Professional Documents

Culture Documents

Material Characteristics

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Characteristics

Uploaded by

Exsan OthmanCopyright:

Available Formats

MATERIAL CHARACTERISTICS

CONTENT

STEELS

PLASTICS

STAINLESS STEELS

OTHER METALS AND GLASS

CERAMICS

- Tl : 33 (0)1 44 29 00 00 - Fax : 33 (0)1 46 22 26 10 - www.cimap.fr

MATERIAL CHARACTERISTICS

STEELS

Materials

Chrome steel

AISI 52100

Symbolic

designation

Numeric

designation

100Cr6

1.3505

Chemical analysis %

Si

Mn

P

S

Cr

Hardness Density

Kg/dm3

0,95 0,15 0,25 0,030 0,025 1,35

60

max max

66 HRC

1,05 0,35 0,45

1,65

7,83

Through hardened

Carbon steel (with

chrome) C65Cr2

0,65 0,15 0,70 0,025 0,025 0,35

max max

60

0,70 0,35 0,80

0,45 66 HRC

7,85

Through hardened

Carbon steel

or AISI 1055

0,50

0,60

0,60

0,030 0,050

0,60 max 0,90

58

66 HRC

7,86

0,83 0,10 0,30 0,040 0,040

max max

0,88 0,30 0,70

60

66 HRC

7,85

Case hardened

Carbon steel

AISI 1010/1015

0,06 0,10

0,2 0,60

60

66 HRC*

7,86

Soft steel F

non hardened

XC 10 or CQ 15

0,17

max

Through hardened

Carbon steel C85

or AISI 1085

C55E (1)

1.1203 (1)

D85.2 (1)

1.0616 (1)

0,3 0,045 0,045

max max

0,9

0,045 0,045

max max

Properties

Bearing steel through hardened,

fine surface finish, high hardness

and load capacity

Through hardened, used in

applications in which case

hardened carbon steel

is not sufficient

Usable when through hardened steel

is not necessary

7,86

Can be machined and welded

* Surface hardness. (1) closest reference. 740 to 900 HV10 for diameters 12,7 according DIN 5401-1993.

PLASTICS

PHYSICAL PROPERTIES

DIN

Units

PA

PA6.6

POM

PP

PUR

PTFE

Standard

PAI

PEEK

(Torlon )

Density

53479

Kg/dm3

1,14

1,15

1,41

0,91

1,23

2,20

1,40

1,32

Water absorption to 23C HR 50%

53495

3,00

2,5

0,22

0,33

0,50

Hardness

53505

Kj/m2

R 100

R 118

R 120

D 73

A 90

R 15

E 86

R 120

Resilience

53453

Kj/m2

>7,00

>5

SR 10

142

Elastic modulus in tension

53457

N/mm

2 800

3 300

2 900

1 300

700

4 900

3 600

-269/+260

+260

-50/+250

49

278

160

THERMICAL PROPERTIES

52 612

T for continuous uses

2

T when deformation on load 1.85 N/mm

C

C

-40/+90 -40/+120 -50/+90 -10/+100

75

104

110

65

PA :

polyamid, Nylon 6,6, Zytel, Ultramid

POM : polyoxymethylene, polyacetal, Hostaform,

Delrin, Ultraform

PAI :

Polyamid-imide, Torlon

PP :

PUR :

PTFE :

PEEK :

polypropylene, Hostalen, Moplen

polyurethane, Vulkollan

polytetrafluorethylene, Teflon

polyetherethercetone, Ketron

GENERAL CHARACTERISTICS

Low density : from 0.92 to ~ 2

Good corrosion resistance

Noiseless use

Possible use as valves

Food contact possible for POM, PP, and PTFE.

APPLICATIONS :

Valves for food industry

Pumps

Hydraulic and electrical devices

Optical application

Filters

Medical and chemical devices

Linear motion

- Tl : 33 (0)1 44 29 00 00 - Fax : 33 (0)1 46 22 26 10 - www.cimap.fr

MATERIAL CHARACTERISTICS

STAINLESS STEELS

Materials

Symbolic

designation

Numeric

designation

Stainless 13 %

AISI 420 C

or Z40C13

X39Cr13

X46Cr13

X45Cr13

1.4031

1.4034

1.3541

0,36 1

1 0,04 0,03 12,5

max max max max

0,50

14,5

52

58

HRC

Good balance between corrosion

7,68 resistance and hardness; through

hardened stainless steel

Stainless 13 %

SEW 400

X65Cr13

1.4037

0,58 1

1 0,04 0,015 12,5

max max max max

0,70

14,6

58

64 HRC

7,7

X105CrMo17

1.4125

Stainless 17 %

AISI 440 C

or

Z100CD17

Stainless 17 %

AISI 430

or Z8C17

X6Cr17

Si

Chemical analysis %

Mn P

S

Cr Ni

0,40

58

64

1,2

0,80

HRC

18

1.4016

16

0,08 1

1 0,04 0,03

max max max max max 18

X14CrMoS17

1.4104

Stainless 18/10

AISI 304

or Z7CN 18-09

X5CrNi18-10

1.4301

17

8

0,07 1

2 0,045 0,03

max max max max max 19,5 10,5

X2CrNi18-09

1.4306

18

0,03 1

2 0,045 0,03

max max max max max 20

Stainless 18/12/3

AISI 316

X5CrNiMo17

or Z6CND 17-12

12.02

1.4401

16,5 10

0,07 1

2 0,045 0,03

max max max max max 18,5 13

1.4404

16,5 10

0,03 1

2 0,045 0,03

max max max max max 18,5 13

10

N:

