Professional Documents

Culture Documents

Pump

Uploaded by

Magin Idelfonso TorreblancaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump

Uploaded by

Magin Idelfonso TorreblancaCopyright:

Available Formats

CENTRIFUGAL PUMP

REV

0

1

2

PREPARED BY

DATE

APPROVAL

CLIENT

EQUIP. NO

PAGE

W.O.

REQUISITION NO.

SPECIFICATION NO.

PROCURED BY

INSTALLED BY

UNIT

AREA

name of pump goes here

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Fluid Service

Number Required

Pump Type

Location

Fluid Pumped

Normal Flow Rate

Design Flow Rate

Pumping Temperature

Vapor Pressure @ P.T.

Viscosity @ P.T.

Specific Gravity @ P.T.

gpm

gpm

deg F

psia

cP

water=1

Terminal Pressure

Static Head

Equipment Loss (see sketch)

Line Loss (per 100 equiv ft)

Equiv. Line Length

Safety Factor in Line Loss (%)

Total friction Loss

Control Valve

Net Suction Pressure

NPSH available

Total Discharge Pressure

Differential Pressure (TDH)

Design Flow Rate

ft / psi

ft / psi

psia

ft / psia

psia

ft / psi

gpm

Suction

Discharge

Area Classification

Power

Horsepower

Notes

psia

ft / psi

ft / psi

ft / psi

ft

Class

Volts

Calculated

Efficiency

Goulds

3196STD

1 x 1-1/2 x 8

Process Data

Mother Liquor

50.0 Corrosive or Non-Corrosive

non-corrosive

50.0 Corrosive Compounds

n/a

95.0 Solids

none

0.5

2.1 Hazards

1.1

Pumping Conditions

Suction

Discharge

14.7

14.7

2.0

1.0

20.0

9.9

6.6

3.3

24.3

12.0

8

380

0%

20%

0.5

0.3

111.0

54.8

15.4

39.3

14.9

79.4

168.4

63.9

50.0

Type

mfg std

6-1/2" diam.

less sleeve

Mechanical

fabricated

Pump Head

Impeller

Shaft

Seal

Baseplate

Connections

General

Pump Manufacturer

Model Number

Size

Mother Liquor

one

ANSI AA Back Pullout

Indoor

1-1/2" ANSI RF

1" ANSI RF

1

Group

460 Phases

1.86 BHP

56%

Mechanical Data

Material

316SS

316SS

316SS

carbon vs ceramic

steel

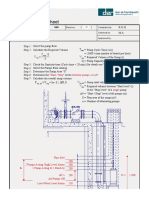

Sketch

Case Drn.

Electrical Data

D

Division

3

Cycles

3.33 Nominal

2

60

5.0

Enclosure TEFC

Frame

145T

RPM

1750

CENTRIFUGAL PUMP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

PREPARED BY

DATE

APPROVAL

EQUIP. NO

PAGE

W.O.

REQUISITION NO.

SPECIFICATION NO.

PROCURED BY

INSTALLED BY

UNIT

AREA

name of pump goes here

General

Fluid Service

Mother Liquor

Pump Manufacturer

Goulds

Number Required

one

Model Number

3196STD

Pump Type

ANSI AA Back Pullout

Size

1 x 1-1/2 x 8

Location

Indoor

Process Data

Fluid Pumped

Mother Liquor

Normal Flow Rate

gpm

50.0 Corrosive or Non-Corrosive

non-corrosive

Design Flow Rate

gpm

50.0 Corrosive Compounds

n/a

Pumping Temperature

deg F

95.0 Solids

none

Vapor Pressure @ P.T.

psia

0.5

Viscosity @ P.T.

cP

2.1 Viscosity cSt

1.8

Specific Gravity @ P.T.

water=1

1.1

SSU

8.6

Data From Published Curve for Selected Pump

Point 1

Point 2

At Best

Point 4

Eff Pt.

Flow Rate on Curve

(gpm)

450.0

600.0

750.0

900.0

Corresponding Head

(ft. liquid)

114.0

108.0

100.0

86.0

Corresponding Efficiency

(%)

72.5%

80.0%

82.0%

79.5%

Pump Performance with Viscous Fluid

Point 1

Point 2

At Best

Eff Pt.

