Professional Documents

Culture Documents

IRC AA CLASS LOADING Load Combination

Uploaded by

chitransh2002Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IRC AA CLASS LOADING Load Combination

Uploaded by

chitransh2002Copyright:

Available Formats

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.

Santha Kumar

7.4 Loads and Load combinations

7.4.1 Loads on bridges

The following are the various loads to be considered for the purpose of

computing stresses, wherever they are applicable.

· Dead load

· Live load

· Impact load

· Longitudinal force

· Thermal force

· Wind load

· Seismic load

· Racking force

· Forces due to curvature.

· Forces on parapets

· Frictional resistance of expansion bearings

· Erection forces

Dead load – The dead load is the weight of the structure and any permanent

load fixed thereon. The dead load is initially assumed and checked after design is

completed.

Live load – Bridge design standards specify the design loads, which are

meant to reflect the worst loading that can be caused on the bridge by traffic,

permitted and expected to pass over it. In India, the Railway Board specifies the

standard design loadings for railway bridges in bridge rules. For the highway

bridges, the Indian Road Congress has specified standard design loadings in

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

IRC section II. The following few pages brief about the loadings to be considered.

For more details, the reader is referred to the particular standard.

Railway bridges: Railway bridges including combined rail and road bridges

are to be designed for railway standard loading given in bridge rules. The

standards of loading are given for:

· Broad gauge - Main line and branch line

· Metre gauge - Main line, branch line and Standard C

· Narrow gauge - H class, A class main line and B class branch line

The actual loads consist of axle load from engine and bogies. The actual

standard loads have been expressed in bridge rules as equivalent uniformly

distributed loads (EUDL) in tables to simplify the analysis. These equivalent UDL

values depend upon the span length. However, in case of rigid frame, cantilever

and suspension bridges, it is necessary for the designer to proceed from the

basic wheel loads. In order to have a uniform gauge throughout the country, it is

advantageous to design railway bridges to Broad gauge main line standard

loading. The EUDLs for bending moment and shear force for broad gauge main

line loading can be obtained by the following formulae, which have been obtained

from regression analysis:

For bending moment:

EUDL in kN = 317.97 + 70.83l + 0.0188l2 ≥ 449.2 kN (7.1)

For shear force:

EUDL in kN = 435.58 + 75.15l + 0.0002l2 ≥ 449.2 kN (7.2)

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Note that, l is the effective span for bending moment and the loaded

length for the maximum effect in the member under consideration for shear. 'l '

should be in metres. The formulae given here are not applicable for spans less

than or equal to 8 m with ballast cushion. For the other standard design loading

the reader can refer to Bridge rules.

Highway bridges: In India, highway bridges are designed in accordance with

IRC bridge code. IRC: 6 - 1966 – Section II gives the specifications for the

various loads and stresses to be considered in bridge design. There are three

types of standard loadings for which the bridges are designed namely, IRC class

AA loading, IRC class A loading and IRC class B loading.

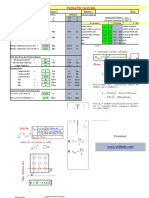

Fig.7.10 IRC AA loading

IRC class AA loading consists of either a tracked vehicle of 70 tonnes or a

wheeled vehicle of 40 tonnes with dimensions as shown in Fig. 7.10. The units in

the figure are mm for length and tonnes for load. Normally, bridges on national

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

highways and state highways are designed for these loadings. Bridges designed

for class AA should be checked for IRC class A loading also, since under certain

conditions, larger stresses may be obtained under class A loading. Sometimes

class 70 R loading given in the Appendix - I of IRC: 6 - 1966 - Section II can be

used for IRC class AA loading. Class 70R loading is not discussed further here.

Class A loading consists of a wheel load train composed of a driving

vehicle and two trailers of specified axle spacings. This loading is normally

adopted on all roads on which permanent bridges are constructed. Class B

loading is adopted for temporary structures and for bridges in specified areas.

For class A and class B loadings, reader is referred to IRC: 6 - 1966 – Section II.

