Professional Documents

Culture Documents

AG150 250 Part 3

Uploaded by

aritmeticsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AG150 250 Part 3

Uploaded by

aritmeticsCopyright:

Available Formats

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

0

Maimulte Urmtorulblog

Creaiblog Autentificare

Acestsitefolosetecookieuripentruaoferiservicii,pentrua

personalizaanunuriipentruaanalizatraficul.Dacfolosiiacest

site,sunteideacordcuutilizareacookieurilor.

Tractorpartsandattachments

AFLAIMAIMULTE

AMNELES

Descriptionandapplicationoftractorsparepartsandcomponents.MasseyFerguson,JohnDeere,CaseIH.

Home

Clutch

Transmission

Gearbox

DieselEngine

Frontaxle

Steering

Rearaxle

Hydraulic

Brakes

Tractorsplit

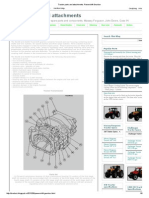

AG150/AG250PowershiftgearboxCreeper

TractorsfittedwithanAG150orAG250Powershiftgearboxmaybefitted,accordingtooptions,with

acreeper.Thisreducerunit(24)comprisesasimpleepicyclicalgeartrainhavingaplanetary

carrierandcrownwheelmountedatthefrontoftheintermediatehousing(19).

Itiscontrolledbyaleverontherighthandsideconsoleinthecabthatislinkedviaacabletoa

linkfittedonthefrontrighthandsideoftheintermediatehousing.Thislinkmovesthecoupler

controlfork.Thecoupler,fittedwithstraightteeth,mustonlybeengagedwhenthetractoris

stationary.

Operation

Thecoupler(29)isintegralviasplineswiththelayshaft(30).Themovingofthecontrollevertothe

"Snail"positionmovesthecouplerrearwardsandlocksittotheplanetarycarrier(20)viacoupler

ring(22).Thespeedoftheoutputshaftis1/4ofthatoftheinputshaft.

SearchThisBlog

Search

PopularPosts

DisassemblyandassemblytheOrbitrolsteeringunit

(125/160cm)

Removethesteeringunitfromthetractor.Placethe

steeringunitinavicefittedwithplasticjaws.Takeout

thescrews(1).Carefu...

Tractorhydraulicsystem

Thehydraulicsystemoftractorisclosedcentrewith

controlledpressureandflowrate.Itconsistsoftwo

separatesystems(highandlow...

BasicDieselEnginePartsandcomponents

Theeightmajormechanicalcomponentsofthebasic

tractordieselenginearethefollowingparts:Cylinder

blockCylinderhead...

CoolingandLubricationSystems

DieselEngineCoolingSystemThetractorengine

coolingsystemhasthefollowingcomponents:Radiator

WaterpumpCylinder...

Danafrontaxle

Thismayormaynotbefittedonthetractordepending

ontheenginefrontaxlemodel.Thefrontaxlesmounted

onthe4WDtractorsconsis...

Lubrication

Thelubricationofthemechanicalcomponentsoftheepicyclicalreducergearisensuredbyanoil

splash.Thedrivepinionandthelayshaft(30)haveanaxialdrilledchannel,thisallowsflow"D"

fromtherighthandsidehydrauliccovertolubricateneedlebearing(34).Thebearingsupportsthe

layshaftandpermitsadifferenceinrotationoftheshaftswheninthe"Creeper"position.

MasseyFerguson

TractorSpecs

MFTractorSpecs

Challenger

TractorSpecs

ChallengerTractor

MasseyFerguson

TractorMF1540

MasseyFerguson

TractorMF5470

MasseyFerguson

TractorMF6490

MasseyFerguson

TractorMF7615

JCBTractor

specifications

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

ChallengerTractor

MT465Bspec

ChallengerTractor

MT525Bspec

ChallengerTractor

MT645Dspec

ChallengerTractor

MT955Cspec

CASEIHTractor

Specifications

1/6

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

JCBTractor2155

specification

CASE105UFarmall

Tractor

JCBTractor3200

specification

CASE120AFarmall

Tractor

JCBTractor7200

specification

CASE125Puma

Tractor

JCBTractor8250

specification

CASE70Farmall

Tractor

Partslist

(1)Snapring(2)Connectingshaft(3)Bolts(4)Sleeve(5)Support(6)Snapring(7)Bearing

carrier(8)Circlip(9)Circlip(10)Ballbearing(11)Snapring(12)Frictionwasher(13)Pin(14)

