Professional Documents

Culture Documents

Ni-Cd battery installation guide

Uploaded by

Prem SagarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ni-Cd battery installation guide

Uploaded by

Prem SagarCopyright:

Available Formats

April 2007

Block battery Ni-Cd range

Block battery Ni-Cd range

Type SBLE, SBM, SBH standard

Installation and operating instructions

Type SBLE, SBM, SBH standard

Installation and operating instructions

Important recommendations

I

Never allow an exposed flame or

spark near the batteries, particularly

while charging.

I Never smoke while performing any

operation on the battery.

I For protection, wear rubber gloves,

long sleeves, and appropriate splash

goggles or face shield.

I The electrolyte is harmful to skin and

eyes. In the event of contact with

skin or eyes, wash immediately with

plenty of water. If eyes are affected,

flush with water, and obtain

immediate medical attention.

I Remove all rings, watches and other

items with metal parts before

working on the battery.

I Use insulated tools.

I Avoid static electricity and take

measures for protection against

electric shocks.

I Discharge any possible static

electricity from clothing

and/or tools by touching an

earth-connected part "ground"

before working on the battery.

1. Receiving the shipment

Unpack the battery immediately upon

arrival. Do not overturn the package.

Transport seals are located under the

cover of the vent plug.

I The battery is normally shipped

empty and discharged, do not remove

the plastic transport seals until ready

to fill the battery.

I If the battery is shipped filled and

charged, the battery is ready for

installation. Remove the plastic

transport seals only before use.

The battery must never be charged

with the transport seals in place as

this can cause permanent damage.

2. Storage

Store the battery indoors in a dry, clean,

cool location (0C to +30C / +32F to

+86F) and well ventilated space on open

shelves.

Do not store in direct sunlight or expose

to excessive heat.

I

Cells empty and discharged

Saft recommends to store cells empty

and discharged. This ensures

compliance with IEC 60623 section

4.9 (storage)

Cells can be stored like this for many

years.

I

Cells filled and charged

If cells are stored filled, they must be

fully charged prior to storage.

Cells may be stored filled and charged

for a period not exceeding 12 months

from date of dispatch.

Storage of a filled battery at

temperatures above +30C (+86F) can

result in loss of capacity. This can be as

much 5 % per 10C (18F) above +30C

(+86F) per year.

I When deliveries are made in cardboard

boxes, store without opening the boxes.

I When deliveries are made in plywood

boxes, open the boxes before the

storage. The lid and the packing material

on top of the cells must be removed.

3. Installation

3.1. Location

Install the battery in a dry and clean

room. Avoid direct sunlight and heat.

The battery will give the best performance

and maximum service life when the

ambient temperature is between +10C

to +30C (+50F to +86F).

3.2. Ventilation

During the last part of charging, the

battery is emitting gases (oxygen and

hydrogen mixture). At normal floatcharge the gas evolution is very small

but some ventilation is necessary.

Note that special regulations for

ventilation may be valid in your area

depending on the application.

3.3. Mounting

Verify that cells are correctly

interconnected with the appropriate

polarity. The battery connection to load

should be with nickel plated cable lugs.

Recommended torques for terminal bolts

are:

M 6 = 11 1.1 N.m

M 8 = 20 2

N.m

M 10 = 30 3

N.m

The connectors and terminals should be

corrosion-protected by coating with a

thin layer of anti-corrosion oil.

Remove the transport seals and close

the vent plugs.

3.4. Electrolyte / cell oil

I

Cells delivered empty and discharged:

If the electrolyte is supplied dry, prepare

it according to its separate instructions

sheet. The electrolyte to be used is E22.

Remove the transport seals just before

filling.

Fill the cells about 20 mm above the

lower level mark with electrolyte.

Wait 4 to 24 hours and adjust if

necessary before commissioning.

It is recommended to add the cell oil

after the commissioning charge, with the

syringe, according to the quantity

indicated in the Table A.

5. Charging in service

Table A: Standard range

Continuous parallel operation, with

occasional battery discharge.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

I Cells delivered filled and charged:

Check the level of electrolyte. It should

not be more than 20 mm below the

upper level mark. If this is not the case,

adjust the level with distilled or deionized

water. Cells delivered filled have already

the cell oil in place.

4. Commissioning

Verify that the ventilation is adequate

during this operation.

A good commissioning is important.

Charge at constant current is preferable.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

If the current limit is lower than indicated

in the Table A, charge proportionally for

a longer time.

I

For cells filled on location or for filled

cells which have been stored more

than 6 months:

charge 10 h at 0.2 C5 A

(recommended)

or charge for 30 h at 1.65 V/cell,

current limited to 0.2 C5 A.

discharge at 0.2 C5 A to 1.0 V/cell

charge according to the section below.

For cells filled and charged by the

factory and stored less than

6 months:

charge 10 h at 0.2 C5 A

(recommended)

or charge 24 h at 1.65 V/cell,

current limited to 0.2 C5 A.

or charge 48 h at 1.55 V/cell,

current limited to 0.2 C5 A.

I

Cell oil & electrolyte after

commissioning: wait for 4 hours after

commissioning. Cells delivered filled by

the factory have already the cell oil in

place.

