Professional Documents

Culture Documents

Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blistering

Uploaded by

andreathomeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blistering

Uploaded by

andreathomeCopyright:

Available Formats

TROUBLE with PAINT

Blistering of Paint Films

on Metal, Part 1:

Osmotic Blistering

by Clive H. Hare, Coating System Design Inc.

his months column will discuss the practical effects of

water absorption into applied

coating systems on metal. The article

begins a two-unit review of blistering failures and delaminations in

terms of the driving forces that produce them. At this stage, our discussion will only address blistering phenomena on metal. While blistering

can affect the service of coatings on

concrete and other substrates, these

will be considered in later segments

of this series, when we direct specific attention to the substrates. Blistering or bubbling produced by agents

other than water, such as gas- or

solvent-induced blistering, will not

be considered.

Water

Low solute

conc.

Paint film [semi-permeable membrane]

High solute

conc.

Water-soluble species

Substrate

Low solute

conc.

Water from environment is absorbed by film.

At lower interface, it contacts soluble species beneath film.

High solute

conc.

Water dissolves the soluble species, forming

a concentrated solution of low osmotic pressure.

As solution concentration drops with additional

migration of water, osmotic pressure

becomes too great for the adhesive forces holding

paint film to the substrate and results in the localized

delamination of film as a solution-filled blister.

Water continues to be drawn through the

film until the osmotic pressure on opposite sides

of the membrane equilibrates.

Low solute

conc.

High solute

conc.

Low solute

conc.

While complete equilibrium is never

achieved as the osmotic differential decreases,

so the rate of water migration and the

rate at which the blister size increases

also grow less.

High solute

conc.

Fig. 2 - Mechanism of osmotic blistering of coating films

From

substrate

(e.g.,

metallic

corrosion

product)

From

contamination

of substrate

(e.g., salts)

From

components

of lower paint films

(e.g., inhibitive

pigments,

solvents,

additives, etc.)

From

components

of paint film

(e.g., inhibitive

pigments,

solvents,

additives, etc.)

From

contamination

of lower paint

films

(e.g., salts)

Aqueous

environment

Finish coat

Soluble

species

Primer

Steel

substrate

Blistering,

Blistering,

delamination, delamination,

substrate

corrosion

deterioration

Fig. 1 - Osmotic blistering of coating on steel

Figures courtesy of the author

Because metal is impervious to

water, water cannot access the interface through the substrate (from beneath), as may occur on coated

wood and concrete. It must always

Copyright 1998, Technology Publishing Company

Blistering,

reduced cohesion,

film splitting,

delamination

Blistering,

reduced cohesion,

delamination,

corrosion

Blistering,

intercoat

delamination

Indicates location of failure

Fig. 3 - Sources, sites, and effects of osmotic blistering in coating films

first go through the coating or at

least progress along the interface

from locally exposed sites such as

pinholes, abrasions, and holidays.

An important key to understanding

continued

JPCL PMC / FEBRUARY 1998

45

TROUBLE with PAINT

the cause of blistering on metal can

be found by isolating the driving

forces that ensure the unidirectionality of water flow through the film to

the substrate and there sustain the

consequent accumulation.

Several recognized driving forces

are associated with the production

of blistering in coatings on metal by

diverse mechanisms. These include

osmotic gradients, producing blistering under fresh water conditions;

electroendosmotic gradients, producing blistering in ionic solutions;

and thermal gradients, producing

the cold wall blistering often seen in

humid environments. Cathodic blistering, produced by the generation

of alkalinity at the cathode, is also

associated with electrical gradients

and is often driven by an externally

impressed current. It is commonly a

consequence of the application of

high potential differences across

coated substrates.

Copyright 1998, Technology Publishing Company

In this article, we will consider

only osmotic blistering, which is

thought to be the most prevalent

type of failure. The article will discuss the mechanism of osmotic blistering, the factors contributing to osmotic blistering (including the

nature and source of the solute),

and the sources of osmotic gradients

from the corrosion process, retained

solvents, and non-carrier solvents.

Corrosion caused by osmotic blistering will be characterized, and osmotic blistering at pinholes will

be described.

The Mechanism of

Osmotic Blistering

We noted in the November 1997

column that intact paint films are

semi-permeable membranes, permeable to water, but impermeable to

dissolved solids. This model is precisely that which accommodates osmotic blistering. The phenomenon

(Fig. 1) depends on the presence of

a water-soluble material at either the

interface of the paint film with the

substrate, or, in multi-coat systems,

at some intermediate interface that is

covered by another coat of paint.

Often, the active material is an inorganic salt of some kind. In addition,

the external face of the paint film

(or system) must be in contact with

an aqueous environment that is either free of or lower in dissolved

material than the environment beneath the film.

Under such conditions, after water

is absorbed by the film, it is subsequently transferred to the lower film

interface (e.g., metal substrate).

