Professional Documents

Culture Documents

40 1en PDF

Uploaded by

Hung Cuong PhamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40 1en PDF

Uploaded by

Hung Cuong PhamCopyright:

Available Formats

Medium-Voltage

Switchgear

Switchgear Types 8DJ and 8DH

for Secondary Distribution Systems

up to 24 kV (General Part),

Gas-Insulated

Catalog HA 40.1

2005

Supersedes:

Catalog HA 40.1 2002

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Contents

Application

Page

Application

Features

8DJ secondary distribution switchgear and 8DH switchgear

2

Product Range

8DJ secondary distribution switchgear

8DH switchgear

Features

3

3

are metal-enclosed, SF6-insulated switchgear types for indoor

installation

8DJ switchgear as non-extendable secondary distribution

switchgear in block-type construction

8DH switchgear as a modular and extendable switchgear in

Requirements

Features, typical application

panel-type construction

4 and 5

Typical uses

Technical Data

Electrical data

Switchgear installation, shipping data

5 to 7

8

8DJ/8DH switchgear types are used for secondary distribution

systems, such as

Substations, customer transfer substations and distribution

substations used by power supply and public utilities

Design and Mode of Operation

Panel design

Components

Three-position switch-disconnector

Operating mechanisms

HV HRC fuse assembly

Indicating and measuring equipment

Interlocks, locking devices

Cable connections

Typical examples include:

10 and 11

11 to 13

14 and 15

16 to 18

19

20 to 28

Standards

Standards, specifications, guidelines

Industrial plants

29 to 31

Notes

31

Wind power stations

High-rise buildings

Airports

Lignite open-cast mines

Underground stations

Sewage treatment plants

Port facilities

Traction power supply systems

Automobile industry

Petroleum industry

Chemical industry

Cement industry

R-HA40-004 eps

R-HA40-002 eps

Catalog HA 45.11: 8DJ10 Secondary Distribution

Switchgear

Catalog HA 45.31: 8DJ20 Secondary Distribution

Switchgear

Catalog HA 41.11: 8DH10 Switchgear

R-HA40-001 eps

For further information, please refer to

Siemens AG 2005

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Product Range

R-HA40-010c eps

R-HA41-013b eps

8DH switchgear in panel-type

construction, extendable and modular

R-HA45-100b eps

R-HA45-119b eps

8DJ secondary distribution switchgear

in block-type construction, non-extendable

Example:

transfer substation

with a 20 kV infeed

Example:

scheme 10 (width 710 mm)

Example:

scheme 10 (width 1060 mm)

Example:

scheme 10 (width 920 mm)

8DJ10 switchgear

8DJ20 switchgear

8DJ30 switchgear

8DH10 switchgear

Overall heights

Overall heights 1200,

Special version

Overall height 1400 mm,

1360 and 1650 mm

For cable T-plugs

Extremely narrow

design

Block versions

up to 6 versions

Detachable lever

mechanism

On request: rotary

operating mechanism

Typical uses

Substations with control

aisles

Compact substations,

substations by pavements

Tower base substations

7.2 to 24 kV

Up to 25 kA

up to 12 kV

with low-voltage compartment 2000 mm

Overall heights

1200 and 1700 mm

Compact design

Conventional cable

connection

Detachable lever

mechanism

Option: for straight

cable plugs

Circuit-breaker panels

Switch-disconnector panels

with/without HV HRC fuses

Metering panels

Bus sectionalizer panels (coupling)

For cable T-plugs

Detachable lever mechanism

No gas work during assembly

or extension on-site

Typical uses

Typical uses

Compact substations

with minimal dimensions

Up to 12 kV

Up to 25 kA

Utilities customer transfer substations

Industrial distribution systems

Distribution substations

Feeder currents up to 630 A

Busbar currents up to 1250 A

7.2 to 24 kV

Up to 25 kA

R-HA40-005 eps

R-HA40-007 eps

R-HA40-006 eps

R-HA40-004 eps

Typical uses

Substations with

control aisles

Compact substations

Tower substations/

basement substations

7.2 to 24 kV

Up to 25 kA

1400 and 1760 mm

High cable connection

For cable T-plugs

Detachable lever mechan.

Option: rotary operating

mechanism

Option: f. outdoor enclos.

Siemens HA 40.1 2005

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Technical Data

Electrical data

Overview

7.2 to 24 kV

Rated lightning

impulse withstand

voltage

Up to 125 kV

Rated short-time

withstand current

Up to 25 kA

Rated normal

current of feeders

Up to 630 A

Rated normal

current of busbar

Up to 1250 A 1)

Up to 630 A 2)

Rated short-circuit

making current

Up to 63 kA

For further technical data refer to pages 6 to 8

R-HA40-013 eps

R-HA40-056 eps

Utilities distribution

substation, industrial plant

R-HA40-055 eps

Utilities customer

transfer substation

Rated voltage

1) For 8DH switchgear

Further utilities substations

2) For 8DJ secondary distribution switchgear

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Technical Data

Electrical data of the switchgear

Filling pressure

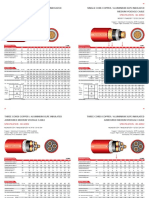

8DJ10 secondary distribution switchgear

Rated insulation

level

Pressure values at 20 C

Rated voltage Ur

kV

7.2

12

15

17.5

24

Rated short-duration power-frequency

withstand voltage Ud

kV

20

28

36

38

50

Rated lightning impulse withstand volt. Up

kV

60

75

95

95

125

Rated normal

current Ir *

for feeders

up to 400 A or up to 630 A

for busbar

1500 hPa

(absolute)

1300 hPa

Minimum

operating pressure pme (absolute)

for insulation

50/60 Hz

Rated frequency fr

Rated

filling pressure pre

for insulation

up to 630 A

Rated short-time for switchgear with tk = 1 s

withstand

for switchgear with t k = 3 s (option)

current Ik

up to kA 25

25

25

25

20

kA 20

20

20

20

20

Rated peak withstand current Ip

up to kA 63

63

63

63

50

Rated short-circuit making current Ima

up to kA 63

63

63

63

50

40 up to +70 oC

Ambient temperature T

8DJ20 secondary distribution switchgear

Rated insulation

level

Rated voltage Ur

kV

7.2

12

15

17.5

24

Rated short-duration power-frequency

withstand voltage Ud

kV

20

28

36

38

50

Rated lightning impulse withstand volt. Up

kV

60

75

95

95

125

50/60 Hz

Rated frequency fr

Rated normal

current Ir *

for feeders

up to 400 A or up to 630 A

for busbar

up to 630 A

Rated short-time for switchgear with tk = 1 s

withstand

for switchgear with t k = 3 s (option)

current Ik

up to kA 25

25

25

25

20

kA 20

20

20

20

20

Rated peak withstand current Ip

up to kA 63

63

63

63

50

Rated short-circuit making current Ima

up to kA 63

63

63

63

50

40 up to +70 oC

Ambient temperature T

8DJ30 secondary distribution switchgear

Rated insulation

level

Rated voltage Ur

kV

7.2

12

Rated short-duration power-frequency

withstand voltage Ud

kV

20

28

Rated lightning impulse withstand volt. Up

kV

60

75

50/60 Hz

Rated frequency fr

Rated normal

current Ir *

for feeders

up to A

630

for busbar

up to A

630

630

630

Rated short-time withstand current Ik

for switchgear with tk = 1 s

up to kA 25

20

Rated peak withstand current Ip

up to kA 63

50

Rated short-circuit making current Ima

up to kA 63

50

40 up to +70 oC

Ambient temperature T

8DH10 switchgear

Rated insulation

level

Rated voltage Ur

kV

7.2

12

15

17.5

24

Rated short-duration power-frequency

withstand voltage Ud

kV

20

28

36

38

50

Rated lightning impulse withstand volt. Up

kV

60

75

95

95

125

Rated frequency fr

Rated normal

current Ir *

for feeders

for busbar

50/60 Hz

up to 400 A or up to 630 A

up to 630 A or up to 1250 A

Rated short-time for switchgear with tk = 1 s

withstand

for switchgear with tk = 3 s (option)

current Ik

up to kA 20

Rated peak withstand current Ip

Rated short-circuit making current Ima

Ambient

temperature T

25

20

25 20

25 20

25

20

20

20

up to kA 50

63

50

63 50

63 50

63

50

up to kA 50

63

50

63 50

63 50

63

50

kA 20

without secondary equipment

40 up to +70 oC

with secondary equipment

5 up to +55 oC

20

20

* The rated normal currents apply to

ambient temperatures of max. 40 C.