Frictionplates(15)Sungears(16)Crownwheel(17)Spacers(18)Rollerbearings(19)Intermediate

housing

(20)Planetarycarrier(21)Snapring(22)Couplerring(23)Bolts(24)Planetarycarrierassembly

(reducergear)(25)Locatingpin(26)Nut(27)Fork(28)Guiderod(29)Coupler(30)Layshaft(31)

Snapring(32)Sleeve(33)Snapring(34)Needlebearing(35)Lockingstud(36)Spring(37)Plug

(38)Pin

(39)Finger(40)Oring(41)Pin(42)Link(43)Bolt(44)Housing(45)Shim(s)

Removingandrefittingtheunit

Uncouplethetractorbetweenthegearboxandtheintermediatehousing.

Removethesleeve(4).Removebolts(3).Removetheshaft(2)andunit(24)assembly.The

locatingpins(25)areforcefittedintotheintermediatehousing(19).Checkforthepresenceofthe

locatingpinsontheintermediatehousing.

Screwtwoguidestudsofsuitablelengthintheplaceoftwobolts(3).

Placecoupler(29)incontactwithsnapring(31).Refitshaft(2)andunit(24)assemblyturningthe

machinedrecess"E"onsupport(5)towardsthe

adjustingnut(26)onguiderod(28).Turnshaft(2)severalturnstoengagetheexteriorsplines

ofcouplerring(22)inthoseofcoupler(29).

Alternatelyanduniformlytightenbolts(3)lightlysmearedwithLoctite241toatorqueof90120

Nm.Couplethetractorbetweenthegearboxandtheintermediatehousing.

Disassembling,reassemblingandadjustingtheselectionmechanism

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

2/6

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

Removeunit(24).Disconnectthecontrolcablefittedtolink(42).

Disassembly

Removeplug(37).Recoverspring(36)andlockingstud(35).

RemovetheAllenscrew(43).Removethelink(42)andpin(41)fittedwithseal(40)andfinger

(39).Recovertheshim(s)(45).Driveoutpin(38)linkingthepinandthefinger.Disengagethe

guiderod(28)fromthefork(27)andtheintermediatehousing(19).Ifnecessary,loosen,unscrew

anddiscardnut(26).Removethefork,couplerandshaft(30)fittedwithneedlebearing(34).

Removesnapring(31).Ifnecessary,extractthebearing.

Cleanandcheckthecomponents.Replaceanypartsfoundtobedefective.

Iffitted,usinganappropriatefixture,insertbearing(34)thrustagainsttheshoulderonlayshaft

(30)andcheckthattheneedlebearingturnsnormally.Placesnapring(31).Lubricateanewseal

(40)andfititonpin(41).Enterthepinthroughthechamferedportoftheintermediatehousing

(19).

Tolimitaxialclearanceofthepin,itisrecommendedtocarryoutshimmingwithatoleranceof

0.1mmto0.6mm.

Shimming

Onthepin,placeanapproximatethicknessofshim(s)(45).Fitfinger(39)andpartiallyfitpin

(39).Reassemblethelink(42)andbolt(43).

Manuallyevaluatetheexistingclearance.

Theadjustmentprincipleconsistsinobtainingaminimumclearancebetweenthevariousparts.

Action

Iftheclearanceisoutsidethemaximumstatedtolerance,determineanewthicknessofshim(s).

Aftershimming,checkforthecorrectorientationofthefingerandthelink.Definitivelyinsertpin

(38),fitandtightenAllenscrew(43).Fittheshaft,couplerandforkintheintermediate

housing.Refittheguiderodandnutassembly.Refittheunit(24).Adjustthefork(seesubsequent

operations).

