Professional Documents

Culture Documents

Ets 06-02-02 LV ABC Fuse Switch v3

Uploaded by

danituno1985Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ets 06-02-02 LV ABC Fuse Switch v3

Uploaded by

danituno1985Copyright:

Available Formats

Ergon Energy Corporation Limited

Technical Specification for LV ABC

Fuse Switch Disconnectors

ETS-06-02-02

Check this is the latest Process Zone version before use.

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

Contents

1.

Purpose and Scope...................................................................................................... 4

2.

References.................................................................................................................... 4

2.1

3.

Applicable Standards .......................................................................................... 4

Drawings....................................................................................................................... 5

3.1

Drawings by the Purchaser ................................................................................. 5

3.2

Drawings by the Tenderer................................................................................... 5

4.

Service Conditions....................................................................................................... 5

5.

Design and Construction ............................................................................................ 5

6.

5.1

General ............................................................................................................... 5

5.2

Maximum Power Dissipation............................................................................... 6

5.3

Ratings................................................................................................................ 6

5.4

Mounting ............................................................................................................. 6

5.5

Housing............................................................................................................... 6

5.6

Contacts.............................................................................................................. 7

5.7

Terminal Connections ......................................................................................... 7

5.8

Corrosion Protection ........................................................................................... 8

5.9

Vibration.............................................................................................................. 8

5.10

Marking ............................................................................................................... 8

Performance and Testing ............................................................................................ 8

6.1

Type Tests .......................................................................................................... 8

6.2

Batch Tests ......................................................................................................... 9

7.

Risk Assessment ......................................................................................................... 9

8.

Quality Assurance........................................................................................................ 9

9.

8.1

Purchasers Policy ............................................................................................... 9

8.2

Documentary Evidence....................................................................................... 9

8.3

Quality Certification Program .............................................................................. 9

Samples ........................................................................................................................ 9

9.1

Production Samples............................................................................................ 9

9.2

Sample Delivery.................................................................................................. 9

Check this is the latest Process Zone version before use.

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

9.3

Sample Purchase................................................................................................ 9

10. Packaging and Marking ............................................................................................. 10

10.1

Packaged Lots .................................................................................................. 10

10.2

Recommended Installation Procedure .............................................................. 10

11. Service Performance ................................................................................................. 10

12. Reliability .................................................................................................................... 10

12.1

Service Life ....................................................................................................... 10

12.2

Evidence in Support of Reliability...................................................................... 10

13. Training....................................................................................................................... 11

13.1

Training Material ............................................................................................... 11

14. Environmental Considerations ................................................................................. 11

15. Information to be Provided ....................................................................................... 11

15.1

Specific Technical Requirements...................................................................... 11

15.2

Checklist of Supporting Documentation ............................................................ 11

16. Attachment 1 Technical Details ............................................................................. 12

17. Attachment 1 Technical Details(Contd)............................................................ 13

18. Attachment 2 Technical Document Checklist ...................................................... 14

Check this is the latest Process Zone version before use.

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

1.

Purpose and Scope

This Specification sets out the technical requirements for ganged three phase, fully

enclosed fuse-switch disconnectors for use on overhead electricity distribution systems in a

totally exposed environment. The units are primarily used for the protection and on-load

switching of low voltage aerial bundled cable (LV ABC) distribution networks.

Items covered by this specification are listed below:

ITEM No

1

2

DESCRIPTION

SWITCH FUSED 415V,400A, 3 pole LV ABC

Solid link 400A to suit item 1

2.

References

2.1

Applicable Standards

STOCK CODE

0675123

2404944

The fuse switch disconnectors shall be designed, manufactured and tested in accordance

with the following Australian Standards and all amendments issued from time to time

except where varied by this specification.

Should inconsistencies be identified between standard and/or this specification, the

Supplier shall immediately refer such inconsistencies to the Corporation for resolution.