The 24-hour mean value is max. 35 C

(acc. to IEC 60 694 / VDE 0670-1000,

standards see page 29).

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Technical Data

Electrical data* of the switching devices (for standards refer to page 29)

Three-position switch-disconnector

Rated voltage

Rated insulation level

Ur

kV

7.2

12

15

17.5

24

Rated short-duration power-frequency withstand volt.

Ud

kV

20

28

36

38

50

Rated lightning impulse withstand voltage

Uw

kV

60

75

95

95

125

fr

Hz

50/60

50/60

50/60

50/60

50/60

Rated frequency

Rated normal

current for

ring-main feeders

Ir

400, 630

400, 630

400, 630

400, 630

400, 630

transformer feeders 1)

Ir

200

200

200

200

200

Rated short-time

withstand current

for switchgear with tk = 1 s

Ik

up to kA

25

25

25

25

20

for switchgear with t k = 3 s

Ik

kA

20

20

20

20

20

Ip

up to kA

63

63

63

63

50

Rated peak withstand current

Rated short-circuit

making current for

transformer feeders 2)

Ima

kA

25

25

25

25

25

ring-main feeders

Ima

up to kA

63

63

63

63

50

1000

1000

1000

1000

1000

630

Mechanical stability (class M1)

No. of operating cycles

Switching capacity of general-purpose switches (class E3)

Test duty 1

Rated mainly active

load breaking current

for 100 switching operations

I1

630

630

630

630

for 20 switching operations

I1

31.5

31.5

31.5

31.5

31.5

Test duty 2a

Rated closed-loop breaking current

I2a

630

630

630

630

630

Test duty 3

Rated transformer breaking current

I3

40

40

40

40

40

Test duty 4a

Rated cable-charging breaking current

I4a (IC or I6)**

68

68

68

68

68

Test duty 4b

Rated line-charging breaking current

I4b

68

68

68

68

68

Test duty 5

Rated short-circuit making current

Ima

up to kA

63

63

63

63

50

Test duty 6a

Rated earth-fault breaking current

I6a (Ie)**

60

60

60

60

60

Test duty 6b

Rated cable-charging breaking current and linecharging breaking current under earth-fault conditions

I6b

(HJ

3 v ICL)**

35

35

35

35

35

Cable-charging breaking current under

earth-fault conditions with superimposed load current

IL + HJ

3 v ICL

630+50

630+50

630+50

630+50

630+50

I4

1150

1150

830

830

830

Switching capacity for switch-disconnector / fuse combination

Rated transfer current

Make-proof earthing switch (earthing function of the three-position switch-disconnector)

Rated voltage

Ur

kV

7.2

12

15

17.5

24

Rated short-circuit making current

Ima

up to kA

63

63

63

63

50

Rated short-time withstand current

Ik

up to kA

25

25

25

25

20

3AH5 vacuum circuit-breaker

Rated voltage

Ur

kV

7.2

12

15

17.5

24

Rated short-duration power-frequency withstand volt.

Ud

kV

20

28

36

38

50

Rated lightning impulse withstand voltage

Up

kV

60

75

95

95

125

Rated frequency

fr

Hz

50/60

50/60

50/60

50/60

50/60

Rated normal current of feeders

Ir

400, 630

400, 630

400, 630

400, 630

400, 630

Rated short-time withstand current

Ik

up to kA

25

25

25

25

20

Rated insulation

level

Rated short-circuit duration

tk

Rated peak withstand current

Ip

up to kA

63

63

63

63

50

Rated short-circuit breaking current

Isc

up to kA

25

25

25

25

20

Rated short-circuit making current

Ima

up to kA

63

63

63

63

50

Electrical service life at rated normal current

10 000 operating cycles

* Higher values of electrical data available upon request.

The rated values of the switchgear are decisive in

accordance with the relevant switchgear type.

See relevant product catalogs.

** Indications in parenthesis acc. to previous standards.

1) Depending on the HV HRC

fuse link

2) Depending on the cut-off

current of the HV HRC fuse

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Technical Data

Switchgear installation, shipping data

Switchgear installation

and pressure relief

HA40-2006c eps

Floor opening

into cable duct

<90

Sealed PE protective foil with

closed wooden crate, with

desiccant bag

HA40-2008c eps

Cooling sheets

made of expanded

metal (not included in

the scope of supply)

Packing: open for container

Switchgear to be covered w. PE

protective foil, with wooden floor

Overseas

by airfreight

Packing: open

Switchgear to be covered with

PE protective foil, with wooden

floor and crate or cardboard cover

* 8DJ10 on request

Transport with fork-lift truck,

suspended

Switchgear

HA40-2013b eps

Pack.: seaworthy crate (standard)

700 700

Overseas

by seafreight

Switchgear to be covered w. PE

protective foil, with wooden floor

Rod ; 40 mm

(observe switchgear weight)

HA40-2012b eps

Pressure relief (arrow)

downwards into

cable duct

For size and weight of the transport units,

see product catalogs 8DJ and 8DH.

Packing: open

Crane transport

with lifting eyes

Transport with lifting truck

with or without pallet

Cable

Siemens HA 40.1 2005

Pressure relief (arrow)

to the rear e.g. into the

transformer room

Lifting

eye

HA40-2047 eps

HA40-2007d eps

700

Cooling sheets

made of expanded

metal (not included in

the scope of supply)

700

Packing (examples)

Transport in

Europe by rail

and truck

<90

Floor opening

into cable duct

Transport (for examples see adjacent figures)

Place of destina- Examples

tion and means of packing

of transport

Rod

; 40 mm

Crane transport

with rod

Switchgear

Crane

hook

Crane

hook

Pressure relief (arrow)

downwards into

cable duct

Type of installation:

Wall-standing arrangement for

8DJ10 *, 8DJ20 and 8DH10 switchgear

Option: free-standing arrangement

for 8DH10 switchgear

8DJ20 switchgear with a height of

1400 mm and 1760 mm, up to 16 kA

8DH10 switchgear with a height of

1700 mm, up to 20 kA

Crane transport with pallet

Cable

Switchgear with

pressure absorber system

Feasibility:

Pallet

Sheet-metal partition

(not included in the

scope of supply)

For the use of maintenance-free and

climate-independent switchgear in older

substation buildings which do not feature

arc-fault testing, the 8DJ20 switchgear can

be designed with modified pressure relief

systems and absorbers.

The pressure absorber system is enclosed

and maintenance-free.

As a special cooling system, it reduces

the pressure-dependent and thermal effects

of arc faults in the switchgear vessel and the

cable connection compartment, and thus

protects both people and buildings.

Cooling sheets made

of expanded metal

HA40-2010b eps

Switchgear

HA40-2009b eps

Absorber system (option) for 8DJ10 *,

8DJ20 secondary distribution switchgear

and 8DH10 switchgear

<90

HA40-2011b eps

Covers for pressure relief outlets and ducts,

expanded metal assemblies, etc. do not

constitute a part of the switchgear. They

must be supplied by the customer.