Couplethetractorbetweenthegearboxandtheintermediatehousing.

Connectthecontrolcableandadjustitifnecessary.

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

3/6

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

Adjustment

Fitthelockingstud(35),spring(36)andplug(38).Partiallytightentheplug.

Positioncoupler(29)inaccordancewithF1,itsforwardfacethrustagainstshaft(2).

MaintaintheforkthrustagainstthecouplerinaccordancewithF2.Turntheguiderod(28)innut

(25)accordingtoF3soastoplaceincontacttheobliquefaceofgrooveG1withlockingstud(35)

whilesimultaneouslyholdingnut(26)againstspotfacedfaceBoftheintermediatehousing(19).

Usingadepthgauge,measureX1betweentheforwardfaceoftheguiderodandfaceAofthe

intermediatehousing(19).

HoldtheforkthrustagainstthecouplerinaccordancewithF2.

TurntheguiderodinthenutinaccordancewithF4soastoplacetheotherobliquefaceofgroove

G1incontactwiththelockingstudwhileholdingnut(26)aspreviously.

MeasureX2inthesamemannerasX1.

DeterminethepositionofadjustmentXusingthefollowingformula:X=(X1+X2):2

Provisionallypositionguiderod(28)todimensionX.

Placecoupler(29)inthe"Creeperunit"position.Manuallycheckforlockingofthecontrolandthe

clearancebetweentheforkandthecoupler.

Ifthischeckissatisfactory,removeunit(24),plug(37),thespringandthelockingstud.

Greasethethreadsoftheguiderodandthethreadsofnut(26).

Tightenthenut,previouslylightlysmearedwithLoctitefreinfiletfaibe,anddefinitivelyposition

theguiderodaccordingtothepreviouslycalculateddimensionX.

Lockthenutbybendingitscollarintothemachinedgrooveoftheguiderod.

Reassemblethelockingmechanism.Tightenplug(37)toatorqueof5070Nm.Refitunit(24).

Disassemblingandreassemblingtheepicyclicalreducergear

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

4/6

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

Removeunit(24).Takeoutbolts(23).Removehousing(44).Disengagereducergear(20)from

shaft(2).Removecrownwheel(16).Separatesupports(5)(7).Ifnecessary,takeoffsnapring(6)

andcirclips(8)(9).Extractbearing(10).Removethefrictionwashers(12).Takeoffcirclip

(11).Driveoutpins(13).Removesungears(15)takingcarenottolosetheneedlebearings(18),

spacers(17)andthefrictionplates(14).

Thecouplerring(22)isfittedintheplanetarycarrierusingapress.Snapring(21)provides

additionallockingofthevariousparts.

Checkandcleanthecomponents.Replaceanypartsfoundtobedefective.

Fiteachsungear(15)withbothneedlebearings(18)andspacer(17)smearedwithmiscible

grease.Refitthesungearsandpositionthefrictionplates(14).Refitpins(13)correctlyturningthe

spotfaceforthefittingofsnapring(11).Fitthesnapring.Manuallychecktheaxialclearanceand

rotationofeachsungear.Lightlysmearthefacesofthereducergearwithmisciblegreaseandfit

thefrictionwashers(12),withthetabslodgedintheappropriategrooves.Ifdisassembled,insert

bearing(10)onshaft(2)usinganappropriatefixture.Fitcirclips(8)(9)andsnapring

(6).Assemblesupports(5)(7).Engagereducergear(20)onshaft(2).Refitthecrownwheel(16).

Positionhousing(44),withthecutoutturneddownward.Assembleandtightenbolts(23)previously

lightlysmearedwithLoctite241andtightentoatorqueof1014Nm.Refitunit(24).

Adjustingthecontrol

Onlever"A"

Placecontrollever"A"inthe"Snail"position.Screwyoke(1)flushwiththeendofthethreaded

partofthecable(6).Fittheyoke(1)ontolever"A"withclip(7).Tightennut(2).Tightennut(3)

againstsheathend(5).

