Professional Documents

Culture Documents

AADE-10-DF-HO-18 Fluid Loss As A Function of Position Around The Wellbore

Uploaded by

Ray RomeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AADE-10-DF-HO-18 Fluid Loss As A Function of Position Around The Wellbore

Uploaded by

Ray RomeyCopyright:

Available Formats

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

Arunesh Kumar, Halliburton

Copyright 2010, AADE

This paper was prepared for presentation at the 2010 AADE Fluids Conference and Exhibition held at the Hilton Houston North, Houston, Texas, April 6-7, 2010. This conference was sponsored by the

Houston Chapter of the American Association of Drilling Engineers. The information presented in this paper does not reflect any position, claim or endorsement made or implied by the American

Association of Drilling Engineers, their officers or members. Questions concerning the content of this paper should be directed to the individuals listed as authors of this work.

Abstract

Overbalanced drilling and workover operations invariably

cause invasion of the drilling and workover fluids into

formation. With increasing horizontal drilling to exploit

reservoirs exhibiting thin pay zones, more and more of the

lateral section of the well is exposed to drilling fluid. In a

horizontal wellbore, a difference in filtration rate between the

upward and downward section of drill pipe along with of

settling of barite can cause variation in filter cake thickness.

This can lead to differential sticking of the drill pipe, increased

torque on the drill pipe while pulling out of the hole, and

wellbore stability problems. An experimental study was

undertaken to address the aforementioned issues.

Experiments were performed using high temperature high

pressure (HPHT) fluid loss equipment and permeability

plugging apparatus (PPA) to measure the fluid loss from

downward and upward section of a drill pipe in a horizontal

wellbore respectively. Aloxite discs of different permeabilities

were used for experiments. Oil-based mud (OBM), waterbased mud (WBM), drill-in fluid and drilling fluid procured

from the field were used for experiments. Experiment results

indicate a strong correlation between difference in fluid loss

from different directions and fluid rheology. Difference in the

fluid loss from upward and downward directions was observed

to decrease with increasing concentration of viscosifier.

Drilling fluids having lower low shear rate yield point

(LSRYP) exhibit a higher tendency toward barite sag, and it

was observed to affect the filtration rate. Increase in pore

pressure due to difference in filtration rate was estimated and

wellbore stability analysis was performed

Introduction

Horizontal wells are being utilized throughout the world in an

ever increasing fashion to attempt to increase production rates

by maximizing reservoir exposure and targeting multiple

zones to exploit thin pay zones. Overbalanced drilling and

workover operations invariably cause invasion of the drilling

and workover fluids into the formation. Invasion of mud

filtrate into the formation leaves behind a mud cake

(deposition of solids) on the formation rock which behaves

like a membrane. It is generally acknowledged that static

filtration governs the initial growth of mud cake and that the

fundamental role of dynamic filtration is to limit this growth.

At the initial exposure of a permeable formation to a drilling

fluid, when the mud solids are building a low permeability

filter cake on the wellbore, a high rate of filtration occurs and

fine mud solids invade the formation. This high rate of initial

filtration is called the spurt loss. The three stages in filter-cake

buildup are: spurt loss during initiation of the filter cake,

buildup of filter cake thickness during which time leak off is

proportional to the square root of time, and limitation of filtercake growth by erosion.1 For a static filtration, flow of the

filtrate through the filter cake is governed by Darcys law.

Vf =

f sc

2k p

A

f sm 1

Equation 1

Equation 1 indicates that for static filtration, fluid loss is

proportional to square root of t (time).

In-situ rock formation properties such as porosity,

absolute permeability, relative permeability, pore pressure,

shale chemistry, capillary pressure, and residual fluid

saturations, also play important roles in controlling both the

dynamic formation of mudcake and the time evolution of the

invasion process. Particle size distribution, cake

compressibility, cake lubricity, state of flocculation and cake

thickness are cited as the most important properties of the

filter cake.

The rate of fluid filtration into the reservoir rock (leak off rate)

is one of the most critical parameters that need to be controlled

carefully during drilling and completion operations. With

increasing open hole completion operations, the problem gets

exacerbated because the fluid remains in the well for a longer

time.

Excessive fluid invasion can give rise to a number of

problems:

Differential sticking of the drill string is in many cases

caused when a high permeability formation permits large

volumes of drilling fluid filtrate to move into the

formation leaving behind a thick wall cake on the

wellbore. If a thick filter cake forms, the risk of

differential pressure sticking of the drill pipe increases.

Invasion of whole mud or filtrate into producing

formations increases the probability of the formation

damage.

Mud filtrate invasion changes the properties of the

formation surrounding the borehole and thus, the

measurements of various types of borehole logging tools.

Arunesh Kumar

Since, most borehole logging tool responses will be

affected by the flushed zone, it is important to know the

volume and shape of the mud filtrate invaded region.

Invasion of the fluid into a rock matrix during

overbalance operation will elevate the pore pressure. If this

increased pore pressure in unable to bleed away quickly (if the

permeability is very low as in shale), the effective in situ stress

decreases, as indicated by Equation 2.

i' = i p p

Equation 2

Compressive rock failure around the borehole is a

function of effective stresses, in situ rock strength, pore

pressure in the formation and pressure in the wellbore. Mohr

Circle shifts towards left with increasing pore pressure, due to

this the failure envelope decreases and the formation becomes

more prone to compression failure. This type of issue is

prominent in shales.

Several numerical models and software tools have been

developed in the industry to determine the depth of filtrate

invasion. Tien compared the conventional filtration theory

results with numerical models and concluded that results from

conventional theory do not match with numerical analysis.2

Waldmann modeled the linear filtration formulation and a

radial single phase formulation to predict fluid invasion depth

of the drilling fluid filtrate.3 Suryanarayana developed a

radially adaptive 3D micro simulator for determining impact

of filtrate invasion on near wellbore saturation and reservoir

pressure.4 Wu developed a 3D reservoir simulator to simulate

the filtrate invasion during the drilling of a horizontal well.5

Simulation result indicates that depth of filtrate invasion is

very sensitive to permeability anisotropy. Distribution of

damage zone along a horizontal well is elliptically shaped and

depends on the degree of permeability anisotropy.