Crane

hook

700 700

It is possible to install 8DJ secondary distribution switchgear, which are resistant to internal

arc faults and feature pressure relief, in e. g.

Compact substations

Substations with control aisles

Switchgear buildings

Types of transport (examples)

Pressure relief (examples)

Transport with fork-lift truck,

standing

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Design and Mode of Operation

Panel design

Basic design of a

switch-disconnector panel

Examples

HA40-2042c eps

Characteristics

Gas-insulated switchgear

vessel

Hermetically welded and

gas-tight switchgear vessel

made of stainless steel

1 Upper bushing for the

HV HRC fuse assembly

2 Connecting bars in

the switchgear vessel

3 Three-position switchdisconnector with makeproof earthing function

Gas-tight, welded bushings

for HV HRC fuse assembly

and cable connection

10

11

Depending on the switch-

6 Transport lug

12

7 HV HRC fuse box

8 Grip at sealing cover for handling

the HV HRC fuse link

4

13

14

9 Cover of HV HRC fuse assembly

10 Operating mechanism for

the three-position switchdisconnector

11 Control board

12 Detachable lever mechanism

15

16

17

13 Bushing as interface type A

for cable plug

with plug-in contact

14 Cable elbow plug (option)

15 Cable connection

compartment

16 Cable compartment cover

Control

level

Transformer feeder

(example 8DJ20 switchgear)

17 Cable bracket

6

HA40-2043b eps

gear type (8DJ or 8DH), up to

6 feeders can be accommodated in one vessel

4 Switchgear vessel, hermetically

welded and filled

with SF6 gas

2 Connecting bars in

the switchgear vessel

9

10

11

3 Three-position switchdisconnector with makeproof earthing function

4 Switchgear vessel, hermetically

welded and filled

with SF6 gas

5 Pressure relief facility

12

4

2

13

6 Transport lug

9 Cover

10 Operating mechanism for

the three-position

switch-disconnector

11 Control board

12 Detachable lever mechanism

14

15

16

17

Ring-main feeder

(example 8DJ20 switchgear)

13 Bushing as interface type C

for cable plug

with bolted contact (M16)

14 Cable T-plug (option)

15 Cable connection

compartment

16 Cable compartment cover

17 Cable bracket

Control

level

Siemens HA 40.1 2005

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Three-position switch-disconnector

Switch positions:

CLOSED OPEN EARTHED

Three-position

switch-disconnector

Designed as a multi-chamber

switch incorporating the

following functions

Switch-disconnector and

Make-proof earthing switch

R-HA35-047 eps

Characteristics

Fixed contact

Arcing chamber

Moving contact, complete

Operation via gas-tight

Switch shaft

welded bushing at the front

of the switchgear vessel

Compression vane (with nozzle)

Switching functions as

general purpose switchdisconnector (Class E3)

according to

IEC 60 265-1/

VDE 0670-301 * and

IEC 62 271-102/

VDE 0671-102 *

Exploded view

Mode of operation

R-HA40-061a eps

R-HA40-062a eps

Control board with

switch position

indicators for

detachable lever

mechanism

(Standard)

R-HA40-064a eps

R-HA40-065a eps

During the switching movement, the compression vanes

generate a pressure difference

between the subchambers.

The SF6 gas flows through a

nozzle, causes a directional

blow-out of the breaking arc

and quenches it rapidly.

R-HA40-060a eps

Compression vanes, which

rotate in conjunction with the

switch shaft, divide the arcing

chamber into two subchambers each of which changes in

conjunction with the rotation.

Switching functions (for description of switching operations refer to page 11)

R-HA40-063a eps

The switch shaft with the

moving contacts rotates inside

the chamber containing the

fixed contacts.

Control board with

switch position

indicators for

rotary operating

mechanism

(Option for 8DJ20)

Availability of operating

mechanisms

Switchgear Detachable Rotary

type

lever

operating

mechanism mechanism

8DJ10

Standard

On request

8DJ20

Standard

Option

8DJ30

Standard

8DH10

Standard

HA40-2018c eps

Interlocking is not necessary

as the CLOSED and EARTHED

functions cannot be implemented simultaneously.

Switch

positions

CLOSED

OPEN

EARTHED

Switch position

CLOSED

* For standards refer to page 29

10

Siemens HA 40.1 2005

Switch position

OPEN

Switch position

EARTHED

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Operating mechanisms

Closing operation

Characteristics

During closing operation, the

switch shaft with the moving

contact blades changes from

the OPEN to the CLOSED

position.

Mechanical service life

The force of the springoperated mechanism ensures

a high closing speed and a

reliable connection of the main

circuit.

The good insulating properties

of the SF6 gas delay striking of

the arc to the arcing contacts

of the fixed contacts.

Opening operation

During opening operation, the

SF6 gas is compressed in the

arcing chamber.

The compressed gas, which

flows from the nozzles of the

moving contact blades, cools

down the opening arc between

the contacts and safely

quenches it in a few

milliseconds.

The isolating distance created

by opening fulfills the conditions applicable to isolating

distances in accordance with

IEC 60 265-1/

VDE 0670-301 * and

IEC 60 694/

VDE 0670-1000 *

Due to the gas flow in the

arcing chamber, which is

controlled by the operating

movement, both load currents

and minor no-load currents are

safely interrupted.

exceeds 1,000 operating

cycles

Parts subjected to mech-

anical stress, are made

of non-rusting materials

Operating mechanisms

R-HA40-066b eps

Three-position

switch-disconnector

Lubricant-free bearings

Manual operation with

the help of a slip-on lever,

with a vertical lift movement (= detachable lever

mechanism)

Option:

motor operating mechanism

Control board with ac-

cordingly cut-out switching gate:

Prevents the three-position switch-disconnector

from being switched

directly from the

CLOSED via the

OPEN to the

EARTHED position,

hence operation of the

three-position switchdisconnector with the

switch-disconnector

function or with the

make-proof earthing

function

EARTHED

CLOSED

SF6 insulation

OPEN

Detachable

lever mechanism

with three-position switch-disconnector

Manual operating

mechanism

1 Three-position switch-disconnector

2 Gear plate 3 Switchgear vessel 4 Operating mechanism rocker

5 Detachable lever mechanism 6 Detachable lever, inserted

Description on page 12

Motor operating

mechanism

Description on page 13

EARTHING is implemented

by moving the operating lever

from the OPEN to the

EARTHED position.

R-HA40-067b eps

Earthing

Rotary operating mechanism

* For standards refer to page 29

Siemens HA 40.1 2005

11

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Operating mechanisms

Manual operating mechanism

(detachable lever mechanism)

Rotary operating mechanisms

Examples according to VDEW designs

Detachable lever mechanisms

The three-position switchdisconnector is operated via a

rocker with metal bellows,

which is gas-tight and welded

with the switchgear vessel.

R-HA40-070 eps

The spring-operated mechanism

is used for three-position switchdisconnectors in ring-main

feeders (as ring-main switches).

R-HA40-068 eps

Spring-operated mechanism

The switching movements are

performed independently of the

operating speed.

Spring-operated/stored-energy

mechanism

The spring-operated/storedenergy mechanism is used for

three-position switch-disconnectors in transformer feeders

(as transformer switches).

After tripping, a red bar appears

in the switch position indicator.

Spring-operated / stored-energy

mechanism for transformer feeders

Operation of the operating

mechanism

Standard: detachable lever

mechanism

Option: rotary operating

mechanism for 8DJ20

Option for detachable lever

mechanisms and for rotary

operating mechanisms:

Different operating levers 1)

for the operating mechanisms

of the switch-disconnector

and of the make-proof

earthing switch

Availability of operating

mechanisms: Refer to page 10.

1) According to VDN */VDEW ** recommendation

* Association of German Network Operators

VDN e.V. at the VDEW in Germany (as of 2003)

** Association of German Power Stations

VDEW e.V.