FitthesheathendandGrowerwasherontothesupport.Tightennut(4)checkingthatthecableis

notpinched.

Onlink"B"

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

5/6

8/10/2015

Tractorpartsandattachments:AG150/AG250PowershiftgearboxCreeper

Placelink"B"inthe"Creeper"position(coupler(29)lockedbysplinestoplanetarycarrier(20)fork

locked).Screwyoke(9)flushwiththethreadedpartofcable(6).Assembleyoke(9)ontolink"B"

usingclip(10).Tightennut(11).

Adjuststop(12)usingnut(13)onsupport(8)whilecheckingthatlink"B"isstillcorrectly

locked.Tightennut(14)andcheckthatthecableisnotpinched.

CheckforcorrectoperationandlockingofthecontrolintheDirectdriveposition.

Recommend this on Google

NewerPost

Home

OlderPost

AwesomeInc.template.PoweredbyBlogger.

http://tractorz.blogspot.ro/2012/09/ag150ag250powershiftgearboxcreeper.html

6/6

You might also like

- Tractor Parts and Attachments: Powershift GearboxDocument6 pagesTractor Parts and Attachments: Powershift Gearboxaritmetics100% (1)

- 3 Short Engine - Assembly (Rg40024)Document2 pages3 Short Engine - Assembly (Rg40024)Tyler Goodwin100% (1)

- Acme A349 Service ManualDocument34 pagesAcme A349 Service ManualCristian DavidNo ratings yet

- Fuel Lift Pump Remote Mounting Kit RevisionDocument2 pagesFuel Lift Pump Remote Mounting Kit RevisionMike PerryNo ratings yet

- Mccormick c60 c75 c85 c95 c105 C Max Workshop ManualDocument8 pagesMccormick c60 c75 c85 c95 c105 C Max Workshop ManualdingleberryspotifyNo ratings yet

- Type2 1200 1600 Shop Manual PDFDocument258 pagesType2 1200 1600 Shop Manual PDFYenni Katherine Jaimes GallardoNo ratings yet

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- Perkins Engines Guide VK - od.UADocument5 pagesPerkins Engines Guide VK - od.UANoui BouzidNo ratings yet

- 6 Speed Transmission Gears & Related PartsDocument5 pages6 Speed Transmission Gears & Related PartsMarcela Liliana MolnarNo ratings yet

- Catalogo PDFDocument4 pagesCatalogo PDFRicardo Rarcia EscorizaNo ratings yet

- S 70302UR2-ZetorDocument94 pagesS 70302UR2-ZetorBrent HNo ratings yet

- New Holland T5000 Series Tractor Specifications: T5040 T5050 T5060 T5070Document2 pagesNew Holland T5000 Series Tractor Specifications: T5040 T5050 T5060 T5070Victor Nunes0% (1)

- Kubota: Diesel EngineDocument45 pagesKubota: Diesel EngineKlapatyk30101991No ratings yet

- R065E2Document7 pagesR065E2Mk MakyNo ratings yet

- SB 4031 eDocument442 pagesSB 4031 eHenry Huayhua100% (1)

- List ForecoDocument8 pagesList ForecoYoungBossHanafiNo ratings yet

- Manual z60-34 From SN 4001 A 4550Document244 pagesManual z60-34 From SN 4001 A 4550Christian Andy H. ChavezNo ratings yet

- Powerfarm 85-105 HC Tractor SpecsDocument2 pagesPowerfarm 85-105 HC Tractor SpecssindasilvaNo ratings yet

- Tn-A Series Tn75saDocument3 pagesTn-A Series Tn75saMADONTOUNo ratings yet

- Download Free Manual Claas Dominator 85 PDFDocument1 pageDownload Free Manual Claas Dominator 85 PDFFlorin SpataruNo ratings yet

- Dodge Speed Reducers Parts Replacement ManualDocument9 pagesDodge Speed Reducers Parts Replacement Manuala04205No ratings yet

