Professional Documents

Culture Documents

Ds Epidermix372

Uploaded by

Virah Sammy ChandraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds Epidermix372

Uploaded by

Virah Sammy ChandraCopyright:

Available Formats

a.b.e.

Construction Chemicals

epidermix 372

EPOXY ADHESIVE, FILLER AND GROUT

DESCRIPTION

epidermix 372 is a two-component, solvent-free,

thixotropic, polyamide cured epoxy adhesive.

USES

As a general purpose adhesive for most materials, excluding

certain plastics and stainless steel. If required in structural load

bearing applications the a.b.e. Technical Department should

be consulted and supplied with full details of the design.

Smooth steel free of millscale, rust and other foreign

matter. Ideally abrasive blast cleaned.

Deformed and threaded steel free of oil, grease

and rust.

Aluminium free of grease. Abrade and degrease.

Bond immediately.

Stainless steel is not a candidate material.

Timber roughen by rasping. Oily woods (e.g. teak)

should be acetone washed.

As a filler where it may be bodied with fine materials such

as wood flour, silica sand and talc, to match the material

being filled.

Glass detergent wash, clean water rinse, alcohol rinse.

As a grouting medium for fixing dowels and bolts,

horizontally into concrete and rock.

Ceramic (unglazed) contamination free and dry.

ADVANTAGES

Rubbers degrease and roughen.

Solvent-free.

Non-slump.

Easy to mix.

Glass fibre laminates abrade to expose fibres and

solvent wash.

Stone free of contamination.

Thermoplastic plastics (except polystyrene) are

not candidate materials.

Polystyrene must be free of foreign matter.

Bonds most materials.

TYPICAL PHYSICAL PROPERTIES

OF WET MATERIAL

Can be filled for use as a grout.

Economical.

Colour

Base: White

Activator: Amber

Mixed: Creamy-yellow

Density

1,15 g/cm

Pot life (minutes)

120 minutes @ 15C

90 minutes @ 20C

60 minutes @ 25C

45 minutes @ 30C

30 minutes @ 35C

Flashpoint

120C

Dilution

Do not dilute

Consistency

Thixotropic paste

SURFACE PREPARATION

Any surface to be treated must be clean, sound and dry.

It must be free of foreign matter such as oil, grease,

paint, dust, debris of preparation and any other form of

contamination. Smooth surfaces should be roughened by

some appropriate method.

Preparation of specific surfaces:

Cast concrete and pockets in concrete free of all

laitance and shutter release.

Drilled concrete and rock if wet drilled, free of all

traces of dry slurry; if dry drilled, free of all

drilling debris.

Fibre cement free of all dust.

a.b.e. is an ISO 9001:2008 registered company

PO Box 5100, Boksburg North, 1461, South Africa

Website: www.abe.co.za | Tel: +27(0) 11 306 9000

Durban | Johannesburg | Cape Town | Port Elizabeth | East London | Bloemfontein | George

DATE UPDATED: 10/06/14

TYPICAL PHYSICAL PROPERTIES

DURING APPLICATION

Volume solids

Curing time @ 25C

Sanding time @ 25C

Overcoating time @ 25C

Fire resistance of wet

material

100%

Touch dry: 6 hrs

Practical use: 24 hrs

Full cure: 7 days

If used as a filler requiring

smoothing, sand after

24 hours cure

Minimum: 12 hrs

Maximum: 48 hrs if being

over-coated with an epoxy

system

Non-flammable

TYPICAL PHYSICAL PROPERTIES

OF CURED MATERIAL

Toxicity

Compressive strength @ 25C

Tensile strength @ 25C

Maximum service

temperature

Modified Arizona Shear test

Grouting test at 15 diameter

embedment

Lap shear (double overlap)

strength on grit blasted steel

Shrinkage during cure

Water resistance

Solvent resistance

be the mixing time. If a filled material is required, add the

filler only after complete mixing of the base and activator

has been achieved. Remove mixed material to a clean surface

and carry on mixing to ensure no unmixed material from the

first mixing area is incorporated in the final product.

COVERAGE

Application rate:

In general 1 litre of mixed epidermix 372 covers 1 m

to a thickness of 1 mm.