12

Siemens HA 40.1 2005

Spring-operated

mechanism for ring-main feeders

R-HA40-071 eps

No additional charging procedure is required for the energy

store. This energy store is

already charged by the switching operation from the

TRIPPED position to the

OPEN position. The precharged energy store also

ensures that the switch-disconnector/fuse combination can

safely switch off all fault types

during closing.

R-HA40-069 eps

The switching operations are

the same as for the springoperated mechanism. An

energy store is available for tripping with the help of a tripping

HV HRC fuse or via the shunt

release.

Spring-operated

mechanism for ring-main feeders

Spring-operated / stored-energy

mechanism for transformer feeders

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Operating mechanisms

Motor operating mechanism

(option)

Operating mechanisms (example 8DJ20 switchgear)

Operating voltages for motor

operating mechanisms:

24, 48, 60, 110, 220 V DC

50/60 Hz 110 and 230 V AC

R-HA40-092 eps

The manual operating mechanisms of the 8DJ/8DH switchgear can be equipped with

motor operating mechanisms

for the three-position switchdisconnector.

1 Terminal strip, located in the

operating mechanism box

2 Auxiliary switch

3 Auxiliary contactors of the

motor operating mechanism for

locking the motor

4 Motor operating mechanism

5 Switch position indicator for

the three-position

switch-disconnector

6 Manual operation of the

detachable lever mechanism for

the earthing function

7 Emergency operation of the

detachable lever mechanism for

the load-break function

Operation:

Local operation by momen-

tary-contact rotary control

switch (option for 8DJ secondary distribution switchgear) or

by pushbutton (option)

Remote operation (standard),

applied to terminal

Shunt release (option)

8

4

Spring-operated/stored-energy

mechanisms can be equipped

with a shunt release. Remote

electrical tripping of the threeposition switch-disconnector is

possible via the magnet coil

of the shunt release, e.g.

transformer overtemperature

tripping.

8 Operating mechanism for

the three-position switchdisconnector (coupled with the

motor operating mechanism)

9 Standard for motor operating

mechanism: locking device

(not shown)

Spring-operated mechanism in ring-main feeder

R-HA40-073 eps

10 Terminal strip, located in the

operating mechanism box

11 Shunt release

To avoid thermal overloading of

the shunt release in the event

of a continuous signal that may

be applied, the shunt release is

switched off via an auxiliary

switch which is mechanically

coupled with the three-position

switch-disconnector.

Auxiliary switch (option)

10

Each operating mechanism of

the three-position switchdisconnector can be optionally

equipped with an auxiliary

switch for the switch position

indication:

11

For 8DJ secondary distribution

switchgear:

Function switch-disconnector:

CLOSED and OPEN:

1NO + 2NC

Function earthing switch:

CLOSED and OPEN:

1NO + 1NC

For 8DH switchgear:

Function switch-disconnector:

CLOSED and OPEN:

2NO + 2NC

Function earthing switch:

CLOSED and OPEN:

2NO + 2NC

Spring-operated/stored-energy mechanisms

in transformer feeder

Technical data of the auxiliary switch

Breaking capacity

Rated switching capacity

AC operation

at 40 Hz to 60 Hz

Operating

Normal

voltage

current

DC operation

up to 230

10

Rated insulation

voltage

250 V AC/DC

Normal current

Resistive Inductive,

T=20 ms

A

A

Insulation group

C acc. to

VDE 0110

24

10

10

Making capacity

48

10

9

7

Operating

voltage

60

Abbreviations:

110

NO = normally open contact

NC = normally closed contact

220

2.5

Continuous current 10 A

50 A

Siemens HA 40.1 2005

13

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

HV HRC fuse assembly

Design

Mode of operation

For switch-disconnector

In the event that an HV

HRC fuse link has tripped, the switch is tripped via an articulation

which is integrated into

the cover of the fuse

box (see figure).

Requirements fulfilled as

HV alternating current

switch-fuse combination

Selection of HV HRC

fuses for transformers

Climate-independent and

maintenance-free, with

fuse box made of cast

resin

Fuse assembly con-

nected to the three-position switch-disconnector

via welded bushings and

connecting bars

Arrangement of the fuse

assembly

Above the switchgear

vessel for 8DJ10, 8DJ20

and 8DH10 switchgear

Beside the switchgear

vessel for 8DJ30

switchgear

Fuse can only be replaced

if feeder is earthed

Option:

with shunt release

Option:

Tripped indication of

the transformer switch

for remote electrical indication with 1 NO contact

In the event that the

fuse tripping fails, e.g.

if the fuse has been inserted incorrectly, the

fuse box is protected

by thermal protection.

The overpressure generated by overheating

trips the switch via the

silicon diaphragm in the

cover of the fuse box

and via an articulation.

This breaks the current

before the fuse box incurs

irreparable damage.

R-HA40-074b eps

according to DIN 43 625

(main dimensions) with

striker pin in medium

version acc. to

IEC 60 282-1/

VDE 0670-4 *

As a short-circuit protection before transformers

With selectivity (depending on correct selection)

to upstream and downstream connected equipment

Single-pole insulation

Inserting an HV HRC fuse link

The above thermal protection works independently

of the type and design of

the HV HRC fuse used.

Like the fuse itself it is

maintenance-free and independent of any outside climatic effects.

Furthermore, the Siemens

HV HRC fuses release the

striker pin depending on

the temperature and trip

the switch-disconnector as

early as in the fuse overload range. Impermissible

heating of the fuse box can

be avoided in this way.

Access to and

replacement of

HV HRC fuse links

Isolating and

Control board of a

transformer feeder

OPEN indication

Indication HV HRC fuse tripped or

shunt release tripped

Subsequently, earthing can be

implemented by means of the threeposition switch-disconnector and e.g.

the fuse can be replaced.

Fuse assembly

1 Fuse box

2 HV HRC fuse link

3 Striker pin of HV HRC fuse link and

articulation for tripping of the

spring-operated / stored-energy

mechanism

earthing the transformer feeder

6

Subsequent manual

replacement of the

HV HRC fuse link

CLOSED indication,

manual operation or motor operation

Following this tripping, the

mechanism for charging the spring

must be switched to the OPEN

position

R-HA40-075b eps

HV HRC fuse links

HA40-2045b eps

panels

4 Bushing

5 Switchgear vessel

6 Sealing cover with seal

7 Tripping pin for spring-operated /

stored-energy mechanism

HA40-2046b eps

Schematic sketches

for fuse tripping

Fuse link in

service condition

Fuse tripped

by striker pin

* For standards refer to page 29

14

Siemens HA 40.1 2005

Fuse tripped by overpressure, e.g. if

HV HRC fuse link has

been inserted incorrectly

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Allocation of HV HRC fuses and transformers, transformer ratings

Allocation of HV HRC

fuses and transformers

The table opposite shows

recommended 3GD HV HRC

fuse links (electrical data valid

for ambient temperatures of

up to 40 C) for the fuse

protection of transformers.

Rated

system

voltage

Transformer

kV

kVA

6 up to 7.2

Recommendation

The three-position switchdisconnector in the transformer feeder (transformer

switch) was combined with

Siemens HV HRC fuse links

of type 3GD and tested *.

10 up to 12

Furthermore, Siemens 8DJ

and 8DH switchgear also

permit the fuse protection of

transformers up to ratings of

2000 kVA. Please contact us

for such applications.

