Professional Documents

Culture Documents

Walnut, White Oak

Uploaded by

- yAy3e -Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Walnut, White Oak

Uploaded by

- yAy3e -Copyright:

Available Formats

21

CHIP BOX

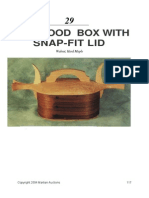

Walnut, White Oak

Copyright 2004 Martian Auctions 84

MAKING THE CHIP BOX

Walnut was used in the construction of this box with care sides and ends to receive the bottom. Then cut and pare

taken to select pieces exhibiting contrasting streaks of white dovetails to fit (see chapter twenty-five). With hand planes,

sapwood. The bail was shaped from white oak. While any bevel the edges of the bottom to allow them to slide in

of a number of woods would do nicely for the box, make their grooves (see chapter one).

the bail from a wood that is not only strong but also pliable Then assemble the box and fit plugs into the ends of

enough to assume the U shape without breaking. Suitable the grooves ploughed into the sides.

woods include oaks, ashes and hickories. After removing the bail from its bending form, give its

Construction is very simple. After milling the stock to two paws their final shape using a paring chisel and a shop

a thickness of 1/2", rip the sides, ends and bottom to width knife. Then fasten the bail to the box with four 1/8" X 1

and cut to length. Then plough a 1/4" X 1/4" groove in 1/4" brass machine screws and nuts.

the

SHAPING THE BAIL

1 The bail requires a 3/8"-thick length of continuous-grain bend-

ing stock. This means that, when viewed from the quarter-

sawn side (the side with the narrow, parallel lines), the grain

should run from end to end. Traditionally, this is achieved by

splitting out the stock with the use of a froe and beetle. However,

few contemporary woodworkers have these tools. You may, there-

fore, choose to use a length of sawn stock selected for straight

grain.

Before bending, work the band-sawn strip with a drawknife

and spokeshave to rough-in the desired shape. At this point, it

isn't necessary to be fussy. The goal is simply to round the edges

on the top side of the bail since this procedure can be carried

out more comfortably now, when the stock is unbent, than later,

when the bail has taken on its U shape.

STEAM BENDING

1 My steamer is a deep fat fryer. I've cut an opening in the

lid the same size as the outside diameter of a length of PVC

which I use as a steam chamber. Three sheet metal screws turned

into the PVC just above its base are allowed to protrude. These

rest on the fryer's lid holding the steam chamber above the

water's surface. A square of hardware cloth that laps the bottom

of the steam chamber and is screwed to the PVC supports the

material being steamed. To hold the entire apparatus upright, a

strip of wood lath is screwed to the PVC and spring-clamped to

a stepladder.

Similarly, functional steamers can be made in a number of

different ways. Many woodworkers use a hot plate and a tea

kettle with a spout fitted with a length of plastic hose which

conducts steam to a chamber of some sort—a wooden box, a

length of downspout, or a section of PVC.

Steam the bending stock long enough to become plastic. In

my steamer, with material of this thickness, that means about

forty-five minutes.

Copyright 2004 Martian Auctions 85

Copyright 2004 Martian Auctions 86

STEAM BENDING (CONTINUED)

SHAVING TOOLS

2 Prepare bending forms beforehand. This particular form, a

2"-thick block of poplar cut to the inside profile of the bail, is

nailed to a block of wood held in a vise. Necessary clamps and

clamping blocks are placed nearby. Gloves are needed because the

steamed oak will be very hot when removed from the steam

chamber.

Although you shouldn't rush, proceed quickly because the

steamed wood will cool rapidly, becoming less pliable.

Place the midway point along the length of the oak strip at

the halfway point across the width of the poplar form. Then

clamp it, using a block of wood to protect the oak from clamp

marks.

