Professional Documents

Culture Documents

XZ 11

Uploaded by

harde2lahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XZ 11

Uploaded by

harde2lahCopyright:

Available Formats

PEH:Immiscible Gas Injection in Oil Reservoirs

Publication Information

Vol5REPCover.png

Petroleum Engineering Handbook

Larry W. Lake, Editor-in-Chief

Volume V

Reservoir Engineering and Petrophysics

Edward D. Holstein, Editor

Copyright 2007, Society of Petroleum Engineers

Chapter 12

Immiscible Gas Injection in Oil Reservoirs

H.R. (Hal) Warner Jr., Warner Consulting Services and E.D. Holstein, Consultant

Pgs. 1103-1147

ISBN 978-1-55563-120-8

Get permission for reuse

This chapter concerns gas injection into oil reservoirs to increase oil recovery

by immiscible displacement. The use of gas, either of a designed composition or

at high-enough pressure, to result in the miscible displacement of oil is not d

iscussed here; for a discussion of that topic, see the chapter on miscible flood

ing in this section of the Handbook. A variety of gases can and have been used f

or immiscible gas displacement, with lean hydrocarbon gas used for most applicat

ions to date. Historically, immiscible gas injection was first used for reservoi

r pressure maintenance. The first such projects were initiated in the 1930s and

used lean hydrocarbon gas (e.g., Oklahoma City field and Cunningham pool in the

United States[1] and Bahrain field in Bahrain[2][3]). Over the decades, a consid

erable number of immiscible gas injection projects have been undertaken, some wi

th excellent results and others with poor performance. Reasons for this range of

performance are discussed in this chapter. At the end of this chapter, a variet

y of case studies are presented that briefly describe several of the successful

immiscible gas injection projects.

Gas injection projects are undertaken when and where there is a readily availabl

e supply of gas. This gas supply typically comes from produced solution gas or g

as-cap gas, gas produced from a deeper gas-filled reservoir, or gas from a relat

ively close gas field. Such projects take a variety of forms, including the foll

owing:

Reinjection of produced gas into existing gas caps overlying producing oil c

olumns.

Injection into oil reservoirs of separated produced gas for pressure mainten

ance, for gas storage, or as required by government regulations.

Gas injection to prevent migration of oil into a gas cap because of a natura

l waterdrive, downdip water injection, or both.

Gas injection to increase recoveries from reservoirs containing volatile, hi

gh-shrinkage oils and into gas-cap reservoirs containing retrograde gas condensa

te.

Gas injection into very undersaturated oil reservoirs for the purpose of swe

lling the oil and hence increasing oil recovery.

The primary physical mechanisms that occur as a result of gas injection are (1)

partial or complete maintenance of reservoir pressure, (2) displacement of oil b

y gas both horizontally and vertically, (3) vaporization of the liquid hydrocarb

on components from the oil column and possibly from the gas cap if retrograde co

ndensation has occurred or if the original gas cap contains a relict oil saturat

ion, and (4) swelling of the oil if the oil at original reservoir conditions was

very undersaturated with gas. Gas injection is particularly effective in high-r

elief reservoirs where the process is called "gravity drainage" because the vert

ical/gravity aspects increase the efficiency of the process and enhance recovery

of updip oil residing above the uppermost oil-zone perforations.

The decision to apply immiscible gas injection is based on a combination of tech

nical and economic factors. Deferral of gas sales is a significant economic dete

rrent for many potential gas injection projects if an outlet for immediate gas s

ales is available. Nevertheless, a variety of opportunities still exist. First a

re those reservoirs with characteristics and conditions particularly conducive t

o gas/oil gravity drainage and where attendant high oil recover

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Confi-Gel XHT Product Data SheetDocument1 pageConfi-Gel XHT Product Data SheetpaimanNo ratings yet

- Alpha Amylase Production PDFDocument31 pagesAlpha Amylase Production PDFGaurav BangarhNo ratings yet

- Primary ClarifierDocument26 pagesPrimary ClarifierDavid Charles Meissner100% (3)

- Reception Class Easter Holiday Homework Pack 2023Document12 pagesReception Class Easter Holiday Homework Pack 2023harde2lahNo ratings yet

- New Hope Agric and Tech Nig LTD - 20227283131579Document1 pageNew Hope Agric and Tech Nig LTD - 20227283131579harde2lahNo ratings yet

- Name: - DateDocument8 pagesName: - Dateharde2lahNo ratings yet

- (Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast AsipaDocument1 page(Poultry Diseases Diagnosis and Aquaculture Lab) Ogere-Remo, Ogun State The M.D Nutridel Farms, Ogdl/0322/052/Ast Asipaharde2lahNo ratings yet

- Broiler Vaccination GuideDocument1 pageBroiler Vaccination Guideharde2lahNo ratings yet

- Exercise 8 Flow ImprovementDocument1 pageExercise 8 Flow Improvementharde2lahNo ratings yet

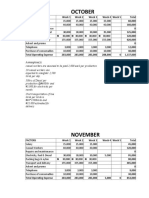

- Poultry Financial ProjectionsDocument28 pagesPoultry Financial Projectionsharde2lahNo ratings yet

- Blue WordsDocument1 pageBlue Wordsharde2lahNo ratings yet

- ZQZ 332Document1 pageZQZ 332harde2lahNo ratings yet

- ZQZ 3321Document2 pagesZQZ 3321harde2lahNo ratings yet

- Jovan Petronic: 2012 FIDE World Youth Chess Champions in ActionDocument8 pagesJovan Petronic: 2012 FIDE World Youth Chess Champions in ActionKasparicoNo ratings yet