0,11

max

Characteristics

close to

AISI 440C

Afford the advantage of maximum

7,75 hardness combined with corrosion

resisting properties. First choice

steel for stainless steel bearings

Intermediate stainless

steel quality between

420 and 304

380 HV*

7,68

Additional sulfur makes

this stainless steel

more machinable

135

7,93

0,20

0,60

Properties

7,68

135

0,10

0,15 15,5

1 1,50 0,04

0,17 max max max 0,35 17,5

Stainless 18/12/3

AISI 316L

X2CrNiMo17

or Z2CND 17-12

12.02

Hardness Density

Kg/dm3

0,95 1

1 0,04 0,03 16

max max max max

Stainless 17 %

AISI 430 F

or Z10CF17

Stainless 18/10

AISI 304L

Z2CN 18-10

Mo Other

2 N:

0,11 380 HV*

2,5 max

7,93

2 N:

0,11

2,5 max

7,98

135

2 N:

0,11 380 HV*

2,5 max

7,97

Austenitic stainless

steel; very good

corrosion and

chemical resistance

Better corrosion

resistance than above

stainless due to

molybdenum

* Indicative values

OTHER METALS AND GLASS

Material

Tungsten carbide

Glass

Titanium

Brass

Bronze

Hastelloy C

Chemical

composition

Hardness

Kg/dm3

Density

94 % Wc + 6 % Co

1550 HV

14,90

70 80 % SiO2

45 HRC

2,5

Properties

Extremely hard and abrasion resistant

Good corrosion resistance used in valves, but also in special

bearings

Pure titanium

130 - 180 HB

4,5

Good corrosion resistance, bio-compatible, low density

63 % Cu

180 - 200 HB

8,4

Good electrical conductivity

68.5 % 71,5 % Cu

200 - 220 HB

8,5

Good electrical conductivity

Ni 57 % Mo 17 % Cr 16 %

80-220 HB

8,94

Very good corrosion and high temperature resistant

- Tl : 33 (0)1 44 29 00 00 - Fax : 33 (0)1 46 22 26 10 - www.cimap.fr

MATERIAL CHARACTERISTICS

CERAMICS

CHARACTERISTICS

Crystalline structure.........................................

Chemical formula.............................................

Purity ........................................................... %

Density................................................. Kg/dm3

Hardness .................................................... HV

Compression strength............................... MPa

Elastic strength ......................................... MPa

Flexural strength ...................................... MPa

Rsilience KIC.................................... MPa.m1/2

Elasticity ................................................... GPa

Thermal expansion coef. .................... 10-6. K-1

Thermal conductivity........................... W/mK

Thermal capacity ................................... J/kgK

Usable maximum temprature.................... C

Acid resistance ................................................

Base resistance .................................................

Sapphire

Ruby

Alumina

Silicon

Nitride

HP

Zirconia

Y-TZP

Tungsten Stainless Chrome

Carbide

Steel

Steel

100 Cr6

*

*

*

mono

Poly

Poly

Poly

Poly

99 %

AI2O3

Si3N4

ZrO2

Wc (6T10)

AI2O3

99,80

90

90 95

Wc94+Co6

99,99 % 1 % Cr2O3

3,99

3,90

3,10 3,20

6,00

15

2 300

1 650

1 600

1 100 1 500

1 550

~ 4 000

2 100

2 400

3 000

5 300

280

400

390

470

1 000

700 1 100

1 900

1

4

6

10

430

380

320

200

610

5,30

4,50

5,50

3,20

10

5,50

36

29

40

2

80

755

900

750

500

201

1 800 2 000

1 500 1 800 1 200 1 500

1 000

very good

very good

very good

good

limited

good

good

good

good

limited

Poly

Poly

8

7,85

500 800

762 865

2 240

500 1 500

30-80

200

205

10 12

300 600

450

limited

non resistant

limited

non resistant

* For comparison.

APPLICATIONS

- High precision and high speed bearings.

- Hip joints.

- Valves.

- Measuring devices.

- Reference balls for 3D measuring machines.

- Ball gauges and triggers for 3D measuring machines and balls

for gauges and triggers.

07/02

ADVANTAGES

- High hardness (>1 300 Vickers).

- Low density (3 6 kg/dm3).

- Wear resistance due to low friction coefficient.

- High elasticity module (200 400 GPa).

- Chemical and thermal resistance. Electrical insulation

- High mechanical resistance (bending resistance :

400 to 1 000 MPa, up to approx. 1 000 C).

- Low porosity (<0,5 %), very high quality surface polish.