As a grout 1 litre of mixed epidermix 372 filled with

an equal volume of abe coarse No. 1 silica sand will

yield approx. 1,3 litres of mortar.

NOTE: This information makes no allowance for site

wastage.

Maximum application rate:

Non-toxic

70 MPa

30 MPa

Dry: 60C

Wet: 40C

55 MPa prisms fail in

concrete

AS AN ADHESIVE: Use thinnest possible film allowing

for full wetting of adherents.

12 mm HT bar fractured

APPLICATION

16 MPa

Negligible

Excellent

Resists aliphatic solvents,

vegetable, mineral oils

greases and petroleum fuels

BONDING/PRIMING

No priming required.

MIXING

MIXING RATIO: 2 base to 1 activator by volume. Carry out

mixing on a flat clean surface, such as a board or plate.

Set up carefully measured quantities (2 volumes base and

1 volume activator) of each component, side by side on the

mixing plate. Do not mix until application site operations

are ready. Use separate tools to remove each component

from its container thus preventing contamination. With

putty knives, paint scrapers or similar flat tools, mix the

two components until a completely homogeneous material

results. The larger the volume of the mix the longer should

AS A FILLER: Up to 15 mm thickness.

AS A GROUT: Do not grout unfilled epidermix 372

into a hole larger than 1,5 times the bar diameter. When

grouting with filled epidermix 372 the hole should be

kept as small as possible.

Application by putty knife, trowel or mastic gun.

AS AN ADHESIVE: Mixed material should be spread onto

the face of one adherent, thickly enough to extrude when

both faces are mated. Bonded mating faces must be kept

under compression until the adhesive layer has set. On heavy

assemblies excess adhesive should be removed immediately

and may be reused on other units. In delicate work such

as jewellery bonding, extruded material should be left to

obtain initial set and then cut off with a fine sharp blade. If

prevention of staining of faces is important a release agent

should be used, care being taken to see that it does not

affect the mating faces.

AS A FILLER: Mixed material should be smoothed into

place using a trowel or similar tool. If filling requires feather

edging, release agent may be applied to surrounding areas

to preserve cleanliness. Use a mastic gun equipped with a

length of tubing long enough to reach the back of the hole,

which must be suitably vented. Once sufficient grout is in the

hole, insert the bar using a rotary motion to ensure wetting

all faces. Seal the mouth of the hole with a little very dry

mortar grout to retain the epoxy grout during setting time.

a.b.e. is an ISO 9001:2008 registered company

PO Box 5100, Boksburg North, 1461, South Africa

Website: www.abe.co.za | Tel: +27(0) 11 306 9000

Durban | Johannesburg | Cape Town | Port Elizabeth | East London | Bloemfontein | George

DATE UPDATED: 10/06/14

Grouting With epidermix 372

PACKAGING

Basis for strength calculations: Given adequate concrete

strength and provided that a bar of deformed or threaded

steel, either mild or high tensile, is embedded to a depth of

at the least 15x the bar diameter, it can be expected that any

failure of the assembly will be due to tensile rupture of the

steel.

epidermix 372 is supplied in 90 ml, 500 ml, 1 litre and

5litrecontainers.

Thus epidermix 372 grouting allows the steel and the

concrete to operate at full design strength. Regarding the

diameter ratio of hole to rod, it has been shown that the

ultimate average bond stress is at its maximum at a ratio of

1,3:1. Ultimate average bond stress reduces as the hole:rod

ratio increases to a value of 1,67:1. Thereafter it remains

constant. An increase of diameter ratio from 1,3:1 to 1,67:1

will reduce bond stress.

CLEANING

Tools and mixing equipment should be cleaned immediately

after use and before material has set with

abe super brush cleaner followed by washing with soap

and water.

PROTECTION ON COMPLETION

If used as a filler and an epoxy coating is required allow a

minimum of 12 hours and a maximum of 48 hours before

commencing with epoxy coating.

APPLICATION TEMPERATURE

10C to 40C. If metal is being grouted, its surface should not

exceed 25C at the time of grouting.

MODEL SPECIFICATION

General-purpose thixotropic epoxy adhesive.

