Professional Documents

Culture Documents

Spe 120632 MS

Uploaded by

José TimanáOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spe 120632 MS

Uploaded by

José TimanáCopyright:

Available Formats

SPE 120632

A New Nodal Analysis Technique Helps Improve Well Completion and

Economic Performance of Matured Oil Fields

M. Rafiqul Awal and Lloyd R. Heinze, Texas Tech University

Copyright 2009, Society of Petroleum Engineers

This paper was prepared for presentation at the 2009 SPE Production and Operations Symposium held in Oklahoma City, Oklahoma, USA, 48 April 2009.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Mature fields lack the sparkle of a new play, and an operator typically will not invest capital for waterflooding, much less

EOR. But prevailing higher oil prices can turn such a mature oil field more profitable by employing innovative production

enhancement techniques. We propose the use of a simple, tapered tubing string completion (using larger internal diameter

(ID) tubing pipes in the upper sections) that can be customized for specific reservoirs. Historically there are few instances of

tapered ID tubing completion, which were basically necessitated by technical constraints (liner, workover, etc.). But our

approach is focused on enhancing economic performance. We have employed nodal analysis technique to develop an

equivalent tubing diameter (ETD) concept. The ETD allows for comparing the well performance for single-ID tubing

completion. The procedure also seeks an optimum length for the larger tubing ID in the upper section. Using reservoir

simulation for full life cycle, and oil prices projected over time until abandonment, the economic performance is evaluated

using NPV and other economic parameters.

The proposed production enhancement method is suitable for wells with moderate to high open flow potentials (AOFP). It is

especially suited for low GOR wells with high future water-cut that will eventually require an ESP system, and also remote

oilfields, where reservoir pressure maintenance and EOR is not viable.

The use of larger tubing ID section entails only a marginal increase in CAPEX. However, the tapered completion gives

increased production rate sustained over a long time, which results in significant economic gain. The economic benefits

accrue from the prevailing high oil price, yielding a quick payout and many returns on investment.

The proposed completion approach does not involve complexity, and the innovative application of nodal analysis coupled

with high oil prices show how to make mature oil fields onshore and offshore, more profitable.

Introduction

Nodal analysis was performed in the sixties and seventies by hand calculations, using vertical pressure traverse graphs

generated in-house by big oil companies. Smaller operators, if they at all used nodal analysis, relied on Browns (1963)

famous pressure traverse graphs. The workflow was tedious at best, discouraging engineers to explore for horizons that nodal

analysis could lead to. However, with the advent of affordable PC software (e.g., Feketes FAST, IHSs PERFORM,

etc.), and even MS-Excel based spreadsheet programs (e.g., Guo et al. 2007), the power of nodal analysis now can be

unleashed even in a classroom setting. One such unexplored horizon is tapered tubing string design with gradually larger

internal diameter (ID) in the upper sections of tubing string.

Conventional tubing string design entails selecting a constant internal diameter for all the tubing sectionsfrom bottom to

top. The upper sections of the string, however, have a greater wall thickness to support the load of the string below. Thus

conventional tubing strings are tapered in terms of outer diameter,which is necessitated by mechanical loading requirements.

SPE 120632

The idea of TIDC is not entirely new, as can be seen in the definition of tapering string for production that exists in the

literature: A tapered production string may be configured with larger OD tubing sections in the upper wellbore area to

optimize the hydraulic performance of the string, (Schlumberger [1]).

However, an extensive search of published literature has revealed few applications of the tapered ID string concept for

optimizing production. Trenchard & Whisenant (1935) reported probably the earliest case of tapered tubing string

completion, which was necessitated by well flow back problems that occurred after shut-in. Conventional methods to flow

back a well in such cases included: pumping, flowing with the aid of valves, and tapered tubing. The tapered tubing string

method was found to be quite satisfactory. It usually consisted of a string of pipe, half of which is -inch, and the other half,

1-inch. The use of the tapered tubing afforded a more continuous flow and probably a smaller amount of injected gas at the

start.

Frederick & DeWeese (1967) reported a similar tapered tubing string in the famous well, "Kaplan Caper" in South Louisiana.

In order to flow the well after initial completion, a tapered macaroni string was installed inside the production tubing (ID).

