Professional Documents

Culture Documents

Risk Assessment Register

Uploaded by

Fareeha WaqarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Register

Uploaded by

Fareeha WaqarCopyright:

Available Formats

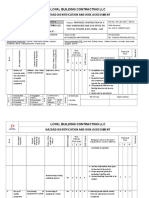

AL MADAR ENGINEERING L.L.C.

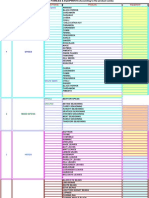

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

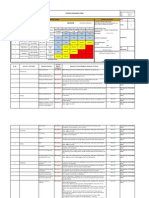

Step 2 Consider Likelihood

What is the likelihood (below) of the

hazard consequence in Step 1

occurring.

Almost

Certain

Is expected to occur in

most circumstances

Extreme Multiple fatalities or

permanent injuries

Critical Single fatality or permanent

Likely Will probably occur at

injury

least once

Major

Medical treatment or lost time Possible Event might occur at

injury

some time

Minor

First aid treatment

Unlikely / Event not expected to

Rare

occur or only in

exceptional

Insignific Incident or near miss no

circumstances

ant

treatment

Activity

If hazard exists

and

who

it

could harm

Hazard

(List the hazards relating to

the work)

1. Poor maintenance of

access equipment (e.g.

ladders,

steps,

Step 3 Calculate Risk

1. Take Step 1 rating and select the correct

column.

2. Take Step 2 rating and select the correct line.

3. Use the risk score where the two ratings cross

on the matrix below.

H = High, S = Serious, M = Medium, L = Low

Consequences

Crit

Ins

Min Maj.

Ext

.

Almost

M

S

H

H

H

Certain

Likely

M

M

S

H

H

Likelihood

Risk Assessment Guide

Step 1 Consider Consequences

What are the consequences of this hazard

occurring? Consider what is the most

probable consequence (below) with

respect to this work hazard.

Page 1 of 8

Possibl

e

Unlikel

y /

Rare

Controls

(List the controls to manage each of the hazards)

Regular inspections of equipment before every use and

records kept.

If hazard

exists

and who it

could harm

Workers,

Staff,

Contractors,

Clients

Risk

Assessment

(With controls in

place: High,

Serious, Medium

or Low)

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

scaffolds).

2. Inappropriate use of

tower scaffolds causing

trips and falls.

3. Working

on

Fragile

surfaces; carrying out

roof work.

Page 2 of 8

Three-monthly inspections of access equipment by a

competent person and records kept.

Defective equipment to be reported to manager.

Immediate removal and disposal of access equipment

found to be defective prior to use.

Suitable personal protective equipment must be

available.

Equipment to be used only where there is a firm, level

surface.

All equipment to be visually inspected before use and

records kept.

Appropriate footwear to be worn.

Safe system of work in place for work involving tower

scaffolds.

Staff who use tower scaffolds to be trained.

Equipment should be suitably stored after use.

Work at height training to be undertaken.

Avoid the need to work on/near/pass across a fragile

surface wherever possible e.g. repairing a skylight from

underneath using a tower scaffold.

No access to fragile surface allowed except by

authorized persons or specialist contractors using

appropriate equipment.

Use of suitable fixed access e.g. stairs/ladders rather

than temporary equipment where possible.

Fragile surface identified with suitable and prominent

signage.

Use of suitable working platforms with guard rails

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

4. Falls from height.

Page 3 of 8

during work on or near a fragile surface.

Use of suitable PPE identified from the Personal

Protective Equipment checklist.

Specific risk assessment to be undertaken prior to all

work at height activities.

Use of long handled tools where appropriate.

Suitable equipment used for specific jobs.

Staff not to use furniture or other inappropriate

fixed/mobile structures for working at height.

Consider use of fall arrest systems depending on

nature of task, equipment and duration.

Adequate and appropriate signs in place to warn of

hazards below work area.

Work scheduled to take place when persons/others are

not in the immediate area.

Ensure operatives trained to work at height.

5. Poor weather conditions

causing slips.

No work at height to be done outside in poor weather.

6. Risk of electrocution.

Contact with overhead and hidden cables.

Use of hand tools or battery operated tools wherever

possible.

All portable equipment must be tested every year.