450.0

600.0

750.0

114.0

108.0

100.0

72.5%

80.0%

82.0%

20.4

23.3

26.3

Viscous Flow Rate

Viscous Head

Viscous Efficiency

Viscous bhp

Point 4

900.0

86.0

79.5%

28.0

Pump Performance with Viscous Fluid

120.0

100.0

ft liquid

REV

0

1

2

CLIENT

80.0

60.0

40.0

20.0

400.0

500.0

600.0

700.0

gpm

Reference:

Sorrell, T., Taylor, R.P., Hodge, B.K., "Estimating Pump

Curves for High-Viscosity Fluids", Heating/Piping/Air

Conditioning, October 1990, p.75

800.0

900.0

1,000.0

You might also like

- British Columbian SBRDocument4 pagesBritish Columbian SBRMagin Idelfonso TorreblancaNo ratings yet

- E Series CEDocument2 pagesE Series CEMagin Idelfonso TorreblancaNo ratings yet

- Corrosion Resistant and Ultra-Pure Rotameters For Accurate Measurement of Liquids and GasesDocument18 pagesCorrosion Resistant and Ultra-Pure Rotameters For Accurate Measurement of Liquids and GasesMagin Idelfonso TorreblancaNo ratings yet

- PVC Hand BookDocument40 pagesPVC Hand Bookchy_81No ratings yet

- Hycor Hydroscreen Static Screen: Model HSDocument2 pagesHycor Hydroscreen Static Screen: Model HSMagin Idelfonso TorreblancaNo ratings yet

- Linedfittings SSMCDocument2 pagesLinedfittings SSMCMagin Idelfonso TorreblancaNo ratings yet

- Aerobic Sludge Digestion ReviewDocument4 pagesAerobic Sludge Digestion ReviewMagin Idelfonso TorreblancaNo ratings yet

- EDocument6 pagesEMagin Idelfonso TorreblancaNo ratings yet

- E8 SeriesDocument2 pagesE8 SeriesMagin Idelfonso TorreblancaNo ratings yet

- Anaerobic Sludge Digestion - Review Checklist: GeneralDocument8 pagesAnaerobic Sludge Digestion - Review Checklist: GeneralMagin Idelfonso TorreblancaNo ratings yet

- Ppro-Seal Natural Polypropylene Piping SystemDocument16 pagesPpro-Seal Natural Polypropylene Piping SystemMagin Idelfonso TorreblancaNo ratings yet

- GlossaryDocument14 pagesGlossaryMagin Idelfonso TorreblancaNo ratings yet

- Carbon Steel Flanges Dimensions and WeightsDocument3 pagesCarbon Steel Flanges Dimensions and WeightsChandan AulakhNo ratings yet

- Chemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionDocument80 pagesChemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionMagin Idelfonso TorreblancaNo ratings yet

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Document2 pagesFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaNo ratings yet

- ASME B36 10M Tableau Des DimensionsDocument2 pagesASME B36 10M Tableau Des DimensionsMichel LupienNo ratings yet

- Effect of Ultrafiltration Permeate Recycling On Deinking Efficiency of Flexo-Printed NewspapersDocument11 pagesEffect of Ultrafiltration Permeate Recycling On Deinking Efficiency of Flexo-Printed NewspapersMagin Idelfonso TorreblancaNo ratings yet

- Dimensions and weights of carbon and stainless steel buttwelding fittingsDocument3 pagesDimensions and weights of carbon and stainless steel buttwelding fittingsgiorselNo ratings yet

- That Is The Question: To Filter or To UltrafilterDocument4 pagesThat Is The Question: To Filter or To UltrafilterMagin Idelfonso TorreblancaNo ratings yet

- UltrafiltrationDocument4 pagesUltrafiltrationHari PrasathNo ratings yet

- Interruptor de Presion KoboldDocument2 pagesInterruptor de Presion KoboldMagin Idelfonso TorreblancaNo ratings yet

- DEC Design Standards for Intermediate Sized Sewerage FacilitiesDocument97 pagesDEC Design Standards for Intermediate Sized Sewerage FacilitiesMagin Idelfonso Torreblanca100% (1)

- API 12F Steel Tank Data Sheet: Form No. API12FDS1Document2 pagesAPI 12F Steel Tank Data Sheet: Form No. API12FDS1Magin Idelfonso TorreblancaNo ratings yet

- Wastewater Technology Fact Sheet - SBRDocument9 pagesWastewater Technology Fact Sheet - SBRJovo BozovicNo ratings yet

- Facility Data Sheet - Wastewater Treatment: Date: Contact InformationDocument1 pageFacility Data Sheet - Wastewater Treatment: Date: Contact InformationMagin Idelfonso TorreblancaNo ratings yet

- ASME B36 10M Tableau Des DimensionsDocument2 pagesASME B36 10M Tableau Des DimensionsMichel LupienNo ratings yet

- MatryxVaneActuators 329738 09-05Document12 pagesMatryxVaneActuators 329738 09-05Magin Idelfonso TorreblancaNo ratings yet