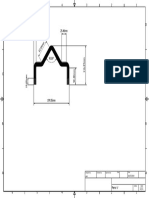

Golan and Whitson (1986) reported the use of a smaller size (ID) of tubing in the liner section of well. In this case, the

smaller tubing size (OD, 27/8) was necessitated following casing collapse above the pay zone. The collapsed section was

repaired by placing a liner inside it. The smaller tubing size was connected to the existing upper tubing (3-in.) section via a

crossover (Fig. 1)

Schlumberger [2] reported using a tapered tubing string of 5.5 to 7 in. in a condensate well with a high GOR. The well was

producing 5500 BOPD with a gas/oil ratio of 9600 SCF/STB through a mono tubing completion consisting of a 7-in.liner. In

order to avoid liquid loading, a tapered tubing string of 5.5 and 7 in. was used, which caused a fluid velocity increase in

excess of the critical velocity of 8 m/s at a flowing wellhead pressure of 1,430 psi.

The most recent case of tapered-string tubing is reported by Tibbles et al. (2004). The well produced at 2,147 STBO/d before

hydraulic fracturing was considered. Pre-fracturing nodal analysis indicated a high AOFP using the designed hydraulic

fracturing parameters. In order to lift the increased volumetric throughput, a larger ID tubing string was needed. A tapered

tubing string (4-in. tubing from surface to 5,000-ft, and 3-in. tubing from 5,000-ft to 5,892-ft.) string indicated a

production rise to 3,145 STBO/d. After fracturing, the measured flow rate was 3,101 STBO/d.

A cursory look at both API and non-API tubing sizes shows two limitations on actual tubing internal diameter (ID) sizes:

1.

2.

There is no size greater than 3.958-in., and

There is only a finite range of sizes: from 0.824-in. to 3.958-in.

The available tubing ID sizes are shown in Table 4. The second limitation on tubing ID size poses a practical problem: How

do we implement the optimum tubing ID size determined from nodal analysis? In our knowledge, the E&P industry has so far

ducked this problem by restricting nodal analysis for optimum tubing size to the available commercial API and non-API

sizes.

Conventional Tubing size optimization procedure for maximizing fluid flow rate:

The routine procedure includes the following steps:

Perform nodal analysis for a given well using all or a few of the tubing sizes available (See Table 1).

Plot a graph of fluid flow rate vs. tubing size (ID), and select the tubing size, di-opt, that corresponds to the highest

fluid flow rate.

If di-opt is not a standard tubing size, select the nearest standard size, which could be either greater or smaller than diopt.

The above procedure is thus a compromise between theory and practice. In this paper, we present an unconventional tapered

string: that of using larger internal diameter tubing pipes in the upper sections of the well. For the sake of discussion, we will

refer to this idea as Tapered Internal Diameter Tubing Completion (TIDC).

Motivation for TIDC

In this paper, we re-introduce the concept of TIDC for the following reasons:

SPE 120632

1.

Technical requirements:

(i) Even with the most rigorous PVT and fluid dynamics modeling that goes into modern nodal analysis software,

the most optimum tubing (ID) size cannot be realized, simply because the design engineer is forced to select the next

best size manufactured commercially. Both API and non-API tubing pipes come in all but a few sizes. With TIDC,

the most optimum tubing size can be selected using the equivalent tubing diametr (ETD) technique presented in this

paper.

(ii) Toward the end of natural flow in the life cycle of an oil well, an artificial lift method (ALM) must be used. With

the advent of high efficiency gas removal system (e.g., helico-axial multiphase pump installed at an ESP intake,

Schlumberger [3]), the electric submersible pump (ESP) has become more popular, Fig. 3. And in fields where

edge-water or bottom-water drive eventually causes high water-cut (WOR). In such cases, even for a minimum

economic production rate of 10 STBO/d, a very high water production rate may result (e.g., 90 STBW/d @ 90%

WOR). In the Middle Eastern oil fields (Dogru et al., 2004; Saadawi, 2007), a gross liquid volume rate of 2,000

STB/d may be necessitated to lift 200 STB/d oil @90% water-cut. Obviously, a tubing string designed previously to

lift 200 STBO/d neat oil may be quite undersized (ID).

2.

Economic requirements:

(i) For the case shown in (1-ii) above, it is obviously more economic to recomplete the well with a tapered string

(TIDC) than use a larger bore constant ID string.

