Professional Documents

Culture Documents

Panasonic NiMH ChargeMethods

Uploaded by

guerberCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Panasonic NiMH ChargeMethods

Uploaded by

guerberCopyright:

Available Formats

CHARGE METHODS FOR NICKEL METAL HYDRIDE BATTERIES

Charge is the process of restoring a discharged

battery to its original capacity. In order for a battery to

be usable for a long period of time, it must be charged

via the proper charge method. Various methods are

used to charge rechargeable cells, but Panasonic

recommends the charge methods described below to

charge its nickel-metal hydride batteries.

(1) Rapid charge current: 1CmA (rapid charge

temperature range: 0C to 40C). In order to

exercise proper control to stop rapid charge, it is

recommended that batteries be charged at over

0.5CmA but less than 1CmA. Charging batteries at

a current in excess of 1CmA may cause the safety

vent to be activated by a rise in the internal

pressure of the batteries, thereby resulting in

electrolyte leakage. When the temperature of the

batteries is detected by a thermistor or other type

of sensor, and their temperature is under 0C or

over 40C at the commencement of the charge,

then trickle charge, rather than rapid charge, must

be performed. Rapid charge is stopped when any

one of the values among the types of control

described in (4), (5), (6), and (11) reaches the

prescribed level.

(2) Allowing a high current to flow to excessively

discharged or deep-discharged batteries during

charge may make it impossible to sufficiently

restore the capacity of the batteries. To charge

excessively discharged or deep-discharged

batteries, first allow a trickle current to flow, and

then proceed with the rapid charge current once

the battery voltage has risen.

(3) Rapid charge start voltage: Approx. 0.8V/cell

Rapid charge transition voltage restoration current:

0.2 ~ 0.3 CmA

(4) Upper battery voltage limit control: Approx. 1.8V/

cell. The charge method is switched over to trickle

if the battery voltage reaches approximately 1.8V/

cell due to trouble or malfunctioning of some kind.

(5) V value: 5 to 10mV/cell. When the battery

voltage drops from its peak to 5 to 10mV/cell

during rapid charge, rapid charge is stopped, and

the charge method is switched over to trickle

charge.

(6) dT/dt value: Approx. 1 to 2C/min. When a rise in

the battery temperature per unit time is detected

by a thermistor or other type of temperature

sensor during rapid charge, and the prescribed

temperature rise is sensed, rapid charge is

stopped and the charge method is switched over

to trickle charge.

(7) TCO: 55C (for A, AA and D sizes), 50C (for

AAA size), 60C (for L-A, L-fatA and SC sizes).

The cycle life and other characteristics of

batteries are impaired if the batteries are allowed

to become too hot during charge. In order to

safeguard against this, rapid charge is stopped

and the charge method is switched over to trickle

charge when the battery temperature has

reached the prescribed level.

(8) Initial delay timer: to 10 min. This prevents the V detection circuit from being activated for a

specific period of time after rapid charge has

commenced. However, the dT/dt detection circuit

is allowed to be activated during this time. As with

Ni-Cd batteries, the charge voltage of nickel-metal

hydride batteries may show signs of swinging

(pseudo -V) when they have been kept standing

for a long time or when they have discharged

excessively, etc. The initial delay timer is needed

to prevent charge from stopping (to prevent

malfunctioning) due to this pseudo -V.

(9) Trickle current: 0.033 to 0.05CmA. When the

trickle current is set higher, the temperature rise

of the batteries is increased, causing the battery

characteristics to deteriorate.

(10) Rapid charge transfer timer: 60 min.

(11) Rapid charge timer: 90 min. (at 1It charge)

(12) Total timer: 10 to 20 hours.

The overcharging of nickel-metal hydride

batteries, even by trickle charging, causes a

deterioration in the characteristics of the

batteries. To prevent overcharging by trickle

charging or any other charging method, the

provision of a timer to regulate the total charging

time is recommended.

Note: The temperature and voltage of nickelmetal hydride batteries varies depending on the

shape of the battery pack, the number of cells,

the arrangement of the cells and other factors.

Therefore Panasonic should be consulted for

more detailed information on the referenced

charge control values. The charge methods

described previously can be applied also when

both nickel-metal hydride batteries and Ni-Cd

batteries are employed in a product, but

Panasonic should be consulted for the control

figures and other details.