The adhesive/grout will be epidermix 372, a twocomponent, solvent-free, thixotropic, polyamide cured epoxy

system applied in accordance with the recommendations

of a.b.e. Construction Chemicals. The compound will

have a 7day compressive strength of 70 MPa and a lap shear

strength on grit blasted steel of 16 MPa.

HANDLING & STORAGE

This product has a shelf life of 24 months if kept in a dry cool

place in the original packaging. In more extreme conditions

this period might be shortened.

HEALTH & SAFETY

Wet epidermix 372 is toxic but non-flammable. Ensure

the working area is well ventilated during application and

drying. Always wear gloves when working with the material

and avoid excessive inhalation and skin contact. If material is

splashed into the eye, wash with plenty of clean water and

seek medical attention.

Cured epidermix 372 is inert and harmless.

IMPORTANT NOTE

This data sheet is issued as a guide to the use of the

product(s) concerned. Whilst a.b.e. Construction

Chemicals endeavours to ensure that any advice,

recommendation, specification or information is accurate

and correct, the company cannot - because a.b.e. has no

direct or continuous control over where and how a.b.e.

products are applied - accept any liability either directly

or indirectly arising from the use of a.b.e. products,

whether or not in accordance with any advice, specification,

recommendation, or information given by the company.

FURTHER INFORMATION

Where other products are to be used in conjunction with

this material, the relevant technical data sheets should

be consulted to determine total requirements. a.b.e.

Construction Chemicals has a wealth of technical and

practical experience built up over years in the companys

pursuit of excellence in building and construction technology.

a.b.e. is an ISO 9001:2008 registered company

PO Box 5100, Boksburg North, 1461, South Africa

Website: www.abe.co.za | Tel: +27(0) 11 306 9000

Durban | Johannesburg | Cape Town | Port Elizabeth | East London | Bloemfontein | George

DATE UPDATED: 10/06/14

You might also like

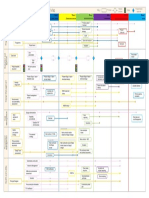

- Ricardo Vargas Pmbok Flow 6ed Color En-A0Document1 pageRicardo Vargas Pmbok Flow 6ed Color En-A0murdi.santoso83% (6)

- Genkem Contact AdhesiveDocument3 pagesGenkem Contact AdhesiveSirGawain9950% (2)

- Your Paint GuideDocument27 pagesYour Paint Guidemanox007No ratings yet

- PD 6547 Guidance To BS en 40-3-1 Lighting ColumnDocument18 pagesPD 6547 Guidance To BS en 40-3-1 Lighting ColumnJoseph Loroy100% (2)

- Stage 6 - HandOver and Close Out ChecklistDocument13 pagesStage 6 - HandOver and Close Out ChecklistVirah Sammy ChandraNo ratings yet

- Project Process Map PDFDocument1 pageProject Process Map PDFShahrirNo ratings yet

- MEP Concept Design DocumentsDocument16 pagesMEP Concept Design DocumentssolarstuffNo ratings yet

- 39ED3050CT - RT49S - AP Service ManualDocument31 pages39ED3050CT - RT49S - AP Service Manualبوند بوند100% (1)

- Masterflex 700 PGDocument3 pagesMasterflex 700 PGHaresh BhavnaniNo ratings yet

- TDS ShaliPrime ScreedDocument2 pagesTDS ShaliPrime ScreedRana MahatoNo ratings yet

- MS JDB 007 - Annexure 2 - ABE Epidermix 344Document2 pagesMS JDB 007 - Annexure 2 - ABE Epidermix 344Ben WalkerNo ratings yet

- Relipoxy P 301: Epoxy Based PrimerDocument3 pagesRelipoxy P 301: Epoxy Based PrimerPRERAKNo ratings yet

- Jazeera Anti-Carbonation ElastexDocument3 pagesJazeera Anti-Carbonation ElastexAhmad BougeisNo ratings yet

- Jazeera 3D FlooringDocument3 pagesJazeera 3D FlooringAhmad BougeisNo ratings yet