STANDARD

TITLE

AS 1125

Conductors in insulated electric cables and flexible cords

AS 1154

AS 1192

Insulator and conductor fittings for overhead power lines

Electroplated coatings - Nickel and chromium

AS 1463

Polyethylene pipe extrusion compounds

AS 1531

Conductors - Bare overhead - Aluminium and aluminium alloy

AS 1856

Electroplated coatings - Silver

AS 60529

Degree of protection provided by enclosures for electrical equipment (IP

Code)

AS 60269

Low voltage fuses - Fuses with enclosed fuse-links

AS 2837

Wrought alloy steels - Stainless steel bars and semi-finished products

AS 3100

Approval and test specification-General requirements for electrical

equipment

AS 3560

Electric cables- XLPE insulated - Aerial bundled - For working voltages

up to and including 0.6.1kV

AS 3947

Low voltage switchgear and control gear

AS 3947.3

Switches, disconnectors, switch-disconnectors and fusecombination units

Supplement 1

Fuse-switch-disconnectors and switch-disconnectors for use with

low-voltage aerial bundled cables

Check this is the latest Process Zone version before use.

Page 4 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

AS 4169

Electroplated coatings - Tin and tin alloys

AS 4680

Hot-dipped galvanised (zinc) coatings on fabricated ferrous articles

AS 5000

Electric cables polymeric insulated

AS/NZS ISO:

9001

Quality management systems - Requirements

3.

Drawings

3.1

Drawings by the Purchaser

There are no drawings attached to this technical specification.

3.2

Drawings by the Tenderer

The Tenderer shall supply with the tender, detailed drawings or pamphlets of the items

tendered.

4.

Service Conditions

The fuse switch disconnectors will be exposed to the following environmental conditions:

Ambient Temperatures

45o summer day time

-5o winter night time

5.

Solar Radiation Level

1000 watts per square metre with high ultraviolet

content

Precipitation

Tropical summer storms with gust wind speeds

above 160km/h, and an annual rainfall in excess of

1500 mm

Humidity

Extended periods of relative humidity in excess of

90% R.H.

Atmospheric Classifications

Areas of coastal salt spray and/or industrial pollution

with equivalent salt deposit densities in the range 2.0

- 3.0 g/m2.

Design and Construction

Design and construction performance parameters are detailed in this section.

5.1

General

The fuse-switch-disconnector shall consist of an upper housing holding the conductor

terminals and the contacts and a hinged lower housing holding the fuse links.

The lower housing of the fuse-switch-disconnector shall be provided with a nominal 20mm

diameter eye or other suitable means to enable the unit to be operated using a standard

operating stick. Special provision shall be made on the lower housing to enable it to be

lowered to the ground on the end of an operating stick.

Check this is the latest Process Zone version before use.

Page 5 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

The switches may be used as fuse-switch disconnectors or isolating switches fitted with

DIN size 1 or 2 in fuse link sizes 160A to 400A and 250A or 400A solid links.

The fuse switch disconnector shall be able to accept fuse links having a minimum power

dissipation value of 34 watts.

5.2

Maximum Power Dissipation

The Tenderers are requested to nominate the maximum power dissipation (watt loss) of the

fuse links that the items tendered can accommodate safety in the service environment.

The switches shall incorporate arc quenching chambers. Details of the arc

quenching arrangement shall be submitted with the tender documents.

5.3

Ratings

The fuse-switch-disconnectors shall have the following ratings:

Rated operational voltage

450 volts

Rated insulation voltage

1000 volts

Rated impulse voltage

12 kV

Rated frequency

50 Hz

Rated short time withstand current

10kA

Degree of protection

IP23

Duty

Uninterrupted

Utilisation category

In accordance with AC 22B (refer Table II of AS

3947.3)

Making and breaking capacity

1.5 times rated operational current.

The tenderer shall state the maximum rating of each switch when used with solid

links or fuse links as stated in clause 5.1 under the ambient conditions specified in

clause 4.

5.4

Mounting

A suitable mounting bracket shall be provided with each unit to allow the disconnector to be

fixed to a timber or concrete pole using two M12 coach screws or bolts at 230mm centres.