For cells filled on location, add the cell

oil with the syringe, according to the

quantity indicated in the Table A.

Check the electrolyte level and adjust it

to the upper level mark by adding:

distilled or deionized water for cells

filled by the factory

electrolyte for cells filled on location.

The battery is ready for use.

For two level charge:

float level

= 1.42 0.01 V/cell for L cells

= 1.40 0.01 V/cell for M and H cells

high level

= 1.47 - 1.70 V/cell for L cells

= 1.45 - 1.70 V/cell for M and H cells.

A high voltage will increase the speed

and efficiency of the recharging.

For single level charge:

1.43 - 1.50 V/cell.

I

Buffer operation, where the load

exceeds the charger rating.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

1.50 - 1.60 V/cell.

6. Periodic Maintenance

I Keep

the battery clean using only

water. Do not use a wire brush or

solvents of any kind. Vent plugs can be

rinsed in clean water if necessary.

I Check

the electrolyte level. Never let

the level fall below the minimum level

mark. Use only distilled or deionized

water to top-up. Experience will tell the

time interval between topping-up.

Note: Once the battery has been filled

with the correct electrolyte either at

the battery factory or during the

battery commissioning, there is no

need to check the electrolyte density

periodically. Interpretation of density

measurements is difficult and could be

misleading.

Cell

type

Char- Electrolyte Quant. Cell

of conging

per cell

Cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per type

(A)

(l) vent pole

(kg)

Char- Electrolyte Quant. Cell

of conging

per cell

Cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per type

(A)

(l) vent pole

(kg)

Char- Electrolyte Quant. Cell

of conging

per cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per

(A)

(l) vent pole

(kg)