Shown are the shaving tools I use in my shop. The two with

turned wooden handles are drawknives. The knife at the top

is a general-purpose tool, while the one at the bottom is a

variety known as the "inshave" used by makers of Windsor

chairs to hollow-out seats. The two middle tools are metal-

bodied spokeshaves. The shave with the straight iron is used

for general-purpose work, while the other, a hollow shave,

can only be used for rounding spindles.

3 Bend the oak strip into its U shape, holding it in place with

a second clamp set perpendicular to the first. Again, use

blocks of scrap to protect the oak. From above, the strip can be

seen to have assumed the shape of the bail.

Green wood is best for bending, but dry material can be

coaxed into the required shapes with enough steam and enough

patience.

Wood bending, particularly bending involving the sharp

curves shown here, is a process rich with opportunities for failure.

Sometimes, even after selecting continuous-grained material,

even after steaming that material thoroughly, fracture can occur

along the bends. When that happens, the only solution is to

start the process all over again.

Copyright 2004 Martian Auctions 87

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Childrens Play StructureDocument7 pagesChildrens Play Structure- yAy3e -100% (1)

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Carved Fruit BowlDocument5 pagesCarved Fruit Bowlkhunchaiyai100% (1)

- Candle Stands PDFDocument2 pagesCandle Stands PDFBenivaldo Do Nascimento JuniorNo ratings yet

- Cherry End TableDocument5 pagesCherry End TablekhunchaiyaiNo ratings yet

- Cabinet BathroomDocument4 pagesCabinet Bathroom- yAy3e -No ratings yet

- Chattahoochee ChairDocument1 pageChattahoochee Chair- yAy3e -No ratings yet

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- Crotch-Grained Chess Table: Walnut, PoplarDocument5 pagesCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- Chairside BookcaseDocument3 pagesChairside Bookcasekhunchaiyai100% (2)

- CandlelabraDocument3 pagesCandlelabrakhunchaiyai100% (1)

- Cappucino BarDocument3 pagesCappucino Bar- yAy3e -100% (1)

- Bunk BedsDocument5 pagesBunk Bedskhunchaiyai100% (4)

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Brydcliffe CabinetDocument3 pagesBrydcliffe CabinetkhunchaiyaiNo ratings yet

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Bread BoxDocument3 pagesBread Box- yAy3e -No ratings yet

- Bungalow MailboxDocument3 pagesBungalow Mailbox- yAy3e -No ratings yet

- Classic Bow SawDocument6 pagesClassic Bow Saw- yAy3e -No ratings yet

- Bookcase 2Document3 pagesBookcase 2mhdridhuanNo ratings yet

- Book Case 1Document6 pagesBook Case 1khunchaiyaiNo ratings yet

- Bookcase PlansDocument7 pagesBookcase PlansBrenda LeeNo ratings yet

- Bit ShelfDocument2 pagesBit Shelf- yAy3e -100% (1)

- Bookcase End TableDocument3 pagesBookcase End Tablekhunchaiyai100% (1)

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- Bentwood Box With Snap-Fit Lid: Walnut, Hard MapleDocument4 pagesBentwood Box With Snap-Fit Lid: Walnut, Hard MaplekhunchaiyaiNo ratings yet

- Book Case 2Document5 pagesBook Case 2khunchaiyai100% (1)

- Blanket ChestDocument3 pagesBlanket ChestkhunchaiyaiNo ratings yet

- Bird House2Document3 pagesBird House2khunchaiyai100% (1)

- Bird HouseDocument3 pagesBird Housekhunchaiyai100% (3)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mpe Installation, Use and Maintenance ManualDocument56 pagesMpe Installation, Use and Maintenance ManualapeirotanNo ratings yet

- HVAC Design Collection Vol. 1Document9 pagesHVAC Design Collection Vol. 1Afsal KalpathyNo ratings yet

- Pressure Drop Calculation - Primary Pump & Secondary PumpDocument6 pagesPressure Drop Calculation - Primary Pump & Secondary PumpAzher ANo ratings yet

