Professional Documents

Culture Documents

Bendwood Boxes

Uploaded by

- yAy3e -Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bendwood Boxes

Uploaded by

- yAy3e -Copyright:

Available Formats

2

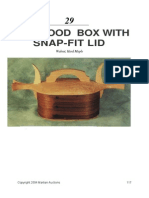

BENTWOOD BOXES

WITH TURNED AND

CARVED LIDS

Walnut, Curly Maple, Cherry

Copyright 2004 Martian Auctions 8

MAKING THE BENTWOOD BOXES

First, make a bending form for the main body of the box. widely available in a variety of species. I would recommend

This can be fabricated from any scrap that can be glued using one of the new waterproof glues between the lamina-

together to make up a sufficient thickness. This is then tions, although I have built boxes using regular aliphatic

band sawn and sanded to the inside profile of the finished resin glue to bond the thicknesses of veneer.

box. Undercut the face of the bending form at one point Then, soak the sidewall stock in a tub of cool water for

to allow for the thickness of the lapped material underneath twenty-four hours; dunk it briefly in warm water and take

the box's glue joint. Screw a thin strip of metal (I used a it directly to the bending form. Tuck one end of this

scrap of aluminum siding) to the form underneath which softened, plasticized material under the metal strip on the

an end of the sidewall material should be inserted prior to bending form. Wrap the remaining length around the form

being wrapped around the form. and secure in place with clamps and the caul.

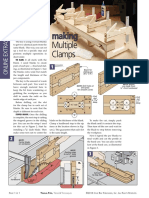

At this time, saw a clamping caul (see photos, below) Four or five days later, remove the sidewall material

with a slightly greater radius than the bending form from from the form and cut the profile of the lap joint. A bench

scrap material. This caul will protect the sidewall material extension to which is nailed a piece of scrap sawn to the

from the clamps. inside radius of the box simplifies the cutting of the joint.

The next consideration is the sidewall material itself. Then, glue the lap, wrap the sidewall material around

There are three possibilities. First, the stock can be resawn, the form once again and clamp with the aid of the caul.

planed and sanded to a thickness of 1/16". Second, This time, however, do not insert the end of the sidewall

Constant-e's Hardware sells 1/16" veneer in cherry, material under the form's metal strip. After being turned,

walnut and mahogany, even though those thicknesses attached the box's bottom to the sidewalls with four 1/8"

aren't listed in their most recent catalogs. Third, the wooden pegs driven into predrilled holes.

sidewall material can be glued-up from two thicknesses of

1/32" veneer, which is

CUTTING THE LAP JOINTS

2

A lap joint is be-

ing cut on the

bench extension.

1 This is the bench extension used to maintain the curved

form of the sidewall material during the cutting of the lap.

The clamping caul is visible on the right.

3Here, the glued lap joint is being clamped with the aid of the

caul. Notice that the end of the sidewall material is not

positioned under the metal strip as it was during its initial clamping

for shape.

Copyright 2004 Martian Auctions 9

TURNING THE LID

AND THE BOTTOM

This is the same blank after being turned. Above the bead,

1 Screw a faceplate to a band-sawn turning blank with large

sheet metal screws. Then, install it on the lathe.

y

notice the flange that will fit inside the box's sidewalls.

DECORATING THE SURFACES

1 Before removing the parts from the lathe, sketch pencil

lines on the lid approximating the shapes to be created. 2 Remove material below the line (as shown above), and create

the stippled texture by repeatedly tapping a nail set into the

Then with gouges of various sweeps, define those lines (shown surface of the wood.

above).

MATERIALS LIST

A Form 1 pc. 3X3/2

B Caul 1 pc. 1/2X3 1/2X3 1/2

C Sidewall 1 pc. 1/16X 3 1/2X15

D Lid 1 pc. variable

E Bottom 1 pc. variable

F Pegs 4 pc. 1/8 X 1/8 X 1/2

Copyright 2004 Martian Auctions 10

You might also like

- Icdt April10 Skansen BenchDocument2 pagesIcdt April10 Skansen Benchapi-239142091100% (1)

- Adirondack Rocking Chair PlansDocument19 pagesAdirondack Rocking Chair PlansMoises BarbosaNo ratings yet

- How To Make A Meat SafeDocument5 pagesHow To Make A Meat SafeChristian Theriault100% (1)

- Wood ThreadDocument23 pagesWood Threadroberto_belyz100% (1)

- A Classic Case: A Project Plan For A Case With A Modern Take On An Arts and Crafts ClassicDocument7 pagesA Classic Case: A Project Plan For A Case With A Modern Take On An Arts and Crafts ClassicMushroom Love Stars CrUz100% (1)