Standards

HV HRC fuse links

medium version with striker

pin and for a tripping energy of

1 + 0.5 Joule according to

IEC 60 282-1/ VDE 0670-4 *

13.8

IEC 60 787/ VDE 0670-402

DIN 43 625

main dimensions

15 up to 17.5

24

* For standards refer to page 29

Rating SN

Relative

impedance

voltage uk

%

Rated

current I1

Rated normal current of the HV HRC fuse

Lowest

Highest

value

value

50

75

100

4

4

4

4.8

7.2

9.6

16

16

20

16

16

25

125

160

200

4

4

4

12.0

15.4

19.2

25

32

40

25

32

40

250

315

400

4

4

4

24.0

30.3

38.4

50

50

63

50

63

100

500

630

4

4

48.0

61.0

63

80

100

100

50

75

100

4

4

4

2.9

4.3

5.8

10

10

16

10

10

16

125

160

200

4

4

4

7.2

9.3

11.5

16

20

25

16

20

25

250

315

400

4

4

4

14.5

18.3

23.1

25

32

40

32

40

50

500

630

800

4

4

5 to 6

29.0

36.4

46.2

50

63

63

63

80

80

1000

5 to 6

58.0

80

100

50

75

100

4

4

4

2.1

3.2

4.2

6

10

10

6

10

10

125

160

200

4

4

4

5.3

6.7

8.4

16

16

16

16

16

20

250

315

400

4

4

4

10.5

13.2

16.8

20

25

32

25

32

32

500

630

800

4

4

5 to 6

21.0

26.4

33.5

40

50

50

50

50

50

1000

5 to 6

41.9

63

63

50

75

100

4

4

4

1.9

2.9

3.9

6

10

10

6

10

10

125

160

200

4

4

4

4.8

6.2

7.7

10

16

16

10

16

20

250

315

400

4

4

4

9.7

12.2

15.5

20

25

32

25

25

32

500

630

800

4

4

5 to 6

19.3

24.3

30.9

32

40

50

40

50

50

1000

1250

5 to 6

5 to 6

38.5

48.2

63

63

63

80

50

75

100

4

4

4

1.5

2.2

2.9

6

6

10

6

6

10

125

160

200

4

4

4

3.6

4.7

5.8

10

10

16

10

10

16

250

315

400

4

4

4

7.3

9.2

11.6

16

20

20

16

20

25

500

630

800

4

4

5 to 6

14.5

18.2

23.1

25

32

32

32

40

32

1000

1250

1600

2000

5 to 6

5 to 6

5 to 6

5 to 6

29.0

36.0

46.5

57.8

40

50

63

On request

40

50

80

On request

Siemens HA 40.1 2005

15

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Indicating and measuring equipment

R-HA40-096 eps

All ring-main feeders can be

optionally equipped with a 3-phase

short-circuit or earth-fault indicator.

Characteristics

Use depends on network conditions

Red indication:

short-circuit indicator

has picked up

R-HA40-094a eps

Short-circuit/earth-fault indicators

(examples)

R-HA40-095 eps

Short-circuit/earth-fault

indicators (option)

Optical signal when a preselected

pickup value is exceeded

Short-circuit indicator ALPHA M

With ring-type sensors

Short-circuit indicator ALPHA E

R-HA40-097 eps

R-HA40-098 eps

Depending on the type, reset

Manually

Automatically after a preset time

(e.g. 2 hours)

Display panel, withdrawable housing,

depending on the type

Response values settable

Earth-fault indicator EKA-3/1

Short-circuit /earth-fault indicator EKA-3

(depending on the type of device)

Remote electrical indication via

contact (1 NO + 1 NC) depending

on the type of device settable as

passing contact (W) or maintained

contact (D).

R-HA40-100 eps

R-HA40-099 eps

Options:

Short-circuit indicator IKI-10 V2 SP

Short-circuit indicator Opto F

Selection of short-circuit and earth-fault indicators

Indicator type 1)

Response values

Response values

Opt.: remote indicat. as

Remote reset:

A: by aux. voltage

B: via NO contact

(floating)

Automatical reset

after return of

power supply

Short-circuit current

IK (A)

Standard, other

values on request

Earth-fault current

IE (A)

Standard, other

values on request

W (passing contact

= standard)

D (maintained contact

= option)

Reset

Ma- Automatical

nual after

Short-circuit indicator

ALPHA M 5)

400, 600, 800, 1000

W, D

ALPHA E 5)

2 h or 4 h

A (12-60 V AC/DC)

400, 600, 800, 1000

W, D

GAMMA 5.0 2) 5)

4 s after return

of power supply

2 h or 4 h

400, 600, 800, 1000

W, D

ALPHA

automatic 5)

3h

A (12-60 V AC/DC)

self-adjusting,

change of current with

150 A w D i w 300 A,

response time: t w 20 ms

W, D

KA-Opto F 3) 5)

with 3 LED

indications

after 2 h or 4 h

B (1S)

400, 600, 800, 1000

W, D

IKI-10 V2 SP 6)

after 2 h or 4 h

B (1S)

400, 600, 800, 1000

W, D

IKI-10 V2 L 6)

after 2 h or 4 h

B (1S)

x (110-230 V AC, 50/60 Hz) 400, 600, 800, 1000

W, D

x (230 V AC, 50 Hz)

Earth-fault/short-circuit indicator

EKA-3 4) 5)

x (230 V AC, 50 Hz)

450

40, 80, 160

W, D

DELTA M 5)

400, 600, 800, 1000

200

W, D

DELTA E 5)

after 2 h or 4 h

A (12-60 V AC/DC)

400, 600, 800, 1000

200

W, D

KA-Opto F+E 5)

after 2 h or 4 h

B (1S)

400, 600, 800, 1000

40, 60, 80

W, D

IKI-10 V2 SP/ES 6) 7) x

after 2 h or 4 h

B (1S)

400, 600, 800, 1000

10% or 25% of IK

W, D

IKI-10 V2 L/ES 6) 7)

after 2 h or 4 h

B (1S)

x (110-230 V AC, 50/60 Hz) 400, 600, 800, 1000

10% or 25% of IK

W, D

EKA-3/1 4) 5)

x (230 V AC, 50 Hz)

IKI-10 V2 L/ES 6) 7)

after 2 h or 4 h

B (1S)

x (110-230 V AC, 50/60 Hz)

Earth-fault indicator

1) Further types and other makes

available on request

2) External auxiliary voltage required

(120 V AC or 240 V AC)

16

Siemens HA 40.1 2005

3) Power supply required for the LED indications

(indication by means of an integrated battery

or 12 V AC to 60 V AC voltage)

4) External auxiliary voltage required

(230 V AC, 50 Hz), device with integrated battery

40, 80, 160

W, D

30, 55, 80, 100

W, D

5) Make: Horstmann

6) Make: Kries Energietechnik

7) Ring-type sensor: d = 110 mm

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Indicating and measuring equipment

Ready-for-service indicator

Ready-for-service indicator

Phase comparison test units

Independent of temperature

and pressure variations

R-HA40-059 eps

Self-monitoring; easy to read

R-HA40-093 eps

Characteristics

Independent of site altitude

Only responds to changes in

gas density

Option: Alarm switch

1 NO contact for remote

electrical indication

Mode of operation

For the ready-for-service indicator, a gas-tight measurement

box is installed on the inside of

the switchgear vessel.

Make: Pfisterer, type EPV

For plug-in voltage detection systems

For integrated voltage detection systems

(CAPDIS-S1+, -S2+)

A coupling magnet, which is

fitted to the bottom end of the

measurement box, transmits

its position to an outside armature through the stainless steel

switchgear vessel. This armature moves the ready-for-service indicator of the switchgear.

R-HA40-089 eps

1 Indicator green:

ready for service

(indicator red:

not ready for service)

2 Alarm switch

(option)

for remote

electrical

indication

R-HA40-077 eps

While changes in the gas

density during the loss of gas,

which are decisive for the

insulating capacity, are displayed, temperature-dependent changes in the gas

pressure are not. The gas in

the measurement box has the

same temperature as that in

the switchgear.