SBLE 7.5

SBLE 15

SBLE 22

SBLE 30

1.5

3.0

4.4

6.0

0.08

0.11

0.17

0.15

0.24

0.35

0.53

0.46

10

10

15

15

M6

M6

M6

M6

SBM 11

SBM 15

SBM 22

SBM 30

2.2

3.0

4.4

6.0

0.10

0.11

0.15

0.15

0.30

0.33

0.46

0.46

15

15

15

15

M6

M6

M6

M6

SBH 8.3

SBH 12

SBH 16

SBH 19

1.7

2.4

3.2

3.8

0.12

0.14

0.16

0.25

0.36

0.44

0.48

0.77

10

15

15

15

M6

M6

M6

M6

SBLE 40

SBLE 47

SBLE 62

SBLE 75

8.0

9.4

12

15

0.29

0.19

0.23

0.32

0.90

0.59

0.70

1.0

30

20

30

25

M6

M6

M6

M8

SBM 43

SBM 56

SBM 65

SBM 84

8.6

11

13

17

0.31

0.36

0.32

0.39

0.95

1.1

1.0

1.2

20

20

25

25

M6

M6

M8

M8

SBH 29

SBH 39

5.8

7.8

0.31

0.36

0.95

1.1

20

25

M6

M8

SBH 49

SBH 59

9.8

12

0.42

0.49

1.3

1.5

30

30

M8

M10

SBLE 95

SBLE 110

SBLE 140

SBLE 185

19

22

28

37

0.39

0.39

0.49

0.65

1.2

1.2

1.5

2.0

25

30

30

40

M8

M10

M10

M10

SBM 112

SBM 138

SBM 161

22

28

32

0.45

0.55

0.61

1.4

1.7

1.9

30

40

40

M8

M10

M10

SBH 69

SBH 79

SBH 88

14

16

18

0.58

0.58

0.74

1.8

1.8

2.3

40

40

50

M10

M10

M10

SBLE 230

SBLE 275

SBLE 325

SBLE 375

46

55

65

75

0.74

0.94

1.13

1.29

2.3

2.9

3.5

4.0

50 M10

60 M10

35 2 x M10

40 2 x M10

SBM 184

SBM 208

SBM 231

SBM 277

37

42

46

55

0.78

0.94

0.94

1.13

2.4

2.9

2.9

3.5

0.71

2.2

50

M10

0.87

1.20

2.7

3.7

60 M10

40 2 x M10

SBLE 415 83

SBLE 460 92

SBLE 510 102

SBLE 550 110

1.39

1.49

1.68

1.88

4.3

4.6

5.2

5.8

45

50

55

60

SBM 300

SBM 323

SBM 346

60

65

69

1.20

1.26

1.42

3.7

3.9

4.4

1.20

1.46

3.7

4.5

40 2 x M10

50 2 x M10

50 2 x M10

60 2 x M10

2.04

2.14

2.23

2.43

6.3

6.6

6.9

7.5

43

47

50

53

4.8

5.3

5.8

4.4

5.7

120

130

140

150

1.55

1.72

1.88

1.42

1.84

SBLE 600

SBLE 650

SBLE 700

SBLE 750

2.20

2.10

6.8

6.5

50 3 x M10

50 3 x M10

1.88

1.84

2.10

5.8

5.7

6.5

2.78

SBLE 830

SBLE 925

SBLE 1020

SBLE 1100

166

185

204

220

2.81 8.7

2.98 9.2

3.36 10.4

3.75 11.6

60

50

55

60

2.33

2.82

7.2

8.7

SBLE 1200

SBLE 1300

SBLE 1400

SBLE 1500

240

260

280

300

3.91

4.30

4.69

5.05

12.1

13.3

14.5

15.6

52

56

60

55

5.44 16.8

5.63 17.4

58

60

SBM 369 74

SBM 392 78

3 x M10 SBM 415 83

3 x M10 SBM 438 88

3 x M10 SBM 461 92

3 x M10 SBM 505 101

3 x M10 SBM 555 111

4 x M10 SBM 625 125

4 x M10

4 x M10 SBM 690 138

SBM 740 148

5 x M10 SBM 830 166

5 x M10

5 x M10 SBM 920 184

6 x M10 SBM 965 193

SBM 1040 208

6 x M10

6 x M10 SBM 1150 230

SBM 1220 244

SBM 1390 278

3.82 11.8

3.69 11.4

4.72 14.6

50 M10 SBH 98 20

60 M10

60 M10 SBH 118 24

40 2 x M10 SBH 137 28

40 2 x M10 SBH 157 31

40 2 x M10 SBH 177 35

50 2 x M10 SBH 196 39

50 2 x M10 SBH 236 47

60 2 x M10 SBH 265 53

60 2 x M10 SBH 294 59

60 2 x M10 SBH 353 71

60 2 x M10

50 3 x M10 SBH 393 79

SBH 471 94

50 3 x M10

60 3 x M10 SBH 491 98

SBH 590 118

60 3 x M10

50 4 x M10 SBH 640 128

60 4 x M10 SBH 705 141

SBH 765 153

60 4 x M10

40 6 x M10 SBH 865 173

60 5 x M10 SBH 920 184

4.66 14.4

5.50 17.0

5.60 17.3

60 5 x M10

60 6 x M10

60 6 x M10

SBLE 1600 320

SBLE 1660 332

2 x M10

2 x M10

2 x M10

2 x M10

2.78 8.6

3.11 9.6

3.79 11.7

8.6

60 3 x M10

2.82 8.7

3.69 11.4

50 4 x M10

60 4 x M10

3.53 10.9

4.63 14.3

50 5 x M10

60 5 x M10

4.21 13.0

5.31 16.4

5.24 16.2

50 5 x M10

60 5 x M10

60 5 x M10

5.92

6.28

57 6 x M10

60 6 x M10

18.3

19.4

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

I Check

every two years that all

connectors are tight. The connectors

and terminal bolts should be corrosionprotected by coating with a thin layer

of anti-corrosion oil.

I Check

the charging voltage. If a battery

is parallel connected, it is important

that the recommended charging

voltage remains unchanged.

The charging voltage should be

checked at least once yearly.

High water consumption of the battery

is usually caused by improper voltage

setting of the charger.

Saft

Industrial Battery Group

7. Changing electrolyte

8. Environment

In most stationary battery applications,

the electrolyte will retain its effectiveness

for the life of the battery. However,

under special battery operating

conditions, if the electrolyte is found to

be carbonated, the battery performance

can be restored by replacing the

electrolyte.

To protect the environment all used

batteries must be recycled.

Contact your local Saft representative

for further information.

The electrolyte type to be used for

replacement in these cells is: E13.

Refer to "Electrolyte Instructions".

Doc N 21124-2-0407

12, rue Sadi Carnot

93170 Bagnolet - France

Tel: +33 1 49 93 19 18

Fax: +33 1 49 93 19 64

Data in this document is subject to change without

notice and becomes contractual only after written

confirmation.

www.saftbatteries.com

Pragma - Printed in France - 5k

Socit anonyme au capital de 31 944 000

RCS Bobigny B 383 703 873

April 2007

Block battery Ni-Cd range

Block battery Ni-Cd range

Type SBL, SBM, SBH non standard

Installation and operating instructions

Type SBL, SBM, SBH non standard

Installation and operating instructions

Important recommendations

I

Never allow an exposed flame or

spark near the batteries, particularly

while charging.

I Never smoke while performing any

operation on the battery.

I For protection, wear rubber gloves,

long sleeves, and appropriate splash

goggles or face shield.

I The electrolyte is harmful to skin and

eyes. In the event of contact with

skin or eyes, wash immediately with

plenty of water. If eyes are affected,

flush with water, and obtain

immediate medical attention.

I Remove all rings, watches and other

items with metal parts before

working on the battery.

I Use insulated tools.

I Avoid static electricity and take

measures for protection against

electric shocks.

I Discharge any possible static

electricity from clothing

and/or tools by touching an

earth-connected part "ground"

before working on the battery.

1. Receiving the shipment

Unpack the battery immediately upon

arrival. Do not overturn the package.

Transport seals are located under the

cover of the vent plug.

I The battery is normally shipped

empty and discharged, do not remove

the plastic transport seals until ready

to fill the battery.

I If the battery is shipped filled and

charged, the battery is ready for

installation. Remove the plastic

transport seals only before use.

The battery must never be charged

with the transport seals in place as

this can cause permanent damage.

2. Storage

Store the battery indoors in a dry, clean,

cool location (0C to +30C / +32F to

+86F) and well ventilated space on open

shelves.

Do not store in direct sunlight or expose

to excessive heat.

I Cells empty and discharged

Saft recommends to store cells empty

and discharged. This ensures

compliance with IEC 60623 section

4.9 (storage)

Cells can be stored like this for many

years.