Provision shall also be made to enable the units to be attached to concrete poles using

"bandit" straps.

Full details of the mounting bracket shall be supplied with the offer.

5.5

Housing

All exposed surfaces of the upper and lower housing of the unit shall be manufactured from

weather and UV resistant, glass fibre reinforced polymer or similar material. The housing

material shall contain carbon black filling to AS1463. It shall be impact resistant and have a

flammability rating of not less than HB 0.

The enclosure shall provide a degree of protection IP23 to the electrical components when

switch is in closed position.

Check this is the latest Process Zone version before use.

Page 6 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

5.6

Contacts

All electrical contact surfaces are to be nickel or silver plated in accordance with AS 1192

or AS 1856. The manufacturer must ensure that the thickness of plating provides durability

of the contact surfaces over a service life of 25 years.

All contacts shall be self-aligning and shall have a wiping action to remove oxide or other

contamination on the contact surfaces and constructed to eliminate arcing to the main

contacts.

Full details of jaw and hinge contacts shall be submitted with the offer.

5.7

Terminal Connections

5.7.1

The fuse-switch shall be fitted with terminal palms suitable for bolted lug connections on

both the supply and load sides of the unit and shall satisfy the temperature rise limits in

accordance with sub-clauses 7.2.2 and 8.3.3.1 of AS 3947.3 and AS 3947.3. (Supplement

1).

5.7.2

The connections shall be designed for use with tinned copper or aluminium lugs suitable for

aluminium or copper conductors (cross sectional area 25-240 mm2) and to minimise the

effects of electrolytic corrosion of dissimilar metals

5.7.3

Each terminal palm shall be provided with a 12mm stainless steel bolt/stud complete with a

stainless steel spring washer, flat washer and a nut for securing the cable lugs to the

terminal palm. Preference will be given to fuse-switch units having terminal palms which

provide for the parallel connection of two cables.

5.7.4

Cable entry points and cable securing bolts are to be located on top of the switch for ease

of cable installation.

5.7.5

Each cable entry point to be covered by individually hinged terminal covers for maximum

safety.

5.7.6

The lower housing is to fitted with a yellow indicator to show if a fuse link/solid link is

installed

Check this is the latest Process Zone version before use.

Page 7 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

5.8

Corrosion Protection

5.8.1

The latch mechanisms of the unit shall be constructed of corrosion resistant metals and

shall include no ferrous parts less than 4mm thick, other than stainless steel.

5.8.2

All current carrying parts shall be of a high electrical conductivity, corrosion resistant metal.

All copper and associated alloys shall be either nickel, electrolytically bright tin or silverplated. The thickness of plating should be sufficient to ensure long term durability of the

current carrying parts. Full details of plating offered to be provided.

5.8.3

Additional corrosion protection shall be provided by the application of grease to the current

carrying parts prior to assembly. Acceptable greases are Shell Alvania R3 or equivalent.

5.8.4

Tenderers are required to state the type of grease used.

5.8.5

All nuts, bolts and washers other than those associated with the mounting bracket shall be

stainless steel in accordance with AS 2837. The bolts and washers shall be Grade 316 and

to avoid binding, the nuts shall be Grade 304 and a suitable lubricant shall be applied to the

threads of all stainless steel bolts before tightening. The lubricant shall not contain graphite.

5.8.6

Mounting bracket and other ferrous parts of the units other than stainless steel shall be

galvanised in accordance with AS 4680.

5.9

Vibration

When the fuse link or switch blade is intact and correctly inserted the carrier shall latch

securely when closed and shall not be dislodged from the fuse contacts by severe vibration

or wind pressure.

5.10

Marking

Switches shall be clearly and durably marked in accordance with Section 5.2 of AS 3947.3

and the year of manufacture.

Link shall be clearly and durably marked with the current rating.

6.

Performance and Testing

6.1

Type Tests

6.1.1

Electrical and Mechanical Type Tests shall be carried out on each fuse-switch disconnector

and submitted with the tender.