Scope of Work

Maintaining a hydrostatic overbalance is necessary to impede

the premature flowing of formation fluids into the wellbore

and prevent a blow out. This pressure overbalance forces

the liquid portion of the mud into the rock formation and

concurrently filters the solids from the mud to form a low

permeability layer at the borehole wall termed the mud

cake. For permeable formations, the mud cake controls the

rate of invasion of the liquid mud filtrate. The invasion

geometry around the wellbore is important because the

properties of the invaded zone will be different from the

undisturbed formation properties.

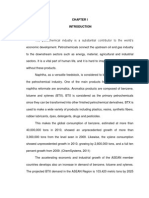

Filtration rate can vary as the function of radial position in

the horizontal wellbore (angle from 0 to 360 as described in

Figure 1). Several factors that can affect the difference in the

filtration rate could be settling of particles blocking the

formation pores and leaving a clear fluid at the top, viscosity

of the drilling fluid, drill pipe eccentricity, and erosion of filter

cake from one location because of drill pipe movement.

Inappropriate size of plugging particles in drilling fluid will

AADE-10-DF-HO-18

also form a thick and permeable filter cake leading to

continuous filtration. In case of shales, difference in filtration

rate can lead to more swelling of shales on one side of well,

causing issues of stuck pipe which will require higher torque

and drag on the drill pipe while tripping, which can cause

wellbore stability issues. To address the aforementioned

issues, a methodical study was undertaken to understand this

phenomenon and filtration rate was determined from three

different radial positions: upward, horizontal and downward.

As invasion of filtrate in the formation increases the pore

pressure and effectively decreases the collapse pressure of the

formation. Early radial flow well testing equation was used to

estimate the increase in the pore pressure due to filtrate

invasion and wellbore stability analysis was performed using

PoroMechanics Institute PBORE-3DTM software.

Experimental Technique

To simulate the fluid loss from different directions in the

wellbore, for each fluid formulation three experiments were

performed by varying the direction from which fluid loss was

collected (Figure 2). PPA and HPHT cells were used for the

experiments. The PPA is a high pressure, high temperature

filtration device designed to evaluate fluid loss and spurt

loss of drilling fluids under filtration conditions that more

closely approximate those encountered downhole, using a

ceramic disc rather than the filter paper normally used. The

main feature of the PPA is the use of porous ceramic disks as

the filtration medium.6 These are available in a wide range of

porosities and permeabilities to match those properties of the

formation much better than filter paper can. Different

orientations of the cells and how they actually simulate the

wellbore conditions is described in the following section:

1.

2.

3.

Downward direction: In HPHT cells filtrate is

collected from the bottom as shown in Figure 3.

Particles in the drilling fluid will settle in the

direction of the filtration. This condition simulates

the fluid loss from the bottom of the horizontal well.

Upward direction: In PPA with a floating piston,

filtrate is collected from the top of the cell as shown

in Figure 4. Particles in drilling fluid will settle in the

direction opposite to the filtration. This condition

simulates the fluid loss from the top of the well.

Horizontal direction: PPA was oriented into

horizontal direction and filtrate was collected as

shown in Figure 5. Certain modifications were done

in the PPA filtrate collection assembly. In this case,

particles in drilling fluid will settle in the direction

perpendicular to the filtration. This condition is

equivalent to the fluid loss from the side walls in the

well.

A constant pressure technique was used for filtration

experiments. Inert gas was used for pressurizing the cells. This

ensured in the maintaining of constant pressure drop across the

cell, especially when filtrate is being collected (with a

hydraulic pump, pressure drops to zero when valve is opened

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

to collect filtrate). Drilling fluid was prepared using a

Silverson mixer. After performing the basic mud check, the

fluid was hot rolled for 16 hrs at 250 oF in a roller oven after

which mud check was performed (rheology, mud weight, pH

for water-based fluid and electrical stability for oil-based

fluid).

Equal volumes of fluid were measured and poured in

three different cells for static aging. Static aging of the drilling

fluid simulated the downhole condition (when drilling

operations halt for a period of time) and created an

environment where barite will settle in the direction of gravity

(only if fluid rheology degrades to the extent that it will allow

barite sag). It is worth mentioning that cell orientation while

static aging was similar to the orientation under which fluid

loss experiment will be conducted. For example, for filtration

from horizontal direction, the cell was placed horizontally in

the static oven.

After 16 hours of static aging at 250 oF, a fluid loss test

was done at differential pressure of 500 psi and temperature of

250 oF. Filtrate was collected at regular intervals and a test

was performed for 30 minutes. Equations 7, 8 and 9 in Table 1

were used to calculate the total filtrate collected spurt loss and

static filtration rate respectively.

Different types of fluid system such as non damaging

reservoir fluid (drill-in fluid), water base drilling fluid and a

fluid procured from the field were used for experiments.

Details of specific type of drilling fluid formulations will be

discussed in next section. Aloxite discs of different pore size

(permeability) were used as filtration medium, the details of

which have been tabulated in

Table 2. Drilling fluid designed to plug a specific pore size

will form a thick and permeable filter cake on other pore sizes,

consequently showing higher fluid loss values. Experiments

performed using different pore/permeability ceramic disc

simulate this condition.

Results and Discussion

Spurt loss is the term used to describe the earliest stages of

filtration and formation invasion. As a drill bit mechanically

exposes new rock to the mud column, whole mud invades the

formation. Solids concentration in the fluid, particle size and

viscosity determine how easily fluid will pass through the

formation. Once the pore spaces have been bridged, implying

formation of the filter cake, the process of mud filtration

begins.

Of more particular interest is the static filtration volume

(ml/min). This value does not include spurt loss and indicates

the continuous fluid loss after formation of the filter cake.