There it may come in contact with

the soluble material on the substrate

and leave the film to dissolve the

material. Under fresh water conditions (distilled water or even high

humidity), such sub-film dissolution

continued

JPCL PMC / FEBRUARY 1998

47

TROUBLE with PAINT

creates a concentration gradient

across the film, which here acts as a

semi-permeable membrane. On the

downstream side of the film where

the solute is dissolved by water from

the film, the solute concentration is

much higher than is the solute concentration at the external (or upstream) face of the film. Under these

conditions, water will be drawn

through the film towards the concentrated solute, under osmotic

pressure. This transfer of water occurs because the water pressure and

salt concentrations on either side of

the membrane attempt to equilibrate. The mechanism of osmotic

blistering is illustrated in Fig. 2.

In quantitative studies of the phenomenon, van der Meek-Lerk and

Heetjes 1 have shown that blisters

initially grow fast, but the growth

slows with time. Growth is still measurable after 160 days immersion.

Accompanying this growth is a progressive decrease in salt concentration within the blister, which increases the water concentration and

progressively reduces the driving

force of the growth.

External water that is relatively

high in dissolved salts (e.g., salt

water) will not favor the formation

of osmotic gradients. In sea water,

osmotic blistering is not normally a

serious problem. However, the

deionized water and condensate

found in power generation facilities

as well as potable water found in

tanks and stand pipes may be particularly troubling. Rain water and

high humidities are more generalized sources of water of low solute

concentration, which can result in

high osmotic pressure. But the duration of the immersion in simple

exterior environments is normally

too short to produce problems.

However, persistent humidity and

condensation in such environments

has caused problems with films

based on highly soluble corrosion

inhibitors, such as zinc yellow.

Copyright 1998, Technology Publishing Company

The Nature and Sources

of the Solute

Inorganic Salts

The nature of the solute below the

semi-permeable membrane seems

unimportant.1 Osmotic blistering has

been related not only to chlorides,

sulfates, and other inorganic solubles often found on substrates, but

also to organics such as sugar.

Notwithstanding this, blistering

from aggressive depassivating salts

such as chlorides and sulfates are of

particular concern to the protective

coatings engineer. These materials

(unlike rust itself) readily accelerate

further underfilm corrosion and blistering. Regarding corrosion, there is

far more evidence of critical thresholds necessary to its initiation than

there seems with respect to blistering. Estimates of permissible salt levels for underfilm rusting vary from

1.2 mg Cl-/cm2 and 10 mg SO4=/

cm 2 (Igetoft 2 ) to 500 mg Cl - /m 2

(West3) and 50-100 mg SO4= (Morcillo4). The subject is reviewed in

detail by Alblas and van Londen.5

In the authors opinion, the search

for permissible salt concentration

thresholds at which corrosion will

not occur is inevitably complicated

by the variety of individual models

possible. Not only is the relationship

complicated by film thickness, but

infinitely more so by film characteristics and the mechanism of corrosion control. (Zinc-based systems

are far less vulnerable to salt contamination than are barrier systems,

for example.) Inhibitor-based systems, relying on anodic passivation

control, will be particularly vulnerable to these contaminations. Tolerable levels will depend upon the type

and loadings of inhibitor used, pigment volume concentration (PVC)/

critical pigment volume concentration (CPVC) ratio, pH of the micontinued

FEBRUARY 1998

49

TROUBLE with PAINT

croenvironment beneath the coatings, and temperature. Other characteristics of the binder itselfpermeability to water, oxygen, saponification

resistance, and dielectric constant

will all have an effect. Thus, it

would appear that permissible salt

levels for underfilm corrosion resistance, if not good blistering resistance, will safely be the lowest level

derived from the general experience,

unless the thresholds for the particular system are known. Unfortunately,

in many models, this position will

inevitably lead to over-engineering.

For osmotic blistering alone, the

type and molar concentration of

solute seems most important to the

size and morphology of the blister

level. Morcillo et al 6 found that

while ferrous sulfate concentrations

produced a large number of fine

blisters, sodium chloride induced

fewer but larger blisters. The actual

difference in the solute concentra-

50

FEBRUARY 1998 / JPCL PMC

tion on either side of the paint film

membrane need not be large to support the continued growth of the

blister. As is noted by van der MeekLerk and Heetjes, even trace

amounts of hydrophilic surface contaminants may be sufficient to cause

osmotic blistering.1

Blistering patterns reminiscent of

fingerprints have betrayed untoward

handling practices and the transfer

of perspiration onto the steel by

workers before painting. Most typically, it is, however, airborne salts

such as chlorides derived from marine environments, bridge deicing

salts, sulfates produced by acid rain

and industrial effluent (SO2, SO3),

and nitrogen oxides that cause frequent trouble. Abrasives (especially

silica sand) have also been noted as

a source of salt contamination7, although SSPC Report 91-07 showed

that the amount of salt transferred to

substrates from abrasive was ex-

tremely low and did not produce

blistering under conditions observed.8 The number and variety of

inorganic contaminants found on

bridge structure surfaces is surprisingly large.9

Significantly, solubles accidentally

or deliberately entrained in the coating itself may also cause difficulties.