I

Cells filled and charged

If cells are stored filled, they must be

fully charged prior to storage.

Cells may be stored filled and charged

for a period not exceeding 12 months

from date of dispatch.

Storage of a filled battery at

temperatures above +30C (+86F) can

result in loss of capacity. This can be as

much 5 % per 10C (18F) above +30C

(+86F) per year.

I When deliveries are made in cardboard

boxes, store without opening the boxes.

I When deliveries are made in plywood

boxes, open the boxes before the

storage. The lid and the packing material

on top of the cells must be removed.

3. Installation

3.1. Location

Install the battery in a dry and clean

room. Avoid direct sunlight and heat.

The battery will give the best performance

and maximum service life when the

ambient temperature is between +10C

to +30C (+50F to +86F).

3.2. Ventilation

During the last part of charging, the

battery is emitting gases (oxygen and

hydrogen mixture). At normal floatcharge the gas evolution is very small

but some ventilation is necessary.

Note that special regulations for

ventilation may be valid in your area

depending on the application.

3.3. Mounting

Verify that cells are correctly

interconnected with the appropriate

polarity. The battery connection to load

should be with nickel plated cable lugs.

Recommended torques for terminal bolts

are:

M 6 = 11 1.1 N.m

M 8 = 20 2

N.m

M 10 = 30 3

N.m

The connectors and terminals should be

corrosion-protected by coating with a

thin layer of anti-corrosion oil.

Remove the transport seals and close

the vent plugs.

3.4. Electrolyte / cell oil

I

Cells delivered empty and discharged:

If the electrolyte is supplied dry, prepare

it according to its separate instructions

sheet. The electrolyte to be used is E22.

Remove the transport seals just before

filling.

Fill the cells about 20 mm above the

lower level mark with electrolyte.

Wait 4 to 24 hours and adjust if

necessary before commissioning.

It is recommended to add the cell oil

after the commissioning charge, with the

syringe, according to the quantity

indicated in the Table B.

I Cells delivered filled and charged:

Check the level of electrolyte. It should

not be more than 20 mm below the

upper level mark. If this is not the case,

adjust the level with distilled or deionized

water. Cells delivered filled have already

the cell oil in place.

4. Commissioning

Verify that the ventilation is adequate

during this operation.

A good commissioning is important.

Charge at constant current is preferable.

When the charger maximum voltage

setting is too low to supply constant

current charging, divide the battery into

two parts to be charged individually.

If the current limit is lower than indicated

in the Table A, charge proportionally for

a longer time.

I

For cells filled on location or for filled

cells which have been stored more

than 6 months:

charge 10 h at 0.2 C5 A

(recommended)

or charge for 30 h at 1.65 V/cell,

current limited to 0.2 C5 A.

discharge at 0.2 C5 A to 1.0 V/cell

charge according to the section below.

For cells filled and charged by the

factory and stored less than

6 months:

charge 10 h at 0.2 C5 A

(recommended)

or charge 24 h at 1.65 V/cell,

current limited to 0.2 C5 A.

or charge 48 h at 1.55 V/cell,

current limited to 0.2 C5 A.

I

Cell oil & electrolyte after

commissioning: wait for 4 hours after

commissioning. Cells delivered filled by

the factory have already the cell oil in

place.

For cells filled on location, add the cell

oil with the syringe, according to the

quantity indicated in the Table B.

Check the electrolyte level and adjust it

to the upper level mark by adding:

distilled or deionized water for cells

filled by the factory

electrolyte for cells filled on location.

The battery is ready for use.

5. Charging in service

high level

= 1.47 - 1.70 V/cell for L cells

= 1.45 - 1.70 V/cell for M and H cells.

A high voltage will increase the speed

and efficiency of the recharging.

For single level charge:

1.43 - 1.50 V/cell.

I Buffer operation, where the load

exceeds the charger rating.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

1.50 - 1.60 V/cell.

6. Periodic Maintenance

I Keep

the battery clean using only

water. Do not use a wire brush or

solvents of any kind. Vent plugs can be

rinsed in clean water if necessary.

I Check

the electrolyte level. Never let

the level fall below the minimum level

mark. Use only distilled or deionized

water to top-up. Experience will tell the

time interval between topping-up.

Note: Once the battery has been filled

with the correct electrolyte either at

the battery factory or during the

battery commissioning, there is no

need to check the electrolyte density

periodically. Interpretation of density

measurements is difficult and could be

misleading.

I Check

every two years that all

connectors are tight. The connectors

and terminal bolts should be corrosionprotected by coating with a thin layer

of anti-corrosion oil.

I Check

the charging voltage. If a battery

is parallel connected, it is important

that the recommended charging

voltage remains unchanged.

The charging voltage should be

checked at least once yearly.

High water consumption of the battery

is usually caused by improper voltage

setting of the charger.

7. Changing electrolyte

In most stationary battery applications,

the electrolyte will retain its effectiveness

for the life of the battery. However,

under special battery operating

conditions, if the electrolyte is found to

be carbonated, the battery performance

can be restored by replacing the

electrolyte.

