Professional Documents

Culture Documents

Biodiesel Distillation Temperature, Cetane Number, and Viscosity vs. Fatty Acid Profile

Uploaded by

sharmashnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Distillation Temperature, Cetane Number, and Viscosity vs. Fatty Acid Profile

Uploaded by

sharmashnCopyright:

Available Formats

The Biodiesel Education Program at the University of Idaho is sponsored in part by the USDA

Synopsis:

Finished biodiesel intended for retail must meet

certain quality criteria. These are specified under

the American Society for Testing and Materials

ASTM D 6751, the technical standard for biodiesel.

Several quality tests are required under ASTM

D 6751 (version 12 as of this printing) to ensure

that biodiesel used at 100% strength, or blended

with petroleum-based diesel, remains a consistent,

high quality alternative fuel and can run in unmodified diesel engines without problems.

Biodiesel Distillation

Temperature, Cetane Number,

and Viscosity

vs. Fatty Acid Profile

As biodiesel becomes a more widely used fuel, supplies of

feedstock oils and fats are becoming harder to find. Oils that

might not have been considered for use as fuels are getting

serious attention. Some of these oils contain fatty acid profiles

that are different from the common oils like soybean oil or

canola oil. Oils such as mustard oil, industrial rapeseed oil,

and camelina contain fatty acids with chain lengths that are

longer than those found in other oils. Common oils have

fatty acid chain lengths that are usually 16 to 18 carbons

long. These other oils contain substantial amounts of fatty

acids with 20, 22 or even 24 carbons. These longer chains

can have a dramatic effect on biodiesel properties although

we have no indication they do not produce high quality fuels.

However, because they were not envisioned as biodiesel

feedstocks when the specifications were developed, they may

not comply with some of the requirements of the ASTM D

6751 specification for biodiesel (or the European specification

EN14214). The specifications of greatest concern with longer

chain fatty acids are the T-90 temperature, the cetane number,

and the viscosity. Some of these oils, such as camelina, also

have high levels of polyunsaturates which can lower the

cetane number, a key indicator of diesel fuel quality.

Distillation Temperature (ASTM D 1160)

The biodiesel specification for the vacuum distillation

procedure is described in ASTM D 1160. The biodiesel

specification, ASTM D 6751, specifies 360C as the maximum T-90 temperature; the temperature at which 90% of a

www.biodieseleducation.org

In this Biodiesel TechNote, we discuss three

particular ASTM quality standards: the distillation

temperature of biodiesel, its cetane number, and

its measurement of viscosity. Our testing demonstrates that certain feedstocks with long chain

fatty acids are destined to fail these standards,

regardless of steps taken by the producer.

200 ml sample has been distilled. This test was developed to

determine the distillation characteristics of petroleum products

and was chosen by ASTM to be included in the biodiesel

specification. A sample is distilled under vacuum and the

temperature at which each 10% increment has been distilled

is noted until 90% of the sample is boiled off and condensed

(see Table 1). Thus, a distillation curve or boiling range is

produced. This boiling range is directly related to viscosity,

vapor pressure, heating value, average molecular weight, as

well as other chemical, physical, and mechanical properties.

Vacuum

distillation

apparatus

Viscosity (ASTM D 445)

Kinematic viscosity is measured at 40C using the procedure

described in ASTM D 445. The ASTM biodiesel specification

sets an acceptable range of between 1.9 and 6.0 mm2/sec for

the viscosity. EN14214 stipulates an upper limit for the viscosity of 5.0 mm2/sec. Like the T-90 temperature, this property is

Biodiesel TechNotes are published by the Department of Biological and Agricultural Engineering at the University of Idaho

www.BiodieselEducation.org biodiesel@uidaho.edu 208-885-7626

Discussion

directly related to the fatty acid profile of the oil or fat used to

make the biodiesel and can also be influenced by the alcohol

used.