(ii) Due to high oil price experienced in recent years, re-completing a well with undersized tubing string with a

TIDC completion will give a quick return-on-investment and additional profit. The price has returned to normal as

of writing this paper, but the probability of upsurge remains due to growing rise in oil consumption in the

developing countries.

Also, it is reasonable to assume that many a well completed in the 1970s and before, and still producing (albeit at a lower

rate than in the early period of production due to reservoir depletion) did not enjoy optimum sizing that requires nodal

analysis. Excepting the big oil companies who could afford expensive mainframe computers, small operators relied on hand

calculation-based nodal analysis using PVT and fluid dynamics modeling.

Results of Nodal Analysis using TIDC

Nodal analyses are performed for mono and the various TIDC completions depicted in Fig. 2 and Table 1, using the

commercial software, PERFORM. The reservoir, well construction, PVT and well test data are shown in Table 2. The

nodal software has more than one correlation for both inflow performance (IPR) and tubing performance (TPR) relationships.

In order to illustrate the use of TIDC, we have used Vogel & Harrison (1968) and Beggs & Brill (1973) correlations,

respectively.

First, we run the base case with mono tubing completion, using five tubing ID sizes: 1.995, 2.441, 2.992, 3.476, and 3.958

inches. The well performance graphs (Flowing bottomhole pressure vs. Fluid flow rate) are shown in Fig. 4. For water-cut

ranges from 50% to 60%, the stabilized gross liquid rate increases with tubing size until 3.476-in., then reverses at 3.958-in.,

indicating that the di-opt value is somewhere between 3.476-in. and 3.958-in. This is shown clearly in Fig. 5. Obviously, this

optimum tubing size is not available from commercial tubing pipes. This shows the need to use a tapered tubing string using

these two standard tubing sizes.

Next, we show the nodal analysis results for the Duplex TIDC realizations. The TIDC realizations shown are simplistic, i.e.,

the depth intervals for various tubing sizes in a TIDC completion are equal. The results are shown in Fig. 6. The Duplex

TIDC gives significantly higher gross liquid rates at all three water-cut values, shown clearly in the Table 4 next to the

graph. This is a spectacular result, which shows that there could be more benefits in using a TIDC than expected intuitively.

For a given well, the length of the upper section in the Duplex TIDC can be optimized. The optimization procedure is simple:

choose several values for length of the upper tubing section, and compare the stabilized flow rates. The procedure is

illustrated in Fig. 7 for a Duplex TIDC. It reveals the optimum length of the upper section (larger ID, 3.958-in.) to be 3,600ft, which much shorter than the smaller ID (3.476-in.), lower section: (9,990 3,600) ft = 6,390-ft.

SPE 120632

In the foregoing duplex TIDC optimized solution, the economic gains are significant, given the high oil price. The duplex

TIDC gives increased gross fluid rates as follows:

10 to 15% compared to the 3.476-in. mono tubing completion, and

10 to 30% compared to the 3.958-in. mono tubing completion,

over the water-cut range of 50 to 70%.

The selection of the optimum length of the upper section can be further refined by including the concept of marginal utility in

economics. This is illustrated in Fig. 8.

The increased fluid lifting performances of higher order TIDC completions are shown in Fig. 9. The same data have been

used, but Hagedorn & Brown correlation was used instead of Beggs & Brills.

Economic Analysis using Well Life Cycle

Before finalizing the tubing ID selection using mono or one of the various TIDC schemes discussed above, a complete

economic analysis including cost and profits is in order. Affanaambomo (2008) presented economic analysis using the mono,

duplex, triplex and quad completions. For this, a single well located at the center of a circular drainage volume is considered.

The reservoir, well and PVT data are taken from Economides et al. (1993).

The economic analysis involves two major steps.

Step-1: Predict the reservoir depletion and well production performance for a specific tubing completion using Tracys

material balance method, and nodal analysis. A MS-Excel spreadsheet program developed by Guo et al. (2007) is

used for these calculations.

Step-2: Calculate, NPV, ROI, etc. using standard economic analysis method.

While Affanaambomo (2008) presented the economic analysis for duplex, triplex and quad completions, we show the results

for a duplex completion only. The data used for cost analysis are shown in Table 5.