Table B: Non standard range

Cell

type

Char- Electrolyte Quant. Cell

of conging

per cell

Cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per type

(A)

(l) vent pole

(kg)

Char- Electrolyte Quant. Cell

of conging

per cell

Cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per type

(A)

(l) vent pole

(kg)

SBL 7.5

SBL 16

SBL 30

SBL 37

1.5

3.2

6.0

7.4

0.08

0.11

0.15

0.22

0.24

0.35

0.46

0.69

10

10

15

15

M6

M6

M6

M6

SBM 86

17

0.42

1.3

30

SBH 25

5.0

0.30

0.92

15

SBM 287

57

1.39

4.3

50 2 x M10 SBH 38

7.6

0.39

1.2

20

M6

SBM 359

72

1.62

5.0

60 2 x M10 SBH 51

10

0.42

1.3

25

M8

SBL 45

SBL 48

SBL 59

SBL 70

9.0

9.6

12

14

0.19

0.28

0.23

0.32

0.59

0.86

0.7

1.0

20

15

30

25

M6

M6

M6

M8

SBM 431

SBL 90

SBL 102

SBL 131

SBL 135

18

21

27

27

0.39

0.39

0.49

0.55

1.2

1.2

1.5

1.7

25

30

30

40

M8

M10

M10

M10

SBL 167

SBL 173

SBL 199

SBL 214

34

35

40

43

0.65

0.65

0.78

0.74

2.0

2.0

2.4

2.3

50

40

60

50

M10

M10

M10

M10

SBL 237

SBL 256

SBL 269

SBL 301

48

52

54

61

0.97

0.94

1.13

1.20

3.0

2.9

3.5

3.7

40 2 x M10

60 M10

40 2 x M10

50 2 x M10

SBL 304

SBL 334

SBL 346

SBL 366

61

67

70

74

1.13

1.26

1.26

1.42

3.5

3.9

3.9

4.4

40

50

40

60

2 x M10

2 x M10

2 x M10

2 x M10

SBL 387

SBL 398

SBL 429

SBL 470

78

80

86

94

1.36

1.55

1.49

1.68

4.2

4.8

4.6

5.2

50

60

50

60

SBL 500

SBL 510

SBL 595

SBL 600

SBL 645

100

102

119

120

129

1.91

1.88

2.33

2.14

2.23

5.9

5.8

7.2

6.6

6.9

SBL 665

SBL 770

SBL 795

SBL 835

133

154

159

167

2.56

2.78

3.11

3.11

SBL 860

SBL 995

SBL 1020

SBL 1070

For two level charge:

float level

= 1.42 0.01 V/cell for L cells

= 1.40 0.01 V/cell for M and H cells

Saft

Industrial Battery Group

M8

M6

86

2.07

6.4

50 3 x M10 SBH 64

13

0.52

1.6

30

M8

SBM 540 108

2.43

7.5

60 3 x M10 SBH 77

15

0.52

1.6

30

M10

SBM 575 115

2.78

8.6

50 4 x M10 SBH 89

18

0.61

1.9

40

M10

SBM 720 144

3.24 10.0

60 4 x M10 SBH 102 20

0.68

2.1

40

M10

SBM 900 180

4.05 12.5

60 5 x M10 SBH 115 23

0.91

2.8

50

M10

SBH 128 26

0.84

2.6

50

M10

SBH 141 28

1.07

3.3

60

M10

SBH 153 31

1.04

3.2

60

M10

SBH 179 36

1.23

3.8

40 2 x M10

SBH 204 41

1.36

4.2

40 2 x M10

SBH 230 46

1.81

5.6

50 2 x M10

SBH 256 51

1.68

5.2

50 2 x M10

SBH 281 56

2.14

6.6

60 2 x M10

SBH 307 61

2.10

6.5

60 2 x M10

SBH 345 69

2.72

8.4

50 3 x M10

SBH 383 77

2.52

7.8

50 3 x M10

2 x M10

2 x M10

2 x M10

2 x M10

SBH 422 84

3.17

9.8

60 3 x M10

SBH 460 92

3.14

9.7

60 3 x M10

SBH 510 102

3.37 10.4

50 4 x M10

50

60

60

47

50

3 x M10

2 x M10

3 x M10

3 x M10

3 x M10

SBH 560 112

4.24 13.1

60 4 x M10

SBH 615 123

4.21 13.0

60 4 x M10

7.9

8.6

9.6

9.6

50

60

60

50

4 x M10

3 x M10

4 x M10

5 x M10

172

199

204

214

2.98 9.2

3.88 12.0

3.72 11.5

3.72 11.5

50

60

60

50

4 x M10

5 x M10

4 x M10

5 x M10

SBL 1280 256

SBL 1450 290

SBL 1540 308

4.66 14.4

5.31 16.4

5.60 17.3

60 5 x M10

57 6 x M10

60 6 x M10

The electrolyte type to be used for

replacement in these cells is: E13.

Refer to "Electrolyte Instructions".

8. Environment

To protect the environment all used

batteries must be recycled.

Contact your local Saft representative

for further information.

Continuous parallel operation, with

occasional battery discharge.