- Woodworker's Journal - Vol.01 No.1 Jan-Feb 1977Document16 pagesWoodworker's Journal - Vol.01 No.1 Jan-Feb 1977BeingNo ratings yet

- 8 X 10 Timber ShedDocument19 pages8 X 10 Timber ShedJeremy Smathers100% (1)

- Comfort in A Morris Chair: Craftsman-StyleDocument5 pagesComfort in A Morris Chair: Craftsman-Stylegromov.kirill1No ratings yet

- Build A Bowsaw: This Classic Tool Still Has A Place in The ShopDocument4 pagesBuild A Bowsaw: This Classic Tool Still Has A Place in The ShopBenjamin BeckerNo ratings yet

- Wood Working Plans 2aDocument11 pagesWood Working Plans 2aNicusor Amihaesei100% (1)

- Garden Bench: Woodworks: Intermediate ProjectDocument9 pagesGarden Bench: Woodworks: Intermediate ProjectRenos Konstantinou100% (1)

- Matching Letter Opener and Desk SetDocument8 pagesMatching Letter Opener and Desk Set- yAy3e -No ratings yet

- Wood TurningDocument63 pagesWood TurningEsequiel Yakueczik100% (1)

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- Build Beautiful Mendocino BenchDocument5 pagesBuild Beautiful Mendocino BenchvdbrogerNo ratings yet

- WOOD Monthly DownloadDocument9 pagesWOOD Monthly DownloadRoomel UrbinaNo ratings yet

- Champion The Lumber HorseDocument3 pagesChampion The Lumber HorseRowina Wamani67% (3)

- Popular Woodworking - 016 - 1984 PDFDocument52 pagesPopular Woodworking - 016 - 1984 PDFKawchhar Ahammed100% (1)

- Popular Woodworking - 012 - 1983 PDFDocument44 pagesPopular Woodworking - 012 - 1983 PDFKawchhar Ahammed100% (1)

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableVia CreazionemxNo ratings yet

- Slatted Outdoor SofaDocument12 pagesSlatted Outdoor SofaJh CtNo ratings yet

- Wooden Scrub Plane From ScrapDocument9 pagesWooden Scrub Plane From ScrapRod HyattNo ratings yet

- Picture BoxDocument3 pagesPicture BoxEmilian BalutaNo ratings yet

- Bowl Basics 2Document5 pagesBowl Basics 2api-522254901No ratings yet

- Shelving, Plain and SimpleDocument2 pagesShelving, Plain and Simplecaballo_blanco_2No ratings yet

- Woodworking TipsDocument13 pagesWoodworking TipsjahemscbdNo ratings yet

- Stickley Side Table 2Document2 pagesStickley Side Table 2- yAy3e -100% (1)

- Tabletop ArtistryDocument5 pagesTabletop ArtistrysossieNo ratings yet

- 09 08 Workshop Summer SwingDocument3 pages09 08 Workshop Summer SwingpatriciachaquilaNo ratings yet

- Bird FeederDocument4 pagesBird FeederJayme LealNo ratings yet

- Home Craftsman No14 (1906)Document4 pagesHome Craftsman No14 (1906)Robert Elliott PH.dNo ratings yet

- Thank You!: WOOD StoreDocument9 pagesThank You!: WOOD StoreRuss HiltonNo ratings yet

- Woodcraft Magazine - Issue 112Document68 pagesWoodcraft Magazine - Issue 112Gary TanNo ratings yet

- Dovetailed Tool BoxDocument13 pagesDovetailed Tool Boxdavid100% (1)

- Pano PDFDocument121 pagesPano PDFjuanNo ratings yet

- Lawn Swing: IMPORTANT: Read This Before You StartDocument6 pagesLawn Swing: IMPORTANT: Read This Before You StartBill RNo ratings yet

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Materials, Supplies, & Cutting Diagram: Large Craftsman TableDocument1 pageMaterials, Supplies, & Cutting Diagram: Large Craftsman TableDavid TuaineNo ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- May/June $3.50: Plywood BasicsDocument108 pagesMay/June $3.50: Plywood BasicsCeberus233100% (1)

- Building A Traditional Coffin SmootherDocument29 pagesBuilding A Traditional Coffin SmootherAnonymous idUWcnaeNo ratings yet

- The Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LDocument4 pagesThe Shel L Game: Ti Ps For Ca Rvi NG A Classic Newpo RT Shel LTAANGTAWAN007No ratings yet

- #P203 - Candy HoldersDocument10 pages#P203 - Candy HoldersgabrielmorosanuNo ratings yet