Ready-for-service indicator installed at the

switchgear vessel

Make: Horstmann, type ORION 3.0

combined test unit for

Phase comparison

Interface testing at switchgear

Voltage detection for

HR and LRM systems and

CAPDIS-S1+, -S2+

Indicator on

control board:

ready for service

Possible by means of a

phase comparison test unit

(can be ordered separately)

Safe-to-touch handling of the

phase comparison test unit by

inserting it into the capacitive

taps (socket pairs) of the

switchgear or the feeders.

Gas monitoring

HA40-2024b eps

Verification of correct

terminal-phase connections

R-HA35-124 eps

The temperature effect is

compensated via the same

pressure change in both gas

volumes.

3

4

Stainless-steel vessel

filled with SF6 gas,

gauge pressure

500 hPa at 20 C

Principle of operation

of gas monitoring

with ready-for-service indicator

Ready-forservice

indicator

3 Measurement box

4 Magnetic coupling

5 Red indication:

not ready for service

6 Green indication:

ready for service

Make: Kries, type CAP-Phase

as combined test unit (HR and LRM)

for:

Voltage detection

Repeat test

Phase comparison

Phase sequence test

Self-test

The unit doesnt require any battery

or other makes

Siemens HA 40.1 2005

17

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Indicating and measuring equipment (verification of safe isolation from supply)

Standard: HR system

Option: LRM system

Option: Integrated voltage detection systems as

LRM system:

CAPDIS-S1+

CAPDIS-S2+

(auxiliary power

required for signals)

Installation of voltage

detection systems

Standard:

In all ring-main and

circuit-breaker feeders

Option:

In transformer feeders

Features of plug-in

voltage detection

systems

auxiliary power

With integrated function

continuous operation

Safe-to-touch

Routine-tested

Measuring system and

voltage indicator can be

tested

Without auxiliary

voltage

Fig. 1: Voltage indicator,

HR system, plugged-in

(standard)

Fig. 2: Voltage detection

system, CAPDIS-S1+,

installed (option)

Fig. 3: Voltage detection

system, HR system

18

Siemens HA 40.1 2005

A1

A2

Degree of protection IP 54,

temperature range

25 C to + 55 C

A3

Fig. 1

With circuit capacity

Features of CAPDIS-S1+

Without auxiliary power

With indication A1 to

A5 (see legend)

A6

ERROR

A0 CAPDIS-S2+: Operating voltage

not present

A1 Operating voltage present

A2 Operating voltage not present

For CAPDIS-S2+:

Auxiliary power not present

A3 Earth fault or failure in phase L1,

operating voltage at L2 and L3

A4 Voltage (not operating voltage)

present

A5 Indication Device-Function-Test

passed

A6 Indication ERROR, e.g. in case

of missing auxiliary voltage

(see: error indication M4)

monitoring

Without signalling relay

(thus without auxiliary

contacts)

With indication A0 to

A6 (see legend)

Device-Function-Test

pushbutton: ERROR

indication (A6), e.g. in case

of missing auxiliary voltage

Device-Function-Test pushbutton

With ready-for-service

monitoring (external auxiliary

power required)

With integrated signalling

Separate circuit capacity

A4

A5

Fig. 2

Without ready-for-service

relay for signalling M1

to M4 (auxiliary power

required):

M1: Operating voltage

present at phases

L1, L2, L3

M2: Voltage not present

at L1, L2 and L3

(= active zero indication)

M3: Earth fault or voltage

failure, e.g. in one phase

M4: External auxiliary

power missing (operating

voltage present or not)

L1 L2 L3

A0

test socket for phase comparison (also suitable for

plug-in voltage indicator)

Only by pressing the

Indicator suitable for

L1 L2 L3

With integrated 3-phase

Verification of safe

flashes if high voltage is

present

Symbols shown on

CAPDIS-S1+

CAPDIS-S2+

test (without auxiliary

power) by pressing the

Device-Function-Test

pushbutton

Features of CAPDIS-S2+

Voltage indicator

Fig. 3

interfaces (self-monitoring)

With voltage indicator:

HR system (standard)

LRM system (option)

isolation from supply

phase by phase

through insertion in

each socket pair

R-HA40-101.eps

Integrated repeat test of the

HA40-2052a eps

Plug-in voltage detection

systems

Integrated display, without

L1

L2

L3

C1

U LE

C2

U2

HA40-2038b eps

tive coupling electrode

in bushings

Maintenance-free

R-HA40-088 eps

Fixed-mounted capaci-

Common features

R-HA40-102 eps

from supply according

to IEC 61 243-5 /

VDE 0682-415

Voltage detection systems

(example HR system and CAPDIS-S1+)

R-HA40-078b eps

To verify safe isolation

Features of integrated

voltage detection systems

R-HA40-079b eps

Voltage detection

systems

volt. indicator mounted

(HR) plugged-in CAPDIS-S1+ or -S2+

Voltage detection via capacitive voltage divider (principle)

C1 Capacitive coupling electrode integrated into bushing

C2 Capacity of the coupling section (as well as connection leads

of the voltage detection system) to earth

ULE= UN / 3 during rated operation in the three-phase system

U2 = Voltage at the interface (for plug-in voltage detection system)

or at the test socket (for integrated voltage detection system)

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Interlocks, locking devices

Interlocks

Interlocks

Locking devices

(option)

tion compartment (e.g. for

cable testing) is only possible

provided that

The feeder is isolated and

The feeder is earthed

(three-position

switch-disconnector in

EARTHED position)

R-HA40-083b eps

Access to the cable connec-

R-HA40-081b eps

Interlocks in ring-main and

circuit-breaker feeder

Option: Closing lock-out

It prevents the three-position

switch-disconnector from

being switched from the

OPEN to the CLOSED

position, when the cable compartment cover is removed

Locking device of the

detachable lever mechanism

e.g. for padlock

(max. diameter of the bracket: 8 mm)

Interlocks in transformer feeder

Access to the cable connec-

tion compartment (e.g. for

cable testing) and to the

HV HRC fuse compartment

(e.g. for the replacement of

HV HRC fuse links) is only

possible provided that

The feeder is isolated and

The feeder is earthed

(three-position

switch-disconnector in

EARTHED position)

compartment is open, the

three-position switchdisconnector (transformer

switch) cannot be operated

(from the EARTHED to

the OPEN position

and from the OPEN

to the CLOSED position)

Locking device of the

rotary operating mechanism

e.g. for padlock

(max. diameter of the bracket: 8 mm)

Option: De-earthing lock-out

for 8DJ20 and 8DH10 switchgear (prevents de-earthing

of the three-position switchdisconnector from the

EARTHED to the OPEN

position, when the cable

compartment cover is removed)

Option:

Locking devices

For padlock

With detachable lever

mechanisms

With rotary operating

mechanisms

R-HA40-084b eps

Removed cable compartment cover

with earthed ring-main feeder

R-HA40-082b eps

When the HV HRC fuse

Interlocks for the

cable compartment cover

Interlocks for the

HV HRC fuse compartment cover

Removed cover of the HV HRC fuse

compartment with earthed transformer

feeder

The three-position switch-

disconnector can be locked

at the operating mechanism

in any switch position

Siemens HA 40.1 2005

19

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Cable connections

Standard connection

HA40-2049c eps

HA40-2048b eps

Double cable connection (examples)

Example for 1400 mm

overall height of switchgear

553

2

3

553

290*

315*

395*

585*

575

575

290*

~560

63

2

3

~560

610***

63

~560

101

635***

750

750

772

775

775

1 Cable compartment cover

900***

1047

852

1075

880

25 mm deeper cable

compartment cover

~245**

~560

715***

800

Standard cable

compartment cover

~190**

~560

101

635***

Standard cable compartment cover

105 mm deeper cable

compartment cover

300 mm deeper cable

compartment cover

Switchgear

Overall height

of switchgear

3 Coupling plug

Type

mm

Standard

+25 mm

+50 mm

+105 mm +150 mm +300 mm

4 Cable plug

8DJ10

1360 1)

o. r.