Regular inspections of equipment before and after use.

7. Lack

of

protective

(PPE).

personal

equipment

PPE may be required; the Personal

Equipment checklist should be completed.

8. Being hit

objects.

by

Good housekeeping in place to ensure nothing is

Falling

Protective

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

powered

machinery and

machining

operations

Page 4 of 8

stored in such a way that it will fall from height.

Materials, tools or debris must not be thrown down

from height.

Areas where there is a risk of a falling object needs to

be clearly indicated and unauthorized people need to

be kept from it.

Tool belts to be used to prevent fall of tools/materials

from pockets etc.

PPE may be required; the Personal Protective

Equipment checklist should be completed.

9. Poor flooring or area

where work at height is

to be carried out.

Each individual area where work at height is to be

carried out needs to be inspected before use e.g. floors

surfaces, guard rails etc. and records kept.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Guards are either permanent fixtures, or are available to

be fitted to machines as necessary. They are correctly

adjusted and used by operators to prevent injury from

the following:

Moving/rotating

machine parts.

Moving/rotating

cutting tools and

blades.

Moving/rotating

work-pieces

Flying

cuttings

and/or coolants

Abrasive wheels or

parts thereof

Work-pieces are securely held with vices, chucks,

Entanglement,

Friction/Abrasion,

Cutting

Shearing,

Stabbing/Puncturing,

Impact,

Crushing,

Drawing in, and

Ejection

i.

ii.

iii.

iv.

v.

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

maintenance of

powered

machinery

use of hand

held Portable

Power Tools:

Machine operators wear suitable protective clothing i.e.

lab coat/boiler suit and eye/face protection. Loose

clothing and jewellery are not worn. Long hair is

required to be tied back.

Machinery is kept in good working order through

regular maintenance and cleaning.

Machinery is stopped and electrically isolated during

maintenance.

2. Electric shock.

1. Electric shock

dust,

fixtures and clamps. Emergency stop/brake mechanisms

are fitted as appropriate.

Adequate space is available around machines to allow

safe movement. Abrasive wheels are mounted and

dressed by trained competent persons.

Rests on bench/pedestal grinders are set by trained

competent persons.

1. Entanglement/drawing in,

crushing

2. Sparks/burns, fire,

small projectiles

Page 5 of 8

Electrical faultfinding and/or safety testing with live

equipment is only done by qualified and competent

persons working to standards.

Portable electrical equipment and power tools are

inspected and tested 6 or 12 monthly in compliance

with the companys Electrical Safety policy. An in line

Residual Current Device (RCD) unit is provided and

used.

Fire resistant boiler suits, safety glasses, face shields

and gloves are provided and used.

A flexible extraction arm is provided and used in

welding area.

Dust masks are provided and used for respiratory

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

protection.

Angle grinding work is done in a designated cordoned

area.

3. Noise

Ear defenders are provided and used if noise levels are

high.

4. Cuts/abrasions.

Guards are fitted, correctly adjusted and used where

required.

Gloves and boiler suits/lab coats are provided and used

as necessary to protect hands and body.

5. Trips.

hot

work

processes

(Soldering,

Brazing

and

Electric

Welding)

Page 6 of 8

1. Fire,

burns,

compressed

flashbacks

fumes,

gas,

2. Electric

shock,

UV

Radiation, flashes, noise

3. (Where applicable)

Trailing leads are routed away from walkways or are

covered to address trip hazard.

Suitable tongs/appliances for holding and moving hot

work-pieces are provided and used.

Suitable fire resistant overalls, lab coats, aprons, hats

and gloves are provided and used.

Suitable welding shields and goggles are supplied and

used.

Working area is kept clear of combustible materials.

Materials are selected carefully to minimise the health

risks.

A flexible fume extraction arm is provided and used in

welding area. Face masks are supplied and used as

appropriate.

UV welding screens are provided and used.

Oxy Acetylene equipment is checked and maintained

annually.

Flashback arrestors are fitted.

Electric welders are checked periodically in accordance

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

Human Factors

1. Unsafe person/practices.

Electricity

in

the Workplace

1. Electric

Manual

Handling

Operations

1. Musculo-skeletal

injury,

cuts,

abrasions, impacts.

fire

shock, burns,

Page 7 of 8

with the Companys Safety Policy.