These materials may be readily

transferred to the interface in water

service. Highly soluble inhibitive

pigments, such as chromates, molybdates, and borates within primer

films may cause osmotic blistering

either between coats or at the metal

interface beneath the primer (Fig. 3).

In 1991, the Pittsburgh Society for

Paint Technology found that blistering could be related to the amount

of water-extractable material in the

paint film.10

Similarly, soluble species may be

derived as a result of reaction or

continued

Copyright 1998, Technology Publishing Company

TROUBLE with PAINT

degradation of pigment or binder.

Investigating severe blistering of an

alkyd film in a mildly alkaline environment (pH 8.2), Bullet and Prosser

attributed the phenomenon to a soluble residue derived from the hydrolysis of the binder.11

Elm12 reports instances of osmotic

blistering over zinc-rich primers that

may become contaminated with

water-soluble salts after priming. Redress may be difficult because of the

porous nature of many zinc-rich

films, especially in cases where the

zinc film binder is non-soluble in

solvents of the finish coat. Washing

and rinsing the primer thoroughly

with fresh water before topcoating

may lessen if not eliminate the problem. Before recoating, the newly

cleaned primer must be dry.

AS SOLUBILITY OF BINDER IN SOLVENT SYSTEM IS PROGRESSIVELY IMPROVED,

PHASE SEPARATION AND MICROVOIDING OCCUR LATER AND LATER IN THE FILM

FORMATION PROCESS.

Phase separation

(resin precipitation)

from non-solvent

systems occurs

very early during

film formation.

Film cohesion is

poor with open pores.

Phase separation

from poor solvent

system occurs

early during

film formation.

Copyright 1998, Technology Publishing Company

No phase separation

occurs in films

deposited from

good solvent system.

No microvoiding

occurs, even near

interface.

Residual hydrophilic solvents

will occupy microvoids in lower

layers of film and attract water

into film, setting up osmotic blistering.

Fig. 4 - Phase separation, microvoiding, and solvent entrapment as a cause of

osmotic blistering

Oxygen-rich water is drawn to interface

osmotically, accumulating in layers until

film delaminates.

a.)

The Products of the

Corrosion Reaction

Osmotic gradients may also arise directly from the corrosion process itself. Water and oxygen can directly

access the metal at isolated sites of

non-adherent film and crevices beneath the film where the paint failed

to wet the substrate. Their corrosion

products, which have some solubility in water, may cause trouble. An

example of these corrosion products

is Fe(OH)2. These too may initiate

osmosis, especially where oxygen

concentrations are low enough to

delay the secondary oxidation

process to the more insoluble ferric

(Fe(III)) compounds. Where chlorides and sulfates are simultaneously

present, the corrosion products (ferrous chloride hydrate and ferrous

hydroxy sulfate) are even more soluble in water. With certain vulnerable

ester-based binders (e.g., oil alkyds),

the high pH generated at the cathode may hydrolyze the polymer.

This reaction not only loosens the

adhesion of the coating at the periphery of a blister (so enlarging it),

but also simultaneously produces

soluble degradation products such

Phase separation

from increasingly

better solvent system

occurs later during

film formation, and

microvoiding occurs

progressively closer

to interface.

b.)

Ferrous corrosion product

Iron dissolves, going into solution as

ferrous ions and, in the presence of oxygen,

forming soluble ferrous corrosion product.

Rust layer

c.)

Fe++ corrosion products are rapidly oxidized to

Fe+++ products, which are deposited as rust

layer on underside of blister dome, cutting off

oxygen supply to blister interior.

At periphery of blister, oxygen availability

through paint film is higher, allowing

cathode reaction.

d.)

Cathodic hydroxyl at periphery of blister

causes film to delaminate, so that blister

expands, rust forms, and cathode sites

advance outward.

Fig. 5 - Corrosion process in osmotic blister

as alkali metal soaps, which also encourage osmotic blistering.11

Retained Solvents

Osmotic blistering can also be

caused by the retention of hydrophilic solvents and diluents within the film (most often high boiling

alcohols, glycol ethers, and esters).

Under suitable conditions, these solvents may remain in the film for

months. Many of these solvents are

highly miscible with water and

residual quantities of these materials

will draw water through the film osmotically, similar to the effects of

soluble salts. Blistering similar in appearance to blisters caused by subfilm salts will result from solvent retention. The reasons for such

discrete blister formation in films

having supposedly uniform solvent

distribution (as opposed to the

continued

JPCL PMC / FEBRUARY 1998

53

TROUBLE with PAINT

wholesale delamination of films so

affected) is explained by Funke.13

Funke has investigated the morphological structure of paint films

deposited from mixtures of solvents

and diluents.13,14 This research has

shown that the onset of incompatibility and phase separation in films

containing low boiling solvents and

high boiling diluents will depend

upon 3 factors:

the type and ratio of the solvents

and the diluents;

the application temperature; and

the glass transition temperature

(Tg) of the binder.