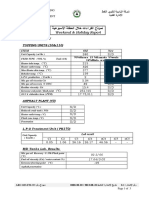

Table 1 shows the measured values of cetane number, T-90

temperature, and viscosity for the 13 fuels. It can be seen

from these tables that fuels made with feedstocks containing

a high percentage of long chain fatty acids may not meet the

specification for T-90 temperature and viscosity. For example,

rapeseed, mustard, and camelina methyl esters have T-90

temperatures above 360C. All of the methyl esters met the

6.0 mm2/sec viscosity requirement of ASTM D 6751, but

rapeseed and mustard methyl esters do not meet the lower

viscosity requirement of 5.0 mm2/sec in the European specification EN14214. It can be seen that biodiesel made with

ethanol (it being a heavier molecule than methanol) is consistently more viscous and has a higher T-90 temperature than the

methyl esters. All of the ethyl esters tested did not meet the

T-90 specification, and rapeseed ethyl ester had a viscosity that

exceeded the limit of 6.0 mm2/sec. All of the fuels tested met

the ASTM specification of 47 for the cetane number, although

camelina methyl ester at 48.9 was within the test-to-test

variability of the method. Three of the fuels failed the higher

standard of 51 in EN14214.

Cetane Number (ASTM D 613)

Cetane Number is measured using ASTM D 613. The ASTM

specification D 6751 requires a minimum of 47 and EN14214

requires a minimum of 51. Both of these specifications set

much higher limits than the minimum level of 40 required for

No. 2 diesel fuel in ASTM D 975.

Results

Thirteen samples were tested for cetane number, distillation

temperature, viscosity, and fatty acid profile (see Tables 1 and

2). Notice that five of the various oils were made into fuel using both methanol and ethanol.

Table 1. Cetane Number, T-90, & Viscosity of Biodiesel

Cetane

T-90

Viscosity

mm2/s

Sample

Rapeseed Methyl Esters

60.1

399

5.60

Rapeseed Ethyl Esters

61.0

419

6.13

Mustard Methyl Esters - PG

49.8

392

5.04

Mustard Ethyl Esters - IG

58.1

403

5.70

Canola Methyl Esters - Distilled

50.1

351

4.79

Canola Methyl Esters - RBD

56.2

359

4.57

Canola Ethyl Esters - RBD

59.8

364

4.80

Soy Methyl Esters - RBD

51.8

355

4.18

Soy Ethyl Esters - RBD

51.5

361

4.44

Camelina Methyl Esters

48.9

368

4.34

Camelina Ethyl Esters

52.8

379

5.02

Palm Methyl Esters

63.0

348

4.24

Coconut Methyl Esters

63.7

337

2.81

So what can be done to rectify the situation? Short of lobbying

all stakeholders, including ASTM, to change the standards;

blending with lower molecular weight oils or fats may be the

easiest way to overcome this obstacle.

Contributor to

this TechNote:

Dr. Joe

Thompson,

biodiesel

production

specialist at

the University

of Idaho

Biological and

Agricultural

Engineering

Department.

Notes:

PG-Pacific Gold and IG-Ida Gold are mustard varieties developed

at the University of Idaho.

RBD-Refined, bleached, deodorized.

Table 2. Fatty Acid Profile

FATTY ACID

16:0

18:0

18:1

18:2

18:3

20:1

22:1

24:0

Rapeseed

Mustard - PG

Mustard - IG

Canola

Soy

2.7

2.8

2.8

4.0

10.2

1.0

1.4

1.1

1.9

4.2

14.2

17.5

27.8

61.9

21.7

11.7

20.5

10.45

19.3

53.1

7.3

12.8

9.15

9.3

7.0

7.3

12.0

9.6

1.2

48.4

24.9

32.75

1.2

1.8

Camelina

Palm

Coconut*

6.1

41.1

10.9

2.9

5.3

3.2

18.2

40.3

7.8

24.8

10.8

1.4

24.3

12.8

2.6

*Coconut oil contains over 70% fatty acid chain lengths from 8 to 14 carbons, including

6.7% of 8:0, 5.4% of 10:0, 44.8% of 12:0 and 19.1% of 14:0.

