Professional Documents

Culture Documents

ABT Molecular Site Planning Guide

Uploaded by

miryangelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABT Molecular Site Planning Guide

Uploaded by

miryangelCopyright:

Available Formats

Biomarker Generator Site Planning Guide

ABT Molecular Imaging, Inc.

Biomarker Generator

Site Planning Guide

530991726A

Biomarker Generator Site Planning Guide

530991726A

Table of Contents

TableofContents

1.0

GeneralInformationandIntroduction.................................................................................................4

2.0

BiomarkerGeneratorPlanningServices..............................................................................................5

2.1. Project Management Services.........................................................................................................5

1. Conceptual Layout of the Biomarker Generator Room and Support Areas.............................5

2. Visits to the Site (3)...........................................................................................................................5

2.2. Site Evaluation...................................................................................................................................5

2.3. Site Plan..............................................................................................................................................5

3.0 List of Responsibilities for Facility Planning/Construction and Equipment Installation................6

4.0 General Specifications.........................................................................................................................10

4.1. Architectural Requirements............................................................................................................10

4.1.1 Floor Space Required...............................................................................................................10

4.1.2 Biomarker Generator Delivery Route.....................................................................................10

4.1.3 Ceiling Height.............................................................................................................................10

4.1.4 Floor Conditions.........................................................................................................................10

4.1.5 Interior Finish..............................................................................................................................10

4.1.7 Local Codes................................................................................................................................11

4.2. Mechanical Requirements..............................................................................................................11

4.2.1 Air Handling and Conditioning.................................................................................................11

4.2.2 Heat Dissipation (Ambient Air)................................................................................................11

4.3. Plumbing Requirements.................................................................................................................12

4.3.1 Chilled Water..................................................................................................................................12

4.3.2 Floor Drains................................................................................................................................12

4.3.3 Gas Bottles.................................................................................................................................12

4.4 Electrical Requirements...................................................................................................................13

4.4.1 Electrical Service (Biomarker Generator Only).....................................................................13

4.4.2 Lighting and Convenience Outlets..........................................................................................13

4.4.3 Lighting Intensity........................................................................................................................13

4.4.4 Emergency Power.....................................................................................................................13

Biomarker Generator Site Planning Guide

530991726A

4.4.5 Dedicated Data Line..................................................................................................................13

4.5. Additional Requirements.................................................................................................................13

4.5.1 Remote Diagnostics..................................................................................................................13

4.5.2 Radiation Protection and Monitoring......................................................................................14

5.0 Radiation Aspects.................................................................................................................................14

6.0 Pre-Installation Construction Information..........................................................................................15

7.0 Dimensions and Weights of the ABT Biomarker Generator...........................................................17

7.0 Additional Reference Materials...........................................................................................................20

TBD............................................................................................................................................................20

8.0 Revision Log..........................................................................................................................................21

Biomarker Generator Site Planning Guide

530991726A

1.0 General Information and Introduction

This guide provides a summary of the ABT BIOMARKER GENERATOR installation specifications and the

physical, electrical, and environmental requirements of the equipment. Included is a general room layout to

assist the user during the conceptual stage of facility planning. This layout should be used as a starting

point, as the physical layout for a Biomarker Generator room will vary from site to site due to limitations

imposed by available space, existing structure, or building codes.

The ABT Biomarker Generator is an integrated, small, self-shielded particle accelerator and microchemistry system with a quality control module. The system produces individual qualified doses tested to

the current US Pharmacopeia standards. The shielding system of the Biomarker Generator reduces the

gamma and neutron fields generated by operation of the Biomarker Generator and the bombardment of

associated targets to an exposure rate of less than 2mR/hr at the surface of the shields.

Biomarker Generator Site Planning Guide

530991726A

2.0 Biomarker Generator Planning Services

2.1. Project Management Services

1. Conceptual Layout of the Biomarker Generator Room and Support Areas

2. Visits to the Site (3)

1.

2.

3.