- DL Conversion TableDocument10 pagesDL Conversion Tableharde2lahNo ratings yet

- ZQZ 33Document1 pageZQZ 33harde2lahNo ratings yet

- ZQZ 331Document2 pagesZQZ 331harde2lahNo ratings yet

- ZQZ 3Document1 pageZQZ 3harde2lahNo ratings yet

- On Linear ProgrammingDocument49 pagesOn Linear Programmingh_badgujarNo ratings yet

- Reservoarfluider Og Strømning: Curtis Hays WhitsonDocument4 pagesReservoarfluider Og Strømning: Curtis Hays Whitsonharde2lahNo ratings yet

- ZQZ 32Document1 pageZQZ 32harde2lahNo ratings yet

- ZQZ 31Document1 pageZQZ 31harde2lahNo ratings yet

- 600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %Document3 pages600.0 Straight-Line (HCPV Const) Pot Aquifer: Cumulative Gas Recovery, GP/G, %harde2lahNo ratings yet

- Zqer 124 WDocument1 pageZqer 124 Wharde2lahNo ratings yet

- ZQZ 2Document1 pageZQZ 2harde2lahNo ratings yet

- ZQZ 1Document2 pagesZQZ 1harde2lahNo ratings yet

- Zqer 124Document1 pageZqer 124harde2lahNo ratings yet

- Zqer 1 DDocument2 pagesZqer 1 Dharde2lahNo ratings yet

- Zqer 124 W 1Document1 pageZqer 124 W 1harde2lahNo ratings yet

- Zqer 1 D 2Document1 pageZqer 1 D 2harde2lahNo ratings yet

- Zqer 12Document1 pageZqer 12harde2lahNo ratings yet

- Zqer 1Document1 pageZqer 1harde2lahNo ratings yet

- ZQD 7211 GDocument2 pagesZQD 7211 Gharde2lahNo ratings yet

- Sect 8 - Ref GalvadermDocument19 pagesSect 8 - Ref GalvadermamymonuskinNo ratings yet

- People VS PascuaDocument11 pagesPeople VS PascuaShiena Lou B. Amodia-RabacalNo ratings yet

- WWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsDocument3 pagesWWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsHany ElGezawyNo ratings yet

- 3 Fire Extinguisher SystemsDocument29 pages3 Fire Extinguisher SystemsLikaaNo ratings yet

- Water Supply Sanitary Eng PDFDocument5 pagesWater Supply Sanitary Eng PDFReddy NaveenNo ratings yet

- Weekly Construction Report - 2011.10.15Document22 pagesWeekly Construction Report - 2011.10.15Farouq SHah100% (5)

- Basic Flow MetersDocument3 pagesBasic Flow Metersladybuzz89No ratings yet

- Campus Piping and Mechanical System NDT - Inspection Presentation To Adn...Document12 pagesCampus Piping and Mechanical System NDT - Inspection Presentation To Adn...Osama LariNo ratings yet

- Recycling Engine CoolantDocument9 pagesRecycling Engine CoolantYendi Kesuma100% (1)

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Nato - Stanag 4582 - Explosives, Nitrocellulose Based Propellants, Stability Test Procedure and Requirements Using Heat Flow CalorimetryDocument25 pagesNato - Stanag 4582 - Explosives, Nitrocellulose Based Propellants, Stability Test Procedure and Requirements Using Heat Flow CalorimetryTetis BrionesNo ratings yet

- Synthesis and Characterization of Cerium Oxide Nanoparticles Using Different Solvents For Electrochemical ApplicationsDocument10 pagesSynthesis and Characterization of Cerium Oxide Nanoparticles Using Different Solvents For Electrochemical ApplicationsVengateshwaran TDNo ratings yet

- PH4211 Statistical Mechanics: Problem Sheet 2Document4 pagesPH4211 Statistical Mechanics: Problem Sheet 2Roy VeseyNo ratings yet

- Waste-Management EDITEDDocument20 pagesWaste-Management EDITEDpshantanu123No ratings yet

- Artículo para ForoDocument7 pagesArtículo para ForoJuan MendozaNo ratings yet

- 2020.04.16 - FinalDocument32 pages2020.04.16 - Final韩龙No ratings yet

- Tablets of Potassium IodideDocument2 pagesTablets of Potassium IodideJai MurugeshNo ratings yet

- 000 3DT 00005 000 - 2Document116 pages000 3DT 00005 000 - 2anbesivam87No ratings yet

- ANSI-AWWA (American Water Works Association)Document1 pageANSI-AWWA (American Water Works Association)Vaniya GoelNo ratings yet

- Landing NippleDocument4 pagesLanding NippleMohamed Abd El-MoniemNo ratings yet

- CH 10 Reading GuideDocument10 pagesCH 10 Reading GuideKapil NathanNo ratings yet

- Srinivasa Coco ProductDocument13 pagesSrinivasa Coco ProductJilly ArasuNo ratings yet

- Waste CladdingDocument9 pagesWaste CladdingBruno AgueroNo ratings yet

- Anexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design CriteriaDocument64 pagesAnexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design CriteriaRusNo ratings yet

- University of Santo Tomas: Williamson Ether Synthesis: Preparation of PhenacetinDocument4 pagesUniversity of Santo Tomas: Williamson Ether Synthesis: Preparation of PhenacetinMarilou MagdalagaNo ratings yet

- Aqueous Reactions and Solution Stoichiometry: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument51 pagesAqueous Reactions and Solution Stoichiometry: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenGopi SureshNo ratings yet