- SN13134 - Mobile Cutoff BinDocument6 pagesSN13134 - Mobile Cutoff BinSKT ProductionsNo ratings yet

- 3 Tool Chest TopDocument5 pages3 Tool Chest TopAguinaldo OliveiraNo ratings yet

- Popular Woodworking - 013 - 1983 PDFDocument44 pagesPopular Woodworking - 013 - 1983 PDFKawchhar Ahammed100% (1)

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorNo ratings yet

- Panel JigDocument16 pagesPanel JigfasdfNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument6 pagesDigital Patterns: Designed by Steve GoodRichard PerezNo ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router Tableiacob_gilberto6473100% (1)

- 10 Quick and Easy Woodworking Gift IdeasDocument50 pages10 Quick and Easy Woodworking Gift Ideaspavel100% (1)

- Booklet 2 Chip CarvingDocument20 pagesBooklet 2 Chip CarvingBernard Captain Hartl PiavauxNo ratings yet

- Woodworking Crafts Issue 65, January 2021Document124 pagesWoodworking Crafts Issue 65, January 2021John Crawford100% (1)

- The Woodworker Woodturner-January 2018Document92 pagesThe Woodworker Woodturner-January 2018Anonymous PcUOts100% (2)

- Foldable Stool Reverse Engineering The Tallon StooDocument37 pagesFoldable Stool Reverse Engineering The Tallon StooEnrique CoronelNo ratings yet

- Splay-Legged Table: A Project Plan For Building A Simple Splay-Legged Table With Refined FlairDocument7 pagesSplay-Legged Table: A Project Plan For Building A Simple Splay-Legged Table With Refined FlairGustavo ApellidoNo ratings yet

- Valet StandDocument9 pagesValet StandflerziNo ratings yet

- How-To Book of Christmas Carving: 32 Projects to Whittle, Carve & PaintFrom EverandHow-To Book of Christmas Carving: 32 Projects to Whittle, Carve & PaintNo ratings yet

- Construct Your Own Living Room Cabinets - Step by Step Instructions to Build Cupboards, Bookshelves, Trays and TablesFrom EverandConstruct Your Own Living Room Cabinets - Step by Step Instructions to Build Cupboards, Bookshelves, Trays and TablesNo ratings yet

- Childrens Play StructureDocument7 pagesChildrens Play Structure- yAy3e -100% (1)

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- CandlelabraDocument3 pagesCandlelabrakhunchaiyai100% (1)

- Cabinet BathroomDocument4 pagesCabinet Bathroom- yAy3e -No ratings yet

- Crotch-Grained Chess Table: Walnut, PoplarDocument5 pagesCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- Cherry End TableDocument5 pagesCherry End TablekhunchaiyaiNo ratings yet

- Cappucino BarDocument3 pagesCappucino Bar- yAy3e -100% (1)

- Chattahoochee ChairDocument1 pageChattahoochee Chair- yAy3e -No ratings yet

- Chairside BookcaseDocument3 pagesChairside Bookcasekhunchaiyai100% (2)

- Carved Fruit BowlDocument5 pagesCarved Fruit Bowlkhunchaiyai100% (1)

- Candle Stands PDFDocument2 pagesCandle Stands PDFBenivaldo Do Nascimento JuniorNo ratings yet

- Classic Bow SawDocument6 pagesClassic Bow Saw- yAy3e -No ratings yet

- Bungalow MailboxDocument3 pagesBungalow Mailbox- yAy3e -No ratings yet

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Blanket ChestDocument3 pagesBlanket ChestkhunchaiyaiNo ratings yet

- Bunk BedsDocument5 pagesBunk Bedskhunchaiyai100% (4)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Book Case 1Document6 pagesBook Case 1khunchaiyaiNo ratings yet

- Bread BoxDocument3 pagesBread Box- yAy3e -No ratings yet

- Bookcase 2Document3 pagesBookcase 2mhdridhuanNo ratings yet

- Brydcliffe CabinetDocument3 pagesBrydcliffe CabinetkhunchaiyaiNo ratings yet

- Bookcase PlansDocument7 pagesBookcase PlansBrenda LeeNo ratings yet

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- Bookcase End TableDocument3 pagesBookcase End Tablekhunchaiyai100% (1)

- Bird House2Document3 pagesBird House2khunchaiyai100% (1)

- Book Case 2Document5 pagesBook Case 2khunchaiyai100% (1)

- Bird HouseDocument3 pagesBird Housekhunchaiyai100% (3)

- Bit ShelfDocument2 pagesBit Shelf- yAy3e -100% (1)