The morphological structure of the

film depends on when incompatibility sets in during conversion of the

film from liquid to solid. In well-formulated systems, films pass into the

glassy phase without any phase separation at all, and clear, continuous

films result. In systems with higher

concentrations of high boiling diluents, incompatibility and phase separation set in more rapidly, potentially resulting in various anomalous

morphologies. In extreme cases, the

development of incompatibility early

in the film formation process will

produce precipitation of the binder,

resulting in a non-continuous film. If

phase separation occurs only slightly

before the onset of gelation, the film

may be coherent, but it will tend to

contain large, open pores. Phase

separation occurring subsequent to

gelation will result in a closed, continuous surface layer covering a microvoided interior. As phase separation occurs nearer and nearer to the

time that the film passes into the Tg

state, the film will be progressively

freer of microvoids.

Significant to our discussion of osmotic blisters is the fact that the reduced microvoiding, noted as phase

separation that occurs later and later

during film formation (or as the solvent system progressively improves),

does not uniformly disappear.

Rather, it shifts downwards, occurCopyright 1998, Technology Publishing Company

ring at deeper layers of the film

nearer to the interface, at which location it is most likely to be found.

Hydrophilic diluents and marginal

solvents are found primarily within

these microvoided areas close to the

interface (Fig. 4).

Under conditions favoring osmosis, water diffuses through the film

towards these microcellular inclusions adjacent to the interface. The

rate of water diffusion under osmotic pressure differentials is much

greater than is any tendency of the

entrapped solvents and diluents to

desorb water from the film. Thus,

water accumulation is progressive

and results in a blister pattern resembling the microstructure itself.

Funke14 used vinyl lacquers for his

investigation. In practical protective

coating systems, the formulation

practices (low boiling solvent, high

boiling diluents) he employed are

the exception rather than the rule.

However, with many thermosets,

Funkes arguments become more

valid. Their molecular weight increases and solubility profiles

change as a result of some conversion process (chemical cure and oxidation). Some degree of phase separation may even occur with truer

solvent systems as the cure progresses and solvency decreases.

These phenomena are aggravated

by increasing film thickness, where

the solvent (and non-solvent) retention is greater and the microcellular

structure more entrenched. The blisters are often found to contain water

and hydrophilic solvent (diluent), although corrosion may not immediately initiate.

If the film is post baked at temperatures well above the Tg before exposure, the offending solvent may

be released, and the osmotic pressures will not develop.

continued

FEBRUARY 1998

55

TROUBLE with PAINT

Osmotic Blistering by

Non-carrier Solvents from the

Service Environment

Related effects may occur from hydrophilic solvent imbibition in service. Coatings on the interior cargo

spaces of tankers handling methanol

have been known to develop severe

blisters, but only after the tanks

were discharged and refilled with

water. This blistering was not seen

where the same coatings were continuously exposed to either methanol

or water alone.15 Methanol uptake

by most coating films is likely. (The

molecule is small and is widely used

for just this purpose in paint removers.) The retention of water-miscible solvent (e.g., methanol) within

the film after the tanks are emptied

and then refilled with water will pull

water more readily into the film, osmotically producing the observed

blistering in a manner similar to that

noted above by Funke.12

In some cases, solvent-induced osmotic blistering may be quite unexpected. It has become common for

epoxy formulators in these days of

low VOC coatings to extend pot

lives of amine-cured epoxy systems

with ketones. Ketone solvents form

latent ketimines with amine curing

agents, which effectively tie up the

amine until after the coating is applied. Upon application, water from

the atmosphere reverses the reaction, releasing the amine as the ketone evaporates. The rate of dissociation will probably depend upon the

type of ketone used, the relative humidity and temperature of application, and other factors such as pigmentation. Platey metallic pigments,

which reduce the rate of moisture

ingress into the wet film and ketone

release out of the film, will prolong

the reaction in the lower layers of

the film. So too will high film thicknesses, which may also cause het-

erogeneous cure with the upper surfaces curing over the uncured or the

lesser cured lower layers.

Very polar solvents (e.g., ketones)

associate quite readily with water.

Some, such as methyl ethyl ketone

(often used in this type of coating),

are in fact water miscible. Should incompletely cured films of this type

be placed in immersion service before complete dissociation of the ketimine (or release of the methyl

ethyl ketone), osmotic gradients can

be set up readily. Water penetrating

the heterogeneously cured film may

release ketone in the lower layers

and associate with that ketone, producing osmotic blisters. While still

rare, the phenomenon is seen more

often with coatings developed since

the early 1980s, when ketimine

cross-linking agents became more

popular. The phenomenon has been

described by Tator.16

Similar phenomena are also possible with condensation cures in

which alcohols are released. One

example is incompletely cured ethyl

silicate zincs after recoating and initiation of immersion service. Here,

however, other failure mechanisms

may predominate, such as pure

stress effects leading to later splitting

of the zinc film.