After spurt loss, the filter cake will control the invasion rate

meaning that the invasion rate will be independent of

formation permeability. Highly compacted filter cake will

have significantly less permeability and static filtration rate. In

the following section major emphasis will be given to static

filtration rate as this determines the total amount of fluid that

will invade the formation.

a) Drill-in fluids

Drill-in fluids are designed to be essentially non-damaging to

the producing formation, provide superior hole cleaning, allow

easy clean-up and be cost effective. These fluids address the

wide range of problems encountered in horizontal drilling,

completion, and workover operations. These systems are

designed to provide the lowest filtration rate possible in order

to minimize or prevent formation damage. When bridging

production zones, the correct sizing of particles becomes

important. The pore diameter of the formation must be known

to help ensure effective bridging. An industry rule of thumb

for estimating an unknown pore diameter (microns) is to take

the square root of the permeability in millidarcies as per

Equation 3. To effectively bridge off the production zone, 2030 percent by weight of the bridging material should be onethird of the pore size in microns as per Equation 4.

Pore Diameter (microns) = Permeability (millidarcy)

Pore Diameter

D ( 50 ) = =

3

3

Equation 3

Equation 4

Filtration tests on drill-in fluids were conducted using a

ceramic disc which simulates as closely as possible the pore

size of the formation. These tests can be utilized in the field to

determine proper application of the drill-in fluid system.

A 9.8 ppg sodium chloride brine solution weighted

up to 10.5 ppg using different grades of calcium carbonate was

used for testing. The concentration of polymeric viscosifier

was varied from 0.25 lb/bbl to 1 lb/bbl whereas the

concentration of polymeric filtration control agent was kept

constant at 8 lb/bbl. A constant amount of 50 lb/bbl of calcium

carbonate was used for weighting as well as plugging

purposes. Experiments were performed on two different sizes

of aloxite disc: 10 and 35 m. The mean particle size required

to effectively plug the 35 m aloxite disc, according to

Equation 4 should be around 12 m. Hydraulics and pore size

modelling software was used to determine the optimum ratio

of different calcium carbonate grades that will be required to

achieve a mean particle size of 12 m. Based on the modelling

results as reported in

Figure 6, two different size grades of calcium carbonate

having mean particle size of 5 and 25 m were mixed together

in 40/60 (wt %). Particle size determined using the Malvern

Particle Size Analyzer for one of the drill-in fluids (Test 7.1)

confirms that fluid has a mean particle size of 12 m (Figure

7). Rheology data for various concentration of viscosifier have

been tabulated in Table 4. With increasing concentration of

viscosifier, the plastic viscosity (cP) and yield point (lb/100

ft2) of the drill-in fluid increase, as expected. Experimental

results indicate that static filtration rate reaches its maximum

from the upward direction and its minimum from the

downward direction. Fluid loss test results for drill-in fluid are

tabulated in Table 5.

Arunesh Kumar

Testing performed on 35 m indicates that with increasing

concentration of polymeric viscosifier static filtration rate

decreases from all upward and downward direction whereas

the static filtration rate increases from the horizontal direction

as shown in Figure 8. The above observation could be

attributed to the return flow phenomena. The solids suspension

capacity of drilling fluid decreases with decreasing viscosity.

Particles begin settling and there is a clear liquid at the top,

which passes through the disc very easily. As particles settle

due to body forces (caused by higher specific gravity), settling

particles displace liquid in the upward direction known as

return flow. This return flow adds to the total fluid loss from

the upward direction in the ceramic disc. Due to additional

flux of displaced fluid, fluid loss from the upward direction

will be greater, compared to fluid loss from downward

direction. Fluid designed for a 35 m aloxide disc gives higher

static filtration rate on a 10 m. This is because of the inability

of the drilling fluid to effectively plug the pores of the aloxite

disc.

b) Water-based drilling fluid

A recent theoretical approach has indicated that the maximum

rate of barite sag for a drilling fluid occurs at approximately

13.0 lb/gal.7 Several other factors like oil water ratio,

viscosity,

solids

suspension

capability,

surfactant

concentration, and hole angle also affect settling of barite, but

the effects of these factors were out of the scope for this

work.8

A 13.0 lb/gal KCl/polymer water-based fluid was

prepared for the experiments. In initial formulations, a

significant reduction in fluid properties (low shear viscosity,

gel strength) consequently reflected in settled barite of 16/32

inch and very high total filtrate (approximately 150-180 ml).

Several tests were done to optimize the concentration of

additives and plugging material. Once a satisfactory fluid was

formulated, tests were performed to determine the filtration

rate from different radial directions. Static filtration rates for

few tests performed with water based mud have been reported

in Table 6. Appropriate size ceramic disc was used after

determining the mean particle size. As barite was only added

to the fluid, mean particle size of the fluid will be somewhere

near to the mean particle size of barite. On a 35 m aloxite

disc, the static filtration rate from upward and downward

direction was observed to be similar (Figure 9). However

comparing the filtration rate from downward direction

performed on two different size aloxite disc, 10 and 35 m, a

lower rate was observed with 10 m aloxite disc (Figure 10).

c) Drilling fluid procured from field

Fluids prepared under laboratory conditions have different

physical properties as compared to fluid prepared at a field

location with the same formulation. This is primarily due to

difference in shear rate observed by the fluid in lab and field

and the extent of exposure to high pressure and high

temperature conditions. Certain additives used in drilling

fluids yield more at higher shear rates. To validate the

applicability of the above results, test was done on fluid

AADE-10-DF-HO-18

procured from field location. Testing was performed with a

14.6 ppg KCl/polymer fluid used to drill to a TVD of 5514 m

with a bottomhole temperature of 220 oF. Xanthan gum was

used to provide the necessary viscosity, and a combination of

starch and cellulose was used as the filtration control agent.

Glycol was added to inhibit shale swelling. Optimised particle

size distribution of calcium carbonate to assist in plugging

high permeability formations was kept for contingency.

As the fluid was already exposed to high temperature, no hot

rolling of fluid was done. Equal volumes of fluid were used

for static aging at 250 oF and 16 hrs. Particle size of the fluid

was determined using the Malvern Particle Size Analyzer.