NICKEL METAL HYDRIDE HANDBOOK

AUGUST 2003

This information is generally descriptive only and is not intended to make or imply any representation, guarantee or warranty with respect to any cells and batteries. Cell and battery designs/specifications are subject to

modification without notice. Contact Panasonic for the latest information.

CHARGE METHODS FOR NICKEL METAL HYDRIDE BATTERIES - CONTINUED

Recommended nickel-metal hydride battery

charge system*

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Rapid charge current

Rapid charge transition

voltage restoration current

Rapid charge start voltage

Charge terminating voltage

-V value

Battery temperature rising

rate dT/dt value

Maximum battery temperature

TCO

Max. 1CmA to 0.5CmA

0.2 to 0.3CmA

Initial -V detection disabling

timer

Trickle current (after rapid

charge)

Rapid charge transfer timer

Rapid charge timer

Total timer

Rapid charge temperature

range

5 to 10 min.

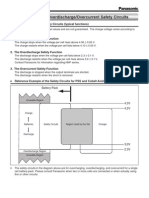

Example of a Rapid Charge System

4

5

8

Approx. 0.8V/cell

1.8V/cel

5 to 10mV/cell

1 to 2C/mm

Battery Voltage

3

13

60C (for L-A, L-fatA and SC sizes)

55C (A, AA and D sizes)

50C (for AAA size)

Battery Temperature

1

(8)

(9)

(10)

(11)

(12)

(13)

0.033 to 0.05CmA

60 min

90 min (at 1CmA charge)

10 to 20 hours

0 to 40C

Matching test is required because these values

vary depending on rapid charge current, number

of cells, configuration of battery pack, etc.

Charge Current

Voltage

Current

Temp.

Time

10

11

12

Fig 1

Basic Pack Configuration Circuit

+

Ther mal Protector

Ther mistor

Fig 2

NiMH H Series Recommended Charge System for back-up power applications

(Applies to HHR210AH, HHR370AH, HHR60AAAH & HHR250SCH Cylindrical cells)

The optimal charge system for the NiMH H Series

for back-up power applications is an intermittent

timer charge. An intermittent timer charge improves

charge efficiency, extends battery life (-vs- trickle

charge) and reduces electricity consumption up to

30% compared to trickle* charge.

Example of intermittent timer charger system:

Average Charge Current: 0.1 ItA

Re-charge time: 16 hours

Pulse charging can be used

Intermittent Charge

Intermittent Timer Charge: (see diagram)

At the beginning of the charge, an IC timer is started

and charging is activated at a current of 0.1It until

the timer stops and the charge is terminated.

When the batteries self discharge down to a set

point (1.3V), the timer charge is re-activated.

*Trickle charge is not recommended for NiMH batteries.

Please consult Panasonic on any NiMH applications

requiring trickle charge.

VB

[h]

Fig. 3

NICKEL METAL HYDRIDE HANDBOOK

AUGUST 2003

This information is generally descriptive only and is not intended to make or imply any representation, guarantee or warranty with respect to any cells and batteries. Cell and battery designs/specifications are subject to

modification without notice. Contact Panasonic for the latest information.

You might also like

- Battery Test Procedures 1997Document7 pagesBattery Test Procedures 1997Tara P. PradhanNo ratings yet

- 220V DCDocument15 pages220V DCsekhar_ntpcNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- SS 551-2009 - PreviewDocument12 pagesSS 551-2009 - PreviewRichard LeongNo ratings yet

- Ni-CD Battery Charger SpecificationDocument18 pagesNi-CD Battery Charger SpecificationAdrianne DouglasNo ratings yet

- Module 2 - SLM - CSS - G8 - TCEW - 4WEEKSDocument28 pagesModule 2 - SLM - CSS - G8 - TCEW - 4WEEKSRonnel SingsonNo ratings yet

- Manual de Partes Gen Set Cummins PDFDocument56 pagesManual de Partes Gen Set Cummins PDFJAIME MEJIA100% (2)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- CT Class Ratio & Phase Angle ErrorsDocument6 pagesCT Class Ratio & Phase Angle ErrorsMahesh Singh0% (1)