- TYM-T233 T273 Engine List (S3L2-S3L)Document46 pagesTYM-T233 T273 Engine List (S3L2-S3L)Fernando Silva100% (1)

- ASV Posi-Track PT-100 Track Loader Service Repair Manual PDFDocument14 pagesASV Posi-Track PT-100 Track Loader Service Repair Manual PDFfisekkkdNo ratings yet

- Perkins M215C and M185C 1006 SeriesDocument2 pagesPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- Massey-Ferguson-298-Tractor de Llantas-Parts-ManualDocument22 pagesMassey-Ferguson-298-Tractor de Llantas-Parts-ManualELKIN MAURICIO RAMIREZ PEREZNo ratings yet

- 2019Document20 pages2019Sherbert OngNo ratings yet

- D60 FD70 CA20 Harvest Header Flex Draper Combine Adapter: Technical ManualDocument558 pagesD60 FD70 CA20 Harvest Header Flex Draper Combine Adapter: Technical Manualguilherme paludoNo ratings yet

- HATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMDocument39 pagesHATZ 1D41 1D42 1D50 1D81 1D90 Diesel IMEdmundas ŽemaitisNo ratings yet

- Manual Manutencao Motor Ford LSG 423Document102 pagesManual Manutencao Motor Ford LSG 423Leandro SantosNo ratings yet

- BmwhandbookDocument34 pagesBmwhandbookNissan-club HrNo ratings yet

- 74 Series 574 Handbrake Cable LayoutDocument2 pages74 Series 574 Handbrake Cable LayoutlzlinuxNo ratings yet

- Accupart Cummins Holset SingleDocument36 pagesAccupart Cummins Holset Singlegestada02350% (2)

- Tran Disasemble 966cDocument46 pagesTran Disasemble 966cHector VallesNo ratings yet

- Manual Perkins GenieDocument206 pagesManual Perkins GenieLauro FerreiraNo ratings yet

- Same Laser 125 150 2009Document2 pagesSame Laser 125 150 2009Silvia De Pedro CamoeirasNo ratings yet

- 51796-Case 410 420Document468 pages51796-Case 410 420Brian EshamNo ratings yet

- SPX Power Team Pt1403bDocument240 pagesSPX Power Team Pt1403bjeedanNo ratings yet

- CT120 6986522 enUS Om 04-10Document214 pagesCT120 6986522 enUS Om 04-10Henry HuayhuaNo ratings yet

- Quick Reference Guide Beko DSFN 1530Document2 pagesQuick Reference Guide Beko DSFN 1530prorenokamp100% (1)

- 8240 PDFDocument785 pages8240 PDFСергій XрестикNo ratings yet

- Parts Manual: Issue 13Document141 pagesParts Manual: Issue 13Юра ПименовNo ratings yet

- CPM Parts Catalog 6-20-13Document60 pagesCPM Parts Catalog 6-20-13Motoc AdrianNo ratings yet

- LEHW0027 00 Cat 3306 PDFDocument4 pagesLEHW0027 00 Cat 3306 PDFHassan ShathakNo ratings yet

- 6ta - Parts - Flypartsguy - Com - 3.2019Document98 pages6ta - Parts - Flypartsguy - Com - 3.2019Kurd SkorvskiNo ratings yet

- Massey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)Document20 pagesMassey Ferguson MF 35X TRACTORS Service Parts Catalogue Manual (Part Number 819045)bvk2980022No ratings yet

- VOLVO SD45F SOIL COMPACATOR Service Repair Manual PDFDocument19 pagesVOLVO SD45F SOIL COMPACATOR Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Flagro Fvo 400 Heater Operations and TroubleshootingDocument30 pagesFlagro Fvo 400 Heater Operations and TroubleshootingJocelyn DuteauNo ratings yet

- Sd300n Om enDocument126 pagesSd300n Om enAimHigh100% (1)

- Axilok InstallatTuercasDocument1 pageAxilok InstallatTuercasalxsscabal100% (1)

- Catalogo Drive One 161110 PDFDocument174 pagesCatalogo Drive One 161110 PDFIdiLab EmprendimientoNo ratings yet