- Machining and polishing precision e.g : for a 14 mm Al2 O3

ball, variation on diameter is less than 0,1 m and surface

roughness (Ra) is less than 0,005 m.

- Tl : 33 (0)1 44 29 00 00 - Fax : 33 (0)1 46 22 26 10 - www.cimap.fr

You might also like

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDocument28 pagesTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNo ratings yet

- PETRONAS Employee Medical Top-Up PlanDocument2 pagesPETRONAS Employee Medical Top-Up PlanExsan OthmanNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- RFET Technique Detects Local and Gradual DefectsDocument4 pagesRFET Technique Detects Local and Gradual DefectsExsan OthmanNo ratings yet

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- EPA RMP OSHA PSM State Law SummaryDocument1 pageEPA RMP OSHA PSM State Law SummaryExsan OthmanNo ratings yet

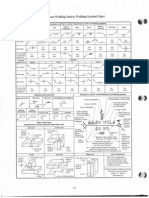

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Nozzle Design Tool AnalysisDocument2 pagesNozzle Design Tool AnalysisArt G. EnziNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- List of Timoshenko BooksDocument6 pagesList of Timoshenko BooksUdhamNo ratings yet

- Ficha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Document1 pageFicha Tecnica Polietileno Chemium Hdpe 2285 (7000f)Carlos SiuNo ratings yet

- Using CES EduPack For Tackling Problems Beyond The TextbookDocument27 pagesUsing CES EduPack For Tackling Problems Beyond The TextbookLula LeleNo ratings yet

- Introduction To Electron Microscopy and MicroanalysisDocument56 pagesIntroduction To Electron Microscopy and MicroanalysisPerlita2013100% (1)

- Worksheet-22 Reflection & Refraction of LightDocument2 pagesWorksheet-22 Reflection & Refraction of Lightanjalitashu01No ratings yet

- SA LAB - Singly Reinforced BeamDocument8 pagesSA LAB - Singly Reinforced BeamAjayNo ratings yet

- CE6402-Strength of MaterialssDocument23 pagesCE6402-Strength of MaterialssSedhu CivilNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument37 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsmanoNo ratings yet

- BS 970 SteelsDocument8 pagesBS 970 SteelsTamal Guha100% (2)

- Government Polytechnic Ambad: (Electric Power Transmission)Document21 pagesGovernment Polytechnic Ambad: (Electric Power Transmission)Sachin PatharkarNo ratings yet

- Macro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellDocument9 pagesMacro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellMuhamad SuharNo ratings yet

- Erickson Josephson J Project ProposalDocument4 pagesErickson Josephson J Project ProposalAdam Graham EricksonNo ratings yet

- Stress and StrainDocument56 pagesStress and StrainAl Faisal SiregarNo ratings yet

- 2020-Machinability of Inconel 718 A Critical Review On The Impact of Cutting TemperaturesDocument40 pages2020-Machinability of Inconel 718 A Critical Review On The Impact of Cutting TemperaturesVikash SrivastvaNo ratings yet

- The Ideal Mos CapacitorDocument33 pagesThe Ideal Mos Capacitortennisbat91No ratings yet

- Risk Analysis of Mercury-Contaminated Aluminum Heat ExchangersDocument16 pagesRisk Analysis of Mercury-Contaminated Aluminum Heat Exchangersmostafa_1000No ratings yet

- 11ADocument2 pages11ALorenzo Daniel Antonio67% (3)

- Cyprus National Annex en 1993-1-1Document11 pagesCyprus National Annex en 1993-1-1ruovNo ratings yet

- Connections in Precast Concrete Structures - Effects of Restrained Creep and ShrinkageDocument20 pagesConnections in Precast Concrete Structures - Effects of Restrained Creep and Shrinkageunix0123No ratings yet

- CE 21 CorrectionDocument4 pagesCE 21 CorrectionGintokiNo ratings yet

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- Titanium Ti-6Al-4V Alloy DataDocument2 pagesTitanium Ti-6Al-4V Alloy DataAdriano100% (1)

- BS ABUTMENT DESIGNDocument17 pagesBS ABUTMENT DESIGNEng Venance Masanja100% (1)

- PT Slab DesignDocument18 pagesPT Slab DesignwelwelNo ratings yet

- Structural AnalysisDocument35 pagesStructural AnalysisNagaraj RamachandrappaNo ratings yet

- Overview of Materials For Acrylonitrile Butadiene Styrene (ABS), MoldedDocument3 pagesOverview of Materials For Acrylonitrile Butadiene Styrene (ABS), MoldedarmandoNo ratings yet

- Modeling Cracked Section Properties For Shear Wall and Slab - ETABS - CSIDocument3 pagesModeling Cracked Section Properties For Shear Wall and Slab - ETABS - CSItrungceNo ratings yet

- Tempered Martensite: H. K. D. H. BhadeshiaDocument20 pagesTempered Martensite: H. K. D. H. BhadeshiaBahaa Eldin Sayed BahaaNo ratings yet

- DLP Electric ChargeDocument13 pagesDLP Electric Chargeapi-668571149No ratings yet