NPV is calculated at 10% interest rate. Prices of oil and gas used are $126.2/bbl and $11.537/MMbtu as of May, 2008,

respectively. The cost of tubing pipes for outside diameters 2.378 in., 2.875 in., 3.5 in., and 4.0 in. are $ 4.02, 5.44, 7.76, and

9.48 per foot as of May, 2008 respectively. Because the well is presumed to be in natural flow, operational expenditure

(OPEX), development cost, and abandonment cost are not considered. In the economic analysis, only the different tubing

costs are considered, and consider all other cost components equal.

The economic analysis shows advantage of TIDC over mono tubing completion (Figs. 10 and 11).

Conclusions

In this exploratory work involving nodal analysis for optimizing tubing string ID for maximizing gross liquid production rate,

the following observations are made:

1.

2.

3.

4.

5.

The E&P industry only performs tubing ID optimization for mono tubing completion only. The use of tapered ID

tubing string are few, mainly motivated by workover and mechanical completion constraints.

This work is the first systematic study that explores the benefits of tapered ID strings.

The TIDC reveals non-intuitive, positive results over mono tubing completions. The production rate from a TIDC

could exceed the highest rate possible from any single tubing size.

The TIDC affords a means to use the theoretically optimum tubing size, by combining commercial sizes suitably.

In the high oil and gas price scenario witnessed in the past two years, attention to TIDC makes good economic

sense.

SPE 120632

Acknowledgements

The authors thank Fekete Associates, Inc., Calgary, Canada and IHC, Inc., Houston, USA for providing nodal analysis

software.

References

Affanaambomo, B.O. 2008. Study Of Tapered Internal Diameter Tubing String Well Completion For Enhanced

Production. MS Thesis, Texas Tech University, Lubbock, TX. pp.77 180.

Beggs, H.D. 1991. Total system analysis, in Production Optimization: Using NODAL Analysis. OGCI Publications,

Tulsa, OK. p.135

Dogru, A.H., Hamoud, A.A. and Balow, S.G. 2004. Multiphase Pump Recovers More Oil in a Mature Carbonate

Reservoir, SPE 83910 in Journal of Petroleum Technology, Feb.

Economides, M.J., Hill, A.D., and Ehlig-Economides, C. 1993. Petroleum Production Systems. Prentice Hall PTR, New

Jersey, MD. p. 593 - 595

Frederick, B. and DeWeese, E., "Kaplan Caper," in Drilling, Vol/Issue: 28/9, June, 1967. p.34 - 39

Golan, Michael, and Whitson, Curtis H., Well Performance, 2nd ed. Englewood Cliffs, Prentice-Hall, New Jersey, 1986.

p.77-78.

Guo, B.W., and Gholambor, Ali. 2007. Petroleum_Production_Engineering-A_Computer_Assisted_Approach. Gulf

Publishing Company, Houston, USA.

Saadawi, H. 2007. An Overview of Multiphase Pumping Technology and its Potential Application for Oil Fields in the Gulf

Region, SPE/IPTC paper 11720, Abu Dhabi, UAE. 4 6 December.

Schlumberger [1]: Oilfield Glossary. http://www.glossary.oilfield.slb.com/Display.cfm?Term=tapered%20string

Schlumberger [2]: GHOST Gas Holdup Optical Sensor Tool brochure, SMP-5762, 2001.

Schlumberger [3]: Case Study Well Life Increased by a Projected 2 Years.

http://www.slb.com/content/services/resources/casestudies/artificial/poseidon_canada_profound.asp

Tibbles, R., Ezzat, A., Mahmoud, K.H., Ali, A.H.A., and Hosein, P. (2004). "Hydraulic fracturing the best producer: A

myth?" presented at New Zealand Petroleum Conference, Auckland from 7-10 March. Slide #9-10.

Trenchard, J. and Whisenant, J. B., "Government Wells Oil Field, Duval County, Texas," Bulletin of the American

Association of Petroleum Geologists Vol. 19, No. 8 August, 1935. p. 1131 - 1147.

SPE 120632

Figure 1. A practical example of TIDC, necessitated by reduced bottomhole diameter after inserting a

liner through the production casing (PC) following collapse of the lower section of the PC (Goan &

Whitson, 1986).

0.824, 1.049, 1.380, 1.610, 1.867, 1.995, 2.041, 2.441,

2.259, 2.750, 2.992, 2.992, 3.068, 3.476, 3.548, 3.958

Table 1. API and non-API tubing sizes

(ID), inches.