Corrosion from

Osmotic Blistering

Corrosion in the local environment

beneath an osmotically formed blister does not necessarily occur immediately, especially if the liquid within

the blister does not contain depassivating salts. Eventually, when corrosion does initiate, the underside of

the dome of the blister becomes

covered in a greenish-black corrosion product, which may itself have

osmotic consequences. As Funke13

notes, corrosion is, however, a sequential process unconnected with

initial blister formation. In this case,

corrosion of the metal beneath the

continued

56

FEBRUARY 1998 / JPCL PMC

Copyright 1998, Technology Publishing Company

TROUBLE with PAINT

blister probably depends upon oxygen permeability of the coating. Corrosion proceeds as shown in Fig. 5.

If the blistering phenomenon results from soluble inhibitive moieties

(chromates and borates) included

within the paint film as pigments,

then the metal beneath the blister

may remain bright without forming

corrosion products for several

months. This condition can occur

even under accelerated high humidity test conditions designed to accelerate blistering failure.

Once the blister is formed, corrosion will occur by general cell activity between localized cathodes and

anodes on the metal beneath the

blister. It will be largely controlled

by oxygen permeability through the

film. Where oxygen permeability is

negligible, corrosion may be delayed

indefinitely. The onset of corrosion

may also be delayed if the external

environment is oxygen deficient.

Given the transmission of oxygen

and water to the interface, osmotic

blistering may well occur in the absence of externally derived salts or

other hydrophilic materials, as a result of the corrosion process. This

scenario requires the pre-existence

of some site of localized deadhesion

where water may first accumulate.

Corrosion rates would initially be

low because of the high resistance

inhibition provided by the non-ionic

water solution. However, the formation of soluble corrosion products

within the blister would set up osmotic gradients under favorable conditions, leading to increased osmotically induced blistering.

Thus, osmotic blistering in deoxygenated, deionized water systems,

such as are used in the nuclear

power industry, does not produce

corrosion within the blister. In nuclear power generation facilities, the

vapor phase of the taurus (the cooling water vessel beneath the primary

containment areas) is flooded with

nitrogen gas. The nitrogen is

thought to maintain bright, uncorroded steel beneath blisters that may

form under the coating in immersed

areas. In this case, the blister growth

is stabilized (as the osmotic pressure

involved is balanced by the hydrostatic pressure of the head of water).

It may be prudent to ignore the

blistering and leave the system in

place without repair. In Japan where

the taurus is never drained, coatings

have provided good service for 18

years or more in spite of such blistering. In the U.S., where similar

vessels are drained for cleaning and

inspection every 2 years (exposing

the interior of the blister to oxygen

during downtime), the blisters reveal

underfilm corrosion. This, together

continued

58

FEBRUARY 1998 / JPCL PMC

Copyright 1998, Technology Publishing Company

TROUBLE with PAINT

with associated cracking and deadhesive propagation, reduces the service life of the coatings to approximately 8 years.17 (Absorbed water

will plasticize the film under wet

conditions, and the wet, distensible

film may easily retain the blister deformation. As the water is desorbed

from the coating during downtime,

the film becomes less plastic. Hygroscopic tensile stresses arising from

the drying process may exceed the

tensile strength of the film, resulting

in a cracking failure.)

In more usual circumstances, corrosion will follow the onset of osmotic

blistering more rapidly, although the 2

phenomena remain sequential rather

than mechanistically related. As noted

above, the rate of corrosion depends

on the rate of oxygen permeability

through the film and into the blister.

Oxygen is consumed at the cathode

Fig. 6 - Photomicrograph of steel surface

beneath osmotically blistered coating.

Note steel surface beneath dome of blister

is bright and surrounded by circular areas

of green-black corrosion product.

Fig. 7 - Underfilm condition after osmotic blister formationshowing the deposit of corrosion

product underneath blister domes (the other side of the interface shown in Fig. 6, from which

film delaminated)

site within the blister in the formation

of hydroxyl ions and cathodic depolarization. It will also react with the initially produced ferrous ions to oxidize

them to the ferric state. This latter reaction soon predominates. Ferrous ions

accumulate within the blister, consum-

60

FEBRUARY 1998 / JPCL PMC

ing the available oxygen immediately

as it enters the blister cavity. The ferric

ions coat the underside of the blister

dome with a precipitated layer of

greenish-black corrosion product

(probably ferroso-ferric hydroxides

and magnetite, Fe304). This layer fur-

ther restricts access of oxygen to the

interior of the actual blister cavity, depriving the underside metal of fuel for

the cathode reaction. This area (beneath the blister dome) thus becomes

uniformly polarized anodically. The

cathode sites shift to the periphery of

the blister where the film is intact but

in contact with water (laterally from

the blister) and oxygen. Oxygen gains

access through the film, which is still

adherent and without the seal of corrosion product. The formation of cathodic hydroxyls at the periphery of

the blister creates an alkaline condition

under which adhesion may be lost;

thus, for certain coatings, the area of

the blister expands. The diffusion of

ferrous ions to the newly formed cathodic sites is followed by their precipitation onto the cathodic steel around

the periphery of the blister as ferric

compounds. If at this point the film is

stripped from the metal, a pattern of

annular rings of greenish-black rust is

noted, while the area of the steel immediately beneath the blister dome is

brighter (Figs. 1 and 6). The undersides of the blister dome are similarly

greenish-black in color (Fig. 7).