Bimodal distribution of the particles is evident from Figure

11, and the fluid had a mean particle size of 7 m. Fluid loss

testing was done on a 10 m aloxite disc and different fluid

loss values have been tabulated in Table 7. The fluid loss

profile and static filtration rate for upward and downward

direction has been plotted in Figure 12. As observed with

other fluid systems, static filtration rate for the field mud from

the upward direction is again greater than fluid loss from

downward direction.

d) Increase in pore pressure because of the drilling

fluid invasion

Wellbore pressure response during the pressure drawdown test

is given by Equation 5.9 Pressure variation during production

for different flow rates is analyzed by this equation. The same

equation can be applied for injection with negative value

of qo .

pi pwf =

162.6qo o o kv k y t

log

+

3.23

0.868

s

2

kv k y L o ct rw

.Equation 5

For injection into formation (negative qo ):

pwf pi =

162.6qo o o kv k y t

log

+

3.23

0.868

s

2

kv k y L o ct rw

.Equation 6

Anisotropy in permeability was ignored (same

permeability in horizontal and vertical direction) for

calculations. Values used for various variables in the Equation

6 have been tabulated in Table 8. Increase in pore pressure for

different static filtration rate was calculated and results have

been tabulated in Table 9.From the theoretical calculations it

seems, for the static filtration rate observed during

experiments, no significant increase in pore pressure will

occur. As pore pressure does not changes significantly, no

issue of wellbore stability will occur, which was confirmed by

performing calculations using PBORE-3D software.10

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

Conclusions

Several experiments were performed to determine the

filtration rate from different radial positions. Increase in pore

pressure due to filtrate invasion was estimated by using well

testing equations and for increased pore pressure, wellbore

stability analysis was performed using PBORE-3D software.

The following conclusions can be drawn from the above work:

1. In a horizontal well while drilling overbalanced, fluid loss

varies for different radial positions.

2. Static filtration rate is always observed to be at its

maximum from the upward direction because of settling

of particles in the direction opposite to filtration, whereas

the minimum rate is observed from downward direction.

3. Improper selection of the particle size for plugging the

pores of the formation can lead to more fluid invasion

causing higher formation damage and potential instability

issues. Numerical models should be used for accurately

determining the ratio of different products to achieve the

particle size.

4. Increases in wellbore pore pressure due to invasion of

filtrate were estimated using well testing correlations. For

the experimental static filtration rate observed, no

significant increase in wellbore pore pressure occurs.

5. Although fluid loss from different radial positions in a

wellbore does not cause any wellbore stability issues, it

can alleviate the issues of differential sticking, stuck pipe,

shale swelling etc.

6. Filter cake is desired while drilling as it helps prevent the

sloughing of the formation. In case of tight filtrate,

uniform filtration occurs from different radial positions,

7. Numerical models developed across the industry should

incorporate this difference in fluid loss to accurately

predict the invasion depth. This will help in proper

determination of skin factor and also in accurate analysis

of the logging data.

Acknowledgements

The author would like to thank Halliburton for allowing this

work to be published. Special thanks to Dale Jamison, Robert

Murphy and Sharath Savari for valuable discussion and input.

Nomenclature

V7,5

V30

VPPT

V1

Vf

t1

t2

PPA

HPHT

AHR

filtrate volume after 7,5 min, in millilitres

filtrate volume after 30 min, in millilitres

PPT volume, in millilitres

spurt loss, in millilitres

static filtration rate (velocity of flow), in

millilitres per minute

time at initial reading, in minutes

time at final reading, in minutes

Permeability plugging apparatus

High pressure high temperature

After hot roll

BHR

pi

pwf

qo

o

kv, ky

o

t

ct

rw

s

L

(x,y,z)

Before hot roll

Pressure (Psi)

Wellbore pressure (psi)

Volumetric flow rate (bbl/hr/ft)

Formation Volume Factor (bbl/STB)

Vertical and horizontal permeability (mD)

Viscosity (cP)

Time (min)

Compressibility (1/psi)

Wellbore radius (feet)

Skin factor (-)

Length (feet)

In situ stress (Psi)

References

1. Outmans, H.D. Mechanics of static and dynamic filtration in

the borehole, SPE 491-PA, 236-244, SPE Journal 1963.

2. Tien, C. and R. Bai. An assessment of the conventional cake

filtration theory, Chemical Engineering Science, 58, 13231336, 2003.

3. Waldmann, A., Matins, L.A., Aragao, L. and T. Lomba.

Predicting and monitoring fluid invasion in exploratory

drilling, SPE 86497 presented at the 2004 SPE International

Symposium and Exhibition on Formation Damage Control,

Lafayette, Louisiana.

4. Suryanarayana, V.P., Wu, Z., Ramalho, J., Himes, R. Dynamic

modelling of invasion damage and impact on production in

horizontal wells, SPE 95861 , SPE Annual Technical

Conference and Exhibition held in Dallas, USA, 9-12 Oct 2005.

5. Wu J., et al., The influence of water base mud properties and

petrophysical parameters on mud cake growth, filtrate invasion

and formation pressure, Petrophysics, 46, 1, 12-32, 2005.

6. Davis, N., Mihalik, P., Lundie, R.P, Growcock, F., Calloni, G.,

and E. Davidson. New Permeability Plugging Apparatus

Procedure Addresses Safety and Technology Issues,

SPE/IADC 52815, SPE/IADC Drilling Conference, Amsterdam,

Holland, 9-11 March 1999.

7. Sassen, A., Liu, D., He, L., Marken, D.C., Sterri, J., Halsey,

W.G., and P. Isambourg. Prediction of barite sag potential of

drilling muds from rheological measurement, SPE/IADC

29410, SPE/IADC Drilling Conference, Amsterdam, 28 Feb - 2

March 1995.

8. Bern, A.P., Zamora, M., Slater, S.K and J. P. Hearn. The

influence of drilling variables on barite sag, SPE 36670, SPE

Annual Technical Conference and Exhibition, Denver,

Colorado, 6-9 October 1996.

9. Chaudhary, U.A., Gas Well Testing Handbook, 2003

10. PBORE-3DTM software owned by PoroMechanics Institute

(PMI), University of Oklahoma, Norman.