Foot Bridges and Footpath on Bridges – The live load due to pedestrian

traffic should be treated as uniformly distributed over the pathway. For the design

of footbridges or footpaths on railway bridges, the live load including dynamic

effects should be taken as 5.0 kN/m2 of the footpath area. For the design of foot-

path on a road bridges or road-rail bridges, the live load including dynamic

effects may be taken as 4.25 kN/m2 except that, where crowd loading is likely,

this may be increased to 5.0 kN/m2.

The live load on footpath for the purpose of designing the main girders has

to be taken as follows according to bridge rules:

(i) For effective spans of 7.5 m or less - 4.25 kN/m2

(ii) The intensity of load is reduced linearly from 4.25 kN/m2 for a span of 7.5 m

to 3.0 kN/m2 for a span of 30m

(iii) For effective spans over 30 m, the UDL may be calculated as given below:

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

1 ⎛ 400 ⎞ ⎛ 17 − W ⎞

P= ⎜13.3 + ⎟⎜ ⎟ kN / m

2

(7.3)

100 ⎝ l ⎠ ⎝ 1.4 ⎠

Where, P = Live load in kN/m2

l = Effective span of the bridge in m.

W = Width of the foot path in m.

Where foot-paths are provided on a combined rail-road bridge, the load on

foot-path for purpose of designing the main girders should be taken as 2.0

kN/m2.

Impact load

Fig 7.11 Impact percentage curve for highway bridges for IRC class A and

IRC class B loadings

The dynamic effect caused due to vertical oscillation and periodical

shifting of the live load from one wheel to another when the locomotive is moving

is known as impact load. The impact load is determined as a product of impact

factor, I, and the live load. The impact factors are specified by different

authorities for different types of bridges. The impact factors for different bridges

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

for different types of moving loads are given in the table 7.1. Fig.7.11 shows

impact percentage curve for highway bridges for class AA loading. Note that, in

the above table l is loaded length in m and B is spacing of main girders in m.

Longitudinal forces – Longitudinal forces are set up between vehicles and

bridge deck when the former accelerate or brake. The magnitude of the force F,

is given by

W δV

F= (7.4)

g δt

Where, W – weight of the vehicle

g – acceleration due to gravity

δV – change in velocity in time d t

This loading is taken to act at a level 1.20 m above the road surface. No

increase in vertical force for dynamic effect should be made along with

longitudinal forces. The possibility of more than one vehicle braking at the same

time on a multi-lane bridge should also be considered.

Table 7.1: Impact factors for different bridges

BRIDGE LOADING IMPACT FACTOR (I)

Railway Broad gauge (a) Single track

bridgesaccording and Meter

to bridge rules gauge

(b) Main girder of double track

with two girders

(c) Intermediate main girder of

multiple track spans

(d) Outside main girders of Specified in (a) or (b)

multiple track spans whichever applies

(e) Cross girders carrying two

or more tracks

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Broad gauge

Rails with ordinary fish plate

joints and supported directly

on sleepers or transverse

steel troughing

Meter gauge

Narrow gauge

IRC class AA (i) Spans less than 9 m.

loading (a) Tracked vehicle 0.25 for spans up to 5

mand linearly reducing

to 0.10 to spans of 9m

(b) Wheeled vehicle 0.25

0.10

(ii) Spans 9 m or more

Highway bridges 0.25 for spans up to 23

(a) Tracked vehicle

according to IRC mand in accordance

regulations with the curve

(b) Wheeled vehicle

indicated inFig .11 for

spans in excess of 23

m

IRC class A

loading and IRC Spans between 3 m and45 m

class B loading In accordance with the

curve indicated inFig

.11 for all spans

No separate impact

Foot bridges

allowance is made

Thermal forces – The free expansion or contraction of a structure due to

changes in temperature may be restrained by its form of construction. Where any

portion of the structure is not free to expand or contract under the variation of

temperature, allowance should be made for the stresses resulting from this

condition. The coefficient of thermal expansion or contraction for steel is 11.7 x

10-6 / oC

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Wind load – Wind load on a bridge may act

· Horizontally, transverse to the direction of span

· Horizontally, along the direction of span

· Vertically upwards, causing uplift

· Wind load on vehicles

Wind load effect is not generally significant in short-span bridges; for

medium spans, the design of sub-structure is affected by wind loading; the super

structure design is affected by wind only in long spans. For the purpose of the

design, wind loadings are adopted from the maps and tables given in IS: 875

(Part III). A wind load of 2.40 kN/m2 is adopted for the unloaded span of the

railway, highway and footbridges. In case of structures with opening the effect of

drag around edges of members has to be considered.