- Jazeera Clear LookDocument3 pagesJazeera Clear LookAhmad BougeisNo ratings yet

- Bitumen PaintDocument2 pagesBitumen PaintjaffliangNo ratings yet

- Life Deck 1200 Series 100 Solids Epoxy Primer SpecDocument2 pagesLife Deck 1200 Series 100 Solids Epoxy Primer SpecEugenio Remis DuranNo ratings yet

- TDS - Masterseal110PDocument2 pagesTDS - Masterseal110PVenkata RaoNo ratings yet

- Jazeera Floor GuardDocument3 pagesJazeera Floor GuardAhmad BougeisNo ratings yet

- Concresive 1438 PDFDocument2 pagesConcresive 1438 PDFanon_770460118No ratings yet

- Durakol G HMDocument3 pagesDurakol G HMpbodooNo ratings yet

- Loctite EPXY WELD T TdsDocument3 pagesLoctite EPXY WELD T TdsNirav DesaiNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Asian Apcodur Epoxy Mio PaintDocument3 pagesAsian Apcodur Epoxy Mio PaintPrinceRaghavNo ratings yet

- Estoseal c500PF - Cold Applied SealantDocument2 pagesEstoseal c500PF - Cold Applied SealantjoshepNo ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- ShaliSeal PS PGDocument3 pagesShaliSeal PS PGpoojaNo ratings yet

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Document5 pages4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808No ratings yet

- TBD 1 Brick + Slasto DressingDocument2 pagesTBD 1 Brick + Slasto DressingJessica SandersNo ratings yet

- 1 DT 2.8 Preparation FillercoatDocument4 pages1 DT 2.8 Preparation Fillercoatyoxan25808No ratings yet

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Document5 pages8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808No ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- Tuffkote Protective CoatingsDocument2 pagesTuffkote Protective CoatingsioginevraNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Joint Guard: General Purpose Ready To Use MasticDocument1 pageJoint Guard: General Purpose Ready To Use MasticmrfreshncoolNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Tank MasticDocument2 pagesTank MasticPrashant BaruaNo ratings yet

- Acrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingDocument2 pagesAcrylic Resin Based Plaster Putty For Interior & Exterior: Green Building RatingVetri Vel PrakashNo ratings yet

- 1 DT 6.4 Speciality HichemepoxyenamelDocument5 pages1 DT 6.4 Speciality Hichemepoxyenamelyoxan25808No ratings yet

- KAS Texcoat EngDocument2 pagesKAS Texcoat EngTưởng Hoàng TiếnNo ratings yet

- Bitumen PaintDocument2 pagesBitumen PaintJagadeesh ReddyNo ratings yet

- HYPERFLOW 1201 To 300MM ThickDocument2 pagesHYPERFLOW 1201 To 300MM ThickAris TesoroNo ratings yet

- Onboard Maintenance Paint Guide Tcm40 67407Document9 pagesOnboard Maintenance Paint Guide Tcm40 67407Costas AggelidisNo ratings yet

- Jazeera Anti-Skid EpoxyDocument3 pagesJazeera Anti-Skid EpoxyAhmad BougeisNo ratings yet

- Nitomortar SSDocument2 pagesNitomortar SSBalasubramanian AnanthNo ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Epilux-78 HB PrimerDocument3 pagesEpilux-78 HB PrimerIqra AngelsNo ratings yet

- Super Cast Fosroc AdmixturesDocument10 pagesSuper Cast Fosroc AdmixturesVedachalam ManiNo ratings yet

- STP Shaliseal Ps PGDocument3 pagesSTP Shaliseal Ps PGShelendraSinghNo ratings yet

- ResiGard SL2Document4 pagesResiGard SL2fhsn84No ratings yet

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- Brush BondDocument4 pagesBrush BondVenkata RaoNo ratings yet

- Primer SC PDFDocument3 pagesPrimer SC PDFFrancois-No ratings yet

- Epidermix 326Document2 pagesEpidermix 326Yasher Meera Saib100% (2)

- Lifemaster OIL Interior/Exterior Semi-Gloss Paint 1506-XXXX: Description SpecificationDocument2 pagesLifemaster OIL Interior/Exterior Semi-Gloss Paint 1506-XXXX: Description SpecificationVenkatesh SridharanNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Technical Data:: Oasis Epoxy ST 8800alDocument2 pagesTechnical Data:: Oasis Epoxy ST 8800alMaurice DavisNo ratings yet