Ear defenders are provided and used as appropriate.

Only people who are adequately trained or are

experienced and deemed as competent by the Work

Premises supervisor are allowed to work independently

in the Work Premises.

Others with limited experience are instructed and

closely supervised if working in the area.

Internal training to meet changing requirements within

the work premises is ongoing.

A range of Personal Protective Equipment is provided

and instructions on its use is provided as appropriate.

Working alone is not allowed in the work premises.

There is adequate provision of trained first aiders and

equipment.

Electrical power is isolated when work premises is

closed.

The consumption of food or drink is not allowed in the

working premises

Visitors are required to report to the office.

Fixed and portable electrical equipment is

maintained and tested by competent electrical

technicians in accordance with the companys

Safety Policy.

Materials are stored so as to minimize moving and

handling.

Key members of staff have been trained and are

experienced in manual handling.

Adequate lifting and moving equipment is available and

used in accordance with manufacturers instructions.

AL MADAR ENGINEERING L.L.C.

RISK ASSESSMENT REGISTER

Document No. AME-HIRA-F-01, Rev. 00, Date : 01-11-2014

1. Crushing,

Overhead

Crane

abrasion

impact,

Use

Materials:

of

1. Inhalation of dusts,

fumes and aerosols.

2. Skin and eye contact

with

harmful

materials.

Page 8 of 8

Portable lifting equipment is inspected annually

Gloves, safety glasses and safety shoes are provided and

used.

Specific training on handling of compressed gas

cylinders has been done by appropriate staff.

Operation of overhead crane is restricted to

trained/experienced staff.

People not involved are cleared from the area when

crane is in use.

Hard hats are provided and worn by people involved.

Cranes must be inspected annually.

Materials are carefully selected to avoid risks to health

where possible. Proprietary products are used in

accordance with manufacturers instructions or safety

data sheets.

COSHH assessments are done for any substances

hazardous to health. All substances, including cleaning

materials and oils are labelled as appropriate and stored

in suitable locations.

Dusts, fumes and vapours are extracted at source if

possible.

An appropriate coolant is used where possible.

Face masks are provided and used as required.

Gloves, safety glasses and face shields are provided and

used as required.

You might also like

- Risk Register AllLevelsDocument5 pagesRisk Register AllLevelsriyaz10100% (4)

- Sample Risk RegisterDocument38 pagesSample Risk Registerdioki100% (8)

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- Proposed Six Story Building For Community Concern Society - Risk RegistryDocument2 pagesProposed Six Story Building For Community Concern Society - Risk Registryjmaasa83% (6)

- Risk RegisterDocument20 pagesRisk Registerzayzan100% (2)

- Risk Register ExampleDocument1 pageRisk Register ExampleLuthfieSangKapten88% (16)

- Risk Register enDocument15 pagesRisk Register enamitdengle100% (1)

- Hses Risk Assessment Register: Equipment Description: N/ADocument51 pagesHses Risk Assessment Register: Equipment Description: N/AHussain Ayub100% (2)

- Risk AssessmentDocument8 pagesRisk AssessmentSubhransu Mohapatra50% (2)

- Risk register for construction projectDocument4 pagesRisk register for construction projectSreekumarNo ratings yet

- Risk RegisterDocument7 pagesRisk RegisterAlhad Panwalkar67% (3)

- Risk Register AllLevelsDocument5 pagesRisk Register AllLevelsSam Atia100% (1)

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDocument29 pagesIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- Site Activities Risk AssessmentDocument50 pagesSite Activities Risk Assessmentjamie542393% (41)

- Forklift Risk AssessmentDocument6 pagesForklift Risk AssessmentMoayed Altaweel76% (29)

- Project Risk RegisterDocument2 pagesProject Risk RegisterNixon100% (4)

- Risk RegisterDocument34 pagesRisk RegisterMohamedMoideenNagoorMeeran33% (3)

- Risk RegisterDocument8 pagesRisk Registerresearchmanager100% (1)

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- QSF 1 - RISK AND OPPORTUNITIES REGISTER-compilation by ClauseDocument26 pagesQSF 1 - RISK AND OPPORTUNITIES REGISTER-compilation by Clausemeth nawog100% (3)

