

2 hr

180

A252

3.1i

3.3m

2.1m

3.4i

3.3m

2.1m

3.5m

3.2m

2.1m

Fire

Rating

1.5 hr

1 hr

1 hr

1.5 hr

Props @

Mid-Span

only

2 hr

Double Span

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

1 hr

1.5 hr

2 hr

160

130

150

150

180

130

160

180

A252

0.9

3.5

3.4i

5.0

3.4i

Total Applied Load (kN/m )

10.0

2.4m

3.5

3.5i

5.0

3.5i

10.0

2.4m

3.5

3.7i

1.2

5.0

3.7i

A142

4.1a

4.0m

2.9m

4.3m

4.0m

2.9m

4.5m

4.1m

A252

4.0e

4.0e

3.5m

4.2e

4.2e

3.5m

4.7i

4.7i

A252

A393

4.0e

3.6m

3.8e

3.8e

3.8e

5.0m

4.8m

3.7m

A393

5.0m

A393

5.0m

A393

4.0e

4.5m

4.7m

3.5m

3.9m

4.2e

4.0a

5.0m

5.1m

5.1m

4.2e

4.0a

4.5j

4.8m

4.7m

3.6m

4.0m

3.6j

3.7m

3.7m

4.7i

4.5e

5.0k

5.2m

5.2m

10.0

2.5m

2.9m

4.7i

3.7m

4.5e

4.4m

4.6k

4.9m

4.8m

3.5m

3.7j

3.7m

3.7m

The load

load span

span tables

tables above

above are

are examples

examples only,

only, Rapid

Rapid Steel

Steel Decking

Decking will

will provide

provide specific

specific calculations

calculations based

based on

on your

your

The

requirements

or

specification.

requirements or specification.

The calculations

calculations will

will show

show detailed

detailed analysis

analysis and

and provide

provide accurate

accurate information

information to

to enable

enable you

you to

to make

make a

a confident

confident

The

decision on

on slab

slab design.

design.

decision

www.rapidsteeldecking.co.uk

13

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 5

MetFloor 80 Design Information www.rapidsteeldecking.co.uk

Contact tel: 01223 654549

MetFloor 80 - span table - Normal weight concrete using mesh

Props @

Mid-Span

only

No Temporary

props

Props

Span**

Single Span

Double Span

Double Span

Fire

Rating

1 hr

1.5 hr

2 hr

1 hr

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

Slab

Depth

(mm)

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

Mesh

0.9

3.5

5.0

Total Applied Load (kN/m )

10.0

3.5

5.0

10.0

3.5

1.2

5.0

10.0

140

A393

4.1a

4.1a

2.8m

4.2i

4.2i

2.9m

4.3i

4.3i

3.0m

180

A393

3.7a

3.7a

2.6m

4.0i

4.0i

2.6m

4.1i

4.1i

2.6m

180

140

160

160

190

140

160

190

A393

A252

A252

A393

A393

3.8a

4.5e

4.4e

4.4e

4.0e

A393

5.2m

A393

5.0m

A393

5.1m

3.8a

2.8m

4.0i

4.0i

2.8m

4.1i

4.1i

4.3m

3.3m

4.6m

4.6m

3.3m

5.1m

4.7m

4.4e

3.7m

4.5e

4.5e

3.8m

5.1e

5.1e

4.4e

4.0e

4.7m

4.6m

4.5m

3.5m

3.7m

3.4g

3.5m

3.5m

4.6e

4.3e

5.2m

5.1m

5.0m

4.6e

4.3e

4.7m

4.6m

4.5m

3.5m

3.8m

3.5g

3.6m

3.5m

5.1e

4.8e

5.2m

5.2m

5.0m

5.1m

4.8e

4.7m

4.7m

4.5m

3.0m

3.5m

3.6m

3.9m

3.9m

3.7m

3.7m

3.5m

MetFloor 80 - span table - Lightweight concrete using mesh

Props @

Mid-Span

only

No Temporary

props

Props

Span**

Single Span

Double Span

Double Span

Fire

Rating

1 hr

1.5 hr

2 hr

1 hr

1 hr

1.5 hr

2 hr

1 hr

1.5 hr

2 hr

Slab

Depth

(mm)

Maximum Span (m) with no additional reinforcements

Deck Thickness (mm)

Mesh

0.9

3.5

5.0

Total Applied Load (kN/m2)

10.0

3.5

5.0

10.0

3.5

1.2

5.0

10.0

140

A393

4.3a

4.3a

2.9m

4.4i

4.4i

2.9m

4.6i

4.6i

3.0m

180

A393

4.0a

3.9m

2.4m

4.0m

3.7m

2.4m

4.0m

3.6m

2.4m

4.6e

3.5m

4.9e

4.9e

3.6m

5.5i

5.2m

3.7m

180

140

160

160

190

140

160

190

A393

A252

A252

A393

4.0a

4.8e

4.6e

4.6e

4.0a

4.8e

4.6e

2.8m

3.5m

3.8m

A393

4.4e

4.4e

3.9m

A393

5.4m

4.9m

3.9m

A393

A393

5.2k

5.2m

4.8k

4.8m

3.8m

3.8m

4.2i

5.1e

4.9e

4.7e

5.2k

5.4m

5.2m

4.2i

4.8m

4.9e

4.7e

4.8k

4.9m

4.8m

2.8m

3.5m

3.9m

4.0m

3.8m

3.9m

3.8m

4.3i

5.5j

5.5e

5.2e

5.3k

5.4m

5.2m

4.3i

5.0m

5.5e

5.2e

4.8k

4.9m

4.8m

2.9m

3.6m

4.0m

4.1m

3.8m

3.9m

3.8m

The load span tables above are examples only, Rapid Steel Decking will provide specific calculations based on your