- Ac Ripple Effects On Lead Acid BatteriesDocument8 pagesAc Ripple Effects On Lead Acid BatteriesRichard Flynn0% (1)

- VRLA BatteryDocument23 pagesVRLA BatteryAlexander Mccormick100% (1)

- AC Motor ProtectionDocument33 pagesAC Motor ProtectionLoretta KimNo ratings yet

- Care and Maintenance of Lead-Acid BatteriesDocument11 pagesCare and Maintenance of Lead-Acid BatteriesBalakrishnan Pedda GovindierNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Charging Information For Lead Acid Batteries - Battery UniversityDocument92 pagesCharging Information For Lead Acid Batteries - Battery UniversityarthurNo ratings yet

- Uninterruptible Power Supply Battery Acceptance/Capacity Test ProcedureDocument9 pagesUninterruptible Power Supply Battery Acceptance/Capacity Test Proceduresjaveeds2003No ratings yet

- Battery ChargingDocument9 pagesBattery Chargingtaiwong167No ratings yet

- Best Battery Sizing ExamplesDocument40 pagesBest Battery Sizing Examplestllmal002No ratings yet

- Mini DV Manual MD80Document6 pagesMini DV Manual MD80guerberNo ratings yet

- Measuring the Open Circuit Voltage of Lead Acid BatteriesDocument6 pagesMeasuring the Open Circuit Voltage of Lead Acid BatteriessafariNo ratings yet

- Varlogic NR12 12-step var controller product data sheetDocument2 pagesVarlogic NR12 12-step var controller product data sheetjhoansilvaNo ratings yet

- 1st Year Electrical Work Shop Lab Manual Book Revised On 3-10-081Document26 pages1st Year Electrical Work Shop Lab Manual Book Revised On 3-10-081Engr. Raheel khanNo ratings yet

- Panasonic Nimh ChargemethodsDocument2 pagesPanasonic Nimh Chargemethodszokandza4092No ratings yet

- Panasonic NiMH ChargeMethods PDFDocument2 pagesPanasonic NiMH ChargeMethods PDFBOLFRANo ratings yet

- Gelcelcharger Diagram PDFDocument6 pagesGelcelcharger Diagram PDFRemus PopescuNo ratings yet

- Guide to Battery Management: Charging Techniques for SLA, NiCd, NiMHDocument4 pagesGuide to Battery Management: Charging Techniques for SLA, NiCd, NiMHjoonimNo ratings yet

- Battery Charging 14-22Document9 pagesBattery Charging 14-22Anonymous U7bJ4KANo ratings yet

- Ek Kaynak LM2576Document19 pagesEk Kaynak LM2576Şakir BayramNo ratings yet

- Samsung 2600mah ICR18650-26CDocument17 pagesSamsung 2600mah ICR18650-26CStreet_skNo ratings yet

- An137 - Lithium Ion Battery Charger Using c8051f300Document36 pagesAn137 - Lithium Ion Battery Charger Using c8051f300oakkar7No ratings yet

- Harging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifeDocument4 pagesHarging EAD CID: Learn How To Optimize Charging Conditions To Extend Service LifebigsloNo ratings yet

- Overcharge/Overdischarge/Overcurrent Safety Circuits: - The Functions of The Safety Circuits (Typical Functions)Document4 pagesOvercharge/Overdischarge/Overcurrent Safety Circuits: - The Functions of The Safety Circuits (Typical Functions)Mahir MahmoodNo ratings yet

- Lead-X Tech Manual PDFDocument20 pagesLead-X Tech Manual PDFgenial72No ratings yet

- Vision User's Manual OpzvDocument10 pagesVision User's Manual Opzvloi130391No ratings yet

- General Information On Sealed Nickel Cadmium BatteriesDocument9 pagesGeneral Information On Sealed Nickel Cadmium BatteriesB.Kailash Krishna PrasadNo ratings yet

- 8003 251Document3 pages8003 251Romie HarieNo ratings yet

- Qualmega KPX Operation ManualDocument2 pagesQualmega KPX Operation ManualKelvin LiewNo ratings yet

- AN626 - Lead Acid Battery Charger Using The PIC14C000Document0 pagesAN626 - Lead Acid Battery Charger Using The PIC14C000mlaura2No ratings yet