- HEALTH & SAFETY RISK ASSESSMENTDocument52 pagesHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- JSA for Night Work at Laydown AreaDocument2 pagesJSA for Night Work at Laydown Areagulryz84100% (9)

- Risk RegisterDocument6 pagesRisk Registergroup2sd1314100% (2)

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- Ergonomics Risk MatrixDocument31 pagesErgonomics Risk Matrixvacky77No ratings yet

- IRP 22 Risk Register 2015Document30 pagesIRP 22 Risk Register 2015Jeya Kumar100% (1)

- Risk assessment for excavation worksDocument3 pagesRisk assessment for excavation worksYaser A. Al-Bustanji72% (18)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Risk Assessment FormDocument9 pagesRisk Assessment FormAbu ZahidNo ratings yet

- Risk Assessment Procedures ManualDocument12 pagesRisk Assessment Procedures ManualTony Gallacher60% (5)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocument3 pages125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Risk RegisterDocument3 pagesRisk Registergroup2sd1314100% (1)

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- Project Risk RegisterDocument14 pagesProject Risk RegisterNatarayan88% (8)

- Risk Assessment ConstructionDocument70 pagesRisk Assessment ConstructionArun Celestin93% (42)

- Incident Investigation Procedure.Document5 pagesIncident Investigation Procedure.Naga Rajan0% (1)

- SWP 002 - Risk AssessmentDocument23 pagesSWP 002 - Risk AssessmentAbhinavBanerjee100% (2)

- Risk Register - OHS - Examples For The OfficeDocument3 pagesRisk Register - OHS - Examples For The OfficeNick Hadley100% (2)

- Manage Risks and Seize OpportunitiesDocument5 pagesManage Risks and Seize Opportunitiesamyn_s100% (2)

- Construction Risk Assessments IndexDocument41 pagesConstruction Risk Assessments Indexmasoodae100% (4)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- 9.hazard Identification & Risk AssessmentDocument10 pages9.hazard Identification & Risk AssessmentMuhammad Javed100% (3)

- Risk AssessmentDocument7 pagesRisk AssessmentMuhammad Ibrahim100% (2)

- Hot Work Risk Assessment and PermitDocument3 pagesHot Work Risk Assessment and Permitstitchvn75% (12)

- UAE Legal Register OK TO USEDocument11 pagesUAE Legal Register OK TO USEPriyanka J75% (4)

- Risk Register ProjectDocument749 pagesRisk Register ProjectmanojmoryeNo ratings yet

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Noise: Guide For Risk Assessment in Small and Medium EnterprisesDocument10 pagesNoise: Guide For Risk Assessment in Small and Medium EnterprisesXozanNo ratings yet

- Contractor Risk Assessment FormDocument5 pagesContractor Risk Assessment FormRoger Simbhoo100% (1)

- Risk Register TemplateDocument10 pagesRisk Register TemplateNigist Woldeselassie100% (1)

- Environmental Risk and Opportunities RegisterDocument15 pagesEnvironmental Risk and Opportunities RegisterArmand Liviu80% (5)

- HP WASHING OF INTERNAL WATER TANK RISK ASSESSMENTDocument5 pagesHP WASHING OF INTERNAL WATER TANK RISK ASSESSMENTAhmad BarriehNo ratings yet

- Risk Assessment ProcedureDocument4 pagesRisk Assessment ProcedureRameeSahiba100% (1)

- All Tyeps Risk Assessment in Construction PDFDocument112 pagesAll Tyeps Risk Assessment in Construction PDFSorin Tec100% (1)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- Fall Protection and Electrical Safety ReportDocument7 pagesFall Protection and Electrical Safety ReportLaisah MindajaoNo ratings yet

- Cosh 19-28Document17 pagesCosh 19-28irikalouisecabradillacabuenasNo ratings yet

- Safe Work Method Statement: Fixed ScaffoldDocument11 pagesSafe Work Method Statement: Fixed ScaffoldJoe Waller100% (1)

- Safety ManualDocument33 pagesSafety ManualFareeha WaqarNo ratings yet

- Safety ManualDocument33 pagesSafety ManualFareeha WaqarNo ratings yet

- ISMS StandardDocument38 pagesISMS StandardFareeha WaqarNo ratings yet

- HACC Plan For MajdiDocument45 pagesHACC Plan For MajdiFareeha WaqarNo ratings yet