Recommended charging voltage (+20C

to +25C / +68F to +77F):

Char- Electrolyte Quant. Cell

of conging

per cell

current

oil nect.

bolt

0.2 C5 A Solid* Liquid ml / per

(A)

(l) vent pole

(kg)

Doc N 21124-2-0407

12, rue Sadi Carnot

93170 Bagnolet - France

Tel: +33 1 49 93 19 18

Fax: +33 1 49 93 19 64

Socit anonyme au capital de 31 944 000

RCS Bobigny B 383 703 873

www.saftbatteries.com

Pragma - Printed in France - 5k

Data in this document is subject to change without

notice and becomes contractual only after written

confirmation.

* Value for initial filling (E22).

The cell type shows the rated capacity in ampere hours (Ah).

You might also like

- BatteryDocument0 pagesBatterymichaelliu123456No ratings yet

- Rolls-Royce engine alertDocument4 pagesRolls-Royce engine alertturboshaftNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument24 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Product Manual ELT 1000 ARTEXDocument62 pagesProduct Manual ELT 1000 ARTEXKumaraswamy RSNo ratings yet

- FAA document details Boeing 757 aircraft type certificationDocument13 pagesFAA document details Boeing 757 aircraft type certificationBRAIYAM ALEXANDER MORENO VARGAS100% (2)

- 3151 GN Fault Khi Nha Leak Measurement Valve Lead To Nws InopDocument2 pages3151 GN Fault Khi Nha Leak Measurement Valve Lead To Nws InopThai NguyenNo ratings yet

- Damage Assessmente Guidelines 737 d6 38669 CDocument97 pagesDamage Assessmente Guidelines 737 d6 38669 Catony357No ratings yet

- Aircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGDocument12 pagesAircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGCHIMONo ratings yet

- Engine Systems PDFDocument5 pagesEngine Systems PDFteknikpembakaran2013No ratings yet

- An 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844Document1 pageAn 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844blackhawkNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument27 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- HAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)Document2 pagesHAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)tenhero92No ratings yet

- Ril Sa71m15017693 R00Document5 pagesRil Sa71m15017693 R00Android100% (1)

- Operator'S Manual: Continental® Aircraft EngineDocument88 pagesOperator'S Manual: Continental® Aircraft Enginekay chikwandaNo ratings yet

- OPzS Installation & Operating InstructionsDocument3 pagesOPzS Installation & Operating InstructionskommuNo ratings yet

- GRAA320NEO-A-30-21-0003-00001-930A-D R0 Dt. 10.05.21Document21 pagesGRAA320NEO-A-30-21-0003-00001-930A-D R0 Dt. 10.05.21Pradeep K sNo ratings yet

- FE-V2500-1IA - Glossary of TermsDocument19 pagesFE-V2500-1IA - Glossary of TermsnegrotettNo ratings yet

- Fuel AnalysisDocument15 pagesFuel Analysisomarzaboub1997No ratings yet

- Engineering SupportDocument6 pagesEngineering SupportSyed Zeeshan UddinNo ratings yet

- Action Item Log: For Document CMM 61-13-12Document8 pagesAction Item Log: For Document CMM 61-13-12Anup Kumar DebnathNo ratings yet

- Easa Pad 18-184 1Document4 pagesEasa Pad 18-184 1cf34No ratings yet

- MC Ka 2006 02Document32 pagesMC Ka 2006 02GeeNo ratings yet

- Sil 26-0233eDocument13 pagesSil 26-0233eKhaled ElmabroukNo ratings yet

- Safety Data Sheet: Nickel-Cadmium Aircraft Cells and BatteriesDocument7 pagesSafety Data Sheet: Nickel-Cadmium Aircraft Cells and BatteriesYun JungNo ratings yet

- SCMM 25-30-48 63367 12754812Document152 pagesSCMM 25-30-48 63367 12754812aeprokofyev100% (1)

- RIL Index 12-JUN-2020Document36 pagesRIL Index 12-JUN-2020Van DiengNo ratings yet

- P03-0201MM Rev 2 EAP FLEET PDFDocument436 pagesP03-0201MM Rev 2 EAP FLEET PDFSergey SereginNo ratings yet

- PO Box 340 Troy, Ohio 45373 Tel: (937) 339-3811 FAX (937) 440-2055Document5 pagesPO Box 340 Troy, Ohio 45373 Tel: (937) 339-3811 FAX (937) 440-2055dsgarcia26No ratings yet

- 51-60!02!500 Control Surface Balancing - Rudder - Adjustment - TestDocument8 pages51-60!02!500 Control Surface Balancing - Rudder - Adjustment - TestArmandoNo ratings yet

- Airbus SB A320-31-1583 R05 Dated 09.apr.2021Document240 pagesAirbus SB A320-31-1583 R05 Dated 09.apr.2021Pradeep K sNo ratings yet

- ATA70standard Practice EngineDocument24 pagesATA70standard Practice EnginearunNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument213 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- Battery Management GuideDocument10 pagesBattery Management GuideR.S. Kumaraswamy100% (1)

- KADEX Seginus Boeing Part Number and Application List 1Document15 pagesKADEX Seginus Boeing Part Number and Application List 1IKMAL HAKIM NABIL IKMALNo ratings yet

- Turco 1495Document2 pagesTurco 1495Are Soo YantoNo ratings yet

- ATA 00 General FamilizationDocument22 pagesATA 00 General FamilizationDiniswari AlrinoNo ratings yet

