Professional Documents

Culture Documents

Casting Elwany Full

Uploaded by

Anonymous mKdAfWifCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casting Elwany Full

Uploaded by

Anonymous mKdAfWifCopyright:

Available Formats

Chapter 11

Metal-Casting Processes

3/20/2006

56:032 Design for Manufacturing

Manufacturing Processes Alternatives

Material Removal Processes

Forming Processes

Assembly

Similar to?

Examples?

And..

Casting Processes

3/20/2006

56:032 :Design for Manufacturing

Metal Casting Processes

The process involves:

Advantages of Metal Casting Processes:

Pour molten metal into a mold patterned after the part to be

manufactured

Allow it to solidify

Remove the part from the mold

Produce part in single step (near-net shape)

Produce large parts

Can produce a wide variety of shapes and sizes

Complex shapes are possible

Internal cavities are possible

Any Disadvantages?

3/20/2006

56:032 :Design for Manufacturing

Examples of Cast Products

Note how difficult it might get to produce these parts using

other manufacturing processes

Fig.

11.1

Fig.

Fig.11.1

11.1dbac

Fig.

11.1

3/20/2006

56:032 :Design for Manufacturing

Categories of Metal-Casting Processes

Expendable Molds:

Typically made out of sand, plaster, ceramics and similar

material

Such material are refractory i.e., capable of withstanding high

temperatures.

After casting the mold is broken up to remove the casting

Permanent Molds:

3/20/2006

Made of metals that maintain their strength at high

temperatures.

Are used repeatedly

Designed in such a way that the casting can be removed

easily

56:032 :Design for Manufacturing

Categories of Metal-Casting Processes

Composite Molds:

3/20/2006

Made of two or more materials (sand, graphite, and metal) in

order to combine the advantages of each

Have both permanent and expendable portions

56:032 :Design for Manufacturing

First: Expendable Mold Casting

Theres a variety of casting processes that use

expendable molds.

We will focus on discussing 2 of them in detail:

3/20/2006

Sand Casting

Investment Casting

56:032 :Design for Manufacturing

Sand Casting

Process outline:

Place a pattern (having the shape of the desired casting) in

sand to make an imprint

Incorporate a gating system

Remove the pattern and filling the mold cavity with molten

metal

Allow the metal to cool until it solidifies

Break away the sand metal

Remove the casting

Example

Can we make hollow parts or parts with internal

cavities? How?

3/20/2006

56:032 :Design for Manufacturing

Sand Casting (contd.)

Sands

Silica sands (SiO2) is widely used as the mold material

High melting point

Factors affecting sand selection

3/20/2006

Fine round grains can be closely packed

Fine grained sand has lower permeability

Mold should have good collapsibility

56:032 :Design for Manufacturing

Sand Mold Terminology

Figure 11.3 Schematic illustration of a sand mold, showing various features.

3/20/2006

56:032 :Design for Manufacturing

10

Finished Casting

3/20/2006

56:032 :Design for Manufacturing

11

Sand Mold Preparation

(a) Mechanical drawing of part

(b & c) Pattern Mounting

(d) Core Production

3/20/2006

56:032 :Design for Manufacturing

12

Sand Mold Preparation (Contd.)

(e) Cores are pasted

(f ) Assembly of the cope half of the mold

(g) The flask is rammed with sand

(h) The drag half is produced in a similar manner

(i) The pattern , flask, and bottom board are inverted; and

the pattern is withdrawn

3/20/2006

56:032 :Design for Manufacturing

13

Pattern Plate

3/20/2006

56:032 :Design for Manufacturing

14

Pattern Considerations/Allowances

Shrinkage Allowance (Why?)

Machining Allowance (?)

Draft Allowance (?)

Round corners (?)

3/20/2006

56:032 :Design for Manufacturing

15

Demonstration of the Draft Allowance

3/20/2006

56:032 :Design for Manufacturing

16

Sand Cores

Cores are used for internal cavities and passages

Removed from the finished part during shakeout

Must be strong, collapsible, permeable, heat resistant

Made in a similar manner to mold making

Figure 11.6 Examples of sand cores showing core prints and chaplets to support cores.