Osmotic Blistering at Pinholes

Osmotic blistering is also possible at

discontinuities in the film, as long as

the defect area is not too large (pinholes and pores rather than abrasions,

gouges, and large holidays). In this

case, however, blistering and corrosion phenomena are more interdependent. The condition is again described by Funke.13 He notes that in

all cases the onset of blistering is preceded by the appearance of corrosion

at the pinhole, which eventually becomes the peak of the blister dome.

The defective, semi-transparent membrane caused by the blister is repaired

by a plug of corrosion product (hydrated iron oxide), which forms at the

bottom of the pinhole channel. Under

the sealed conditions, blister formation by osmosis can now occur. The

continued

Copyright 1998, Technology Publishing Company

TROUBLE with PAINT

soluble species is soluble ferrous

compounds. Corrosion products beneath the plug sites set up an osmotic

gradient across the now repaired film.

Again, the growing blister becomes

oxygen depleted because the ferrous

to ferric oxidation process consumes

the available oxygen as soon as the

oxygen enters the blister. Anodic polarization of the base of the blister site

and the shift in cathodes to the blister

peripheries follow as noted above.

Conclusion

Next months article will review

non-osmotically driven blistering of

coatings on metal.

References

1. L.A. van der Meer-Lerk and P.M.

Heertjes, Blistering of Varnish

Films on Substrates Induced by

Salts, JOCCA (March 1979), 79.

2. L. Igetoft, Relation between Surface Cleanliness and Durability

of Anticorrosive Paints on Structural Steel, in Proceedings of

2nd World Bridge Conference,

New York, NY, October 26-27,

1982 (St. Louis, MO: University

of Missouri-Rolla, 1983), p. 5.

3. J. West, The Relationship Between Coating Thickness and

Salt Contamination on Blistering

of Coatings, UK Corrosion/85

Harrogate, November 4-6, 1985.

4. M. Morcillo, S. Feliu, J.C. Galvan,

and J.M. Bastidas, Some Observations on Painting Contaminated Rusty Steel, JPCL (September

1987), 38.

5. B.R. Alblas and A.M. van Londen, The Effects of Chloride

Contamination on the Corrosion

of Steel Surfaces: A Literature Review, Protective Coatings Europe (February 1997), 18.

6. M. Morcillo, S. Hernandez, J.

Simancas, S. Feliu Jr., and S.

Gimenez, Underfilm Corrosion of

Steel Induced by Saline Contaminants at the Metal/Paint Interface, JOCCA (January 1990), 24.

Copyright 1998, Technology Publishing Company

7. W.C. Johnson, Detrimental Materials at the Steel/Paint Interface, New Concepts for Coating

Protection of Steel Structures,

ASTM STP 841, eds. D.M. Berger

and R.F. Wint (Washington, DC:

ASTM, 1984), p. 28.

8. B.R. Appleman, S.K. Boocock, R.E.

Weaver, and G. Soltz, Effect of

Surface Contamination on Coating

Life, SSPC Report 91-07 (FHWA

Report RD-91-011) (Pittsburgh,

PA: SSPC, June 1991).

9. H. Gross, Examination of Salt

Deposits Found under German

Painted Bridges, Materials Performance (October 1983), 28.

10. W. Wettach and the Pittsburgh Society for Paint Technology, A

Study of Factors Affecting the Rusting of Steel and Blistering of Organic Metal CoatingsII, Official

Digest (November 1961), 1427.

11. T.R. Bullet and J.L. Prosser, Correspondence on Swelling and

Blistering in Paint Films, JOCCA

(December 1962), 836.

12. A.C. Elm, Zinc Dust Metal Protective Coatings, New Jersey

Zinc Co. Publication, New York,

NY, May 1968.

13. W. Funke, Blistering of Paint

Films & Filiform Corrosion,

Progress in Organic Coatings,

Vol. 9, p. 29.

14. W. Funke, Preparation and

Properties of Paint Film with Special Morphological Structure,

JOCCA (November 1976), 398.

15. Private Communication, G. Tinklenberg, 1996.

16. K.B. Tator, Can Failures Still

Occur When the Correct Coating

(for a Given Environment) Is Selected and Applied Properly? in

Corrosion Control by Organic

Coatings, ed. H. Leidheiser (Houston, TX: NACE, 1981), p. 122.