SUMMER ISSUE: July, 2013

You might also like

- DDC SVC Man 0189 - 2018Document194 pagesDDC SVC Man 0189 - 2018RuthAnayaNo ratings yet

- Canola Oil Physical Chemical Properties 1Document6 pagesCanola Oil Physical Chemical Properties 1elpancaseroNo ratings yet

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Document122 pagesDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesNo ratings yet

- Course O-3001Document42 pagesCourse O-3001Saurabh ShineNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Manual Perkins 2800 SeriesDocument122 pagesManual Perkins 2800 SeriesAnonymous tXzjQAJttH100% (1)

- IOCL Haldia Refinery Summer Training ReportDocument47 pagesIOCL Haldia Refinery Summer Training ReportAmit Datta70% (10)

- Material Science Phase Diagrams MCQsDocument3 pagesMaterial Science Phase Diagrams MCQsPrince AbhishekNo ratings yet

- Heat Pump CycleDocument25 pagesHeat Pump CycleDario Rajmanovich100% (1)

- MB C Klasse Maintenance BookletDocument116 pagesMB C Klasse Maintenance BookletAlex BereanuNo ratings yet

- Biodiesel Methyl EsterDocument10 pagesBiodiesel Methyl EsterCiobanu MihaiNo ratings yet

- Fuel Field ManualDocument26 pagesFuel Field ManualFREDIELABRADORNo ratings yet

- Biodiesel ProductionDocument8 pagesBiodiesel ProductionHosam Hasan Abd ElhadyNo ratings yet

- Biodiesel Processing and Production: Jon Van GerpenDocument12 pagesBiodiesel Processing and Production: Jon Van GerpenNataly FajardoNo ratings yet

- Diesel fuel chemistry and properties explained in detailDocument58 pagesDiesel fuel chemistry and properties explained in detailPradeep MunnaNo ratings yet

- Laboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryDocument36 pagesLaboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryArpit Kumar Jain100% (1)

- Distillation Characteristics of Petroleum DieselDocument30 pagesDistillation Characteristics of Petroleum DieselT Richie100% (2)

- Lab BiodieselDocument7 pagesLab Biodieselskb89No ratings yet

- Marine FuelDocument17 pagesMarine FuelviviwulanNo ratings yet

- Doosan DX140LC-3 Excavator Parts ManualDocument778 pagesDoosan DX140LC-3 Excavator Parts ManualDjalmaNo ratings yet

- Distillation and Vapor Pressure Test of Gasoline Fuel 1Document19 pagesDistillation and Vapor Pressure Test of Gasoline Fuel 1Krishna Belela100% (1)

- Instruction ManualDocument575 pagesInstruction ManualАлександр Тихомиров67% (6)

- CavitationDocument39 pagesCavitationzfrl100% (1)

- Dissolved Gas Analysis of Overheating FaultDocument4 pagesDissolved Gas Analysis of Overheating FaultTedy MTNo ratings yet

- Nuffield HazID GuidewordsDocument24 pagesNuffield HazID Guidewordsuserscribd2011100% (1)

- Effect of Incompletely Converted Soybean Oil On Biodiesel QualityDocument8 pagesEffect of Incompletely Converted Soybean Oil On Biodiesel QualityCharles CivinelliNo ratings yet

- Metdo Astm d6584 Esplicado X AgilentDocument8 pagesMetdo Astm d6584 Esplicado X Agilentleidy29ospinaNo ratings yet

- Biofuels Properties InvestigationDocument6 pagesBiofuels Properties InvestigationJohn MaguireNo ratings yet

- Energy Conversion and Management: Mohamed Y.E. SelimDocument8 pagesEnergy Conversion and Management: Mohamed Y.E. SelimNikhil NambiarNo ratings yet

- 5 Test SpecificationsDocument6 pages5 Test SpecificationsMarie CloudNo ratings yet

- Biodiesel Fuel (B100) Blend Stock (B100) For Middle Distillate FuelsDocument7 pagesBiodiesel Fuel (B100) Blend Stock (B100) For Middle Distillate FuelsNguyễn Bằng NộiNo ratings yet

- 5.1 Properties of Tested Fuels: S.No Properties Jatroph A Coconu T Palm Sterculia Foetida OilDocument14 pages5.1 Properties of Tested Fuels: S.No Properties Jatroph A Coconu T Palm Sterculia Foetida OilAbdurohmanNo ratings yet

- 1 s2.0 S0016236110005855 MainDocument3 pages1 s2.0 S0016236110005855 MainMohamed ElshabrawyNo ratings yet

- D6448Document5 pagesD6448rimi7alNo ratings yet

- Use Ofvegetable Oils As I.C. Engine Fuels-A ReviewDocument16 pagesUse Ofvegetable Oils As I.C. Engine Fuels-A ReviewMohit KulkarniNo ratings yet