3/20/2006

56:032 :Design for Manufacturing

17

Investment Casting Process

Another common casting process with expendable

molds.

Also known as lost-wax process

Advantages

The mold material and labor is costly

Suitable for high-melting-point alloys

Good surface finish

Few or no finishing operations thus reducing cost

Typical parts

3/20/2006

Mechanical components such as gears, cams, valves.

Lately, titanium aircraft-engine

Parts up to 2500 lbs were successfully produced

56:032 :Design for Manufacturing

18

Investment Casting Process (Contd)

Figure 11.13 Schematic illustration of investment casting (lost-wax) process. Castings

by this method can be made with very fine detail and from a variety of metals.

3/20/2006

56:032 :Design for Manufacturing

19

Disadvantages of Metal Casting

Depending on the casting process used, and specially

for expendable mold casting processes discussed in this

lecture:

Production rate can be slow

Finished Casting usually needs finishing operations

Casting Defects

3/20/2006

56:032 :Design for Manufacturing

20

Casting Defects and How to Avoid them

3/20/2006

56:032 :Design for Manufacturing

21

Next Time

Permanent Molds Casting Processes

Other Technicalities in various casting processes

3/20/2006

56:032 :Design for Manufacturing

22

You might also like

- FKM Lab - Metal Casting Process Lab ReportDocument20 pagesFKM Lab - Metal Casting Process Lab Reportzazaeureka0% (1)

- Non-Ferrous Metals Casting QuizDocument7 pagesNon-Ferrous Metals Casting Quizabhi100% (10)

- Summer Training Report CastingDocument29 pagesSummer Training Report CastingFaisal Bin Shabbir100% (1)

- Ch11metalcastingprocDocument74 pagesCh11metalcastingprocCharurat KongyangNo ratings yet

- CH 11Document77 pagesCH 11Davinder SinghNo ratings yet

- Metal Casting ProcessesDocument98 pagesMetal Casting ProcessestmcoachingcentreNo ratings yet

- Metal Casting ProcessesDocument87 pagesMetal Casting ProcessesgggNo ratings yet

- ME364 Casting ProcessesDocument5 pagesME364 Casting Processesjegan_tamilNo ratings yet

- METAL CASTING GUIDEDocument18 pagesMETAL CASTING GUIDEvelavansuNo ratings yet

- 4 Various Types of Expendable Mold and Permanent Mold CastingDocument45 pages4 Various Types of Expendable Mold and Permanent Mold CastingLiaquat AliNo ratings yet

- MCW!!!Document9 pagesMCW!!!badshahsaadNo ratings yet

- MM Experiment ReportDocument10 pagesMM Experiment ReportAbdullah ArshadNo ratings yet

- Week 2 Advanced Workshop PracticeDocument28 pagesWeek 2 Advanced Workshop PracticeBasit AliNo ratings yet

- Module 3 Lecture 2 FinalDocument22 pagesModule 3 Lecture 2 Finaltejap314No ratings yet

- Metal Casting ProcessesDocument169 pagesMetal Casting ProcessesSajeed Shaik100% (1)

- Casting Process GuideDocument74 pagesCasting Process Guidevinu1977No ratings yet

- DFM ch-2Document114 pagesDFM ch-2Trâp A NâtïøñNo ratings yet

- Found AryDocument14 pagesFound Aryluv_leo007No ratings yet

- ME364 - Casting - Processes Nptel PDFDocument8 pagesME364 - Casting - Processes Nptel PDFvijaykumarNo ratings yet

- Sand CastingDocument5 pagesSand CastingEfy BellaNo ratings yet

- EIN 3390 Chap 12 Expendable-Mold Cast B Spring - 2012Document51 pagesEIN 3390 Chap 12 Expendable-Mold Cast B Spring - 2012Deepak SharmaNo ratings yet

- Metal Casting and Welding 15Me35ADocument29 pagesMetal Casting and Welding 15Me35A01061975No ratings yet

- Metal casting processes and design considerationsDocument78 pagesMetal casting processes and design considerationstvishal8No ratings yet