6.1.2

The test certificates shall include the tests carried out in accordance with the requirements

of Clause 8 of AS 3947.3, Supplement 1.

6.1.3

Type test certificates shall be written in ENGLISH.

6.1.4

Where test reports to AS 3947 are not available, tests carried out to other International

Standards may be considered acceptable provided that the Tenderer provides a detailed

comparison of the test results so obtained with the requirements of AS 3947.

6.1.5

Testing shall have been undertaken at a NATA registered testing authority and must have

been carried out within the last two- (2) years.

Note: Should tenderers be unable to provide Type Test reports from a NATA registered

testing authority, then that the testing authority shall be:

INDEPENDENT of the MANUFACTURER; and

NATIONALLY ACCREDITED to carry out the relevant tests.

Check this is the latest Process Zone version before use.

Page 8 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

Tenderers shall state the credentials of the Testing Authority used to complete the Type

Tests.

6.2

Batch Tests

Tenderers are requested to advise the availability of Batch Tests for the products offered.

7.

Risk Assessment

There is no requirement for manufacturer provided safety risk assessments for the items

covered in this specification.

8.

Quality Assurance

8.1

Purchasers Policy

It is the Purchasers policy to procure goods, equipment and services from sources that

demonstrate the ability to supply quality products.

8.2

Documentary Evidence

Documentary evidence shall be provided concerning the level of quality system certification

associated with the supplier and/or manufacturer. This documentation shall include the

Capability Statement associated with the Quality System Certification.

8.3

Quality Certification Program

Tenderers shall provide details of their program to upgrade their Quality Certification to

meet the requirements of ISO 9001.

9.

Samples

9.1

Production Samples

When requested, production samples of each item offered shall be submitted to assist in

the evaluation of the offer.

9.2 Sample Delivery

Each sample shall be delivered freight free, suitably crated and packaged and labelled with

the following information:

Name of Tenderer and this Contract No.

Contract Item Numbers

Any supporting data on features or characteristics

9.3 Sample Purchase

Ergon Energy may, at its discretion, either purchase the items at the tendered price or

return the samples to the respective tenderer after the contract has been awarded.

Check this is the latest Process Zone version before use.

Page 9 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

10.

Packaging and Marking

10.1

Packaged Lots

All items are to be supplied in packaged lots in accordance with the quantities agreed

between the successful tenderer and the purchaser.

Each packaged lot shall be marked with the following information:

Item Description

Ergon Stock Code

Purchase Order Number

Contract No

Manufacturers Name

Pack Size

Pack Weight

10.2

Recommended Installation Procedure

Each packaged shall include the manufacturers recommended installation procedure

document.

11.

Service Performance

The tenderer shall provide the following information with respect to the items offerer.

(a)

The period of service achieved by the items offered within Australian service

conditions;

(b)

Australian electricity supply authorities who have a service history of the items

offered; AND

(c)

Contact names and phone numbers of relevant employees of those supply

authorities who can verify the service performance claimed.

12.

Reliability

12.1

Service Life

Suppliers are required to comment on the reliability of the equipment and the performance

of the materials offered for a service life of 25 years under the specified system/duty (see

Clause 1) and environmental conditions (see Clause 4).

12.2

Evidence in Support of Reliability

Such comments shall include evidence in support of the reliability and performance claimed

including information on Failure Mode and Effect Analysis.

Check this is the latest Process Zone version before use.

Page 10 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

13.

Training

13.1

Training Material

Training material in the form of drawings, instructions and/or audiovisuals shall be provided

for the items accepted under the offer unless the items have been supplied previously.

Tenderers shall state the availability of training materials which should include but is not

limited to the following topics:

14.

Handling

Storage

Application (particularity in areas of heavy coastal pollution)

Installation

Maintenance

Environmental performance

Mechanical performance

Disposal

Environmental Considerations

Suppliers are required to comment on the environmental soundness of the design and the

materials used in the manufacture of the items tendered. In particular, comments should

address such issues as recycling and disposal at the end of service life.

15.