- Nitotile Ep GroutDocument2 pagesNitotile Ep GroutBalasubramanian AnanthNo ratings yet

- PC 7298 - Apcodur 804Document3 pagesPC 7298 - Apcodur 8048mzpdsjzsdNo ratings yet

- Apcoglass Mastic 2000Document3 pagesApcoglass Mastic 2000replyrajanNo ratings yet

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanNo ratings yet

- Apcodur CF 699: Product DescriptionDocument4 pagesApcodur CF 699: Product DescriptionShravana PrasadNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- FINAL Appendix Building Control (Accessibility and Gender Compliance in Buildings) RegulationsDocument17 pagesFINAL Appendix Building Control (Accessibility and Gender Compliance in Buildings) RegulationsVirah Sammy ChandraNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetVirah Sammy ChandraNo ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Sikatop 71 CuringDocument3 pagesSikatop 71 CuringVirah Sammy ChandraNo ratings yet

- Design Calculation of Project Sign Boards Between Island House Interchange andDocument37 pagesDesign Calculation of Project Sign Boards Between Island House Interchange andVirah Sammy ChandraNo ratings yet

- BS 6297-1988 PDFDocument50 pagesBS 6297-1988 PDFisempogo100% (1)

- Fibreglass Septic Tanks: SpecificationsDocument4 pagesFibreglass Septic Tanks: SpecificationsAnonymous 2ZiabUZNo ratings yet

- Overview of 49 Processes From PMBOK GuideDocument11 pagesOverview of 49 Processes From PMBOK GuideVirah Sammy ChandraNo ratings yet

- 2019 SMTE Conference Proceedings - 6-9 November 2019 - University of Curtin and The Mauritius Institute of EducationDocument144 pages2019 SMTE Conference Proceedings - 6-9 November 2019 - University of Curtin and The Mauritius Institute of EducationVirah Sammy ChandraNo ratings yet

- Project Management Professional Certification Program (Pmi - PMP)Document11 pagesProject Management Professional Certification Program (Pmi - PMP)Virah Sammy ChandraNo ratings yet

- Format of Curriculum Vitae22012012Document6 pagesFormat of Curriculum Vitae22012012Virah Sammy ChandraNo ratings yet

- 8 Wastewater Collection, Treatment and Disposal: 8.1 The ApproachDocument11 pages8 Wastewater Collection, Treatment and Disposal: 8.1 The ApproachVirah Sammy ChandraNo ratings yet

- Uputstvo Za Advance Steel 2019Document55 pagesUputstvo Za Advance Steel 2019Zoran SimićNo ratings yet

- BS 6399-Part2Document124 pagesBS 6399-Part2Lina NgahNo ratings yet

- Technical Bulletin Plaste-Fix FinDocument2 pagesTechnical Bulletin Plaste-Fix FinVirah Sammy ChandraNo ratings yet

- Innovative Tower Crane Foundation Designs by Katlkodikara: June 2013Document5 pagesInnovative Tower Crane Foundation Designs by Katlkodikara: June 2013mmrahman93No ratings yet

- BS 648 1964 Schedule of Weights of BuildDocument51 pagesBS 648 1964 Schedule of Weights of BuildVirah Sammy ChandraNo ratings yet

- Tower Crane Footing Structural Design ReDocument14 pagesTower Crane Footing Structural Design ReVirah Sammy ChandraNo ratings yet

- Stage 5 - Construction Stage ChecklistDocument21 pagesStage 5 - Construction Stage ChecklistVirah Sammy ChandraNo ratings yet

- Sample Design InformationDocument1 pageSample Design InformationVirah Sammy ChandraNo ratings yet

- Stage 4 - Technical Design ChecklistDocument23 pagesStage 4 - Technical Design ChecklistVirah Sammy ChandraNo ratings yet

- BLP GuideDocument68 pagesBLP GuideKarish_J89No ratings yet

- Stage 3 - Developed Design ChecklistDocument16 pagesStage 3 - Developed Design ChecklistVirah Sammy ChandraNo ratings yet