2)

o. r.

1650

o. r.

2)

o. r.

8DJ20

1200 1)

2)

o. r.

8DJ20 / 8DH10

1400

2)

o. r.

8DJ20

1760

possible

2)

o. r. = on request

o. r.

2 Cable T-plug

5 Surge arrester

Deep cable compartment cover

for 8DH switchgear with pressure absorber system (overall

height of switchgear 1700 mm):

Connection with cable plug and surge arrester (examples)

Required cable

compartment cover,

deeper by mm

+25 +105 +150 +300

K+K

K+

K+K+

possible

HA40-2050c eps

Possible connection combinations

Arrangement of

connection

combinations

Example for 1400 mm

overall height of switchgear

Dimension a

610 mm up to type RDA21

635 mm for type RDA24

553

not possible

290*

interface type C with

bolted contact (M16)

and/or surge arrester

of cable plug

~560

63

2) No double cable connection or

surge arresters for cable compartment covers deeper by +50 mm

are available on the market at

present

3) Not possible, because the surge

arrester would reach below the

closed cable compartment cover

Siemens HA 40.1 2005

435*

~560

1

~560

1

~560

a***

610***

610***

610***

750

772

797

897

775

1) In the case of 1200 or 1360 mm

overall height of the switchgear the

cable T-plugs of the double cable or

the surge arresters protrude into

the cable basement

341*

* Max. mounting space for cable

** Dependent on the type

315*

5

575

B Dimension for bushing as

20

Required cable compartment cover deeper by

800

Standard cable

compartment cover

825

25 mm deeper cable

compartment cover

925

50 mm deeper cable

compartment cover

150 mm deeper cable

compartment cover

Switchgear

Overall height

of switchgear

Type

mm

Standard

+25 mm

+50 mm

+105 mm +150 mm +300 mm

8DJ10

1360 1)

3)

3)

2)

3)

1650

2)

1200

3)

3)

2)

3)

8DJ20

Required cable compartment cover deeper by

8DJ20 / 8DH10

1400

2)

8DJ20

1760

possible

2)

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Cable connections

Double cable connection (depending on the overall height of the switchgear; refer to page 20)

Double cable plugs

Connection combination

Make

Design

Se- Cable plugs

rial

No.

Arrangement

Mount- Standard

deeper by (. . . mm)

ing

(depth 36 mm) + 25 1) + 50 1) + 105 2) + 150 2) + 300 2)

depth

Available depth (. . . mm)

290

315

341

395

435

585

mm

Type

Euromold

Sdkabel

(ABB)

nkt cables

Tyco

Electronics

Raychem

Required cable compartment cover

(K) 400 TB/TBS + (K) 400 TB/TBS

screened

with screw-type coupling insert (K) 400 CP

K+K

505

(K) 400 TB/G + (K) 400 LB/G

(with (K) 400 CP-LB)

screened

K+K

447

430 TB + 300 PB - 630 A

(without coupling insert)

screened

K+K

290

(K) 400 TB/G + 430 TB (with (K) 400 CP)

screened

K+K

403

AGT 20/630 + AGT 20/630

each with metal housing

screened

K+K

370

AGTL 20/630 + AGTL 20/630

each without metal housing

screened

K+K

370

SEHDT (13/23) + SEHDT (13/23) + KU 23

screened

K+K

540

SEHDT (13/23) + SET (12/24) + KU 23

screened

K+K

450

SET (12/24) + SET (12/24)

with coupling piece KU 23.2

screened

K+K

378

10

CB 24-630 + CB 24-630

with coupling piece CP 630C

screened

K+K

370

o. r.

11

CB 24-630 + CC 24-630

screened

K+K

290

12

AB 24-630 + AB 24-630

with coupling piece CP 630A

insulated

K+K

370

o. r.

13

AB 24-630 + AC 24-630

insulated

K+K

290

o. r.

14

RSTI 56xx + RSTI 56CP

screened

K+K

365

o. r.

15

RSTI-L56xx + RSTI-CC-L56xx

screened

K+K

290

Connection with cable plug and surge arrester (depending on the overall height of the switchgear; refer to page 20)

Cable plugs with surge arrester

Connection combination

Make

Design

Arrangement

Mount- Standard

deeper by (. . . mm)

ing

(depth 36 mm) + 25 1) + 50 1) + 105 3) + 150 1) + 300 1)

depth

Available depth (. . . mm)

290

315

341

395

435

585

mm

Se- Cable plugs + surge arrester

rial or

No. surge arrester + cable plugs

Type

Euromold

Sdkabel

(ABB)

nkt cables

Tyco

Electronics

Raychem

1)

2)

3)

4)

Required cable compartment cover

(K) 400 TB/G + 400 PB - . . SA

screened

K+

410

430 TB + 300 SA-5, -10

screened

K+

290

400 PB- . . SA + (K) 400 LB/G

screened

+K

355

400 PB- . . SA + AGT 20/630 (screened 4))

screened

+K

330

400 PB- . . SA + AGTL 20/630 (screened)

screened

+K

330

SET (12/24) + SET (12/24) + MUT (13/23)

with coupling piece KU 23.2

screened

K + K + 491

SET (12/24) + MUT (13/23)

screened

K+

301

SEHDT (13/23) + MUW (12/22)

each with metal housing

screened

K+

435

SEHDT (13/23) + MUT 33

each with metal housing

screened

K+

516

10

CB 24-630 + CSA 24-5

screened

K+

290

11

AB 24-630 + ASA 24-5

insulated

K+

285

12

RICS 5139 + RDA . . .

insulated

K+

275

13

RSTI-L56xx + RSTI-L56 SA - xx - 05 +

screened

coupling piece (= RSTI 56 - CC - L56 SAxx 05)

K+

290

Cable compartment cover closed towards the bottom

Cable routing in extended base frame for arrangement of K + K

Cable routing in extended base frame for arrangement of + K

With metal housing

possible

not possible

o. r. = on request

Abbreviations

K = Cable plug

= Surge arrester

Siemens HA 40.1 2005

21

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Cable connections with bolted contact

for ring-main and circuit-breaker feeders in 8DJ and 8DH switchgear

Cable sealing ends

Cable plugs (examples) Euromold

Examples

Characteristics

L1

L2

202

255

L3

For bushings acc. to EN 50 181 /

cables with adapter systems

For straight cable plugs in 8DJ30

switchgear

HA40-2029d eps

For paper-insulated mass-impregnated

HA40-2026d eps

For thermoplastic-insulated cables

~400

246

~310

DIN EN 50 181 1) 2) with outside cone and

with bolted contact M16 as interface

type C in 8DJ10, 8DJ20 and 8DH10

switchgear

Cable T-plug (1)

with M16 bolted contact

Cable elbow plug (2)

with M16 bolted contact

Access to the cable connection compartR-HA40-046a eps

ment only if feeder has been isolated

and earthed

As screened (conductive) version

independent of the installation height

each as single cable connection

Cable elbow plug

with M16 bolted contact

(example: 8DJ20 switchgear)

Connection options

To bushings acc. to EN 50 181 /

Euromold

1 Phase L1:

Make Euromold, type K400 LB

2 Phase L2:

Make Raychem, type RICS 5133

with type SMOE 61 748

3 Phase L3:

Make Sdkabel (ABB),

type SEHDT 23.1

with metal housing

Threaded

coupling

unit

HA40-2030d eps

Connection of

Cable elbow plugs or cable T-plugs with

bolted contact M16 for 630 A to 8DJ10,

8DJ20 and 8DH10 switchgear

Paper-insulated mass-impregnated cables

via conventional adapters

Straight cable plugs to 8DJ30 switchgear

Power cables as thermoplastic single-core

cables with the above-mentioned plugs

and adapters

~310

~400

DIN EN 50 181 1) as interface type C:

Option: Mounted cable clamps

L1

L2

L3

Options

Mounted cable clamps on cable bracket

447

Cable T-plug (1) with cable elbow plug (2)

as double cable connection

for deep cable compartment cover

290

(for example: C-rails or similar)

nkt cables

Overvoltage protection relays of same

5

Surge arresters are recommended if, at

the same time,

The cable system is directly connected

to the overhead line

The protective range of the arrester at the

terminal tower of the overhead line does

not cover the switchgear

Surge limiters

Can be plugged into the cable T-plug

Cable plug (5) type CB 24-630 with

coupling plug (6) type CC 24-630

Cable T-plug

with M16 bolted contact

(example: 8DH10 switchgear)

as double cable connection

for standard cable compartment cover

290

4 Make Pirelli, type FMCTs-400

nkt cables

Option: Mounted cable clamps

Cable plugs, cable sealing ends

and cable clamps are not included in the scope of supply.