- Application Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationDocument36 pagesApplication Note 68 December 1996:, LTC and LT Are Registered Trademarks of Linear Technology CorporationHahdNo ratings yet

- Railacpuri: Home Drawings Smi Technical Maintenance Manual Faq Photo Galery Contact UsDocument14 pagesRailacpuri: Home Drawings Smi Technical Maintenance Manual Faq Photo Galery Contact UsMukesh SainiNo ratings yet

- Samsung 2400mah ICR18650-24EDocument15 pagesSamsung 2400mah ICR18650-24EStreet_skNo ratings yet

- Gen 01480985055Document4 pagesGen 01480985055Bruno FrezzarinNo ratings yet

- BATTERY TUTORIAL ON CHARGING, RUN TIMES, AND DEEP DISCHARGEDocument3 pagesBATTERY TUTORIAL ON CHARGING, RUN TIMES, AND DEEP DISCHARGEManuelNo ratings yet

- LC R127r2na 0912Document7 pagesLC R127r2na 0912fachrudin_faridiNo ratings yet

- Rechargeable Batteries Ni-Cd, Ni-MH, Li-Ion, Li-Ion PolymerDocument17 pagesRechargeable Batteries Ni-Cd, Ni-MH, Li-Ion, Li-Ion Polymer360_TW100% (2)

- Battery ChargingDocument7 pagesBattery Charging123olympiakosNo ratings yet

- 504pet23 PDFDocument9 pages504pet23 PDFsickdogNo ratings yet

- Battery TypesDocument19 pagesBattery Typessasa hhNo ratings yet

- Vibration Test Procedure 2.3Document10 pagesVibration Test Procedure 2.3Georgino SilvaNo ratings yet

- Tripping BatteriesDocument5 pagesTripping BatteriesAashwinAndeNo ratings yet

- S65 AC Balance Charger GuideDocument29 pagesS65 AC Balance Charger GuideJulian COULETNo ratings yet

- Samsung 3000mah ICR18650-30ADocument14 pagesSamsung 3000mah ICR18650-30AStreet_skNo ratings yet

- Generator, Starter, Battery and Spark Plug Repair InstructionsDocument10 pagesGenerator, Starter, Battery and Spark Plug Repair InstructionsSoporte Tecnico AutoMotrixNo ratings yet

- 555 NiCd Battery RejuvenatorDocument3 pages555 NiCd Battery RejuvenatorAnonymous vKD3FG6RkNo ratings yet

- Ex 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleDocument23 pagesEx 2. To Acquaint With The Charging Methods of Batteries and Calculation of Their Life CycleKunal TanwarNo ratings yet

- Gaston Batt Data SheetDocument23 pagesGaston Batt Data SheetAntony Sifuna WanjalaNo ratings yet

- Ni-Cd Battery Maintenance ManualDocument18 pagesNi-Cd Battery Maintenance Manualhathanhchinh2279No ratings yet

- Battery Charge MaintenanceDocument9 pagesBattery Charge MaintenanceGibson DubeNo ratings yet

- Presentation On Overall DC & AC Distribution and Station Auxiliary System and Maintenance & Routine Inspection of DC Battery SystemDocument51 pagesPresentation On Overall DC & AC Distribution and Station Auxiliary System and Maintenance & Routine Inspection of DC Battery Systemabu sayedNo ratings yet

- Battery Basics and ConstructionDocument10 pagesBattery Basics and ConstructionHisyammudin RoslanNo ratings yet

- Basic Battery Princeple Avition CourseDocument17 pagesBasic Battery Princeple Avition CourseabyNo ratings yet

- Versatile Ics Enable Chemistry-Independent Battery ChargingDocument7 pagesVersatile Ics Enable Chemistry-Independent Battery Chargingsa920189No ratings yet

- TB12Document2 pagesTB12chiri003No ratings yet

- Engine Electric Devices: GeneralDocument8 pagesEngine Electric Devices: GeneralBernd EikersNo ratings yet

- Schaffler Battery ChargersDocument4 pagesSchaffler Battery ChargersRudy IndrawanNo ratings yet

- Electrical Power-2 Lab ManualDocument6 pagesElectrical Power-2 Lab ManualAditya SanjeevNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Dicas para Melhorar A Performance Do PC GG - PcworkshopDocument177 pagesDicas para Melhorar A Performance Do PC GG - PcworkshopguerberNo ratings yet