- Casting and Welding GuideDocument27 pagesCasting and Welding GuidePavaniNo ratings yet

- A402072949 - 17676 - 17 - 2018 - Casting 2Document39 pagesA402072949 - 17676 - 17 - 2018 - Casting 2KushNo ratings yet

- Ssignment Topic: Casting Process, Material & Technique Course Title: Moulding and Casting Course No. F-ART-S 3204Document16 pagesSsignment Topic: Casting Process, Material & Technique Course Title: Moulding and Casting Course No. F-ART-S 3204muntasir id1No ratings yet

- MT Merged PDFDocument273 pagesMT Merged PDFavcNo ratings yet

- Casting Process: Steps of Casting AreDocument10 pagesCasting Process: Steps of Casting AreReham Emad Ezzat MohamedNo ratings yet

- Manufacturing ProcessesDocument134 pagesManufacturing ProcessesB J ISAC ABRAHAM PAULNo ratings yet

- 15ume302 - MT - I BankDocument17 pages15ume302 - MT - I BankKARTHICK MNo ratings yet

- NPTL CompressedDocument228 pagesNPTL CompressedAniketan kumar Singh - EC-32No ratings yet

- MME 512 Note 1Document36 pagesMME 512 Note 1faithNo ratings yet

- Casting ProcessesDocument20 pagesCasting ProcessesVv4HNo ratings yet

- Special CastingDocument24 pagesSpecial CastingManohara ErlaNo ratings yet

- Unit I Sand CastingDocument36 pagesUnit I Sand CastingSrinivas Gowda100% (1)

- Casting LabDocument11 pagesCasting Labfawad naeemNo ratings yet

- Microsoft PowerPoint - LECTURE3Document36 pagesMicrosoft PowerPoint - LECTURE3Sugumar MuthusamyNo ratings yet

- EAT227-Lecture 2.1 - Metal CastingDocument42 pagesEAT227-Lecture 2.1 - Metal CastingQim SvNo ratings yet

- Unit 3Document42 pagesUnit 3Anup M UpadhyayaNo ratings yet

- Chapter 7Document43 pagesChapter 7Bairoju Shiva KumarNo ratings yet

- METAL CASTING PROCESS OPTIMIZATIONDocument10 pagesMETAL CASTING PROCESS OPTIMIZATIONcarrespmNo ratings yet

- Adama Science and Technology University: School of Mechanical, Chemical & Materials EngineeringDocument12 pagesAdama Science and Technology University: School of Mechanical, Chemical & Materials EngineeringAbel MeketaNo ratings yet

- Steps Involved in Sand Casting Process: BY Aravindkumar BDocument39 pagesSteps Involved in Sand Casting Process: BY Aravindkumar BanilNo ratings yet

- Recent Advances in Sand CastingDocument25 pagesRecent Advances in Sand Casting9591007896No ratings yet

- Basics of Metal Casting Methods and ProcessesDocument14 pagesBasics of Metal Casting Methods and ProcessesMathew Joel MathewNo ratings yet

- Mft-I Two & 13 Marks QuestionDocument16 pagesMft-I Two & 13 Marks QuestionrahulNo ratings yet

- Ch11 More Metal CastingDocument87 pagesCh11 More Metal CastingNaresh N BabuNo ratings yet

- UNit 3 Part A RevisedDocument76 pagesUNit 3 Part A Revisedraymon sharmaNo ratings yet

- 1 Expendable and Permanent Moulding ProcessesDocument275 pages1 Expendable and Permanent Moulding Processesvasanthakumarsk17No ratings yet

- Unit 1 Metal Casting ProcessesDocument115 pagesUnit 1 Metal Casting ProcessesMadhav MaheshwariNo ratings yet

- Foundry Asguest57564 Download: Share Add To Flagembed Views: 5846 Category: EducationDocument9 pagesFoundry Asguest57564 Download: Share Add To Flagembed Views: 5846 Category: EducationGurjinder SinghNo ratings yet