- Belimo Room-And-Zone-Control CR24 Application Brochure En-GbDocument24 pagesBelimo Room-And-Zone-Control CR24 Application Brochure En-GbLaurentiu LapusescuNo ratings yet

- Introduction to Pivot Table AnalysisDocument14 pagesIntroduction to Pivot Table AnalysisSupanut KaewumpaiNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: Control Valve Body Assembly - Front - Gen. 2 6T40 ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Control Valve Body Assembly - Front - Gen. 2 6T40 ShownFabiano Silva AzechiNo ratings yet

- Rakh Agf Set Ren Tube ModelDocument1 pageRakh Agf Set Ren Tube Modelbenaya prasetyaNo ratings yet

- Bolt Action 3Document10 pagesBolt Action 3browar444100% (2)

- Iso PDFDocument1 pageIso PDFel_sharkawy2011No ratings yet

- TurningDocument252 pagesTurningMichael KashiotisNo ratings yet

- Longsword Glossary PDFDocument3 pagesLongsword Glossary PDFwintermute57No ratings yet

- Grinding Equipment: Product CatalogueDocument32 pagesGrinding Equipment: Product CatalogueSebastian Nuñez RiquelmeNo ratings yet

- Fixture Occupancy Type of Supply Control Load Values, in Water Supply Fixture Units (Wsfu) Cold Hot TotalDocument1 pageFixture Occupancy Type of Supply Control Load Values, in Water Supply Fixture Units (Wsfu) Cold Hot Totalnader yassinNo ratings yet

- Instrument Air Consumption Calculation: BasisDocument1 pageInstrument Air Consumption Calculation: BasisYew100% (1)

- GEMTECH CATALOG 2019 FinalDocument52 pagesGEMTECH CATALOG 2019 FinalAleksandr D.No ratings yet

- Pneumatic symbols overviewDocument47 pagesPneumatic symbols overviewVladan MilojevićNo ratings yet

- Ressure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsDocument1 pageRessure Elief Alves: Model 7000 Model 7200 For Fire Sprinkler SystemsrajeshNo ratings yet

- 7 PPT - Bolt TighteningDocument31 pages7 PPT - Bolt TighteningJavier adrian gutierrez retanaNo ratings yet

- South Bend lathe threading chart calculations <40Document12 pagesSouth Bend lathe threading chart calculations <40martik777100% (1)

- Maint Instructions For Ferrule FittingsDocument13 pagesMaint Instructions For Ferrule FittingsLakhwant Singh KhalsaNo ratings yet

- Jigs and FixturesDocument112 pagesJigs and FixturesAakash Singh100% (4)

- Work and Simple Machines ExplainedDocument47 pagesWork and Simple Machines ExplainedEp LohNo ratings yet

- Parts Catalog: H270E Harvester HeadDocument145 pagesParts Catalog: H270E Harvester HeadjulianoNo ratings yet

- Chassis and Braking Systems: An OverviewDocument31 pagesChassis and Braking Systems: An OverviewPaul Adriane TornerosNo ratings yet

- BOQ LG Multi V VRF System (Bhilwara) PDFDocument4 pagesBOQ LG Multi V VRF System (Bhilwara) PDFAjayNo ratings yet

- Kitchen Cabinet Sizes and SpecificationsDocument7 pagesKitchen Cabinet Sizes and SpecificationsjprakashusNo ratings yet

- TFP720 02 2016Document8 pagesTFP720 02 2016Jun AntonioNo ratings yet

- Filter ListDocument170 pagesFilter ListpranayNo ratings yet

- Service Bulletin Trucks: Special Tools, Group 4Document6 pagesService Bulletin Trucks: Special Tools, Group 4mattkidoNo ratings yet

- CMT Orange Tools English Catalogue 2012Document299 pagesCMT Orange Tools English Catalogue 2012Diablo 66No ratings yet