17. Private Communication, S.J.

Oechsle, 1996.

FEBRUARY 1998

63

You might also like

- European Patent Specification C09D 5/03, C09D 167/06,: Printed by Jouve, 75001 PARIS (FR)Document24 pagesEuropean Patent Specification C09D 5/03, C09D 167/06,: Printed by Jouve, 75001 PARIS (FR)andreathomeNo ratings yet

- Allnex Liquid Coating Resins Product Guide - LRA1006-En-AM-0314Document17 pagesAllnex Liquid Coating Resins Product Guide - LRA1006-En-AM-0314andreathomeNo ratings yet

- Thesis - Gel-L Scott CrumpDocument187 pagesThesis - Gel-L Scott CrumpandreathomeNo ratings yet

- Advanced UV Powder Coatings Oct 2006Document6 pagesAdvanced UV Powder Coatings Oct 2006andreathomeNo ratings yet

- Bastani UV Curable Powder Coatings Containing Interpenetrating Polymer Networks IPNs Progress in Organic Coatings 2006-56-248Document4 pagesBastani UV Curable Powder Coatings Containing Interpenetrating Polymer Networks IPNs Progress in Organic Coatings 2006-56-248andreathomeNo ratings yet

- ToolKit 21 CureandSolventResistantToolkitDocument2 pagesToolKit 21 CureandSolventResistantToolkitandreathomeNo ratings yet

- Allnex Powder BrochureDocument28 pagesAllnex Powder BrochureandreathomeNo ratings yet

- Painting FailureDocument21 pagesPainting FailureNnamdi Celestine NnamdiNo ratings yet

- Buysens - UCB - UV-Curable Powder Coatings on Wood Beneတts and Performance - Fatipec-2001Document10 pagesBuysens - UCB - UV-Curable Powder Coatings on Wood Beneတts and Performance - Fatipec-2001andreathomeNo ratings yet

- PDF PolymerDiafiltrationDocument10 pagesPDF PolymerDiafiltrationandreathomeNo ratings yet

- Cleaning Instructions For Organophilic Polymeric Membranes Version 25-07-2014Document1 pageCleaning Instructions For Organophilic Polymeric Membranes Version 25-07-2014andreathomeNo ratings yet

- Effect of PH On Fouling Attachments and Power Consumption inDocument13 pagesEffect of PH On Fouling Attachments and Power Consumption inandreathomeNo ratings yet

- Clements - Reactive Applications of Cyclic Alkylene Carbonates - Huntsman - January-15-2003Document12 pagesClements - Reactive Applications of Cyclic Alkylene Carbonates - Huntsman - January-15-2003andreathomeNo ratings yet

- PDF Membrane Filtration Using The SpintekDocument9 pagesPDF Membrane Filtration Using The SpintekandreathomeNo ratings yet

- Buss SMS Canzler - Thin Film EvaporatorsDocument16 pagesBuss SMS Canzler - Thin Film EvaporatorsandreathomeNo ratings yet

- Ulrich-et-Al - Membrane-Assisted VOC Removal From Aqueous Acrylic Latex - Journal of Membrane Science 452 (2014) 426-432Document7 pagesUlrich-et-Al - Membrane-Assisted VOC Removal From Aqueous Acrylic Latex - Journal of Membrane Science 452 (2014) 426-432andreathomeNo ratings yet

- Alexandria - Tue.nl Extra2 719470 Simons Membrane Thesis TUEDocument131 pagesAlexandria - Tue.nl Extra2 719470 Simons Membrane Thesis TUEandreathomeNo ratings yet

- Marijke Aerts - TUE-Thesis-2012 - Residual Monomer Reduction in Polymer Latex Products by Extraction With Supercritical Carbon DioxideDocument169 pagesMarijke Aerts - TUE-Thesis-2012 - Residual Monomer Reduction in Polymer Latex Products by Extraction With Supercritical Carbon DioxideandreathomeNo ratings yet

- Sulzer Process TechnologyDocument16 pagesSulzer Process Technologyandreathome100% (1)

- Bayer Poly NCODocument24 pagesBayer Poly NCOandreathomeNo ratings yet

- Brochure Polyisocyanates Polyaspartics Change The Coatings Game 14-06-2011 EDocument20 pagesBrochure Polyisocyanates Polyaspartics Change The Coatings Game 14-06-2011 Eandreathome100% (1)

- Chemistry of Fatty AcidsDocument44 pagesChemistry of Fatty Acidshenry_madumere1365100% (3)

- Fatty Acids Building Blocks For IndustryDocument20 pagesFatty Acids Building Blocks For IndustryThichiyona Kesuma SomopawiroNo ratings yet