Arunesh Kumar

AADE-10-DF-HO-18

Table 1: Equations used to determine filtration rate

Total Filtrate Collected

VPPT = 2V30

Equation 7

Spurt Loss

V1 = 2 V7.5 (V30 V7.5 ) = 2 ( 2V7.5 V30 )

Equation 8

Static Filtration Rate

Vf =

2 (V30 V7.5 )

t2 t1

2 (V30 V7.5 )

2.739

Equation 9

Table 3: Formulation of drill-in fluid (10.5 PPG)

Table 2: Porosity and permeability relationship for ceramic disc

using in the experiments

Mean Pore Diameter

Permeability (mD)

(Air)

Product

Concentration (lb/bbl)

Water

As required

NaCl

91.09

3 micron

500

5 micron

750

Viscosifier

Varied from 0.25 to 1

10 micron

950

Filtration Control

20 micron

2.8

Plugging and weighing material

As required

35 micron

5.5

Alkalinity

0.25

60 micron

6.7

90 micron

13.5

150 micron

26.5

Table 4: Rheology data for different drill-in fluid formulation

D2.1

D3.2

D4.1

D5.1

D7.1

D8.1

BHR

AHR

BHR

AHR

BHR

AHR

BHR

AHR

BHR

AHR

BHR

AHR

MW

10.5

10.5

10.4

10.4

10.4

10.4

10.5

10.5

10.5

10.5

10.5

10.5

Temp

120

120

120

120

120

120

120

120

120

120

120

120

600 RPM

78

40

66

52

55

43

40

26

78

56

70

45

300 RPM

57

28

48

38

39

33

26

19

57

40

50

31

200 RPM

48

23

40

31

31

29

21

15

48

28

42

26

100 RPM

36

17

29

24

22

16

15

11

36

23

30

19

6 RPM

12

12

3 RPM

10

10

10 Sec Gel

10

10

10 Min Gel

14

14

pH

10.5

8.5

10.13

8.9

10.34

9.1

10.1

9.1

10.5

8.5

---

---

PV

21

12

18

14

16

10

14

21

16

20

14

YP

36

16

30

24

23

23

12

12

36

24

30

17

LSRYP

0.52

0.56

0.48

0.46

0.53

0.47

0.63

0.49

0.47

0.61

0.49

0.58

2.03

1.09

2.42

2.23

1.39

2.04

0.50

0.97

2.93

0.82

2.27

0.75

Tau

4.57

4.21

1.88

0.67

1.48

2.51

2.88

2.05

3.70

3.87

2.07

4.29

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

Table 5 :Filtration rate for drill-in fluids (10.5 ppg)

Test no

D2.1

D3.2

D4.1

D5.2

D7.1

D8.1

Amount of

viscosifier

Disc size Used

lb/bbl

(m)

35

0.75

35

0.5

35

0.25

35

10

0.75

10

Filtration

property

Downward

Upward

Horizontal

Vppt(ml)

17.2

25.2

21.6

V1(ml)

10.8

9.2

8.0

Vf (ml/min)

1.2

2.9

2.5

Vppt(ml)

11.2

24.8

24.8

V1(ml)

3.2

9.6

10.4

Vf (ml/min)

1.5

2.8

2.2

Vppt(ml)

10.0

22.4

18.8

V1(ml)

1.2

8.0

8.4

Vf (ml/min)

1.6

2.6

1.9

Vppt(ml)

14.4

60.0

--

V1(ml)

1.6

28.0

--

Vf (ml/min)

2.3

5.8

--

Vppt(ml)

14.0

32.0

--

V1(ml)

2.8

3.2

--

Vf (ml/min)

2.0

5.3

--

Vppt(ml)

15.6

34.8

30.8

V1(ml)

3.6

14.0

14.0

Vf (ml/min)

2.2

3.8

3.1

Table 6: Static filtration rate for WBM (13 ppg)

Test no

Static Filtration Rate Vf (ml/min)

Disc size Used

Downward

Upward

Horizontal

(m)

W4.1

5.48

5.48

--

35

W4.2

2.19

--

--

10

Table 7 : Static filtration rate for FIELD MUD (14.6 ppg)

Test no

Static Filtration Rate Vf (ml/min)

Downward

Upward

Horizontal

4.38

6.21

6.57

Disc size Used

(m)

Total filtrate in 30 min (Vppt,ml)

28

51

74

Spurt Loss (V1, ml)

F1

8.5

10

19

Arunesh Kumar

Table 9: Increase in pore pressure

Table 8: Input values for parameters of Equation 5

Parameters

Unit

Value

Wellbore Radius ( rw )

feet

0.365

Permeability (k)

mD

0.01 0.0001

0.02 mD for Shales

Viscosity ( o )

cP

Length (L)

feet

1/psi

Porosity ( )

---

Skin Factor (s)

---

Static filtration rate

(experimental, ml/min)

Initial Pore Pressure

Gradient (Psi/ft)

Changed Pore Pressure

gradient (Psi/ft)

0.48

0.48

50

0.48

0.48

100

0.48

0.48

1.3E-05

5000

0.48

0.486

0.3 for shales

0.15 for sandstones

1

50000

0.48

0.54

100000

0.48

0.598

Formation Volume Factor ( o ) bbl/STB

Compressibility ( ct )

AADE-10-DF-HO-18

1.2

Flow rate( qo -ve for injection) bbl/hr/ft

varied

Vertical Depth (TVD)

Feet

10000

Initial Pore Pressure (pfm)

Psi/ft

0.48

0o V ( )

r 1

Vr(2)

Upward direction

(Top of the well)

Horizontal direction

(Side of the well)

A

Vr(i)

90o

270o

Downward direction

(Bottom of the well)

180o

Figure 1:Different direction of fluid loss in a

horizontal wellbore

Figure 2: Description of directions from which fluid loss was collected and its relevance

to a horizontal well.