The load span

above are examples only, Rapid Steel Decking will provide specific calculations based on your

requirements

or tables

specification.

requirements or specification.

The calculations will show detailed analysis and provide accurate information to enable you to make a confident

The calculations

will show detailed analysis and provide accurate information to enable you to make a confident

decision

on slab design.

decision on slab design.

14

For supply or technical information please call 01245 861490

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 4

Frequently Asked Questions

Is Metfloor the same as Holorib, Ribdeck

80, & Ribdeck E60?

Metfloor is a better than equivalent to the

Holorib, Ribdeck 80 & Ribdeck E60 product

range, we can say this confidently as the

Metfloor product range has been rigorously

tested independently and jointly designed by

CMF Ltd and the SCI to maximise the design

specification to out perform all other similar

products on the market with superior fire

rating results, acoustic and spanning abilities.

Which Metfloor is the direct equivalent to

Holorib?

alternatives for one another only the spanning

abilities vary due to stiffner design on the

profile, Metfloor is now the market leader in

performance so this is used as alternative to

all deck on the market.

Which Metfloor profile is a direct

equivalent to the Ribdeck 80?

The Metfloor 80 is the direct equivalent to the

Ribdeck 80 product range and is also 600mm

cover width and spans further than any other

equivalent on the market.

Which Metfloor is the equivalent to

Ribdeck E60?

The Metfloor 55 is the direct equivalent, the

sheet gives you a cover width of 600mm, the

same as Holorib, and the profile shape is a

similar re-entrant design to Holorib, the

stiffner design within the Metfloor profile is

what distinguishes the difference between the

two profiles giving it a slightly different

appearance.

The Metfloor 60 is the direct equivalent, to the

Ribdeck E60 product range, the only

difference here is that our Metfloor profile is a

easy to handle 600mm cover width as oppose

to the Ribdeck E60 being a 1000 cover width

profile, however as previously stated the

Metfloor is a better performing deck.

The number generally signifies the profile

depth and across the product range these

numbers represent the depth of the profile,

the shallow profiles are 50, 51, or 55mm

which are all re-entrant profiles, the 60 and 80

are trapezoidal profiles which are all

Metfloor has been on the market since 2005,

the profile is manufactured from state of the

art modern facilities and delivered out to

satellite stockyards from Wales to Chelmsford

Essex where we prepare material to site

specific lengths and deliver efficiently on our

own specially adapted vehicles.

What significants does the number

associated with the profile name have on

the profile type?

How do you supply the decking so

quickly?

www.rapidsteeldecking.co.uk

15

Rapid Steel Decking Brochure_Rapid Steel Decking Brochure 05/08/2012 19:33 Page 1

Just a few reasons why to use

Composite Flooring from

Rapid Steel Decking

Sustainability benefits of composite floor construction

Composite flooring systems offer clients and designers a number of benefits which address

the social, environmental and economic dimensions of sustainable construction.

Speed of construction

Composite flooring systems facilitate fast track construction; up to 400m2 of decking

can be installed by one team in a day! Speed, simplicity of design and affinity for

steel-framed buildings make composite floors the system of choice where time, and hence

speed of construction, are key drivers. Steel decking can be ordered from us and delivered

to order, efficiently stacked on lorries that can carry many square metres of decking in a

single load.

Rapid construction minimises plant hire costs, in particular cranage. The use of the decking

as a safe working platform during construction, speeds up the work of others and follow-on

trades and offers logistical benefits on congested sites. The minimal steel reinforcement

required can be fixed quickly and large areas of floor poured using pumped concrete.

By shortening the construction programme, the impacts on neighbours and the public

within the vicinity of the construction site, such as noise, dust and traffic congestion are

minimised.

Resource efficiency Composite flooring systems are structurally efficient, thereby

minimising the resources used in constructing the building (particularly concrete) and

reducing the waste generated when it is necessary to deconstruct it. Less concrete means

fewer site deliveries and less localised traffic congestion.

Composite floor systems are stiffer, stronger and lighter than many other floor systems.

This means that the weight and size of the primary structure and the foundations can often

be reduced again minimising resource consumption and end-of-life waste generation.

Head Office:

Sheraton House, Castle Park, Cambridge CB3 0AX

Tel: 01223 654549 Fax: 01223 654429

Essex Stockyard:

Boyton Hall Farmhouse, Boyton Cross, Chelmsford, Essex CM1 4LN

Tel: 01245 861490

E-mail: sales@rapidsteeldecking.co.uk

Website: www.rapidsteeldecking.co.uk

You might also like

- Specification Data: Performance Data at Standard Embedment DepthDocument1 pageSpecification Data: Performance Data at Standard Embedment DepthatiattiNo ratings yet

- Design of Steel Beam in Torsion PDFDocument148 pagesDesign of Steel Beam in Torsion PDFdaeealiNo ratings yet

- 04 Acciaio Connection DesignDocument62 pages04 Acciaio Connection DesignSultano78No ratings yet

- Halfen Detan BrochureDocument12 pagesHalfen Detan BrochureatiattiNo ratings yet

- Terrace Railing HeightsDocument2 pagesTerrace Railing HeightsatiattiNo ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- Roof Systems: Eaves BeamsDocument75 pagesRoof Systems: Eaves BeamsatiattiNo ratings yet

- Complete Rawl Product CatalogueDocument154 pagesComplete Rawl Product CatalogueatiattiNo ratings yet

- G1398 STA 01 RevA All en Build Station Lane WindPostDocument5 pagesG1398 STA 01 RevA All en Build Station Lane WindPostatiattiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Trebilcock Farmhouse, Roche, CornwallDocument4 pagesTrebilcock Farmhouse, Roche, CornwallFuzzy_Wood_PersonNo ratings yet

- 11 - TopXI - Infra - Transport Planning PDFDocument60 pages11 - TopXI - Infra - Transport Planning PDFLEONARD S. ALCALANo ratings yet

- Aptitude Questions: Icici PapersDocument46 pagesAptitude Questions: Icici PapersRavi Kr YadavNo ratings yet

- Basehor Public Input Review (12!20!2021)Document92 pagesBasehor Public Input Review (12!20!2021)confluencescribdNo ratings yet

- Cable Bridge PDFDocument9 pagesCable Bridge PDFJam PelNo ratings yet

- Challenges Faced by Indian RailwaysDocument1 pageChallenges Faced by Indian Railways001iammohitsharmaNo ratings yet

- Times Leader 05-14-2012Document24 pagesTimes Leader 05-14-2012The Times LeaderNo ratings yet

- تصميم كونكريت الطرق PDFDocument50 pagesتصميم كونكريت الطرق PDFSamer al sadikNo ratings yet

- Cirrus FomDocument222 pagesCirrus FomPreston BakicNo ratings yet

- IE416 problem sets flow networks shortest paths budgets crashesDocument6 pagesIE416 problem sets flow networks shortest paths budgets crashesMA FNo ratings yet

- Cycleroutes DKDocument33 pagesCycleroutes DKlucaswxyzNo ratings yet

- ENR 1.2 Visual Flight Rules: 1 CivilDocument4 pagesENR 1.2 Visual Flight Rules: 1 CivilNaguibNo ratings yet

- Truck Drivers GuidebookDocument39 pagesTruck Drivers GuidebookCrisstiMNo ratings yet

- Air Traffic Control Important DefinitionsDocument4 pagesAir Traffic Control Important DefinitionsNithya MohanNo ratings yet

- Oakland Green Bike Lane StandardsDocument5 pagesOakland Green Bike Lane StandardsRobertPrinzNo ratings yet

- Average Daily TrafficDocument5 pagesAverage Daily TrafficHoney Lhien LucidoNo ratings yet

- 010 090eng - v3Document245 pages010 090eng - v3ayushNo ratings yet

- TRH26Document89 pagesTRH26nephembaniNo ratings yet

- Final PresentationDocument58 pagesFinal Presentationagey agoy-agoyNo ratings yet

- UNIT-2 Traffic EnggDocument56 pagesUNIT-2 Traffic EnggGundrathi Narendra GoudNo ratings yet

- Structural Supports For Highway Signs, Luminaires and Traffic SignalsDocument492 pagesStructural Supports For Highway Signs, Luminaires and Traffic SignalsHeather Sullivan100% (1)

- HCM 2016 Vol 3 PDFDocument540 pagesHCM 2016 Vol 3 PDFAngie Suescún86% (7)

- ATPL Study and Reference Guide (PDF Library)Document41 pagesATPL Study and Reference Guide (PDF Library)Anonymous yekn8BdNo ratings yet

- No Transit in IrelandDocument6 pagesNo Transit in IrelandNadine El AshkarNo ratings yet

- Learn Escalator Safety BasicsDocument22 pagesLearn Escalator Safety BasicsHarshit TanwarNo ratings yet

- Overton Park Design GuidelinesDocument55 pagesOverton Park Design GuidelinesfcharafNo ratings yet

- Leaflet L410 NG en ViewDocument2 pagesLeaflet L410 NG en ViewAhmad Yani S Noor100% (1)

- Fast Construction Precast Concrete BridgesDocument27 pagesFast Construction Precast Concrete Bridgesrizky100% (1)

- Sedona Vortex Map: What Is A Vortex?Document2 pagesSedona Vortex Map: What Is A Vortex?Vak AmrtaNo ratings yet