- Bunel 250204 E-Polymers 2004 No. 011 Characterization of An Isophorone-Based Polyisocyanate IPDI-Isocyanurates .Document9 pagesBunel 250204 E-Polymers 2004 No. 011 Characterization of An Isophorone-Based Polyisocyanate IPDI-Isocyanurates .andreathomeNo ratings yet

- Resin Shrinkage Values Chart Under 40 CharactersDocument2 pagesResin Shrinkage Values Chart Under 40 CharactersandreathomeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Brochure Aqua Armour - 1Document2 pagesBrochure Aqua Armour - 1Jaime Alarcón BizarroNo ratings yet

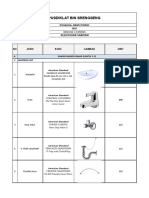

- List Sanitair AsramaDocument6 pagesList Sanitair Asramairvan ramdhaniNo ratings yet

- Bunker PlansDocument26 pagesBunker PlansKevin100% (3)

- IGBCDocument84 pagesIGBC04-AR-17-28 PRASAD SALONI PRAVEEN SUCHITANo ratings yet

- Research 3-5-20Document33 pagesResearch 3-5-20Dan Louie Jubay100% (1)

- Effluent Treatment3Document14 pagesEffluent Treatment3Mirza Md. Nazmus SakibNo ratings yet

- 2 - Water Quality Analysis and ManagementDocument29 pages2 - Water Quality Analysis and ManagementAntonio Z Manchete100% (3)

- China PTA IndustryDocument26 pagesChina PTA IndustryAnil kapadia100% (1)

- Water Tanks For Fire ProtectionDocument4 pagesWater Tanks For Fire Protectionwfjerr100% (1)

- Regional Environmental Corridors September 2005 (Unprotected)Document182 pagesRegional Environmental Corridors September 2005 (Unprotected)apierce246No ratings yet

- Rettenmaier France Natural Fiber DocumentDocument4 pagesRettenmaier France Natural Fiber DocumentKhaoula GougniNo ratings yet

- Chapter 9 HydrogenDocument19 pagesChapter 9 HydrogenYash PlayNo ratings yet

- Washer-D Isi Nfectors: List of ContentsDocument132 pagesWasher-D Isi Nfectors: List of ContentsМилош СтарчевићNo ratings yet

- Lesson Plan in Epp 6 (Crop Production)Document8 pagesLesson Plan in Epp 6 (Crop Production)Jackaii Waniwan IINo ratings yet

- Activity 1 2017Document3 pagesActivity 1 2017NelsonTingNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedCriss JungNo ratings yet

- Paper Plant Energy Audit ReportDocument77 pagesPaper Plant Energy Audit ReportAnubhav Gupta100% (2)

- BTS + MVE AJ Bladeless Fluid Machinespo + Small Hydroelectric Power Station 060404Document2 pagesBTS + MVE AJ Bladeless Fluid Machinespo + Small Hydroelectric Power Station 060404Martin KubíčekNo ratings yet

- Growth and Biochemical Composition of Kappaphycus (Rhodophyta) in Customized Tank Culture SystemDocument7 pagesGrowth and Biochemical Composition of Kappaphycus (Rhodophyta) in Customized Tank Culture SystemMuhammadNo ratings yet

- Experiment 3 - States of MatterDocument6 pagesExperiment 3 - States of MatterJade Paquing100% (1)

- Questions 1-13 Are True or False. Write T For True and F For False, Respectively, in The Left Margin Preceding The Question NumberDocument20 pagesQuestions 1-13 Are True or False. Write T For True and F For False, Respectively, in The Left Margin Preceding The Question Numberhshshs hshs sshdgNo ratings yet

- Safety Data Sheet: Product Name: GAS OILDocument10 pagesSafety Data Sheet: Product Name: GAS OILJustice MachiwanaNo ratings yet

- Drying LectureDocument85 pagesDrying LectureHaroon RahimNo ratings yet

- Gardosol: Description: GARDOSOL Has Been Registered Under The NSF International Registration Guidelines ForDocument2 pagesGardosol: Description: GARDOSOL Has Been Registered Under The NSF International Registration Guidelines ForAardwolf PestkareNo ratings yet

- 76BDocument4 pages76BJamie SchultzNo ratings yet

- Regeneration Protocol of Dr. Robert O. Becker, M.D.Document19 pagesRegeneration Protocol of Dr. Robert O. Becker, M.D.---0% (1)

- DMT For The MassesDocument5 pagesDMT For The MassesJose Rodriguezz100% (7)

- Physics Book 5054 o Level PDFDocument1,015 pagesPhysics Book 5054 o Level PDFSuhaan HussainNo ratings yet

- Ecologix EcoPack pdf-4 (EcoPack)Document1 pageEcologix EcoPack pdf-4 (EcoPack)Citramanda ServicesNo ratings yet

- 07 Aug 2018 172414570O3K63CU9PreFeasibilityReport (PFR)Document38 pages07 Aug 2018 172414570O3K63CU9PreFeasibilityReport (PFR)devesh bhoyarNo ratings yet