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

Figure 4: Upward direction

Figure 3: Downward Direction

Figure 5: Horizontal direction

10

Arunesh Kumar

AADE-10-DF-HO-18

Calcium Carbonate 5 = 0.4 lb/bbl

Calcium Carbonate 25 = 0.6 b/bbl

Figure 6:Determination of optimum size of calcium carbonate using solids modelling for plugging the ceramic disc for drill-in fluid (Test D2.1)

Figure 7: Particle size distribution determined using Malvern Particle Size analyzer for D7.1

AADE-10-DF-HO-18

Fluid Loss as a Function of Position around the Wellbore

11

7

Static filtration rate (ml/min)

Downward

6

Upward

5.84

5

4

3

2

2.34

2.63

2.77

1.61

1.46

2.92

1.17

1

0

0.25

0.5

0.75

Amount of polymeric viscosifier (lb/bbl)

6

5

5.48

5.48

4

3

2

1

Static Filtration Rate (ml/min)

Static Filtration Rate (ml/min)

Figure 8: Effect of varying concentration of polymeric viscosifier on static filtration rate (experiments performed on 35 m ceramic discs).

5.48

4

3

2

2.19

1

0

Downward

Upward

Figure 9: Variation of static filtration rate for WBM. Test was done on 35

m aloxite disc.

35 m

10 m

Figure 10: Variation of static filtration rate from downward direction with

varying aloxite pore size for WBM.

12

Arunesh Kumar

AADE-10-DF-HO-18

Figure 11: Particle size distribution determined using Malvern Particle Size analyzer for Field Mud

30

Upward

Static filtration rate (ml/min)

Downward

Fluid Loss (ml)

25

20

15

10

5

0

1.00

2.24

2.74

3.16

3.54 3.87 4.24

time

4.58

5.00

5.24

5.48

6.21

5

4

4.38

3

2

1

0

Downward

Upward

Figure 12: Fluid loss profile with time and static filtration rate from upward and downward direction for drilling fluid procured from field.

You might also like

- Sans 10137 2011Document107 pagesSans 10137 2011Pamps Mangampo50% (2)

- Cohesive Sediments in Open Channels: Erosion, Transport and DepositionFrom EverandCohesive Sediments in Open Channels: Erosion, Transport and DepositionNo ratings yet

- Concrete CanvasDocument20 pagesConcrete CanvasJet Espejon JavierNo ratings yet

- SPE-184308-MS Effects of Mud Filtrate Invasion On Well Log MeasurementsDocument12 pagesSPE-184308-MS Effects of Mud Filtrate Invasion On Well Log MeasurementsCamiloAndresGuerreroNo ratings yet

- Lost Circulation Zone Prevention TechniquesDocument5 pagesLost Circulation Zone Prevention TechniquesAhmed GharbiNo ratings yet

- The Effect of Drilling Fluid Rheological Properties On Hole CleaningDocument5 pagesThe Effect of Drilling Fluid Rheological Properties On Hole CleaningJorge Gomez PortillaNo ratings yet

- 17 Drilling Fluids DifferentialDocument5 pages17 Drilling Fluids DifferentialSLACKENGINEERNo ratings yet

- DRILLING FLUIDS HandoutDocument10 pagesDRILLING FLUIDS HandoutHans SamNo ratings yet

- A Modelled Approach To Effective Hole Cleaning Techniques in Vertical and Deviated WellsDocument8 pagesA Modelled Approach To Effective Hole Cleaning Techniques in Vertical and Deviated WellsAuref Rostamian100% (1)

- Sedaghatzadeh 2016Document17 pagesSedaghatzadeh 2016mustafasavci900No ratings yet

- SPE/IADC 140144 Dynamic Aspects Governing Cement Plug Placement in Deepwater WellsDocument14 pagesSPE/IADC 140144 Dynamic Aspects Governing Cement Plug Placement in Deepwater WellsCoolProphetNo ratings yet

- General Knowledge of Fracturing Fluid DesignDocument7 pagesGeneral Knowledge of Fracturing Fluid Designbenny setyoNo ratings yet

- 2005 - Modeling of Fluid Filtration and Near-Wellbore Damage Along A Horizontal WellDocument12 pages2005 - Modeling of Fluid Filtration and Near-Wellbore Damage Along A Horizontal WellAndres RomeroNo ratings yet

- Surge and Swab Pressure in Oil DrillingDocument7 pagesSurge and Swab Pressure in Oil DrillingIJRASETPublicationsNo ratings yet

- Factors Affecting Surface Heave in Horizontal Directional Drilling OperationsDocument11 pagesFactors Affecting Surface Heave in Horizontal Directional Drilling OperationsSammy OmbiroNo ratings yet

- Stuck Pipe and Filter CakeDocument14 pagesStuck Pipe and Filter CakeKolawole AdisaNo ratings yet

- SPE 116226 Bell and Cuthill - FinalDocument10 pagesSPE 116226 Bell and Cuthill - FinalSherif MorsyNo ratings yet

- Hole CleaningDocument8 pagesHole Cleaninganon_850924421No ratings yet

- Capillary Pressure and Rock Wettability Effects On Wireline Formation Tester Measurements PDFDocument16 pagesCapillary Pressure and Rock Wettability Effects On Wireline Formation Tester Measurements PDFreborn2No ratings yet

- Assessment of Drill Cuttings Behaviour I PDFDocument9 pagesAssessment of Drill Cuttings Behaviour I PDFAhmed GharbiNo ratings yet

- Drilling Technology Ii (Pet401)Document88 pagesDrilling Technology Ii (Pet401)Ugo UmeojiakuNo ratings yet

- Smart DecisionDocument15 pagesSmart DecisionTripoli ManoNo ratings yet

- Chapter One 1.1 Hydraulic ExplorationDocument23 pagesChapter One 1.1 Hydraulic ExplorationNkem OkonkwoNo ratings yet

- A New Approach To Estimate Invasion Radius of Water-Based-Drilling-Fluid Filtrate To Evaluate Formation Damage Caused by Overbalance DrillingDocument11 pagesA New Approach To Estimate Invasion Radius of Water-Based-Drilling-Fluid Filtrate To Evaluate Formation Damage Caused by Overbalance DrillingAndres RomeroNo ratings yet

- Pore Pressure and Methods of Analysis ExplainedDocument72 pagesPore Pressure and Methods of Analysis ExplainedRrelicNo ratings yet

- Drilling Fluids Selection Criteria FactorsDocument5 pagesDrilling Fluids Selection Criteria FactorsMohamedElAbbasyNo ratings yet