Racking force – This is a lateral force produced due to the lateral movement

of rolling stocks in railway bridges. Lateral bracing of the loaded deck of railway

spans shall be designed to resist, in addition to the wind and centrifugal loads, a

lateral load due to racking force of 6.0 kN/m treated as moving load. This lateral

load need not be taken into account when calculating stresses in chords or

flanges of main girders.

Forces on parapets - Railings or parapets shall have a minimum height

above the adjacent roadway or footway surface of 1.0 m less one half the

horizontal width of the top rail or top of the parapet. They shall be designed to

resist a lateral horizontal force and a vertical force each of 1.50 kN/m applied

simultaneously at the top of the railing or parapet.

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Seismic load – If a bridge is situated in an earthquake prone region, the

earthquake or seismic forces are given due consideration in structural design.

Earthquakes cause vertical and horizontal forces in the structure that will be

proportional to the weight of the structure. Both horizontal and vertical

components have to be taken into account for design of bridge structures.

IS:1893 – 1984 may be referred to for the actual design loads.

Forces due to curvature - When a track or traffic lane on a bridge is curved

allowance for centrifugal action of the moving load should be made in designing

the members of the bridge. All the tracks and lanes on the structure being

considered are assumed as occupied by the moving load.

This force is given by the following formula:

W V2

C= (7.5)

12.7 R

Where, C - Centrifugal force in kN/m

W - Equivalent distributed live load in kN/m

V - Maximum speed in km/hour

R - Radius of curvature in m

Erection forces – There are different techniques that are used for

construction of railway bridges, such as launching, pushing, cantilever method,

lift and place. In composite construction the composite action is mobilised only

after concrete hardens and prior to that steel section has to carry dead and

construction live loads. Depending upon the technique adopted the stresses in

the members of the bridge structure would vary. Such erection stresses should

Indian Institute of Technology Madras

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

be accounted for in design. This may be critical, especially in the case of erection

technologies used in large span bridges.

7.4.2 Load combinations

Stresses for design should be calculated for the most sever combinations

of loads and forces. Four load combinations are generally considered important

for checking for adequacy of the bridge. These are given in Table 7.2 and are

also specified in IS 1915 - 1961.

Table 7.2: Load combinations

SNo Load combination Loads

Dead load, live load, impact load and

1 Stresses due to normal loads

centrifugal force

Normal load as in (1) + wind load, other lateral

Stresses due to normal loads +

2 loads, longitudinal forces and temperature

occasional loads

stresses

3 Stresses due to loads during erection -

Stresses due to normal loads +

Loads as in (2) + with seismic load instead of

4 occasional loads + Extra-ordinary loads

wind

like seismic excluding wind load

Indian Institute of Technology Madras

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- App5 EC2 DesignDocument70 pagesApp5 EC2 Designm_ganea268973No ratings yet

- Doubly Reinforced Beams: Chapter 4 (Continuation)Document4 pagesDoubly Reinforced Beams: Chapter 4 (Continuation)Yo FangirlsNo ratings yet

- Errata For ACI 318-14 1st PrintingDocument9 pagesErrata For ACI 318-14 1st PrintingKikoCanNo ratings yet

- ThesisDocument362 pagesThesisajayNo ratings yet

- Structural Engineering TalkDocument43 pagesStructural Engineering TalkVince Bagsit PolicarpioNo ratings yet

- Errata For ACI 318-14 2nd PrintingDocument4 pagesErrata For ACI 318-14 2nd PrintingKikoCanNo ratings yet