- Bentwood Box With Snap-Fit Lid: Walnut, Hard MapleDocument4 pagesBentwood Box With Snap-Fit Lid: Walnut, Hard MaplekhunchaiyaiNo ratings yet

- Burda KrojDocument1 pageBurda Krojanja9No ratings yet

- Inkscape TutorialDocument9 pagesInkscape TutorialMazry100% (4)

- Europass CV - English Cosmin Ion MunteanuDocument9 pagesEuropass CV - English Cosmin Ion MunteanuMihaela MtnNo ratings yet

- Franklin ParamoreDocument4 pagesFranklin ParamoreAndy CandyNo ratings yet

- Grammar GuideDocument78 pagesGrammar GuideMalashini MalaNo ratings yet

- Videos: Best Oud Instrumentals (Mixed by Billy Esteban)Document2 pagesVideos: Best Oud Instrumentals (Mixed by Billy Esteban)Stephen HMPLNo ratings yet

- Criteria For Judging - Ms GAY 2023Document13 pagesCriteria For Judging - Ms GAY 2023John Eric OliverNo ratings yet

- Dotgov Flash and Various Cult Film ItemsDocument59 pagesDotgov Flash and Various Cult Film ItemsDogmeatNo ratings yet

- 4 Mallet Fundamentals by Garwood WhaleyNeil GroverDocument5 pages4 Mallet Fundamentals by Garwood WhaleyNeil Grovergizzy9dillespie0% (1)

- Ethernet Cable CrimpingDocument3 pagesEthernet Cable CrimpingsunilsjadhavNo ratings yet

- Swimming Pool ReportDocument11 pagesSwimming Pool ReportVarun Jawalekar100% (1)

- Contemporary ArtsDocument59 pagesContemporary ArtsJeuel RobiatoNo ratings yet

- All Samsung CodesDocument3 pagesAll Samsung CodesLalitMohanPandeyNo ratings yet

- Juanele Interviews Sebastián FriedmanDocument8 pagesJuanele Interviews Sebastián FriedmanRick PowellNo ratings yet

- ElectricIR Sample ReportDocument5 pagesElectricIR Sample ReportAnonymous Wu6FDjbNo ratings yet

- Andy MuschiettiDocument2 pagesAndy Muschiettiapi-479739265No ratings yet

- 2013-14 Vancouver Canucks Media GuideDocument274 pages2013-14 Vancouver Canucks Media GuideYosooNo ratings yet

- One Direction: Background Information Origin Years Active Associated Acts Website MembersDocument12 pagesOne Direction: Background Information Origin Years Active Associated Acts Website MembersOlivia Linseman100% (1)

- Corcovada - Hermeto Arr (With Elis Regina) Montreux 1979 & Articles and Interviews About Their Performance TogetherDocument37 pagesCorcovada - Hermeto Arr (With Elis Regina) Montreux 1979 & Articles and Interviews About Their Performance Togetherzimby12No ratings yet

- Possesives ExercisesDocument3 pagesPossesives ExercisesNicoleta GrosuNo ratings yet

- Updated Rehearsal Schedule - Are Ya Dancin' 2023Document3 pagesUpdated Rehearsal Schedule - Are Ya Dancin' 2023Rory ChadwickNo ratings yet

- Pokémon Scarlet & Violet - Version Exclusives - PokémonDocument1 pagePokémon Scarlet & Violet - Version Exclusives - PokémonTomaNo ratings yet

- For Professional Results: Digital Videocassette RecorderDocument9 pagesFor Professional Results: Digital Videocassette Recorderflorinou51No ratings yet

- Patito AmigurumiDocument7 pagesPatito AmigurumiElisa Camargo100% (3)

- Avantree SP850 UManualDocument6 pagesAvantree SP850 UManualVenuNo ratings yet

- Events/Activities Secondary Time VENUE: Buenavista SPED ES, Buenavista, Agusan Del NorteDocument1 pageEvents/Activities Secondary Time VENUE: Buenavista SPED ES, Buenavista, Agusan Del NorteMae Uayan Prisco-TagaraoNo ratings yet

- Nata Drawing QuestionsDocument6 pagesNata Drawing QuestionsTwinkleNo ratings yet

- Bosch Bizgram Asia Pte LTD Singapore SMS 87776955 Email Sales@Document7 pagesBosch Bizgram Asia Pte LTD Singapore SMS 87776955 Email Sales@Bizgram AsiaNo ratings yet

- ORION Brochure PDFDocument31 pagesORION Brochure PDFparagbholeNo ratings yet

- Kevin LynchDocument3 pagesKevin LynchKevinLynch17No ratings yet