- Apparel CategoriesDocument32 pagesApparel CategoriesKumar Mayank100% (4)

- Panty Dama Rizada PDFDocument14 pagesPanty Dama Rizada PDFadriana50% (2)

- Bandhini (1) CompressedDocument42 pagesBandhini (1) CompressedVINODHINI 1No ratings yet

- Costing of Apparel ProductsDocument30 pagesCosting of Apparel ProductsSugandha Rathore100% (2)

- Market Share of Dabur Real JuiceDocument66 pagesMarket Share of Dabur Real JuiceAazam75% (4)

- As 3789.3-1994 Textiles For Health Care Facilities and Institutions Apparel For Operating Theatre StaffDocument7 pagesAs 3789.3-1994 Textiles For Health Care Facilities and Institutions Apparel For Operating Theatre StaffSAI Global - APACNo ratings yet

- Production Dept Shantanu NikhilDocument3 pagesProduction Dept Shantanu Nikhilkanikaluthra8No ratings yet

- ARWG Encampment Guide (2010)Document9 pagesARWG Encampment Guide (2010)CAP History LibraryNo ratings yet

- DIY Fermentation Lock - WikiHowDocument7 pagesDIY Fermentation Lock - WikiHowRizalito Lloven BrionesNo ratings yet

- Worksheets ClothesDocument2 pagesWorksheets Clothesadan oreaNo ratings yet

- IKEA's Global Marketing StrategyDocument3 pagesIKEA's Global Marketing StrategyJacky Nguyen0% (1)

- Whole Garment Production SystemDocument61 pagesWhole Garment Production SystemKriti Singh50% (4)

- Monthly Wholesale Price Index, Inflation and ContributionDocument210 pagesMonthly Wholesale Price Index, Inflation and Contributionnisarg_No ratings yet

- Exercises: Answer 1Document3 pagesExercises: Answer 1Naresh world SinghNo ratings yet

- Buying HouseDocument9 pagesBuying HouseujjwalaNo ratings yet

- Assignment: Orange Juice ManufacturingDocument10 pagesAssignment: Orange Juice ManufacturingAhmed AbuNasserNo ratings yet

- A Study of The European Cosmetics IndustryDocument165 pagesA Study of The European Cosmetics IndustryJae Chan LeeNo ratings yet

- Aeg Cooling Brochure - September 2008 PDFDocument16 pagesAeg Cooling Brochure - September 2008 PDFPieter SteenkampNo ratings yet

- A Project Report On A COMPARATIVE MARKET PDFDocument49 pagesA Project Report On A COMPARATIVE MARKET PDFdiksha palNo ratings yet

- Polvoron Marketing PlanDocument13 pagesPolvoron Marketing PlanAnonymous UKAWw4Bq85% (82)

- Consumer vs Industrial Goods Classification GuideDocument2 pagesConsumer vs Industrial Goods Classification GuideUnknown WandererNo ratings yet

- Acme BrochureDocument88 pagesAcme BrochurephaniNo ratings yet

- MRC-107T Tadiran RADIO PALLET TMDocument74 pagesMRC-107T Tadiran RADIO PALLET TMΒΕΗΣ ΣΤΕΛΙΟΣ Veis Stelios0% (1)

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- Lantec LH Series Hoists CatalogDocument16 pagesLantec LH Series Hoists CatalogAnonymous 1qAH6CKC100% (1)

- How Proper Stitching Impacts QualityDocument1 pageHow Proper Stitching Impacts QualityAbdullah MundasNo ratings yet

- Presentation ON Export Strategy Presented By-Monika & Renu ROLL NO. - 03, 04 M.B.A (5.5)Document13 pagesPresentation ON Export Strategy Presented By-Monika & Renu ROLL NO. - 03, 04 M.B.A (5.5)Subodh SaharanNo ratings yet

- For Vented Tumble Dryer T 430: Operating InstructionsDocument28 pagesFor Vented Tumble Dryer T 430: Operating InstructionsmbilgravNo ratings yet

- Indian Restaurant RecipesDocument14 pagesIndian Restaurant Recipesraj2192No ratings yet

- Work Request For New InstallationDocument28 pagesWork Request For New Installationsharlz001No ratings yet