- 3196 b725-1Document19 pages3196 b725-1Magin Idelfonso TorreblancaNo ratings yet

- Signet 8860 Two-Channel Conductivity Controller: FeaturesDocument2 pagesSignet 8860 Two-Channel Conductivity Controller: FeaturesMagin Idelfonso TorreblancaNo ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IGS Piping GuideDocument61 pagesIGS Piping GuidemvrengarajanNo ratings yet

- PVCMC 0296 Us - tcm106 35825Document233 pagesPVCMC 0296 Us - tcm106 35825enrique.riera7693No ratings yet

- List of MEP Equipment-BhatiaDocument1 pageList of MEP Equipment-Bhatiakhanna786No ratings yet

- Circuit Balancing Valves Flow DataDocument27 pagesCircuit Balancing Valves Flow DataShoukat Ali ShaikhNo ratings yet

- Design calculation sheet: V V n−1) - ΔH. SDocument8 pagesDesign calculation sheet: V V n−1) - ΔH. SMoh Amm0% (2)

- Setting The HYDRAULIC VALVE BANKDocument6 pagesSetting The HYDRAULIC VALVE BANKAlex RamirezNo ratings yet

- PSC-Concrete Pump Spare PartsDocument20 pagesPSC-Concrete Pump Spare PartsSyahrul PBSNo ratings yet

- Lube Oil and H.P. Seal Oil Diagram For Reciprocating Compressor (Typical)Document3 pagesLube Oil and H.P. Seal Oil Diagram For Reciprocating Compressor (Typical)zsmith100% (1)

- ValvDocument12 pagesValvWilliams MedinaNo ratings yet

- Vertical Can Type Centrifugal LPG Pump Data SheetDocument1 pageVertical Can Type Centrifugal LPG Pump Data Sheetnecio77No ratings yet

- Catogarization Plan For Chlorination System-C&IDocument1 pageCatogarization Plan For Chlorination System-C&IpukhrajsoniNo ratings yet

- b16 10Document39 pagesb16 10Gustavo FamaNo ratings yet

- Orifice, Nozzle and Venturi Flow Rate MetersDocument9 pagesOrifice, Nozzle and Venturi Flow Rate MetersDian Ahmad HapidinNo ratings yet

- Vane Pump Guide: Types, Components, UsesDocument18 pagesVane Pump Guide: Types, Components, UsesPridhar ThiagarajanNo ratings yet

- Two Phase Flows and Practice: Learning ObjectivesDocument7 pagesTwo Phase Flows and Practice: Learning Objectivesbikas_sahaNo ratings yet

- Types of Sprinkler Systems PDFDocument4 pagesTypes of Sprinkler Systems PDFAhmad SirojiNo ratings yet

- Pump sizing calculationDocument6 pagesPump sizing calculationAtty Atty100% (1)

- Chiller Air Cooled Daikin Applied Scroll (030 070 Ton) PkgdAndPumpPkgd MPP (AGZ E)Document2 pagesChiller Air Cooled Daikin Applied Scroll (030 070 Ton) PkgdAndPumpPkgd MPP (AGZ E)Trương Ngọc TrọngNo ratings yet

- Check Valve: Valve Fluid Liquid GasDocument5 pagesCheck Valve: Valve Fluid Liquid GasMarcelene Justine DionisioNo ratings yet

- 325C Excavator Hydraulic System SchematicDocument2 pages325C Excavator Hydraulic System SchematicMgc Elektronik86% (7)

- Valve Sizing and Selection: FREE ResourcesDocument6 pagesValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARNo ratings yet

- SE115 Assignment 3 Due 02/03Document2 pagesSE115 Assignment 3 Due 02/03Bill WilliamsNo ratings yet

- BFV Butterfly Valve Features and SpecificationsDocument18 pagesBFV Butterfly Valve Features and Specificationsyash100% (1)

- Bridas Slip On Grandes b16.47Document1 pageBridas Slip On Grandes b16.47Nilton Inca TitoNo ratings yet

- Unit Ii: Isentropic Flow With Variable AreaDocument37 pagesUnit Ii: Isentropic Flow With Variable AreaMuthuvel MNo ratings yet

- Consolidated: Consolidated Safety Relief Valve Type 1900Document8 pagesConsolidated: Consolidated Safety Relief Valve Type 1900Peerasak ArunNo ratings yet

- Qty519 Impeller 2020Document1 pageQty519 Impeller 2020erofik72No ratings yet

- TYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsDocument4 pagesTYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsPeter RhoadsNo ratings yet