- Mud Viscosity and RhelogyDocument8 pagesMud Viscosity and RhelogyHafizszul FeyzulNo ratings yet

- High Temprature and High Pressure 2Document16 pagesHigh Temprature and High Pressure 2Sushmita SatiNo ratings yet

- Functions and Properties of A Drilling FluidDocument8 pagesFunctions and Properties of A Drilling Fluiddekra abdoNo ratings yet

- Direct Shear Test: 1. Importance of The Shear Strength in SoilDocument9 pagesDirect Shear Test: 1. Importance of The Shear Strength in SoilIMJ JNo ratings yet

- Effective Hole Cleaning at High - Angle and Horizontal WellsDocument14 pagesEffective Hole Cleaning at High - Angle and Horizontal WellsColin100% (3)

- Pressure Qualitative: AssessmentDocument13 pagesPressure Qualitative: AssessmentLeidy TarquiNo ratings yet

- Rastegar 2015Document17 pagesRastegar 2015bayuNo ratings yet

- AADE 17 NTCE 094 EzeakachaDocument9 pagesAADE 17 NTCE 094 EzeakachaNamam Muhammad SalihNo ratings yet

- 55 - Formation FracturingDocument12 pages55 - Formation Fracturingrizal tri susiloNo ratings yet

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDocument8 pagesDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinNo ratings yet

- SPE 28053 McLellan Wang Predicting Pore Pressure PenetrationDocument11 pagesSPE 28053 McLellan Wang Predicting Pore Pressure PenetrationAndrés Eduardo Guzmán VelásquezNo ratings yet

- Temas de Tesis de Ingenieria de Petroleo y GasDocument23 pagesTemas de Tesis de Ingenieria de Petroleo y GasEver Baptista M67% (3)

- 6 Spe26402Document14 pages6 Spe26402juan joseNo ratings yet

- How Operating and Environmental Conditions Affect ErosionDocument24 pagesHow Operating and Environmental Conditions Affect ErosionPeaceMaker AmirahNo ratings yet

- Drilling Mud Properties and FunctionsDocument7 pagesDrilling Mud Properties and Functionsdavid100% (1)

- Apparent friction factor calculation and influencing factorsDocument3 pagesApparent friction factor calculation and influencing factorsNanda RizkyNo ratings yet

- Reservoir Characterization Using Pressure Derivative Method in Na-20 Well Senja FieldDocument6 pagesReservoir Characterization Using Pressure Derivative Method in Na-20 Well Senja FieldTripoli ManoNo ratings yet

- 2009-SPE-120473-MS Correlating Flowing Time and Condition For Perforation Plugging by Suspended ParticlesDocument16 pages2009-SPE-120473-MS Correlating Flowing Time and Condition For Perforation Plugging by Suspended ParticleshaimuoiNo ratings yet

- DST ManualDocument57 pagesDST ManualpaullodosNo ratings yet

- 01-Section 02 Drilling Fluids Functions PDFDocument11 pages01-Section 02 Drilling Fluids Functions PDFLazharNo ratings yet

- Causes and Consequences in Geopressured Systems: AADE-08-DF-HO-22 Loss of CirculationDocument5 pagesCauses and Consequences in Geopressured Systems: AADE-08-DF-HO-22 Loss of CirculationAline VenturaNo ratings yet

- Group-5 HF AssignmentDocument42 pagesGroup-5 HF AssignmentHitakshi KubavatNo ratings yet

- Operational Procedures: 7.04 Stuck PipeDocument7 pagesOperational Procedures: 7.04 Stuck Pipeciucalata88No ratings yet

- Shale Stability: Drilling Fluid Interaction and Shale Strengthspe - 54356Document10 pagesShale Stability: Drilling Fluid Interaction and Shale Strengthspe - 54356LightninWolf32No ratings yet

- SPE 90580 Productivity of Selectively Perforated Horizontal WellsDocument7 pagesSPE 90580 Productivity of Selectively Perforated Horizontal WellsmsmsoftNo ratings yet

- UBD Reservoir DesignDocument22 pagesUBD Reservoir DesignAli MuseNo ratings yet

- Iptc 14944 Experimental Study On The Phenomenon of Barite SagDocument14 pagesIptc 14944 Experimental Study On The Phenomenon of Barite SagD. Nathan MeehanNo ratings yet

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Drillingfluids (L15)Document78 pagesDrillingfluids (L15)Erison KaramaniNo ratings yet

- Drilling Engineering Ahmed-3Document83 pagesDrilling Engineering Ahmed-3Loh Chun Liang100% (2)

- Physical and Chemical Techniques for Discharge Studies - Part 1From EverandPhysical and Chemical Techniques for Discharge Studies - Part 1No ratings yet

- Erosion in Geomechanics Applied to Dams and LeveesFrom EverandErosion in Geomechanics Applied to Dams and LeveesStephane BonelliNo ratings yet

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Chevron Pascagoula RefineryDocument39 pagesChevron Pascagoula RefineryRay Francisdeo RomeyNo ratings yet

- + - + - LT (X' - 28. (x+1) 2-4 (X+L) +4 0 19. Y'+2 10-4v-5 - 2yDocument1 page+ - + - LT (X' - 28. (x+1) 2-4 (X+L) +4 0 19. Y'+2 10-4v-5 - 2yRay RomeyNo ratings yet

- PinatuboDocument2 pagesPinatuboRay RomeyNo ratings yet

- Carbon Anode Production Plant PDFDocument94 pagesCarbon Anode Production Plant PDFRay Romey100% (1)

- Utsira FormationDocument36 pagesUtsira FormationRay RomeyNo ratings yet

- Plant Layout Ayos PDFDocument204 pagesPlant Layout Ayos PDFRay RomeyNo ratings yet

- CHAPTER II Objectives CHAPTER II ObjectivesCHAPTER II ObjectivesCHAPTER II ObjectivesCHAPTER II ObjectivesDocument3 pagesCHAPTER II Objectives CHAPTER II ObjectivesCHAPTER II ObjectivesCHAPTER II ObjectivesCHAPTER II ObjectivesRay RomeyNo ratings yet