- Metal Casting Methods and ApplicationsDocument31 pagesMetal Casting Methods and ApplicationsKelvin KVNo ratings yet

- Casting ProcessDocument30 pagesCasting ProcessParas ThakurNo ratings yet

- Metal Casting Processes Lecture on Shell Molding, Vacuum Molding and Other Expendable Mold TechniquesDocument18 pagesMetal Casting Processes Lecture on Shell Molding, Vacuum Molding and Other Expendable Mold TechniquesSports GloballyNo ratings yet

- CastingDocument30 pagesCastingwatcharpNo ratings yet

- Learn Critical Aspects of Pattern and Mould Making in FoundryFrom EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Concrete-Block Manufacture - Processes and MachinesFrom EverandConcrete-Block Manufacture - Processes and MachinesRating: 5 out of 5 stars5/5 (1)

- Manufacturing Technology for Aerospace Structural MaterialsFrom EverandManufacturing Technology for Aerospace Structural MaterialsRating: 5 out of 5 stars5/5 (2)

- Prison Camp LatheDocument6 pagesPrison Camp LatheChukwuRapNo ratings yet

- ZlatarstvoDocument1 pageZlatarstvokosinNo ratings yet

- DemoDocument4 pagesDemoAnonymous mKdAfWifNo ratings yet

- Prison Camp LatheDocument6 pagesPrison Camp LatheChukwuRapNo ratings yet

- Solidworks:: Lesson 1 - Basics and Modeling FundamentalsDocument48 pagesSolidworks:: Lesson 1 - Basics and Modeling FundamentalsmekoxxxNo ratings yet

- Primena 3D Stampe U ObrazovanjuDocument4 pagesPrimena 3D Stampe U ObrazovanjuAnonymous mKdAfWifNo ratings yet

- S.E Mechanical EngineeringDocument35 pagesS.E Mechanical EngineeringRahul KalathilNo ratings yet

- Taper Basics PDFDocument3 pagesTaper Basics PDFAnonymous mKdAfWifNo ratings yet

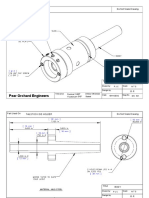

- Pear Orchard Engineers: Do Not Scale Drawing Part Used OnDocument4 pagesPear Orchard Engineers: Do Not Scale Drawing Part Used OnAnonymous mKdAfWifNo ratings yet

- Home Shop Machinist's Gears GuideDocument8 pagesHome Shop Machinist's Gears Guidegaragepunkfan100% (1)

- En Metalwork General Metal WorkDocument90 pagesEn Metalwork General Metal WorkAnonymous mKdAfWifNo ratings yet

- Owners Manual 4 The Human BodyDocument184 pagesOwners Manual 4 The Human BodyAnonymous mKdAfWifNo ratings yet

- Three Wire MethodDocument4 pagesThree Wire MethodmaivizhiNo ratings yet

- Machining Operations and Machine ToolsDocument18 pagesMachining Operations and Machine ToolsAnonymous mKdAfWifNo ratings yet

- GearsDocument4 pagesGearsR@XNo ratings yet

- Zadatak 1a Vitlo SkidDocument2,018 pagesZadatak 1a Vitlo SkidAnonymous mKdAfWifNo ratings yet

- 01 MaterialsDocument6 pages01 MaterialsAnonymous mKdAfWifNo ratings yet

- A Few Project Images: Tool Posts Lathe Cutting ToolsDocument4 pagesA Few Project Images: Tool Posts Lathe Cutting ToolsAnonymous mKdAfWifNo ratings yet

- Workshop Practice Series - BooksDocument8 pagesWorkshop Practice Series - Bookscatapix100% (5)

- 08 Milling Full SlidesDocument35 pages08 Milling Full SlidesAnonymous mKdAfWifNo ratings yet

- FertDocument7 pagesFertBibi NiniNo ratings yet

- Testing Lathe For AccuracyDocument4 pagesTesting Lathe For AccuracyArnieTNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument36 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingAnonymous mKdAfWif0% (1)

- Atlas Cut-Off Tools PDFDocument2 pagesAtlas Cut-Off Tools PDFhugo@wideas.comNo ratings yet