- Top Tier Diesel Fuel Performance Standard: Revision A - February 2017Document7 pagesTop Tier Diesel Fuel Performance Standard: Revision A - February 2017RabatangNo ratings yet

- Process Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineDocument3 pagesProcess Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineSivakumarNo ratings yet

- D4806Document4 pagesD4806rimi7alNo ratings yet

- Natural Gas Engines LubricationDocument9 pagesNatural Gas Engines Lubricationjameel babooramNo ratings yet

- Advantage of Real Atmospheric Distillation Astm d7345Document10 pagesAdvantage of Real Atmospheric Distillation Astm d7345Yair LopezNo ratings yet

- Ab 02417411746Document6 pagesAb 02417411746IJMERNo ratings yet

- Foods: Changes in Physical and Chemical Properties of Thermally and Oxidatively Degraded Sunflower Oil and Palm FatDocument14 pagesFoods: Changes in Physical and Chemical Properties of Thermally and Oxidatively Degraded Sunflower Oil and Palm FatMehdi KhfifiNo ratings yet

- Application of Hydraulic and Gear Oils in The Food Processing IndustryDocument8 pagesApplication of Hydraulic and Gear Oils in The Food Processing IndustrymitarjocNo ratings yet

- Alternative Fuel Properties of Tall Oil Fatty Acid Methyl Ester-Diesel Fuel BlendsDocument6 pagesAlternative Fuel Properties of Tall Oil Fatty Acid Methyl Ester-Diesel Fuel BlendsericconchamunozNo ratings yet

- Standard Specification July 9 2015Document10 pagesStandard Specification July 9 2015Ade Nur FauzanNo ratings yet

- Preparation and Research On Properties of Castor Oil As A Diesel Fuel AdditiveDocument8 pagesPreparation and Research On Properties of Castor Oil As A Diesel Fuel Additivezin berNo ratings yet

- Fatty Acid Methyl Esters Characteristic and Esterification of Some Vegetable Oils For P Roduction of BiodieselDocument4 pagesFatty Acid Methyl Esters Characteristic and Esterification of Some Vegetable Oils For P Roduction of BiodieselresearchinventyNo ratings yet

- Fuel Specs For 4000 SereisDocument3 pagesFuel Specs For 4000 SereismohamedNo ratings yet

- The Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilDocument17 pagesThe Performance and Emissions of A Diesel Engine Fueled With Biodiesel From Yellow Grease and Soybean OilSmith SteinNo ratings yet

- Ijert Ijert: "Characterization of Biodiesel: A Review"Document6 pagesIjert Ijert: "Characterization of Biodiesel: A Review"Siraj SayyedNo ratings yet

- Transesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.Document7 pagesTransesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.hanifahNo ratings yet

- CURRENT PROBLEMS. Alternative Fuels: Use of Baru Oil (Dipteryx Alata Vog.) TO PRODUCDocument4 pagesCURRENT PROBLEMS. Alternative Fuels: Use of Baru Oil (Dipteryx Alata Vog.) TO PRODUCAntonio Carlos Flash BatistaNo ratings yet

- Palm oil as a renewable fuel sourceDocument17 pagesPalm oil as a renewable fuel sourceanantNo ratings yet

- 29 Kapilan Natesh 1-3 (278-282)Document5 pages29 Kapilan Natesh 1-3 (278-282)Fitriani Indah LestariNo ratings yet

- Quenching and Heat Transfer Properties of Aged and Unaged Vegetable OilsDocument7 pagesQuenching and Heat Transfer Properties of Aged and Unaged Vegetable OilsSEP-PublisherNo ratings yet

- Biodiesel Density ModelsDocument8 pagesBiodiesel Density ModelsSofaiiSitthisukNo ratings yet

- Production of Biodiesel From Jatropha Oil (Jatropha Curcas) in Pilot PlantDocument8 pagesProduction of Biodiesel From Jatropha Oil (Jatropha Curcas) in Pilot PlantDebasishNo ratings yet

- EN 14103 ADJUSTMENTSDocument8 pagesEN 14103 ADJUSTMENTSJORGE SANTANDERNo ratings yet