- Standard Clutch PDFDocument136 pagesStandard Clutch PDFEduar Drink Lozano100% (1)

- Manual Datos Tecnicos ZetorDocument127 pagesManual Datos Tecnicos ZetoredhuamNo ratings yet

- Lamborghini R340 Engine Parts CatalogDocument19 pagesLamborghini R340 Engine Parts CatalogRazvan BorsNo ratings yet

- Kubota M7500Document2 pagesKubota M7500Pinto RaharjoNo ratings yet

- Bulldog Cat 3056 Engine KitsDocument1 pageBulldog Cat 3056 Engine KitsDavid Fernando Castillo NisttahuzNo ratings yet

- 96-97 FedEx Express Body Parts ManualDocument88 pages96-97 FedEx Express Body Parts ManualTasfin Habib0% (1)

- TM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical ManualDocument11 pagesTM1403 John Deere 450G, 455G, 550G, 555G, 650G Crawler Diagnostic Operation Test Technical Manualtteelsars0% (1)

- Kent MotoniveladorasDocument1 pageKent MotoniveladorasMOZAMBiCAR100% (1)

- SM Mla 628 - 547860enDocument749 pagesSM Mla 628 - 547860enaritmeticsNo ratings yet

- Manitou Ml635-Mlt1740 InstructionsDocument196 pagesManitou Ml635-Mlt1740 InstructionsaritmeticsNo ratings yet

- SM E215B-E245B 9 ENDocument40 pagesSM E215B-E245B 9 ENaritmeticsNo ratings yet

- SM E215B-E245B 4 ENDocument38 pagesSM E215B-E245B 4 ENaritmetics100% (2)

- Router Digi Manual Hg8121hDocument14 pagesRouter Digi Manual Hg8121haritmeticsNo ratings yet

- Service Manual - E175B-E195B - Cap6 - ENDocument18 pagesService Manual - E175B-E195B - Cap6 - ENaritmeticsNo ratings yet

- DP 50 Operator S Manual Basic 9 0Document199 pagesDP 50 Operator S Manual Basic 9 0aritmeticsNo ratings yet

- Lenovo Tab M10 (HD) : User GuideDocument22 pagesLenovo Tab M10 (HD) : User GuidearitmeticsNo ratings yet

- Spooky2 Users Guide 20200917Document241 pagesSpooky2 Users Guide 20200917aritmetics100% (1)

- The Seven Chakras - Deepak ChopraDocument20 pagesThe Seven Chakras - Deepak ChopraD!m!80% (5)

- Service Manual - E175B-E195B - Cap6 - ENDocument18 pagesService Manual - E175B-E195B - Cap6 - ENaritmeticsNo ratings yet

- SM E215B-E245B 7 ENDocument110 pagesSM E215B-E245B 7 ENaritmeticsNo ratings yet

- Daewoo Sl015plus-Sl018vt Operator Sec WatDocument190 pagesDaewoo Sl015plus-Sl018vt Operator Sec Wataritmetics100% (1)

- Service Manual - E215B-E245B - 5 - ENDocument118 pagesService Manual - E215B-E245B - 5 - ENaritmetics100% (4)

- 2013Document102 pages2013ctorres_505746100% (1)

- Presentare AgroclimberDocument89 pagesPresentare Agroclimberaritmetics0% (1)

- Belarus 1025, 1025.2, 1025.3 Operation Manual MTZDocument205 pagesBelarus 1025, 1025.2, 1025.3 Operation Manual MTZMtzindex100% (4)

- TPL Header Height Valve TestDocument8 pagesTPL Header Height Valve TestaritmeticsNo ratings yet

- Belarus 1025, 1025.2, 1025.3 Operation Manual MTZDocument205 pagesBelarus 1025, 1025.2, 1025.3 Operation Manual MTZMtzindex100% (4)