- Nexus Montagem EV-SG-3C41-2330B - v1 - m56577569830704663Document1 pageNexus Montagem EV-SG-3C41-2330B - v1 - m56577569830704663guerberNo ratings yet

- Cable Modem SB4100 User GuideDocument28 pagesCable Modem SB4100 User GuideguerberNo ratings yet

- Opamp CircuitDocument24 pagesOpamp Circuitlinuxlism100% (1)

- Gt-750f Gps DatasheetDocument4 pagesGt-750f Gps DatasheetguerberNo ratings yet

- GutorDocument4 pagesGutorFakhr-e-Alam100% (1)

- A TV Pattern Generator Part1Document4 pagesA TV Pattern Generator Part1riverajluizNo ratings yet

- 210 (590 605) ASTRO 6 Semi - CHSM60M-HC - 2172x1303x35 - EN - 20220616Document2 pages210 (590 605) ASTRO 6 Semi - CHSM60M-HC - 2172x1303x35 - EN - 20220616RichardNo ratings yet

- Motor circuit breaker data sheet and performance curvesDocument8 pagesMotor circuit breaker data sheet and performance curvesYexiongWaherNo ratings yet

- Design The Electrical SystemDocument25 pagesDesign The Electrical SystemBudi Santoso100% (1)

- The Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Document4 pagesThe Product Life Cycle Support Policy See Life Cycle Overview Is (1) ...Pradeep KumarNo ratings yet

- RPADocument2 pagesRPAmehdivinciNo ratings yet

- Distributed Active and Reactive Power Control With Smart Microgrid DemonstrationDocument9 pagesDistributed Active and Reactive Power Control With Smart Microgrid DemonstrationAcademic JournalNo ratings yet

- Generación W/Time: Gaussiana PVDocument2 pagesGeneración W/Time: Gaussiana PVCarlos Terraza OyagaNo ratings yet

- Current Limiting Reactors ApplicationsDocument24 pagesCurrent Limiting Reactors Applicationsmayalasan1No ratings yet

- Elcompo-FbtDocument3 pagesElcompo-Fbtkachappilly2012No ratings yet

- Branch Panel: SMDB-02 Branch Panel: SMDB-01: Reference DrawingsDocument1 pageBranch Panel: SMDB-02 Branch Panel: SMDB-01: Reference DrawingsAnonymous 7z6OzoNo ratings yet

- DC MachineDocument40 pagesDC Machinedsfsdf sdfdsNo ratings yet

- lm2940 N PDFDocument35 pageslm2940 N PDFyovaniNo ratings yet

- MCCB - TemBreak2 Product Information Main Catalogue 19-I61EU WebDocument435 pagesMCCB - TemBreak2 Product Information Main Catalogue 19-I61EU WebFCSNo ratings yet

- EE4450 Syllabus - Spring 2015yoloDocument3 pagesEE4450 Syllabus - Spring 2015yoloJonathan ButlerNo ratings yet

- Speed Control Methods of Induction MotorDocument6 pagesSpeed Control Methods of Induction MotorsahebraoNo ratings yet

- SEO PV AnalyzerDocument5 pagesSEO PV AnalyzerPrecisionNo ratings yet

- OperatingInstructions RPS Modular VEC621R0Document128 pagesOperatingInstructions RPS Modular VEC621R0bpchimera100% (1)

- ES MANUAL Cafetera Bomba Tradicional EC155 DelonghiDocument10 pagesES MANUAL Cafetera Bomba Tradicional EC155 DelonghiEduardo GonzalezNo ratings yet

- MCQ Pe 162Document162 pagesMCQ Pe 162rajuNo ratings yet

- Sew MovidriversDocument164 pagesSew Movidriverskallorindo scribNo ratings yet

- Ieee On Energy 3: TransactionsDocument6 pagesIeee On Energy 3: TransactionsMuhammad Tilal AshrafNo ratings yet

- Installation & Commissiioning of 2 10 KVA UPS System in BUH-BQ Station Cable ScheduleDocument2 pagesInstallation & Commissiioning of 2 10 KVA UPS System in BUH-BQ Station Cable ScheduleArun MangalasserilNo ratings yet