- Rapeseed Oil and Methyl Ester of Rapeseed Oil As Alternative Fuels For Diesel EnginesDocument10 pagesRapeseed Oil and Methyl Ester of Rapeseed Oil As Alternative Fuels For Diesel Enginesdimon5000No ratings yet

- HP-5MS Column AnalysisDocument3 pagesHP-5MS Column Analysischoksi himanshuNo ratings yet

- Unit 4 Biodiesel: Sources of Bio DieselDocument6 pagesUnit 4 Biodiesel: Sources of Bio DieselMalli ReddyNo ratings yet

- Bio-Diesel Production Using Heterogeneous Catalyst: XIII Refinery Technology Meet (RTM)Document21 pagesBio-Diesel Production Using Heterogeneous Catalyst: XIII Refinery Technology Meet (RTM)akgupta1946No ratings yet

- CoProcessing of HEFA Feedstocks With Petroleum Hydrocarbons For Jet Production June192015Document26 pagesCoProcessing of HEFA Feedstocks With Petroleum Hydrocarbons For Jet Production June192015OumorsyNo ratings yet

- Fuel Properties of Biodiesels Produced From Blends of Canola Oil and Animal TallowDocument10 pagesFuel Properties of Biodiesels Produced From Blends of Canola Oil and Animal TallowdckristantoNo ratings yet

- Renewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuDocument7 pagesRenewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuLacramioara Iuliana VladulescuNo ratings yet

- 2 131 Acpi 2 (1) 2012 PDocument7 pages2 131 Acpi 2 (1) 2012 PBreKB MéndezNo ratings yet

- Renewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixDocument7 pagesRenewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixIka SulistyaningtiyasNo ratings yet

- Biodiesel 7666 LS5ej57Document15 pagesBiodiesel 7666 LS5ej57venky venkatNo ratings yet

- Biodiesel: A Seminar Report OnDocument15 pagesBiodiesel: A Seminar Report OnmujeebNo ratings yet

- BiodieselFuelQuality NelsonDocument43 pagesBiodieselFuelQuality NelsonManisha JourwalNo ratings yet

- Z. Franco, Q.D. Nguyen: SciencedirectDocument6 pagesZ. Franco, Q.D. Nguyen: Sciencedirectscorpion2001glaNo ratings yet

- Lec 24Document7 pagesLec 24مروان ابراهيم حمد عبدNo ratings yet

- Biodiesel Production From Jatropha CurcaDocument7 pagesBiodiesel Production From Jatropha CurcaManharsinh DodiyaNo ratings yet

- Hydro and Nuclear Power PlantDocument40 pagesHydro and Nuclear Power PlantsharmashnNo ratings yet

- What Are Heat Exchangers For?Document33 pagesWhat Are Heat Exchangers For?captainhassNo ratings yet

- Power Plant Economics and TarrifsDocument36 pagesPower Plant Economics and TarrifssharmashnNo ratings yet

- Belachew Renewable JourDocument25 pagesBelachew Renewable JoursharmashnNo ratings yet

- Unified Mechanical Engineering Lab-2Document38 pagesUnified Mechanical Engineering Lab-2sharmashnNo ratings yet

- Biodiesel Fuel at UconnDocument22 pagesBiodiesel Fuel at UconnsharmashnNo ratings yet

- CarburetorsDocument10 pagesCarburetorssharmashnNo ratings yet

- Risk Management Strategies For Beginning and Small Farmers and Ranchers ConferenceDocument37 pagesRisk Management Strategies For Beginning and Small Farmers and Ranchers ConferencesharmashnNo ratings yet

- T13 Introduction To Gear TrainsDocument17 pagesT13 Introduction To Gear TrainsAli El-GazzarNo ratings yet

- Test 1Document2 pagesTest 1sharmashnNo ratings yet

- MosfetDocument12 pagesMosfetsharmashnNo ratings yet

- EdmDocument5 pagesEdmsharmashnNo ratings yet

- Basic hydraulic and pneumatic circuit design conceptsDocument20 pagesBasic hydraulic and pneumatic circuit design conceptssharmashnNo ratings yet

- Static Force AnalysisDocument26 pagesStatic Force AnalysissharmashnNo ratings yet