- Cpuz ReadmeDocument10 pagesCpuz ReadmeAndrian SyahNo ratings yet

- HandyAvi Soft HelpDocument269 pagesHandyAvi Soft HelparitmeticsNo ratings yet

- Binocular Universe - Happy New Year - January 2015Document3 pagesBinocular Universe - Happy New Year - January 2015aritmeticsNo ratings yet

- Telescope Equations Guide for Exploring the Night SkyDocument97 pagesTelescope Equations Guide for Exploring the Night SkyAnimalesProtegidosAhora100% (1)

- Rigel Tonight BestDocument2 pagesRigel Tonight BestaritmeticsNo ratings yet

- Webcam Imaging LessonDocument4 pagesWebcam Imaging LessonaritmeticsNo ratings yet

- Setup ConfigDocument1 pageSetup ConfigLavakumar Reddy MNo ratings yet

- Binocular Universe - Aurigan Treasures - February 2012Document6 pagesBinocular Universe - Aurigan Treasures - February 2012aritmeticsNo ratings yet

- Astronomy Polar Aligning StepDocument7 pagesAstronomy Polar Aligning SteparitmeticsNo ratings yet

- Telescope Equations: Useful Formulas For Exploring The Night Sky Randy CulpDocument97 pagesTelescope Equations: Useful Formulas For Exploring The Night Sky Randy CulparitmeticsNo ratings yet

- Focus WiresDocument816 pagesFocus Wiresionutnespus100% (2)

- Virgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsDocument6 pagesVirgilio S. Delima V. Susan Mercaida Gois GR NO. 178352 - June 17, 2008 FactsNikki BarenaNo ratings yet

- C J L F S: Vinod TiwariDocument21 pagesC J L F S: Vinod TiwariVinod TiwariNo ratings yet

- Tambunting Pawnshop Vs CIR Re VATDocument7 pagesTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNo ratings yet

- Research Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormDocument13 pagesResearch Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormBikaZee100% (1)

- Stellar Competent CellsDocument1 pageStellar Competent CellsSergio LaynesNo ratings yet

- Characteristics: Wheels Alloy Aluminium Magnesium Heat ConductionDocument4 pagesCharacteristics: Wheels Alloy Aluminium Magnesium Heat ConductionJv CruzeNo ratings yet

- Sampling Fundamentals ModifiedDocument45 pagesSampling Fundamentals ModifiedArjun KhoslaNo ratings yet

- AssDocument9 pagesAssJane SalvanNo ratings yet

- Literature Review 5Document4 pagesLiterature Review 5api-463653994No ratings yet

- Maximizing Revenue of IT Project DevelopmentDocument4 pagesMaximizing Revenue of IT Project DevelopmentJulius Mark CerrudoNo ratings yet

- SC invalidates Ordinance allowing oil depots in Pandacan due to population densityDocument2 pagesSC invalidates Ordinance allowing oil depots in Pandacan due to population densityMigs Raymundo100% (1)

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDocument7 pagesUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataNo ratings yet

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonNo ratings yet

- Shri Siddheshwar Co-Operative BankDocument11 pagesShri Siddheshwar Co-Operative BankPrabhu Mandewali50% (2)

- Managing operations service problemsDocument2 pagesManaging operations service problemsJoel Christian Mascariña0% (1)

- Management Reporter Integration Guide For Microsoft Dynamics® SLDocument22 pagesManagement Reporter Integration Guide For Microsoft Dynamics® SLobad2011No ratings yet

- Czar Alexander IIDocument11 pagesCzar Alexander IIMalachy ChinweokwuNo ratings yet

- Capran+980 CM en PDFDocument1 pageCapran+980 CM en PDFtino taufiqul hafizhNo ratings yet

- Youtube AlgorithmDocument27 pagesYoutube AlgorithmShubham FarakateNo ratings yet

- Farmers InterviewDocument5 pagesFarmers Interviewjay jariwalaNo ratings yet

- Lea 201 Coverage Topics in Midterm ExamDocument40 pagesLea 201 Coverage Topics in Midterm Examshielladelarosa26No ratings yet

- 34 Annual Report 2019 20Document238 pages34 Annual Report 2019 20Rahul N PatelNo ratings yet