Information to be Provided

15.1

Specific Technical Requirements

The specific technical requirements for the items offered shall be as stated in Attachment

1 of this specification. The supplier shall provide all details requested by Attachment 1

and shall guarantee such data.

15.2

Checklist of Supporting Documentation

Attachment 2 details a checklist supporting technical documentation which is required to

be submitted with the offer.

Check this is the latest Process Zone version before use.

Page 11 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

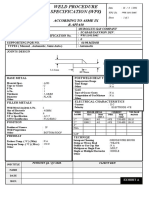

16.

Attachment 1 Technical Details

NOTE: A separate schedule is to be provided for each item offered except where

information common to all items only needs to be provided once.

PARTICULARS

UNITS

DETAILS

Specification Item Number

Stock Code

Manufacturers Name & Address

Place of Manufacture

Manufacturers Product Catalogue Number

Manufacturers Drawing Number

Will Batch Test Certificate be Supplied?

Yes/No

Type Test Report/Certificate No.

Electrical Characteristics:

Rated Voltage

Ue

KV

Rated Current with Fuse Links

Ie

Amps

Rated Current with Solid Links

Ie

Amps

Rated Frequency

Hz

Load-break Current

Ic/Ie

Rated Breaking Capacity

Amps

Maximum rated power acceptance of the

switch fuse in the service environment.

(minimum value 34watts)

Watts

Rated Short Current making Capacity with

Solid Links

Icm

Amps

Rated Impulse Withstand Voltage

16kV

Power Factor

Physical Characteristics:

Material Details:

Body

Check this is the latest Process Zone version before use.

Page 12 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

17.

Attachment 1 Technical Details(Contd)

PARTICULARS

UNITS

DETAILS

Fixed Contact

Quenching Chamber

Blade Base plate

Terminals

Blade Securing Tabs

Fixed Contact:

(a)

Plating Material

(b)

Plating Thickness

Terminals:

(a)

Plating Material

(b)

Plating Thickness

(c)

Type of Grease

Conductor Capacity:

(a)

Material

(b)

Minimum Conductor OD

(c)

Minimum Conductor Sectional Area

(d)

Maximum Conductor OD

(e)

Maximum Conductor Sectional Area

(f)

Maximum number of circuits per phase

mm

25mm2

mm

240mm2

Degree of Protection:

IP23

Utilisation Category:

AC22B

Grease:

Type

Copper

Minimum Drop Point Temperature

Type

Aluminium

Minimum Drop Point Temperature

Packaging:

Pack Size

Pack Weight

kg

SIGNATURE OF TENDERER:

_________________________________

Check this is the latest Process Zone version before use.

Page 13 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

Technical Specification for LV ABC Fuse

Switch Disconnectors

18.

Attachment 2 Technical Document Checklist

The Tenderer shall complete the relevant items (as applicable):

Clause

Ref.

Particulars

Tenderers

Response

Have full and comprehensive details been submitted WITH the tender documents associated

with each of the following items?

5.3

Switch Rating with Link & Fuse

Yes/No

5.4

Full details of the mounting bracket

Yes/No

5.6

Contact details

Yes/No

5.8.4

Type of Grease

Yes/No

6.1

Electrical & Mechanical Type test certificates

Yes/No

6.1

Alternative Testing Standards

Yes/No

6.1

Testing Authority credentials

Yes/No

6.2

Availability of Batch Certificates

Yes/No

8.2 &

8.3

Quality systems certification of BOTH the SUPPLIER and the Yes/No

MANUFACTURER

11

Service Performance

Yes/No

12

Reliability

Yes/No

13

Training Materials Availability

Yes/No

14

Environment Consideration

Yes/No

15

Completed Attachments of Technical Details

Yes/No

NAME OF TENDERER:

ADDRESS OF TENDERER:

SIGNATURE:

DATE:

FOR AND ON BEHALF OF TENDERER

______________________

Check this is the latest Process Zone version before use.