Initial visit

1.1. Introduction

1.2. Review space

1.3. Preliminary Plan

1.3.1. Rigging path

1.3.2. Flooring review

1.3.3. Customer workflows

Construction kickoff

2.1. Customer, Contractor and architect drawing review

2.2. Project schedule

2.3. Permit timelines

Final Site Readiness

3.1. Site walk through

3.2. Power review

3.3. HVAC review

3.4. Chilled water review

3.5. Delivery confirmation

The customer is responsible for radioactive materials, pharmacy and other licenses required for the

operation of the Biomarker Generator.

2.2. Site Evaluation

As part of the available services referenced above, the customer will be provided with documents to support

the planning of the Biomarker Generator facility. In order for ABT Project Management to accurately

evaluate your site and preparation of these documents, the Customer must provide the following minimum

information:

1.

2.

3.

Dimensioned Floor Plan

Room or Building Section showing the proposed Biomarker Generator location

Site Photos (if building is existing)

Provision of the following additional information will enable ABT Biomarker Generator Project Management

to refine the drawings more accurately:

1.

2.

3.

4.

Space utilization on the surrounding four sides of the proposed Biomarker Generator location

Space utilization directly above the proposed Biomarker Generator location

Patient, pedestrian, technician and vehicular traffic flow patterns

Applicable regulations for facilities

2.3. Site Plan

Based on the information received, ABT Biomarker Generator Project Management will prepare a drawing

for review and approval by the Customer and Customers Design Team. The site plan will consist of a room

concept, proposed rigging path, room and rigging dimensions and other technical specifications such as

electrical and architectural requirements.

Biomarker Generator Site Planning Guide

530991726A

3.0 List of Responsibilities for Facility Planning/Construction and

Equipment Installation

Within the context of Biomarker Generator facility project development, there are multiple tasks assigned to

the participating parties. The development is broken down into these phases: site planning, facility

construction, rigging, and testing and commissioning. Each of these is discussed in this section.

The following table presents the standard list of responsibilities for the participating project parties.

Additional responsibilities may be defined within the Terms and Conditions of the Purchase Agreement.

Site Planning

1. Cost estimates for modifications, renovation, construction, licensing, and any

other costs analysis related to the facility.

Customer

2. Designate a project leader that will act as the principle contact for

communicating all matters related to site planning and construction of the

facility.

ABT and

Customer

3. Provide the documentation with the specifications for planning the facility

including major component dimensions and weights, room size and

environmental requirements, radiation shielding guidelines, conduit layout,

power requirements, etc.

ABT

4. Generate initial facility layout drawings.

Customer

5. Provide drawings for equipment layout and installation.

ABT

6. Generate all drawings used for the construction of the facility.

Customer

7. Calculate and design all radiation shielding within facility to meet local and

national codes. This includes radiation shielding for: a) Biomarker Generator

room walls, ceiling, and floor b) isotope transfer lines c) other rooms where

radioisotope delivery is requested.

Customer

8. Determine requirements for radiation monitoring system for the facilitys rooms

and air ventilation/exhaust system.

Customer

9. Approve architectural drawings before construction begins.

ABT

10. Apply for all licenses and permits for construction and operation of a

radioisotope producing facility including any permits required for ABT to install

and test the Biomarker Generator at the new facility.

Customer

11. Provide project schedule and scheduling changes.

Customer

Biomarker Generator Site Planning Guide

530991726A

Facility Construction

1. Procure all materials required for the facilitys construction and operation

including all conduits, cable trays, radiation shielding, area radiation monitors,

water plumbing, electrical power outlets and fixtures, electrical power

transformers, water chiller, air conditioning equipment, safety interlock devices.

Customer

2. Ensure that all conduits, cable trays, water piping, and all customer purchased

equipment in general meet local safety code.

Customer

3. Provide electrical power for the Biomarker Generator as specified in Site

Planning Guide

Customer

4. Provide main electrical fused disconnect breaker for the Biomarker Generator

main power.

Customer

5. Provide dedicated electrical transformer for the Biomarker Generator main

power. Minimum 25 kVA

Customer

6. Provide main power lines to main electrical fused disconnect (4 wires: single

phase lines +Neutral + Earth Ground) Conductors should be copper and meet

local code for 208-230 V single-phase, 70 Amperes.