- Engineerirgung Online Distance Learning Fees 201516Document2 pagesEngineerirgung Online Distance Learning Fees 201516Ray RomeyNo ratings yet

- Coal Preparation PlantDocument51 pagesCoal Preparation PlantsuraiaNo ratings yet

- Liquid-Liquid Extraction Distribution CoefficientDocument17 pagesLiquid-Liquid Extraction Distribution CoefficientRay RomeyNo ratings yet

- Well Design Case StudyDocument36 pagesWell Design Case StudyAvinash KaurNo ratings yet

- Philippine National Standard For Petroleum Products & Other Fuel Related ProductsDocument1 pagePhilippine National Standard For Petroleum Products & Other Fuel Related ProductsRay RomeyNo ratings yet

- Well Design Case StudyDocument36 pagesWell Design Case StudyAvinash KaurNo ratings yet

- Blooms of The Colonial Green Algae, Botryococcus Braunii Kützing, in Paoay Lake, Luzon Island, PhilippinesDocument6 pagesBlooms of The Colonial Green Algae, Botryococcus Braunii Kützing, in Paoay Lake, Luzon Island, PhilippinesRay RomeyNo ratings yet

- L-ffi.J'o': Ilut+sur+t, Ut Ir, .61Document1 pageL-ffi.J'o': Ilut+sur+t, Ut Ir, .61Ray RomeyNo ratings yet

- Designing & Managing Drilling FluidDocument11 pagesDesigning & Managing Drilling Fluidfisco4rilNo ratings yet

- Drilling Fluid ComponentsDocument27 pagesDrilling Fluid ComponentsMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Society of Petroleum Engineers: 2014 SPE President 2015 SPE President 2013 SPE President History BackgroundDocument1 pageSociety of Petroleum Engineers: 2014 SPE President 2015 SPE President 2013 SPE President History BackgroundRay RomeyNo ratings yet

- 2 - ExxonMobil - Rose - enDocument10 pages2 - ExxonMobil - Rose - enRay RomeyNo ratings yet

- Society of Petroleum Engineers (Spe), Inc.: Section I. NameDocument2 pagesSociety of Petroleum Engineers (Spe), Inc.: Section I. NameRay RomeyNo ratings yet

- Processes 1:: Hydrode Alkylation UnitDocument5 pagesProcesses 1:: Hydrode Alkylation UnitRay RomeyNo ratings yet

- Ior and EorDocument2 pagesIor and EorRay RomeyNo ratings yet

- Patent SearchDocument1 pagePatent SearchRay RomeyNo ratings yet

- Drilling ProblemsDocument7 pagesDrilling ProblemsMEUBRONo ratings yet

- Benchmark OilsDocument2 pagesBenchmark OilsRay RomeyNo ratings yet

- ME6008 WELDING TECHNOLOGY Part B IQDocument1 pageME6008 WELDING TECHNOLOGY Part B IQVikram mNo ratings yet

- Performance Based Evaluation of Industrial Grade Resins Duolite ARA-9366 and Duolite A-368Document8 pagesPerformance Based Evaluation of Industrial Grade Resins Duolite ARA-9366 and Duolite A-368misterno2No ratings yet

- 6 Microbial ControlDocument36 pages6 Microbial ControlGladish RindraNo ratings yet

- The Changing World of OleochemicalsDocument9 pagesThe Changing World of OleochemicalsMarta Szymańska100% (1)

- Land Deep Production Casings in Menengai Geothermal FieldDocument30 pagesLand Deep Production Casings in Menengai Geothermal FieldShafeeq ChappuNo ratings yet

- Bio HGHDocument19 pagesBio HGHapi-240332064No ratings yet

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohNo ratings yet

- Process Integration Using Pinch Analysis: A Cement Industry Case StudyDocument4 pagesProcess Integration Using Pinch Analysis: A Cement Industry Case StudyReggie DueñasNo ratings yet

- Hydrogen BondsDocument2 pagesHydrogen BondsJohnNo ratings yet

- Surgical Nursing Calculation PracticesDocument2 pagesSurgical Nursing Calculation PracticesJéssica OinonenNo ratings yet

- COC-Dosing Skid - NalcoDocument11 pagesCOC-Dosing Skid - NalcodeyprasenNo ratings yet

- A Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryDocument4 pagesA Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryFirdaus Mat SoibNo ratings yet

- RN FDocument52 pagesRN Fhassan SardarNo ratings yet

- 109 Sodium ChlorideDocument6 pages109 Sodium Chlorideeng20072007No ratings yet

- Solutions of ElectrolytesDocument55 pagesSolutions of Electrolytesneha_dand1591100% (1)

- Alkyl HalideDocument54 pagesAlkyl HalideNelvianaNo ratings yet

- U15 S1-2 HW KeysDocument6 pagesU15 S1-2 HW KeysRohith GudatiNo ratings yet

- Product and Company Identification: Safety Data SheetDocument7 pagesProduct and Company Identification: Safety Data SheetZirve PolimerNo ratings yet

- Is 10204 PDFDocument4 pagesIs 10204 PDFDimple EntertainmentNo ratings yet

- 2 Basic Clinical Genetic - ppt-1Document24 pages2 Basic Clinical Genetic - ppt-1Najib M. NauvalNo ratings yet

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Removal of Hardness 1Document35 pagesRemoval of Hardness 1KISHAN PATELNo ratings yet

- 810-701 CRSeals Handbook PRESSURE Apr-2018Document4 pages810-701 CRSeals Handbook PRESSURE Apr-2018Anonymous VNu3ODGavNo ratings yet

- Agoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticDocument6 pagesAgoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticAlejandro De la GarzaNo ratings yet

- Astm A181-2001 PDFDocument3 pagesAstm A181-2001 PDFMohammed TariqNo ratings yet

- Ti OSO4Document4 pagesTi OSO4Liz AfanadorNo ratings yet

- Advance Engine Timing with STCDocument28 pagesAdvance Engine Timing with STCLuisPupiales100% (1)

- Solid Waste Management Not FinishDocument32 pagesSolid Waste Management Not FinishMans LaderaNo ratings yet