Surge limiters are recommended if

7

350

when fitting surge arresters

(depending on make)

Arrangement of

surge arrester

exchangeable

depending on

make and type

HA40-2028f eps

Larger switchgear depth possible

R-HA40-048a eps

Can be plugged into the cable T-plug,

cable elbow plug or elbow adapter

AKE 20/630 (make: Siemens, refer to

page 24)

HA40-2027d eps

Surge arresters

245

make, in connection with the respective

cable T-plugs

motors are connected

1) Standard: Plug-in type bushings above 1 kV up to 36 kV and from 250 A to 1.25 kA for

equipment other than liquid filled transformers.

2) Previously: DIN 47 636-6 for bushings AS 36-400 or AS 36-630.

22

Siemens HA 40.1 2005

Cable T-plug (5) with surge arrester (7)

for standard cable compartment cover

Switchgear Types 8DJ and 8DH for Secondary Distribution Systems up to 24 kV (General Part), Gas-Insulated

Components

Selection data (further types of cable sealing ends on request)

Cable type

Cable sealing end

Make

Thermoplastic-insulated cable

1 or 3-core cable,

PE and XLPE-insulated

Comment

Se- Type

rial

No.

Design Conductor Insucross-sect. lation

T/ W 1)

mm2

12 kV to IEC 60 502-2 / VDE 0276-620

Euromold

1

2

3

4

N2YSY (Cu) and

N2XSY (Cu)

or

NA2YSY (AI) and

NA2XSY (AI)

nkt cables

Sdkabel (ABB)

Pfisterer

Cooper Power Systems 2)

Prysmian Kabel

und Systeme

(Pirelli Elektrik)

3M Germany

Tyco Electronics

Raychem

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

400 TB/G, 430 TBG

400 LBG

440 TB/G

AGT 10/630

T

W

T

T

35300

35300

185630

95240

EPDM

EPDM

EPDM

Silicone

UC 412 L

ASI 10

CB 24-630 (ASTS 10/630)

AB 24-630 (AWKS 10/630)

On request: CB 36-630

SET 12

SEHDT 13

CAT 20/680

DT 400 P

FMCTs-400

FMCTsm-400

FMCTj-400

92-EE9...-4/...

92-EM9...-4/...

RICS 51... with IXSU

RSTI 56..

W

W

T

T

T

T

T

T

T

T

T

T

T

T

T

T

35300

150240

25300

25300

400630

50300

50300

95240

50400

25300

25300

25300

95300

95300

25300

25300

EPDM

Silicone

Silicone

Silicone

Silicone

Silicone

Silicone

Silicone

EPDM

EPDM

EPDM

EPDM

EPDM

EPDM

Silicone

Silicone

conductive

conductive

conductive

conductive, with metal housing,

general purpose version

not safe-to-touch

not safe-to-touch

conductive, option: with metal housing

insulated

for 12, 24, 36 kV

conductive, option: with metal housing

conductive, option: with metal housing

conductive

conductive

conductive, without metal housing

conductive, with metal housing

conductive, suitable for cable sheath testing

conductive, without metal housing

conductive, with metal housing

T-adapter with sealing end (Elastomer)

conductive, with capacitive measuring point

Thermoplastic-insulated cable 15/17.5/24 kV to IEC 60 502-2 / VDE 0276-620

1 or 3-core cable,

PE and XLPE-insulated

N2YSY (Cu) and

N2XSY (Cu)

or

NA2YSY (AI) and

NA2XSY (AI)

Euromold

21

22

23

24

K400 TB/G, 430 TBG

K400 LBG

K440 TB/G

AGT 20/630

T

W

T

T

35300

35300

185630

25240

EPDM

EPDM

EPDM

Silicone

25

26

27

Sdkabel (ABB)

28

29

Pfisterer

30

Cooper Power Systems 2) 31

Prysmian Kabel

32

und Systeme

33

(Pirelli Elektrik)

34

3M Germany

35

36

for 1-core cable 37

Tyco

Electronics

38

Raychem

for 3-core cable 39

40

AGTL 20/630

CB 24-630

AB 24-630

SET 24

SEHDT 23

CAT 20/630

DT 400 P

FMCTs-400

FMCTsm-400

FMCTj-400

93-EE9...-4/...

93-EM9...-4/...

RICS 51.. with IXSU

RSTI 56..

RICS 51.. with IXSU

RSTI 56.. with EAKT

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

25240

25300

25300

25240

35300

95240

35400

25240

25240

25300

50300

50300

25300

25300

25300

25300

Silicone

Silicone

Silicone

Silicone

Silicone

Silicone

EPDM

EPDM

EPDM

EPDM

EPDM

EPDM

Silicone

Silicone

Silicone

Silicone

nkt cables

Paper-insulated mass-impregnated cable

3-core cable as a belted

cable, paper-insulated

N(A)KBA: 6/10 kV

1 or 3-core cable as a

sheathed cable, paper-ins.

N(A)EKEBA: 6/10 kV

conductive

conductive

conductive

conductive, with metal housing,

general purpose version

conductive

conductive, option: with metal housing

insulated

conductive, option: with metal housing

conductive, option: with metal housing

conductive

conductive

conductive, without metal housing

conductive, with metal housing

conductive, suitable for cable sheath testing

conductive, without metal housing

conductive, with metal housing

T-adapter with sealing end

conductive, with capacitive measuring point

T-adapter with sealing end

conductive, with capacitive measuring point

12 kV to IEC 60 055-2 / VDE 0276-621

Sdkabel (ABB)

Tyco Electronics Raychem

41 KSNW 12

42 RICS 51.. with UHGK

W

T

35150 Silicone

95300 Silicone

T-adapter with sealing end

Tyco Electronics Raychem

nkt cables

43 RICS 51.. with IDST 51.. T

44 AWM 10/400 with SKV 10 W

50300 Silicone

25240 Silicone

50240

T-adapter with sealing end

Cu cross-section

Al cross-section

25185

35240

25150

70185

T-adapter with sealing end

Paper-insulated mass-impregnated cable 15/17.5/24 kV to IEC 60 055-2 / VDE 0276-621

1 or 3-core cable,

paper-insulated

N(A)KLEY, N(A)KY

or N(A)EKBA: 12/20 kV

Sdkabel (ABB)

Tyco Electronics Raychem

nkt cables

45

46

47

48

MEHW 22

RICS 51.. with IDST 51..

AWM 20/400 with GKV 20

AWM 20/400 with SKV 15

1) T = Cable T-plug, W = Cable elbow plug

W

T

W

W

Thermopl.

Silicone

Silicone

Silicone

2) IEC 60 071, VDE 0278, BS 7215, ANSI / IEEE 386, CENELEC HD 629.1 S1

Siemens HA 40.1 2005

23