- 272 Concept Class Mansoura University DR Rev 2Document8 pages272 Concept Class Mansoura University DR Rev 2Gazzara WorldNo ratings yet

- STS Chapter 5Document2 pagesSTS Chapter 5Cristine Laluna92% (38)

- Iso 4624Document15 pagesIso 4624klkopopoonetdrghjktl100% (2)

- Parasim CADENCEDocument166 pagesParasim CADENCEvpsampathNo ratings yet

- 63db2cf62042802 Budget Eco SurveyDocument125 pages63db2cf62042802 Budget Eco SurveyNehaNo ratings yet

- ECED Lab ReportDocument18 pagesECED Lab ReportAvni GuptaNo ratings yet

- Ridge Regression: A Concise GuideDocument132 pagesRidge Regression: A Concise GuideprinceNo ratings yet

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDocument6 pagesMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNo ratings yet

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- The Mountain of My Fear and Deborah: Two Mountaineering ClassicsFrom EverandThe Mountain of My Fear and Deborah: Two Mountaineering ClassicsRating: 4.5 out of 5 stars4.5/5 (20)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- 127 Hours Movie Tie- In: Between a Rock and a Hard PlaceFrom Everand127 Hours Movie Tie- In: Between a Rock and a Hard PlaceRating: 4 out of 5 stars4/5 (46)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- The Optimist: A Case for the Fly Fishing LifeFrom EverandThe Optimist: A Case for the Fly Fishing LifeRating: 4.5 out of 5 stars4.5/5 (17)

- One Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2From EverandOne Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2Rating: 4.5 out of 5 stars4.5/5 (15)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerFrom EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerRating: 4 out of 5 stars4/5 (23)

- Dark Summit: The True Story of Everest's Most Controversial SeasonFrom EverandDark Summit: The True Story of Everest's Most Controversial SeasonRating: 4 out of 5 stars4/5 (154)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailFrom EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailRating: 4.5 out of 5 stars4.5/5 (308)

- Lost in the Wild: Danger and Survival in the North WoodsFrom EverandLost in the Wild: Danger and Survival in the North WoodsRating: 4.5 out of 5 stars4.5/5 (107)

- Divided: A Walk on the Continental Divide TrailFrom EverandDivided: A Walk on the Continental Divide TrailRating: 4 out of 5 stars4/5 (17)

- Alta California: From San Diego to San Francisco, A Journey on Foot to Rediscover the Golden StateFrom EverandAlta California: From San Diego to San Francisco, A Journey on Foot to Rediscover the Golden StateRating: 5 out of 5 stars5/5 (1)

- The Essential Fishing Handbook: 161 Fishing Tips and TricksFrom EverandThe Essential Fishing Handbook: 161 Fishing Tips and TricksRating: 5 out of 5 stars5/5 (1)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyFrom EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyRating: 4.5 out of 5 stars4.5/5 (12)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailFrom EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailRating: 4 out of 5 stars4/5 (167)

- Survival Hacks: Over 200 Ways to Use Everyday Items for Wilderness SurvivalFrom EverandSurvival Hacks: Over 200 Ways to Use Everyday Items for Wilderness SurvivalRating: 4.5 out of 5 stars4.5/5 (11)

- The Voyage of The Aegre: From Scotland to the South Seas in a Shetland boatFrom EverandThe Voyage of The Aegre: From Scotland to the South Seas in a Shetland boatRating: 4.5 out of 5 stars4.5/5 (3)

- Nuclear War Survival Skills: Lifesaving Nuclear Facts and Self-Help InstructionsFrom EverandNuclear War Survival Skills: Lifesaving Nuclear Facts and Self-Help InstructionsRating: 4.5 out of 5 stars4.5/5 (10)

- Hiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailFrom EverandHiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailRating: 4 out of 5 stars4/5 (99)

- The Lost Explorer: Finding Mallory on Mount EverestFrom EverandThe Lost Explorer: Finding Mallory on Mount EverestRating: 4.5 out of 5 stars4.5/5 (31)