- Assignment 2Document1 pageAssignment 2sharmashnNo ratings yet

- Assignement 1Document1 pageAssignement 1sharmashnNo ratings yet

- Hydraulic CircuitDocument17 pagesHydraulic CircuitPrashanth PrakashNo ratings yet

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Brakes and DynamometersDocument16 pagesBrakes and DynamometerssharmashnNo ratings yet

- LMMEC355PDocument15 pagesLMMEC355PsharmashnNo ratings yet

- Test 1Document1 pageTest 1sharmashnNo ratings yet

- Injection SystemDocument19 pagesInjection SystemsharmashnNo ratings yet

- Gas Turbine Power PlantDocument18 pagesGas Turbine Power Plantsharmashn100% (1)

- Sari 2019 J. Phys. Conf. Ser. 1364 012003Document8 pagesSari 2019 J. Phys. Conf. Ser. 1364 012003istiqamahNo ratings yet

- PosterDocument1 pagePosterHassan AnwerNo ratings yet

- How Fuel Integrity Programs Can Help Developing Asian EconomiesDocument25 pagesHow Fuel Integrity Programs Can Help Developing Asian EconomiesAsian Development Bank - TransportNo ratings yet

- Chemistry Safety Lab 1Document3 pagesChemistry Safety Lab 1Toni MasilNo ratings yet

- Application of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesDocument5 pagesApplication of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesdislocationNo ratings yet

- Locomotive Fleet Bangladesh Railway RollingstockDocument14 pagesLocomotive Fleet Bangladesh Railway RollingstockAbm Faruk E MonjurNo ratings yet

- CHEMCON 2023 Book of AbstractsDocument441 pagesCHEMCON 2023 Book of AbstractsSayan ChatterjeeNo ratings yet

- 027 Environmental Impact and Control MeasuresDocument26 pages027 Environmental Impact and Control MeasuresnsearunNo ratings yet

- TLT Techbeat 9 06Document9 pagesTLT Techbeat 9 06alexsv_17No ratings yet

- Refinery Configurations - Designs For Heavy Oil - Hydrocarbon Processing - October 2011Document12 pagesRefinery Configurations - Designs For Heavy Oil - Hydrocarbon Processing - October 2011SumitAggarwalNo ratings yet

- Synthetic 10W-30 SAE 30 Heavy Duty Diesel OilDocument2 pagesSynthetic 10W-30 SAE 30 Heavy Duty Diesel Oilbrian5786No ratings yet

- Azzawiya Oil Refining Weekend ReportDocument3 pagesAzzawiya Oil Refining Weekend ReportrawadNo ratings yet

- D.C. Boffito, C. Pirola, F. Galli, A. Di Michele, C.L. BianchiDocument8 pagesD.C. Boffito, C. Pirola, F. Galli, A. Di Michele, C.L. BianchiArif HidayatNo ratings yet

- Environmental Pollution ControlDocument125 pagesEnvironmental Pollution ControlMDR PRAPHU100% (1)

- Coal and PetroleumDocument9 pagesCoal and PetroleumnamanlohadeNo ratings yet

- Study Guide Introduction To ft4 Part3Document11 pagesStudy Guide Introduction To ft4 Part3Sergio TrucksNo ratings yet

- An Optical Investigation of Fischer-Tropsch Diesel and Oxymethylene Dimethyl Ether Impact On Combustion Process For CI EnginesDocument12 pagesAn Optical Investigation of Fischer-Tropsch Diesel and Oxymethylene Dimethyl Ether Impact On Combustion Process For CI EnginesMarcelo TavaresNo ratings yet

- Thermal Power PlantsDocument16 pagesThermal Power PlantsakshayNo ratings yet

- Working Paper - 2015 Sulphur Impact - 5.14. 13Document30 pagesWorking Paper - 2015 Sulphur Impact - 5.14. 13Naresh SharmaNo ratings yet

- BP Tank Cleaning GuideDocument1 pageBP Tank Cleaning Guidesergey328No ratings yet

- Turbocharged Engines PDFDocument72 pagesTurbocharged Engines PDFVeler VelericNo ratings yet

- Australian Petroleum Statistics: Issue 258, January 2018Document40 pagesAustralian Petroleum Statistics: Issue 258, January 2018Alia ShabbirNo ratings yet