Customer

7. Provide all electrical cables, switches, relays, and other devices

Customer

8. Provide chilled water for the Biomarker Generator as specified in Site Planning

Guide

Customer

9. Provide and install chilled water piping with insulation to designated point at the

Biomarker Generator water cabinet.

Customer

10. Provide and install cut-off valves, temperature and pressure gauges, and flowrate meter on primary facility chilled water lines

Customer

11. Provide room air-conditioning and ventilation for the Biomarker Generator as

specified in Site Planning Guide

Customer

12. Provide and install air-conditioning ventilation monitoring devices for negative

room pressure in the Biomarker Generator room and other rooms where

radioisotope may be present.

Customer

13. Provide rigging access to Biomarker Generator room for the Biomarker

Generator as specified in Site Planning Guide.

Customer

Biomarker Generator Site Planning Guide

530991726A

Rigging the Biomarker Generator into the Facility

1. Inspect site for facility readiness to install the Biomarker Generator.

ABT

2. Provide clear entrance with adequate space to deliver the Biomarker Generator

to the entrance of the Biomarker Generator room. NOTE: The Biomarker

Generator will be packed and shipped on a single flat bed trailer. The truck

hauling the Biomarker Generator must have clear access to a landing pad 8 X

8 adjacent to the Biomarker Generator room. If this is not possible then the

scope of work will be outside of the standard rigging.

Customer

3. Rigging of the Biomarker Generator into the facility. Unless otherwise stated on

the sales agreement.

Customer

4. Providing crane, forklift, and other heavy rigging equipment for installing the

Biomarker Generator. Unless otherwise stated on the sales agreement.

Customer

5. Providing specialized fixtures for lifting and moving the major Biomarker

Generator components.

ABT

6. Providing supervision for rigging the Biomarker Generator into the facility

ABT

Biomarker Generator Installation and Testing

1. Ensure that the facility is ready to begin the installation and that all conditions

related to facility electrical, ventilation, water, etc. meet the specifications in the

Site Planning Guide. NOTE: ABT will only start the installation when all items on

the Site Planning Guide Check-off sheet are complete. The Customer must

complete this list and send a copy to ABT prior to beginning the installation.

Customer

2. Provide and install regulators with CGA fittings on gas cylinders. ABT will

provide the initial lecture size bottle of hydrogen and the customer must provide

a medium sized bottle of Argon and regulator for chemistry and accelerator

operation.

Customer

3. Connect the Biomarker Generator main power lines to the main fused

disconnect (4 wires: Single-phase lines +Neutral + Earth Ground)

ABT

4. Inform ABT personnel of all special safety and regulatory procedures that must

be followed during installation.

Customer

5. Provide tools and equipment for routine maintenance and general

housekeeping (i.e., broom, mop, buckets, hand tools, drill, vacuum cleaner, etc.)

Customer

6. Provide specialized tools and equipment for installation.

ABT

7. Assemble and connect all Biomarker Generator components.

ABT

Biomarker Generator Site Planning Guide

8. Optimize and test the Biomarker Generator (IQ, OQ)

9. Provide standard laboratory equipment and consumables (i.e., latex gloves,

glass and plastic wear, syringes, medical vials, de-ionized water, acetone,

methanol, etc.)

10. Perform acceptance testing (PQ)

ABT

Customer

ABT

530991726A

Biomarker Generator Site Planning Guide

530991726A

4.0 General Specifications

4.1. Architectural Requirements

4.1.1 Floor Space Required

A Biomarker Generator room will include the self-shielded accelerator including a control cabinet, an ISO 5

chemistry and QC area, and an operators console and utilities access adjacent to the shielding. In

addition, ABT will provide a 20 kW water-to-water chiller which should be installed in a separate location.

The room is recommended to have inside dimensions of 18ft X 18ft (5.5m X 5.5m) clear INSIDE room

dimensions.

Radioactive products from the Biomarker Generator are delivered directly to the Biomarker Generator

chemistry area attached to the Biomarker Generator shields. An option is available to allow radioisotope

from the Biomarker Generators targets to be delivered to customers own hot cell or adjacent to a

Biomarker Generator. In this case, a second operators console can be located adjacent to the customers

hot cell. The facility design must include conduits and shielding for delivery of the product from the

Biomarker Generator to the customer designated areas. Delivery to hot cells or chemistry areas other than

adjacent to the Biomarker shielding must be within 15 ft. (4.5m) of the shielding.

Additional space for the storage of spare parts, tools and consumables in close proximity to the Biomarker

Generator room is recommended. In addition, the customer must provide an area for long-lived waste

storage. A minimal amount of waste is expected so an area no more than 2ft X1ft X1ft will be sufficient.

4.1.2 Biomarker Generator Delivery Route

The Biomarker Generator will be delivered through any opening with a minimum of 48in (1.22m) in width

and 7ft (2.13m) tall. If the delivery path utilizes internal corridors, the path must have clear dimensions of at

least 48in (1.22m) wide by 8 ft. (2.44m) high. The delivery path must also be structurally capable of

handling a dynamic load of 8,000 lbs (3,600 kg) during delivery. The clear working height inside the room

during Biomarker Generator rigging shall be a minimum height of 8 ft. (2.44m).

4.1.3 Ceiling Height

The minimum height of the interior finished ceiling of the Biomarker Generator room is 8.0 ft. (2.44m).

4.1.4 Floor Conditions

Surface finish flatness: 1/8 in. (3mm) over 10 ft. (3.0m) run

Thickness: Six inch cement slab with a layer of number five rebar in one foot centers at a depth of three

inches.

4.1.5 Interior Finish

10

Biomarker Generator Site Planning Guide

530991726A

The ceiling and interior walls of the Biomarker Generator room can be finished to the customer's desired

specification. It is recommended that the floor be covered with a seamless vinyl covering for ease of

cleaning. In addition, the Biomarker Generator room should have low particulate ceiling tiles.

4.1.7 Local Codes

If local construction codes conflict with the specifications in this guide, the local codes will overrule

specifications. The resulting change, as well as the final design, must be accepted by ABT before

construction begins. Changes effected after acceptance of final design may seriously affect the time

required to install the Biomarker Generator once it arrives on your site. For this reason, designers,

contractors, and subcontractors should work closely with the ABT Project Manager on all proposed changes

to the accepted design.

4.2. Mechanical Requirements

4.2.1 Air Handling and Conditioning

The Biomarker Generator room shall be maintained at negative pressure relative to the surrounding areas.

Ambient temperature: 70F 8F (21C 3C)

Relative humidity: 40%-55%, non-condensing

It is recommended that the customer provide an appropriate monitor with an audible alarm to insure that the

differential pressure between spaces is maintained. It is also recommended that the customer provide an

appropriate visual humidity monitor with an audible alarm to ensure that the specified humidity levels are

maintained. It is the responsibility of the customer to ensure that the exhaust control and monitoring system

complies with applicable state and local regulations.

4.2.2 Heat Dissipation (Ambient Air)

Biomarker Generator: 23,373 Btu/h (6.9 kW) which will be reduced to 10,748 BTU (3,150 kW) by a 20 kW

water-to-water chiller supplied by ABT. Customer will provide chilled water source. If customers facility

does not have access to an acceptable chilled water source, ABT can provide specifications for an air to

water option.

Biomarker Generator Cooling Water Requirements

Component

RF Cabinet

Magnet

RF

Ion Source

Target

Mechanical Pump

Utility Cabinet

Chemistry

Chiller**

Net kW/HR

kW/Hr

500

2,000

4,000

100

40

60

100

50

6,850**

Heat Exchange via

Outside/Water-to-Water Chiller

(1,500)

(2,000)

(100)

(40)

(60)

(2,700)

Net Heat Load to

HVAC

500

500

2000

100

50

3,150*

* 3,150 kW = ~ 11,000 BTUs = ~ 1 ton HVAC required

** If indoor air-to-water required, additional 2,500 kW in heat from chiller = 9,350 kW = ~32,000 BTUs = 2.6 ton HVAC

11

Biomarker Generator Site Planning Guide

530991726A

Note: The facility air handling and conditioning system must automatically compensate for the changing load

conditions that occur when the Biomarker Generator is operating (maximum heat dissipated to the air) and when the

Biomarker Generator is at rest (minimum heat dissipated to the air). Under NO circumstances is the heat load from the

cabinets and the Biomarker Generator to be assumed as available for supplemental humidity control. Such

consideration will result in reduced cooling capacity provided to this room during Biomarker Generator operations.

4.3. Plumbing Requirements

4.3.1 Chilled Water

A 20 kW heat exchanger and deionizer water system adequate to maintain the Biomarker Generator and

ancillary equipment is provided by ABT. The customer must supply chilled water to the heat exchanger as

follows:

Inlet water temperature: 45 F 5 F (7 C 3C)

Required flow rate: 10 gal/min (38 L/min)

Heat exchanger load: 70,000 Btu/h (20.5 kW) at full load

Max inlet water pressure: 40 psig (37.9 l/min)

Supply line CX: 1 in. NPT Female

Return line CX: 1 in. NPT Female

The party providing the external cooling system is responsible for connecting the chilled water to the ABT

water recirculation system and for installing a manual cutoff valve, pressure and temperature gauges, and a

flow meter to monitor chilled water parameters.

If an existing chilled water plant of sufficient thermal/volumetric capacity is to be utilized, the system must

be operational continuously. All reductions/restrictions/outages must be coordinated with the Biomarker

Generator staff as a loss of chilled water results in Biomarker Generator shutdown.

Note: The chilled water system must automatically compensate for the changing load conditions that occur when the

Biomarker Generator is operating and at rest.

4.3.2 Floor Drains

The 20 kW water-to-water chiller contains less than 3 gallons of water at any one time and therefore a floor

drain is not necessary. There is no constant drainage from the Biomarker Generator. A floor drain can be

added by the customer if required by local building codes.

4.3.3 Gas Bottles

A cylinder of hydrogen gas is required for the system. ABT provides the initial hydrogen container (less than

one liter) and regulator which will be contained in the utility enclosure provided with the Biomarker

Generator. A medium sized bottle of Argon is required for the operation of the Biomarker Generator which

is to be supplied by the customer, as well as the appropriate regulators. The location of the Argon gas does

not have to be in the Biomarker Generator room but must be within 50 feet of the Biomarker Generator.

The production of future radioisotopes may have additional gas requirements which will increase the total

gas bottles required. Installation of a secure, approved mounting system and any signage required is the

responsibility of the customer.

12

Biomarker Generator Site Planning Guide

530991726A

4.4 Electrical Requirements

4.4.1 Electrical Service (Biomarker Generator Only)

Main disconnect: 208 - 230V, 70 A, single-phase, fused disconnect, with slow blow fuses, provided and

installed by the customer

Regulation: 5% of nominal voltage (not to be less than 200 VAC during full load)

Lines: 2 single phase lines, 1-neutral and 1-insulated ground (copper)

Ground: separate copper rods driven into the earth outside the facility (if not already provided)

Power draw: ~ 15 kVA

Note: This power is dedicated to the Biomarker Generator only.

4.4.2 Lighting and Convenience Outlets

Interior lighting, environmental conditioning equipment, general purpose receptacles, and any other

electrical functions must be powered from an electrical panel that is independent of the Biomarker

Generator power supply.

4.4.3 Lighting Intensity

Lighting levels during normal operation are at the discretion of the customer.

4.4.4 Emergency Power

No emergency power is required for the operation or protection of the BIOMARKER GENERATOR. It is

recommended that an uninterrupted power supply (UPS) with battery backup be provided for the control

station with a minimum battery backup time no less than thirty (30) minutes.

4.4.5 Dedicated Data Line

A dedicated Ethernet line located near the control console is required for system support.

4.5. Additional Requirements

4.5.1 Remote Diagnostics

The Remote Diagnostics Option for the Biomarker Generator system allows for the monitoring and

diagnosis of remote systems without a special service engineer visit to the site. This option allows ABT

service technicians to connect to the remote site, observe the actions of the local site personnel and control

system responses, and intervene to run diagnostics or other data gathering functions. This service is

available 24 hours a day and provides remote sites with the best service support possible. The method of

connection to the remote site will vary from site to site depending on the infrastructure the customer has

chosen or the infrastructure that is available to the customer. All sites require LogMeIn remote control

software package for this purpose.

It is very important that the planning for Remote Diagnostics occurs early in the Site Planning phase of a

project. The infrastructure needs to be in place by the time the Installation Engineer arrives to connect,

13

Biomarker Generator Site Planning Guide

530991726A

start-up and test the Biomarker Generator. This allows the capability to be used during the installation

process, which shortens the overall installation time.

ABT will coordinate the configuration of the network with the customers network manager, who will be

responsible for setting up and maintaining security and access.

4.5.2 Radiation Protection and Monitoring

The ABT Biomarker Generator produces Fluorine at the millicurie level. The Biomarker Generator room

must be a controlled radiation area for badged workers. The shielding is designed to result in a radiation

measurement of less than 2 mR/hr on the shield surface. Radiation survey monitors for the facility shall be

provided by the customer. The room dimensions and self-shielding will allow rooms outside the Biomarker

Generator room to be general occupancy with standard 8 cinderblock walls.

The Biomarker Generator will be exhausted into the room without additional connection to the facilities

HVAC system. Based upon the 5000 L internal volume and the cooling airflow through the shield, ABT

estimates that exposure from activation of air from operation of the cyclotron for a single 20 minute run

would be at least a factor of 1000 less than the regulatory limits of 50 mR/yr and 2 mR/hr.

Some jurisdictions may have different requirements with respect to pressure requirements within the

cyclotron room and exhaust monitoring. For additional information, consult your local Radiation Safety

Officer and ABT.

5.0 Radiation Aspects

DoseCalculationsfromtheABTBiomarkerGeneratorprototypewith1AontargetarereflectedinFigure

3.

14

Biomarker Generator Site Planning Guide

530991726A

6.0 Pre-Installation Construction Information

The following pre-installation construction is the customer's responsibility.

15

Biomarker Generator Site Planning Guide

530991726A

Provision of a concrete loading/unloading/staging pad with a minimum size of 10 ft. by 12 ft. (3.05m

by 3.6m) next to Biomarker Generator entranceway. The size of this pad must be increased to

accommodate for any building eaves that overhangs the entranceway in a depth greater than 12 in.

(30.5 cm). Contractors shall coordinate the location of this pad with Project Management Planning

staff.

A stable, compacted surface for routing the delivery trucks and rigging equipment that will be

brought onto the site. The surface must be capable of supporting the weight of the trucks and

equipment. Recommended surfaces are asphalt paving, concrete paving, or steel plate over a

compacted subsurface. ABT is not responsible for any structural improvements needed to bring

heavy equipment on site for the rigging of the Biomarker Generator. ABT will not be responsible for

repairs to surfaces that are not sufficient to support the applied loads.

16

Biomarker Generator Site Planning Guide

530991726A

7.0 Dimensions and Weights of the ABT Biomarker Generator

Figure 1 ABT Biomarker Generator

E&F

E&F

A

B&C

B&C

A1 A3

A1A3

17

Biomarker Generator Site Planning Guide

J

I

18

530991726A

Biomarker Generator Site Planning Guide

530991726A

Dimensions, Weight and Floor Load of the Biomarker Generator

Item

Description

Width in

Diameter

Depth in

Height in

Accelerator

48

42

7,000 (3,200)

B&C

Lower Shields

(Stationary)

27

10,000 (4,550) Total

5,000 (2,300) / each

Floor Shielding

(Not Pictured)

48

14

3,900 (1,800)

E&F

Top Shields

37

13,400 (6,100) Total

6,700 (3,050) / each

500 (230)

Control Cabinet

28

32

78

Water-to-Water Chiller

14.5

27.6

22.6

TOTAL ACCELERATOR

168 (76)

34,968 (15,895)

A1 A3

Accelerator Legs

B&C

Floor Load Top Down

48

64

*700 (320) / sq foot

G (3)

Screw Jacks Top Up

12

48

12

94

*4,400 (2,000) /sq foot

*2,400 (1,100) / each

Chemistry Table

52

30

40

1,100 (500)

Table w/ Laminar Flow

Hood

52

30

80

1,300 (600)

19

Weight lb (kg)/

*Floor Load lb (kg)

Biomarker Generator Site Planning Guide

530991726A

7.0 Additional Reference Materials

Following is a list of additional documents that can be obtained from ABT for site planning purposes:

TBD

20

Biomarker Generator Site Planning Guide

8.0 Revision Log

ECONumber

201004007

EffectiveDate

04/16/2010

Revision

A

Pages

All

21

ReasonforRevision

InitialIssue

530991726A

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The NicotinaDocument8 pagesThe Nicotinab0beiiiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MAS Assessment Exam Answer Key SolutionDocument7 pagesMAS Assessment Exam Answer Key SolutionJonalyn JavierNo ratings yet

- PWC Annual ReportDocument46 pagesPWC Annual ReportAigulNo ratings yet

- Trend Graphs - Sample AnswerDocument4 pagesTrend Graphs - Sample AnswerannieannsNo ratings yet

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingAkmaldeen AhamedNo ratings yet

- Computer & Desk Stretches (Estiramientos. Ordenador y Silla) (English)Document2 pagesComputer & Desk Stretches (Estiramientos. Ordenador y Silla) (English)Salvatore VargasNo ratings yet

- Abinitio Interview QuesDocument30 pagesAbinitio Interview QuesVasu ManchikalapudiNo ratings yet

- Delimano Healthy Pancakes Ebook PDFDocument25 pagesDelimano Healthy Pancakes Ebook PDFmiryangel100% (1)

- PQ of Vial Washer Ensures Removal of ContaminantsDocument25 pagesPQ of Vial Washer Ensures Removal of ContaminantsJuan DanielNo ratings yet

- Coduri Boala 999Document16 pagesCoduri Boala 999Valentin100% (6)

- Coduri Boala 999Document16 pagesCoduri Boala 999Valentin100% (6)

- Oboseala Cronica PDFDocument58 pagesOboseala Cronica PDFmiryangel100% (1)

- Winmodems and Linux HowtoDocument10 pagesWinmodems and Linux Howtoa.gNo ratings yet

- Its MagicDocument16 pagesIts MagicRaju100% (15)

- Adaptive Mechanisms in Stress Management in The Professional Organizations With Medical ProfileDocument6 pagesAdaptive Mechanisms in Stress Management in The Professional Organizations With Medical ProfilemiryangelNo ratings yet

- Operating Manual Ergometrics ER 900 (English) PDFDocument84 pagesOperating Manual Ergometrics ER 900 (English) PDFmiryangelNo ratings yet

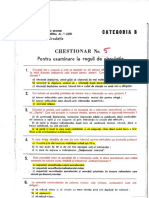

- M1HISTEIUl DE INTONE ClTESOIIA B lJT1EI ..SPECTORATUl GENERAl At Direcfia Circulafie CHESTIONAR Nr. \() Pentru examinare la reguli de circulafieDocument5 pagesM1HISTEIUl DE INTONE ClTESOIIA B lJT1EI ..SPECTORATUl GENERAl At Direcfia Circulafie CHESTIONAR Nr. \() Pentru examinare la reguli de circulafiemiryangelNo ratings yet

- Chestionar 18Document5 pagesChestionar 18miryangelNo ratings yet

- Chestionar 12Document5 pagesChestionar 12miryangelNo ratings yet

- mn_OntiCfld CilCUidlle CHESTIONAR Nr. \':\Pentru examinare la reguli de circulatieDocument5 pagesmn_OntiCfld CilCUidlle CHESTIONAR Nr. \':\Pentru examinare la reguli de circulatiemiryangelNo ratings yet

- Oboseala CronicaDocument58 pagesOboseala Cronicamiryangel100% (13)

- Chestionar 14Document5 pagesChestionar 14miryangelNo ratings yet

- Chestionar 13Document5 pagesChestionar 13miryangelNo ratings yet

- Chestionar NR.: Categoiia BDocument5 pagesChestionar NR.: Categoiia BmiryangelNo ratings yet

- Winmodems and Linux HowtoDocument10 pagesWinmodems and Linux Howtoa.gNo ratings yet

- The Respiratory System: Symptoms, Examination, and SyndromesDocument27 pagesThe Respiratory System: Symptoms, Examination, and SyndromesmiryangelNo ratings yet

- Alfabetul FlorilorDocument33 pagesAlfabetul Florilorsfinx100007696No ratings yet

- Arhitectura CalculatoarelorDocument22 pagesArhitectura CalculatoarelormiryangelNo ratings yet

- Bake Perfect Bread with the HD9040 BreadmakerDocument160 pagesBake Perfect Bread with the HD9040 BreadmakermiryangelNo ratings yet

- Johnson SugarDocument45 pagesJohnson SugarmiryangelNo ratings yet

- Sleeve Gastrectomy DietDocument26 pagesSleeve Gastrectomy DietmiryangelNo ratings yet

- Operating Manual Ergometrics ER 900 (English)Document84 pagesOperating Manual Ergometrics ER 900 (English)miryangelNo ratings yet

- FormuleDocument3 pagesFormulemiryangelNo ratings yet

- Arhitectura CalculatoarelorDocument29 pagesArhitectura CalculatoarelormiryangelNo ratings yet

- Pakage PAU (Fruits)Document70 pagesPakage PAU (Fruits)Gary Bhullar57% (7)

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Document35 pagesEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiNo ratings yet

- Mechanical Function of The HeartDocument28 pagesMechanical Function of The HeartKarmilahNNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingFranklin SilvaNo ratings yet

- Name: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh MishraDocument5 pagesName: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh Mishrachakshu purohitNo ratings yet

- Polygon shapes solve complex mechanical problemsDocument6 pagesPolygon shapes solve complex mechanical problemskristoffer_mosshedenNo ratings yet

- Baella-Silva v. Hulsey, 454 F.3d 5, 1st Cir. (2006)Document9 pagesBaella-Silva v. Hulsey, 454 F.3d 5, 1st Cir. (2006)Scribd Government DocsNo ratings yet

- Applying Graph Theory to Map ColoringDocument25 pagesApplying Graph Theory to Map ColoringAnonymous BOreSFNo ratings yet

- All Paramedical CoursesDocument23 pagesAll Paramedical CoursesdeepikaNo ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- New Pacific Timber v. Señeris, 101 SCRA 686Document5 pagesNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamNo ratings yet

- IPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesDocument40 pagesIPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesОлегNo ratings yet

- Phenolic Compounds in Rice May Reduce Health RisksDocument7 pagesPhenolic Compounds in Rice May Reduce Health RisksMuhammad Usman AkramNo ratings yet

- ListDocument4 pagesListgeralda pierrelusNo ratings yet

- Alarm Management Second Ed - Hollifield Habibi - IntroductionDocument6 pagesAlarm Management Second Ed - Hollifield Habibi - IntroductionDavid DuranNo ratings yet

- Chapter 3-The Hospitality & Travel Marketing SystemDocument14 pagesChapter 3-The Hospitality & Travel Marketing SystemCharis AbadNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- Commu I ReviewedDocument45 pagesCommu I ReviewedCabdirisaaq CabdisalanNo ratings yet

- 2018 JC2 H2 Maths SA2 River Valley High SchoolDocument50 pages2018 JC2 H2 Maths SA2 River Valley High SchoolZtolenstarNo ratings yet

- MT8820C LTE Measurement GuideDocument136 pagesMT8820C LTE Measurement GuideMuthannaNo ratings yet

- Going to the cinema listening practiceDocument2 pagesGoing to the cinema listening practiceMichael DÍligo Libre100% (1)

- Biometric SecurityDocument495 pagesBiometric SecurityPlay100% (1)

- Assignment - Stocks and CBDocument2 pagesAssignment - Stocks and CBGhulam HassanNo ratings yet