- 11-Turning Equations FullDocument21 pages11-Turning Equations FullmagzigioNo ratings yet

- Working Drawings-Full SlidesDocument14 pagesWorking Drawings-Full SlidesAnonymous mKdAfWifNo ratings yet

- Prison Camp LatheDocument6 pagesPrison Camp LatheChukwuRapNo ratings yet

- IC Learning Series 2012 - Metal Cutting Processes - TurningDocument15 pagesIC Learning Series 2012 - Metal Cutting Processes - TurningSorin FrentoniNo ratings yet

- Machining Operations and Machine ToolsDocument18 pagesMachining Operations and Machine ToolsAnonymous mKdAfWifNo ratings yet

- GATE MFG LatestDocument210 pagesGATE MFG LatestRanjan Kumar PathakNo ratings yet

- Casting NotesDocument32 pagesCasting NotesGanesh MandpeNo ratings yet

- Emm 315 Materials Forming Processes - CastingDocument40 pagesEmm 315 Materials Forming Processes - CastingNehemiah LemombianNo ratings yet

- Sand Casting and Other Casting ProcessesDocument74 pagesSand Casting and Other Casting ProcessesRashid KareemNo ratings yet

- Metal CastingDocument93 pagesMetal CastinghashimtkmceNo ratings yet

- Metal Casting TechniquesDocument81 pagesMetal Casting TechniquesAshok PradhanNo ratings yet

- Fundamental of Metal Casting 2018Document69 pagesFundamental of Metal Casting 2018Mohd MuhaiminNo ratings yet

- Lec 1 - Casting and Molding ProcessDocument18 pagesLec 1 - Casting and Molding ProcessEslam MansourNo ratings yet

- India Foundry Best Practice GuideDocument325 pagesIndia Foundry Best Practice GuideSiddharth Gupta100% (2)

- Carpentry Joints & Pattern MakingDocument2 pagesCarpentry Joints & Pattern MakingKunalNo ratings yet

- Expendable Mold CastingDocument18 pagesExpendable Mold CastingCheeragNo ratings yet

- Imp ExamDocument15 pagesImp ExamMalvin Roix OrenseNo ratings yet

- Slide Manufacturing Process Week 5 UTHMDocument37 pagesSlide Manufacturing Process Week 5 UTHMwhosamiruladliNo ratings yet

- Casting Process GuideDocument25 pagesCasting Process GuiderahulNo ratings yet

- Foundry Notes by ShiftyDocument22 pagesFoundry Notes by ShiftyRaiyan Shifty100% (1)

- CAD System in Pattern Production 2Document65 pagesCAD System in Pattern Production 2Lengamo L AppostilicNo ratings yet

- Sand CastingDocument81 pagesSand Castingkumarrohit91100% (2)

- Fundamentals of Metal Casting Processes and Mold DesignDocument5 pagesFundamentals of Metal Casting Processes and Mold DesignVignesh SelvarajNo ratings yet

- Casting Technology'Document40 pagesCasting Technology'yakarim0% (1)

- 7 Nptel CastingDocument26 pages7 Nptel CastingmayilsvhecNo ratings yet

- ReportDocument38 pagesReportManojMeenaNo ratings yet

- Appendix I - Pattern Making ProceduresDocument6 pagesAppendix I - Pattern Making ProceduresRafiah N Kamal100% (2)

- Foundry LabDocument50 pagesFoundry Labanon-76437486% (21)

- FW Taylor - Bio Timeline - 010611Document3 pagesFW Taylor - Bio Timeline - 010611Jeffrey Endaya100% (1)

- Pattern CastingDocument17 pagesPattern CastingKishor kumar Bhatia100% (1)

- CastingDocument10 pagesCastingAkshay GargNo ratings yet

- Foundry Process:: Casting TermsDocument23 pagesFoundry Process:: Casting TermskalaivananmekNo ratings yet

- Solutions Manual SM Ch11-20Document88 pagesSolutions Manual SM Ch11-20محمد فطري فيك نظام25% (4)