Table 2. Tubing IDs for the mono and various TIDC realizations.

Tubing ID

Realizations

Mono tubing ID

Duplex TIDC

Triplex TIDC

Quad TIDC

Tubing size (ID), in.

1.995

(Depth interval,

ft)

(0 9,990)

(0 5,000)

(0 2,500)

(0 2,500)

2.441

(Depth interval,

ft)

(0 9,990)

(5,000 9,990)

(2,500 5,000)

(2,500 5,000)

2.992

(Depth interval,

ft)

(0 9,990)

3.340

(Depth interval,

ft)

(0 9,990)

(5,000 9,990)

(5,000 7,500)

(7,500 9,990)

Table 3. Reservoir, well construction, and operating data (Beggs, 1991).

Parameter

Value

Avg. reservoir pressure, psig

3,483

Bubble point pressure, psig

3,600

Flowing wellhead pressure, psig

400

Mid perforation depth, ft

10,000

Tubing shoe depth, ft

9,990

Oil density, oAPI

35

Gas gravity (air 1.00)

0.65

Water-cut, %

50

GLR, SCF/STB

400

Well Test data:

Stabilized flow rate, STB/d

320

Flowing bottomhole pressure,

3,445

psig

SPE 120632

(a)

(b)

(c)

Figure 2. Three realizations of tapered internal diameter tubing completion, TIDC, in order to optimize the

fluid dynamics. (a) Duplex, (b) Triplex, and (c) Quad.

(a)

(b)

Figure 3. Augmented productivity by modern ESP. (a) Production profile showing ESP operation before

and after adding a helicon-axial gas handling pump. (b) The high-capacity gas handling device

enables a greater percentage of free gas to be produced.

(Ref. Schlumberger [3]).

SPE 120632

4000

Tbg.ID=1.995-in.

3900

Tbg.ID=2.441-in.

3800

Tbg.ID=2.992-in.

pwf, psig

3700

Tbg.ID=3.476-in.

3600

Tbg.ID=3.958-in.

3500

IPR

3400

3300

3200

3100

3000

0

500

1000

1500

2000

2500

3000

QL, STB/d

Figure 4. Well performance graphs (IPR and TPRs) for various standard tubing ID sizes in monobore

tubing string completion.

Gross Liquid rate, STB/d

2500

2000

1500

1000

W-cut: 50%

W-cut: 60%

500

W-cut: 70%

0

1.5

2.5

3.5

4.5

Tubing ID, inch

Figure 5. Graphical method to determine the optimum tubing ID size for a mono tubing string.

SPE 120632

Flowing bottomhole pressure, psig

3500

3450

Mono-1

3400

Mono-2

3350

Dual

3300

IPR

Table 4. Comparison of mono and Duplex

tubing string fluid lift performance.

Gross liquid rates, STB/d

Water-cut

Dual

%

Mono-1

Mono-2

3250

3200

50

60

70

3150

3100

3050

3000

0

1000

2000

3000

4000

1911

1729

1554

1908

1635

1282

2137

2048

1854

5000

Gross liquid rate, STB/d

Figure 6. Comparison of mono and Duplex tubing string fluid lift performance. The length of the upper

section in a Duplex TIDC is 5,000 ft.

2100

Water-cut: 70%

Gross liquid rate, STB/d

2000

1900

1800

1700

1600

1500

1400

0

2000

4000

6000

8000

Length of upper tubing, ft

Figure 7. Graphical method to determine the optimum length of the upper section in a Duplex TIDC. For

this case, the optimum length is approx. 3,500 ft. The lower section

10

SPE 120632

Stabilized flow rate

Ideally, the optimum length of the upper

section should be LU-1., which

corresponds to the maximum production

rate, Q1.

But overall economics based on

marginal utility may dictate the optimum

length at LU-2

Q1

Q2

LU-2

LU-1

Length of upper section of tubing string

Figure 8. Graphical procedure to optimize the length of the upper section of a Duplex TIDC.

Stabilized Flow Rate, q* L (STB/d)

4000

Mono: 1.995@9990ft

3500

3000

Dual:2.441in@5000ft;

1.995@9990ft

2500

2000

1500

Tripple: 2.992@2500ft;

2.441in@5000ft;

1.995in@9990ft

1000

500

0

200

400

600

GLR (SCF/STB)

800

1000

Quad:3.476@2500ft;

2.992@5000ft;

2.441@7500ft;

1.992@9990ft

Figure 9. Increased fluid lifting performances of various TIDC completions.

SPE 120632

11

Table 5. Data used for cost analysis (Affanaambomo, 2008).

Figure 10. Rate of and cumulative production over

full life cycle: mono and duplex tubing

(Affanaambomo, 2008).

Figure 11. Net present value (NPV) over full life

cycle: mono and duplex tubing (Affanaambomo,

2008).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MSS SP 97 PDFDocument15 pagesMSS SP 97 PDFOlinser BacelisNo ratings yet

- Revisiting Some Rules of ThumbDocument6 pagesRevisiting Some Rules of Thumbhamidrezaee008No ratings yet

- Rack Server Teech Sheet ManualDocument20 pagesRack Server Teech Sheet ManualTim WiseNo ratings yet

- 1610ig-E 2Document4 pages1610ig-E 2yrdgcgf5664No ratings yet

- NH3 RiskDocument59 pagesNH3 RiskDave CNo ratings yet

- 5 Dasar-Dasar k3 & Pencegahan Kecelakaan (RM)Document68 pages5 Dasar-Dasar k3 & Pencegahan Kecelakaan (RM)Muhammad Akbar Al BardawiNo ratings yet

- Volkswagon 02a5bDocument27 pagesVolkswagon 02a5bPatryk RączyNo ratings yet

- Celda Carga - KIS-2BA - 5KNDocument4 pagesCelda Carga - KIS-2BA - 5KNJosé TimanáNo ratings yet

- XK3118T4F Technical ManualDocument4 pagesXK3118T4F Technical ManualJosé TimanáNo ratings yet

- BVD 2257 GBDocument4 pagesBVD 2257 GBmichaelNo ratings yet

- Approvals: Weigh Module Available Paramounts HE Paramounts HSDocument1 pageApprovals: Weigh Module Available Paramounts HE Paramounts HSJosé TimanáNo ratings yet

- sb14 Beam Datasheet en PDFDocument3 pagessb14 Beam Datasheet en PDFJosé TimanáNo ratings yet

- ABB Sales SpecialistDocument2 pagesABB Sales SpecialistJosé TimanáNo ratings yet

- Request Quote Conveyor Belt ScaleDocument1 pageRequest Quote Conveyor Belt ScaleJosé TimanáNo ratings yet

- Perno VDocument1 pagePerno VJosé TimanáNo ratings yet

- Vocabulary HP Back UpDocument18 pagesVocabulary HP Back UpJosé TimanáNo ratings yet

- 2019 Iqube2 Junction BoxDocument3 pages2019 Iqube2 Junction BoxJosé TimanáNo ratings yet

- Resumen Ejecutivo As 0322018 20181009 123751 468Document3 pagesResumen Ejecutivo As 0322018 20181009 123751 468José TimanáNo ratings yet

- RuedaCocheMinero (AI2018)Document1 pageRuedaCocheMinero (AI2018)José TimanáNo ratings yet

- OIMLR60Document97 pagesOIMLR60Waleed MouhammedNo ratings yet

- Conduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesDocument1 pageConduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesJosé TimanáNo ratings yet

- ACSEWDocument1 pageACSEWJosé TimanáNo ratings yet

- Aluminum Liquidtight ST Series Connectors With Plain ThroatDocument1 pageAluminum Liquidtight ST Series Connectors With Plain ThroatJosé TimanáNo ratings yet

- Payi : at 1971 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncDocument12 pagesPayi : at 1971 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncJosé TimanáNo ratings yet

- Setra Field Guide To Understanding Pressure TransducersDocument9 pagesSetra Field Guide To Understanding Pressure TransducersJosé TimanáNo ratings yet

- ARDYDocument4 pagesARDYJosé TimanáNo ratings yet

- Ardy PDFDocument4 pagesArdy PDFJosé TimanáNo ratings yet

- Cable Glands Cross ReferenceDocument8 pagesCable Glands Cross ReferenceUrip S. Setyadji100% (1)

- Spe 123561 MSDocument10 pagesSpe 123561 MSJosé TimanáNo ratings yet

- Fluids and Proppants Selection Qa&Qc in Hydraulic FracturingDocument41 pagesFluids and Proppants Selection Qa&Qc in Hydraulic FracturingJosé TimanáNo ratings yet

- Empalme Bombas SumergiblesDocument12 pagesEmpalme Bombas SumergiblesHugoCabanillasNo ratings yet

- Ukavala Nge Mod 01b Introd Phsbeh (Base) (v20140528) PDFDocument58 pagesUkavala Nge Mod 01b Introd Phsbeh (Base) (v20140528) PDFJosé TimanáNo ratings yet

- Expr 2 Ac 33 eDocument10 pagesExpr 2 Ac 33 eJosé TimanáNo ratings yet

- Expr 2 BP 29 eDocument12 pagesExpr 2 BP 29 eJosé TimanáNo ratings yet

- Manual PerformDocument129 pagesManual PerformJosé TimanáNo ratings yet

- Spe 30342 PaDocument3 pagesSpe 30342 PaJosé TimanáNo ratings yet

- Spe 58788 MSDocument5 pagesSpe 58788 MSJosé TimanáNo ratings yet

- Sealant cross reference chartDocument1 pageSealant cross reference chartElias ZabanehNo ratings yet

- PIA Business Policy ProjectDocument68 pagesPIA Business Policy ProjectRao Waqas100% (1)

- Administering JMS Resources For Oracle WebLogic ServerDocument146 pagesAdministering JMS Resources For Oracle WebLogic ServeritshezzNo ratings yet

- Roles IncludeDocument14 pagesRoles IncludeAisha IshuNo ratings yet

- SRK64Document2 pagesSRK64deliaabreguNo ratings yet

- SMK 345 A7 DM PDFDocument1 pageSMK 345 A7 DM PDFMelchorRdzNo ratings yet

- Airline Case Study 1time FinalDocument3 pagesAirline Case Study 1time Finalcorporate businessNo ratings yet

- NR467 - Rules For Steel Ships - PartAVol01Document262 pagesNR467 - Rules For Steel Ships - PartAVol01Meleti Meleti MeletiouNo ratings yet

- ITC Green Centre Banaswadi Mai Road Eflyer July 2018Document2 pagesITC Green Centre Banaswadi Mai Road Eflyer July 2018chaithan kumarNo ratings yet

- Apostila Civil 3D - Brazil ContentsDocument50 pagesApostila Civil 3D - Brazil ContentsDervan DuqueNo ratings yet

- Determining Asphalt Binder Bond Strength by Means of The Binder Bond Strength (BBS) TestDocument3 pagesDetermining Asphalt Binder Bond Strength by Means of The Binder Bond Strength (BBS) TestSaurav BhattacharjeeNo ratings yet

- Specification (GTX-35VS Kaveri) : Afterburning TurbofanDocument18 pagesSpecification (GTX-35VS Kaveri) : Afterburning Turbofanandrw1987No ratings yet

- 18mec207t - Unit 5 - Rev - w15Document54 pages18mec207t - Unit 5 - Rev - w15Asvath GuruNo ratings yet

- SAD Chaper8Document33 pagesSAD Chaper8VJ Tang100% (1)

- Ampco-Fristam-Replacement-Parts-GuideDocument2 pagesAmpco-Fristam-Replacement-Parts-GuideИбрагим НурмамедовNo ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertrayNo ratings yet

- Windows10 QOSDocument1 pageWindows10 QOSLeandro RigoNo ratings yet

- Export PDF Form Data CSVDocument2 pagesExport PDF Form Data CSVSeanNo ratings yet

- TSP-408L-1 P/N 32441-002: ApplicationDocument2 pagesTSP-408L-1 P/N 32441-002: ApplicationSajjad ShamimNo ratings yet

- Allan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentDocument15 pagesAllan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentRaymond Manalo PanganibanNo ratings yet

- 2ST Seated Leg Curl DiagramDocument10 pages2ST Seated Leg Curl DiagramJEREMEE MICHAEL TYLERNo ratings yet

- Network - Shortest RouteDocument22 pagesNetwork - Shortest RouteNoor AsikinNo ratings yet

- Mfs ResumeDocument1 pageMfs Resumeapi-421988846No ratings yet