Page 14 of 14

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Specification ETS 06-02-02 Ver 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 4BSEN TBM TERB4RU Agustus 2018Document98 pages4BSEN TBM TERB4RU Agustus 2018Dani IsnandarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFDocument30 pagesAWS - PHB-3-2004 The Everyday Pocket Handbook On Welded Joint Details For Structural Applications PDFahmedabdelaziz851647No ratings yet

- LPI® Copper & Stainless Steel Earth Rods: o o o oDocument3 pagesLPI® Copper & Stainless Steel Earth Rods: o o o oCecep NanuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Beshay Long Products BroDocument44 pagesBeshay Long Products BroMahmoud OsamaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Awwa c501-1992 铸铁闸阀Document24 pagesAwwa c501-1992 铸铁闸阀allauScribd0% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hot Dip Galvanizing Design ConsiderationsDocument10 pagesHot Dip Galvanizing Design ConsiderationsAndreasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- U1. T2. Activity 1. Heat Treatments of SteelDocument11 pagesU1. T2. Activity 1. Heat Treatments of SteelTygaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Mfr. Technical OfferDocument35 pagesMfr. Technical OfferAlireza GolpesarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Welding Inspector Interview QuestionsDocument5 pagesWelding Inspector Interview Questionsவிஷ்ணு ராஜசெல்வன்No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Bessemer FurnaceDocument4 pagesBessemer FurnaceHariman El EmirNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Steel Grating WeightDocument4 pagesSteel Grating WeightCane CirpoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Astm A765 PDFDocument4 pagesAstm A765 PDFCristian OtivoNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Process Pumps: Made by KSBDocument16 pagesProcess Pumps: Made by KSBEdgar CalatayudNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- API 577 EXAM QUESTION For 653 ExamsDocument27 pagesAPI 577 EXAM QUESTION For 653 ExamsEjaz AsgharNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 6 Tube Plate Heat Exchanger Graphite Blocks Mersen 01Document20 pages6 Tube Plate Heat Exchanger Graphite Blocks Mersen 01mohsen123No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- An Empirical Study of The Company Sriram Cold Forgings PVTDocument61 pagesAn Empirical Study of The Company Sriram Cold Forgings PVTVPLAN INFOTECHNo ratings yet

- All Outokumpu SS GradesDocument1 pageAll Outokumpu SS Gradespipedown456No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- TDS Hardcarb 60 (#ETT - EN - 20.1)Document2 pagesTDS Hardcarb 60 (#ETT - EN - 20.1)Jimit ShahNo ratings yet

- MRM Product Guide 2019Document104 pagesMRM Product Guide 2019Eng Kyalo NzukiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Etag 032 Part 4 May 2013Document34 pagesEtag 032 Part 4 May 2013coolkaisyNo ratings yet

- HSE KIK Monitoring Hot Work Ceilling Dan OfficeDocument13 pagesHSE KIK Monitoring Hot Work Ceilling Dan Officeandri setiawanNo ratings yet

- Material Property Requirements For API Spec 6A, and 16A BodiesDocument3 pagesMaterial Property Requirements For API Spec 6A, and 16A BodiesomarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Consolidated-Relief Valve CatalogueDocument89 pagesConsolidated-Relief Valve CatalogueAshvin ParmarNo ratings yet

- CT 194111Document48 pagesCT 194111liebofreakNo ratings yet

- Drawing B BS 499 Part. 2Document10 pagesDrawing B BS 499 Part. 2محمد اظهرNo ratings yet

- Divisional Engineer National Highways, Vellore: M/S. Cmec-Megastar (JV)Document1 pageDivisional Engineer National Highways, Vellore: M/S. Cmec-Megastar (JV)Devapradatta NathNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- ASTM-A304 Standard Specification For Carbon and Alloy Steel Bar Subject To End Quench HardenabilityDocument50 pagesASTM-A304 Standard Specification For Carbon and Alloy Steel Bar Subject To End Quench HardenabilityNoel Francis100% (1)

- A Novel Flash Ironmaking - US Department of EnergyDocument2 pagesA Novel Flash Ironmaking - US Department of EnergyprmthsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)