- 3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3Document357 pages3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3mikeNo ratings yet

- 78 31 20 000 000 - DisassembleTR - CDuctAssyLHDocument31 pages78 31 20 000 000 - DisassembleTR - CDuctAssyLHParas PaudelNo ratings yet

- Chapter 8 - Environmental Control System: REV 3, May 03/05Document40 pagesChapter 8 - Environmental Control System: REV 3, May 03/05julian marinNo ratings yet

- Mega Ac25Document93 pagesMega Ac25Nariaki SumiNo ratings yet

- Air Ion Counter PDFDocument4 pagesAir Ion Counter PDFRombang Rizky SihombingNo ratings yet

- Job Application FormDocument2 pagesJob Application FormRam prakash verma0% (1)

- DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015Document20 pagesDFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015KamalVirkNo ratings yet

- 35-10-25 30.07.2011 Revision6Document66 pages35-10-25 30.07.2011 Revision6noureldinkamalNo ratings yet

- Ian Rosewarne A320 Edp-Acmp h205Document34 pagesIan Rosewarne A320 Edp-Acmp h205Gdchavez326 ChavezNo ratings yet

- 429E Operation Manual PDFDocument32 pages429E Operation Manual PDFjorge furtado de freitasNo ratings yet

- BE-Aerospace-Filter Replacement of Air ChillerDocument3 pagesBE-Aerospace-Filter Replacement of Air ChillerJason JiaNo ratings yet

- Appendix A - Part 7Document3 pagesAppendix A - Part 7shakil612No ratings yet

- 200-32-325 R01 Dt. 14.07.21Document18 pages200-32-325 R01 Dt. 14.07.21Pradeep K sNo ratings yet

- Guidance for Foreign Repair Station CertificationDocument59 pagesGuidance for Foreign Repair Station CertificationJindarat KasemsooksakulNo ratings yet

- CatalogDocument132 pagesCatalogAyman MousaNo ratings yet

- Fernando Shashen s3655990 Aero2410 Ind AssignmentDocument5 pagesFernando Shashen s3655990 Aero2410 Ind AssignmentShashen FernandoNo ratings yet

- 0fwe1 Acmm 008Document35 pages0fwe1 Acmm 008Shah M. ArifNo ratings yet

- B737 Hydraulic Systems OverviewDocument32 pagesB737 Hydraulic Systems OverviewzeblaouarNo ratings yet

- Boeing Distribution Services Discount Part ListDocument12 pagesBoeing Distribution Services Discount Part ListHasan RazaNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim Khalil100% (1)

- Airbus A380 Wings AnalysisDocument4 pagesAirbus A380 Wings AnalysisPett PeeveNo ratings yet

- CMM 26 20 32 Rev 5 Dated Jan 2019Document34 pagesCMM 26 20 32 Rev 5 Dated Jan 2019TESTNo ratings yet

- Alcad Batt SpecDocument2 pagesAlcad Batt SpecIsaac VoonNo ratings yet

- Instrument Transformer.: Y. K. PandharipandeDocument19 pagesInstrument Transformer.: Y. K. PandharipandePrem SagarNo ratings yet

- Transformer Protection: by Y. K. PandharipandeDocument33 pagesTransformer Protection: by Y. K. PandharipandePrem SagarNo ratings yet

- Numerical Protections.: Y. K. PandharipandeDocument8 pagesNumerical Protections.: Y. K. Pandharipandenetygen1No ratings yet

- Turbine Speed DemandDocument2 pagesTurbine Speed DemandPrem SagarNo ratings yet

- Power To Influence - Participant Refresher Guide - RInfra - V1Document31 pagesPower To Influence - Participant Refresher Guide - RInfra - V1Prem SagarNo ratings yet

- Combustion FundamentalsDocument30 pagesCombustion FundamentalsPrem SagarNo ratings yet

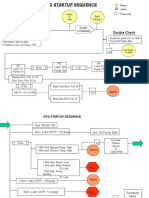

- Start Permissive: Double CheckDocument7 pagesStart Permissive: Double CheckPrem SagarNo ratings yet

- VFD Pumping SystemsDocument22 pagesVFD Pumping Systemsrajurajangam100% (1)

- Trouble ShootingDocument25 pagesTrouble ShootingPrem SagarNo ratings yet

- Instructions: Dual Frequency Infrared Detector/Controller U7099Document9 pagesInstructions: Dual Frequency Infrared Detector/Controller U7099Prem SagarNo ratings yet

- 1209101347260854kerala HistoryDocument15 pages1209101347260854kerala HistoryPrem SagarNo ratings yet

- PWM Digital Regulator: User's GuideDocument100 pagesPWM Digital Regulator: User's GuidePrem Sagar0% (1)

- Adoption of Supercritical TechnologyDocument25 pagesAdoption of Supercritical TechnologySurendra MallenipalliNo ratings yet

- K 8 VMXDocument72 pagesK 8 VMXPrem SagarNo ratings yet

- ABB POW08 P059FinalDocument17 pagesABB POW08 P059FinalRamya KuturuNo ratings yet

- ISRO Electronics SyllabusDocument2 pagesISRO Electronics SyllabusPrem SagarNo ratings yet