- Proponent's Eia GuidelinesDocument19 pagesProponent's Eia GuidelinesVirah Sammy Chandra100% (1)

- Workbook Master Your People Skills PDFDocument164 pagesWorkbook Master Your People Skills PDFVirah Sammy ChandraNo ratings yet

- YellowstoneDocument1 pageYellowstoneOana GalbenuNo ratings yet

- ASCE Snow Loads On Solar-Paneled RoofsDocument61 pagesASCE Snow Loads On Solar-Paneled RoofsBen100% (1)

- Iron Ore ProcessDocument52 pagesIron Ore Processjafary448067% (3)

- MATLAB Fundamentals Quick ReferenceDocument43 pagesMATLAB Fundamentals Quick ReferenceCarlos Manuel Cardoza EspitiaNo ratings yet

- RhythmDocument10 pagesRhythmSalcedo NoelNo ratings yet

- LJ-V7080 DatasheetDocument2 pagesLJ-V7080 DatasheetOrhan DenizliNo ratings yet

- Tsel Manual ThermoselDocument25 pagesTsel Manual ThermoselPedro AlvelaisNo ratings yet

- Chapter 1 (PLC)Document9 pagesChapter 1 (PLC)Kibria PrangonNo ratings yet

- Propert 447-445Document11 pagesPropert 447-445LUNA100% (1)

- Reactive Dyes For Digital Textile Printing InksDocument4 pagesReactive Dyes For Digital Textile Printing InksDHRUVNo ratings yet

- Future AncestorsDocument44 pagesFuture AncestorsAlex100% (1)

- Salapare Et Al 2015 ZambalesDocument12 pagesSalapare Et Al 2015 ZambalesTiqfar AhmadjayadiNo ratings yet

- Table 1 Minimum Separation DistancesDocument123 pagesTable 1 Minimum Separation DistancesjhonNo ratings yet

- DCS YokogawaDocument17 pagesDCS Yokogawasswahyudi100% (1)

- Ventricular Septal DefectDocument9 pagesVentricular Septal DefectpepotchNo ratings yet

- Do Roman Catholics KnOw About The Great Pyramids of China?Document11 pagesDo Roman Catholics KnOw About The Great Pyramids of China?.No ratings yet

- (G. Lakshmi Narasaiah) Finite Element Analysis PDFDocument349 pages(G. Lakshmi Narasaiah) Finite Element Analysis PDFmoljaime1326No ratings yet

- Full Download Short Term Financial Management 3rd Edition Maness Test BankDocument35 pagesFull Download Short Term Financial Management 3rd Edition Maness Test Bankcimanfavoriw100% (31)

- Datasheet Ark XH Battery System EngDocument2 pagesDatasheet Ark XH Battery System EngLisa CowenNo ratings yet

- Sheet Metal Manufacturing Companies NoidaDocument9 pagesSheet Metal Manufacturing Companies NoidaAmanda HoldenNo ratings yet

- Binder 3 of 4 Dec-2018Document1,169 pagesBinder 3 of 4 Dec-2018Anonymous OEmUQuNo ratings yet

- Accuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionDocument4 pagesAccuity: High Speed Automated 2D & 3D Optical Gauging Single Click Setup and InspectionAPPLENo ratings yet

- Ecotopia Remixed II-FormattedDocument54 pagesEcotopia Remixed II-FormattedthisisdarrenNo ratings yet

- Intumescent Paint For Steel NZ - Coating - Co.nzDocument8 pagesIntumescent Paint For Steel NZ - Coating - Co.nzPeter ThomsonNo ratings yet

- 3161 GIS Data ModelsDocument13 pages3161 GIS Data Modelsapi-3788255No ratings yet

- Opex and CapexDocument5 pagesOpex and CapexATM Shafiq Ul AlamNo ratings yet

- Monkeys PawDocument4 pagesMonkeys PawKaitlin HartmanNo ratings yet

- Uji Efektivitas Mikroba Rumpun BambuDocument7 pagesUji Efektivitas Mikroba Rumpun BambuUse Real ProjectNo ratings yet

- Moses ManualDocument455 pagesMoses ManualDadypeesNo ratings yet