- Chapter 2 Outline: NSCP Strength and Serviceability RequirementsDocument7 pagesChapter 2 Outline: NSCP Strength and Serviceability RequirementsYo FangirlsNo ratings yet

- TP19 Adiaz PDFDocument11 pagesTP19 Adiaz PDFJefreyMatuanMondranoNo ratings yet

- M. Sc. Steel Structures: Lecture # 6Document61 pagesM. Sc. Steel Structures: Lecture # 6SSNo ratings yet

- Case Study Bridge Crosshead Cracking PDFDocument60 pagesCase Study Bridge Crosshead Cracking PDFKhay SaadNo ratings yet

- Ple-02 VSL Brian LimDocument22 pagesPle-02 VSL Brian LimAsep SummitNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument6 pagesPile Cap Design Calculations With CSI SAFEroshanNo ratings yet

- KK Bullet Constraints-Builder PDFDocument7 pagesKK Bullet Constraints-Builder PDFrigaschNo ratings yet

- OSD Span Fabrication Details With PicsDocument17 pagesOSD Span Fabrication Details With PicsIndra Nath MishraNo ratings yet

- TWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINALDocument6 pagesTWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINALHeru WibowoNo ratings yet

- Design Loads for Sub-StructuresDocument72 pagesDesign Loads for Sub-Structuresmayank007aggarwalNo ratings yet

- Thesis VMP PHD PDFDocument173 pagesThesis VMP PHD PDFWaqas AnjumNo ratings yet

- Time History Analysis For Performance Based DesignDocument8 pagesTime History Analysis For Performance Based DesignhuyxpkissNo ratings yet

- Finite Element Study of The Effect of Interfacial Gaps On The in 2017 StrucDocument12 pagesFinite Element Study of The Effect of Interfacial Gaps On The in 2017 StrucSedaNo ratings yet

- Tubular Truss OptimizationDocument124 pagesTubular Truss Optimizationarunkumar.mgsNo ratings yet

- NBT - Wind Load Effects On SkyscraperDocument66 pagesNBT - Wind Load Effects On SkyscraperSYED SOHAILNo ratings yet

- Modern Tall Building Cities – West vs East DifferencesDocument13 pagesModern Tall Building Cities – West vs East DifferencesAravind BhashyamNo ratings yet

- Dynamic Earth PressureDocument2 pagesDynamic Earth PressureMahadev D. BhandareNo ratings yet

- Errata For ACI 318-14 5th Printing PDFDocument1 pageErrata For ACI 318-14 5th Printing PDFKikoCanNo ratings yet

- Idspl B 2212 MNB 007+614DN 101Document36 pagesIdspl B 2212 MNB 007+614DN 101khushikaadi56No ratings yet

- Earthquake Collapse PatternDocument16 pagesEarthquake Collapse Patterngaurav jagtap0% (1)

- TP07 Castillo PDFDocument8 pagesTP07 Castillo PDFJefreyMatuanMondranoNo ratings yet

- New Seismic Design Provisions in JapanDocument19 pagesNew Seismic Design Provisions in JapanBrian Taylor100% (1)

- Long and Short Column Design BasisDocument2 pagesLong and Short Column Design BasisMUTHUKKUMARAMNo ratings yet

- Pa MRVC Truss S DN 4027Document134 pagesPa MRVC Truss S DN 4027AJAY SHINDENo ratings yet

- The State of Codes On Structural Engineering in India: Ashok K. JAINDocument7 pagesThe State of Codes On Structural Engineering in India: Ashok K. JAINSadatcharaMoorthi NNo ratings yet

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112Rupendra palNo ratings yet

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 pagesTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangNo ratings yet

- Possibility of using sea water in concreteDocument10 pagesPossibility of using sea water in concreteJefreyMatuanMondranoNo ratings yet

- Design of Retaining Wall: 1 Preliminary DataDocument3 pagesDesign of Retaining Wall: 1 Preliminary DataAjayvidyanand SharmaNo ratings yet

- Tp17-Padilla Crisolo PDFDocument13 pagesTp17-Padilla Crisolo PDFJefreyMatuanMondranoNo ratings yet

- Lecture 10 - Introduction To Earthquake Resistant Design of RC Structures (Part II) ColorDocument54 pagesLecture 10 - Introduction To Earthquake Resistant Design of RC Structures (Part II) Coloraizaz ahmadNo ratings yet

- Hollo BoltDocument1 pageHollo Boltmr_hazzardNo ratings yet

- Ductile Detailing of Beam As Per IS 13920Document4 pagesDuctile Detailing of Beam As Per IS 13920Civil FundaNo ratings yet

- TP02 Cornejo PDFDocument8 pagesTP02 Cornejo PDFJefreyMatuanMondranoNo ratings yet

- Seismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Document14 pagesSeismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Shantanu DateraoNo ratings yet

- Streamline Chicago Building PermitsDocument4 pagesStreamline Chicago Building Permitstaw1021966mNo ratings yet

- Numerical Analysis of Concrete Temperature Using Semi-Adiabatic Temperature MeasurementsDocument13 pagesNumerical Analysis of Concrete Temperature Using Semi-Adiabatic Temperature MeasurementsHarshana PrabhathNo ratings yet

- Design Basic ReportDocument6 pagesDesign Basic ReportManinder ChaudharyNo ratings yet

- Dynamic Analysis of RC Frame Under Blast LoadingDocument140 pagesDynamic Analysis of RC Frame Under Blast LoadingMahesh OzardeNo ratings yet

- DMRC DBR Chennai PDFDocument25 pagesDMRC DBR Chennai PDFTarun Kant Goyal100% (1)

- Handouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesDocument105 pagesHandouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesChaitu Rishan100% (1)

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKNo ratings yet

- Br. No.-312 ADocument99 pagesBr. No.-312 AShashibhushan SinghNo ratings yet

- Bridge 3exampleDocument84 pagesBridge 3exampletrabajosicNo ratings yet

- Concrete slab strengthening designDocument4 pagesConcrete slab strengthening designSherwin CairoNo ratings yet

- 70r Loading - PDFXHRXHRDocument14 pages70r Loading - PDFXHRXHRbalwant_negi7520No ratings yet

- Comparative Design of RCC and Prestressed Concrete FlyoverDocument3 pagesComparative Design of RCC and Prestressed Concrete FlyoverPriyanka BasuNo ratings yet

- Two Mark QuestionsDocument18 pagesTwo Mark QuestionsMailbroNo ratings yet

- Effectiveness of IRC Live Loads on RC Bridge PiersDocument4 pagesEffectiveness of IRC Live Loads on RC Bridge Piersdhaval2011No ratings yet

- Static and Dynamic Analysis of Tee Beam Bridge DeckDocument4 pagesStatic and Dynamic Analysis of Tee Beam Bridge DeckfarrukhNo ratings yet

- All Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingDocument6 pagesAll Rights Reserved © 2017 IJERMCE 412 Analysis and Design of R.C.C. T-Girder Bridge Under IRC Class AA and Class A LoadingSudarshan PatilNo ratings yet

- Analysis of T-Beam Bridge Using Finite Element MethodDocument7 pagesAnalysis of T-Beam Bridge Using Finite Element MethodRahil QureshiNo ratings yet

- DM-Intro 2019R1 WS2.1 SketchingDocument41 pagesDM-Intro 2019R1 WS2.1 SketchingAnonymous b9fkTYfEoRNo ratings yet

- Abutment Cap UlsDocument194 pagesAbutment Cap UlsAnonymous b9fkTYfEoRNo ratings yet

- Output TanggaDocument320 pagesOutput TanggaPanji KurniawanNo ratings yet

- Chapter 4: Design ConsiderationsDocument34 pagesChapter 4: Design ConsiderationsAnonymous b9fkTYfEoRNo ratings yet

- Technical Note - Review of Supports in E&M Niche V & VIDocument3 pagesTechnical Note - Review of Supports in E&M Niche V & VIAnonymous b9fkTYfEoRNo ratings yet

- Abutment Cap UlsDocument194 pagesAbutment Cap UlsAnonymous b9fkTYfEoRNo ratings yet

- Table: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly GlobalzDocument6 pagesTable: Joint Coordinates Joint Coordsys Coordtype Xorr Y Z Specialjt Globalx Globaly GlobalzAnonymous b9fkTYfEoRNo ratings yet

- Quotation of Package-3Document3 pagesQuotation of Package-3Anonymous b9fkTYfEoRNo ratings yet

- Quotation of Package-3Document3 pagesQuotation of Package-3Anonymous b9fkTYfEoRNo ratings yet

- Quotation of Package-3Document3 pagesQuotation of Package-3Anonymous b9fkTYfEoRNo ratings yet

- Quotation of Package-3Document3 pagesQuotation of Package-3Anonymous b9fkTYfEoRNo ratings yet

- Portal-Excavation Plan & SectionsDocument1 pagePortal-Excavation Plan & SectionsAnonymous b9fkTYfEoRNo ratings yet

- A G S LLP: Ligarh Eo ErvicesDocument1 pageA G S LLP: Ligarh Eo ErvicesAnonymous b9fkTYfEoRNo ratings yet

- Sumerpur Abutment ProtectionDocument5 pagesSumerpur Abutment ProtectionAnonymous b9fkTYfEoRNo ratings yet

- Curtain WallDocument1 pageCurtain WallAnonymous b9fkTYfEoRNo ratings yet

- Prathap. D Mohammed Rafi. DDocument9 pagesPrathap. D Mohammed Rafi. DVaibhav SawantNo ratings yet

- Letter For SumerpurDocument1 pageLetter For SumerpurAnonymous b9fkTYfEoRNo ratings yet

- SLS PierDocument188 pagesSLS PierAnonymous b9fkTYfEoRNo ratings yet

- Paper On Design Voded SlabDocument9 pagesPaper On Design Voded SlabAnonymous b9fkTYfEoRNo ratings yet

- Cement Block ManufacturingDocument5 pagesCement Block ManufacturingAnonymous b9fkTYfEoRNo ratings yet

- Khurda Bolangir: Tunnel Portal: M:N Interaction Chart For 1,000 X 3,000 Section, Grade 30 ConcreteDocument1 pageKhurda Bolangir: Tunnel Portal: M:N Interaction Chart For 1,000 X 3,000 Section, Grade 30 ConcreteAnonymous b9fkTYfEoRNo ratings yet

- Top Non-Conventional Energy SourcesDocument15 pagesTop Non-Conventional Energy SourcesAnonymous b9fkTYfEoRNo ratings yet

- SVR - (436+720 To 436+870) - 08-09 Mar22 - 31.03.22Document8 pagesSVR - (436+720 To 436+870) - 08-09 Mar22 - 31.03.22Anonymous b9fkTYfEoRNo ratings yet

- How Transverse Prestressing Increases Concrete Bridge CapacityDocument85 pagesHow Transverse Prestressing Increases Concrete Bridge CapacityAnonymous b9fkTYfEoRNo ratings yet

- Product and Availability Guide: Low Relaxation (LR) StrandDocument7 pagesProduct and Availability Guide: Low Relaxation (LR) StrandAnonymous b9fkTYfEoRNo ratings yet

- Quotation For Tunnel DPRDocument1 pageQuotation For Tunnel DPRAnonymous b9fkTYfEoRNo ratings yet

- Analysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011Document6 pagesAnalysis and Design of Prestressed Deck Slab Bridge With IRC 112-2011Anonymous b9fkTYfEoRNo ratings yet

- BOM of EPC UttarakhandDocument8 pagesBOM of EPC UttarakhandAnonymous b9fkTYfEoRNo ratings yet

- Applsci 10 08221 v2Document19 pagesApplsci 10 08221 v2Anonymous b9fkTYfEoRNo ratings yet

- Bill of Material for Single HookDocument5 pagesBill of Material for Single HookAnonymous b9fkTYfEoRNo ratings yet