- GTG Local Check ListDocument7 pagesGTG Local Check ListPrem SagarNo ratings yet

- Conveyor - 7A Motor 1 Fire DIDocument8 pagesConveyor - 7A Motor 1 Fire DIPrem SagarNo ratings yet

- A Proposed Cost Effective Prototype Model For PLC Based GSM Remote Control in Home and Industrial AutomationDocument12 pagesA Proposed Cost Effective Prototype Model For PLC Based GSM Remote Control in Home and Industrial AutomationInternational Organization of Scientific Research (IOSR)No ratings yet

- 2443 Taco Commercial Hydronic SystemsDocument11 pages2443 Taco Commercial Hydronic SystemsIsmael Llamelo PerezNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area GuidekarthipetroNo ratings yet

- ChemistryDocument14 pagesChemistryPrem SagarNo ratings yet

- 1209101347260854kerala HistoryDocument15 pages1209101347260854kerala HistoryPrem SagarNo ratings yet

- Latest Banking & Financial Awareness Journal March 2010 Special IssueDocument0 pagesLatest Banking & Financial Awareness Journal March 2010 Special Issuenishantjain123No ratings yet

- Iso 13438 2018Document9 pagesIso 13438 2018Phạm Hùng CườngNo ratings yet

- WS3Document2 pagesWS3dextercitomanNo ratings yet

- L-5 Secondary TreatmentDocument53 pagesL-5 Secondary Treatmentzubair k peerzadeNo ratings yet

- Lecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaDocument565 pagesLecture Notes On Mixed Signal Circuit Design by Prof Dinesh.K.sharmaSumanth VarmaNo ratings yet

- Quality of Jelly Candy Made of Acid-Thinned Starch Added With Different Non-Starch PolysaccharidesDocument9 pagesQuality of Jelly Candy Made of Acid-Thinned Starch Added With Different Non-Starch PolysaccharidesjeffersonNo ratings yet

- Methods For Waste Waters Treatment in Textile IndustryDocument5 pagesMethods For Waste Waters Treatment in Textile Industryjpsingh75No ratings yet

- Guide To Expansion Joints (Choosing and Maintenance)Document16 pagesGuide To Expansion Joints (Choosing and Maintenance)stevebeanNo ratings yet

- Physico-chemical Water Treatment Processes AssignmentDocument6 pagesPhysico-chemical Water Treatment Processes AssignmentAbir HasanNo ratings yet

- Protons, Neutrons, and Electrons Practice WorksheetDocument2 pagesProtons, Neutrons, and Electrons Practice WorksheetRedHoeBeerNo ratings yet

- Water Cycle Questions AnwarDocument4 pagesWater Cycle Questions Anwarapi-124758305No ratings yet

- Pamphlet 152 - Edition 4 - April 2018Document29 pagesPamphlet 152 - Edition 4 - April 2018acidoanimalNo ratings yet

- Callister Ch09Document90 pagesCallister Ch09Nemish KanwarNo ratings yet

- Wobbe Index - WikipediaDocument3 pagesWobbe Index - Wikipediabala rNo ratings yet

- Kanthal LT CatalogDocument3 pagesKanthal LT CatalogRichard SyNo ratings yet

- Nickel CobaltDocument8 pagesNickel CobaltSunnyNo ratings yet

- Chapter 17Document97 pagesChapter 17Marco KrugerNo ratings yet

- Mineral Nutrition MycorrhizaDocument34 pagesMineral Nutrition MycorrhizaZella PurnamaningtyasNo ratings yet

- Usp42-Nf37 202Document4 pagesUsp42-Nf37 202Mohamed Hassan100% (1)

- PLD 105Document8 pagesPLD 105madx44No ratings yet

- SSIP GR 11 Acids N BasesDocument10 pagesSSIP GR 11 Acids N BasesMangwane Sello100% (1)

- MSDS 853021 Dry Charge BatteryDocument3 pagesMSDS 853021 Dry Charge Batteryjian0889No ratings yet

- Steel Metallurgy For The Non-Metallurgist: January 2007Document11 pagesSteel Metallurgy For The Non-Metallurgist: January 2007Anurag RamdasNo ratings yet

- 04 - Spektroskopi UV-Vis - 3Document16 pages04 - Spektroskopi UV-Vis - 3muktadi-amri-8721No ratings yet

- Abrasive-A ReviewDocument43 pagesAbrasive-A ReviewA.YusoffNo ratings yet

- 12.co Ordination CompoundsExerciseDocument34 pages12.co Ordination CompoundsExerciseMaster Of HakingNo ratings yet

- PDF Cecil BrochureDocument20 pagesPDF Cecil Brochurechiralic100% (1)

- STM 124 Electronic Configuration and Quantum NumbersDocument18 pagesSTM 124 Electronic Configuration and Quantum NumbersIvana BalanoNo ratings yet

- Notice IchloreDocument228 pagesNotice IchloreHervé MunozNo ratings yet

- Formula Ergun Manto LodosDocument22 pagesFormula Ergun Manto LodosReinaldoNo ratings yet

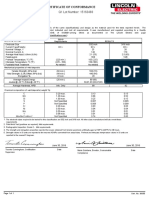

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet