Professional Documents

Culture Documents

Radiant Heater Burner With Dual Fuel-Syn Gas Cog and Dri Top Gas

Uploaded by

INDRAJIT SAOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radiant Heater Burner With Dual Fuel-Syn Gas Cog and Dri Top Gas

Uploaded by

INDRAJIT SAOCopyright:

Available Formats

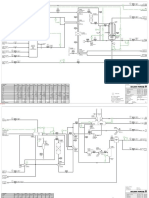

One (1) Reducing Heater

System for Jindal DR

Plant at Angul, Orissa,

India

Project No:

7618 3258 / 7610A04J

Code:

Angul-Jindal / Angul 1

Doc No:

Client

Project No:

H3003HEA01

Client Code:

&AD B-DE 4100

Client Doc. No.:

Page 1 of 7

Burner Datasheet

for

Reducing Gas Heater

Status

06

06/08/2015

MJ

VL

VL

Revised as per JSPL comments

05

04

16/07/2015

22/07/2011

MJ

RA

KG

VL

KG

VL

Supplier`s Information added

03

18/11/2010

MJ

FMS

FMS

Revised as marked

Revised for new syngas tips

02

27/08/2010

MJ

FMS

FMS

Revised as marked

01

Issue

23/07/2010

Date

MJ

Prepared by

FMS

Checked by

FMS

Approved by

For inquiry

Remark

Refer to protection notice ISO 16016

Komm.- Nr. / Job-No.

Burner - Datasheet

SELAS-LINDE

GMBH

7618 3258

Iss-Nr./No.

6

1

2

Client:

SL - Inquiry N.:

vom/of

&AD B-DE 4100

Seite/Page

06.08.15

Jindal

Seiten/Pages

von/of

Client Reference N.:

Project:

Angul

GENERAL SITE DETAILS

Site Location

Equipment Location

Outside, steel mill

Altitude

170 m

Barometric Pressure

995.5 mbar

Ambient Temperature

Min: 5 C

10

Relative Humidity

Max: 100 %

11

Rainfall

Annual average: 1542 mm

12

Maximum Wind Velocity

180 km/h

13

Seismic Condition

UBC zone 2A, India seismic zone III

14

Area Classification

HOLD

15

Weather Protection

16

Electrical Supplies

HOLD

17

Allowable Noise Level

85 dB(A) in 1 m distance for complete heater, fans and burners included

18

General site details are given for information only and pertain to the site as a whole. This information is superseded if stated elsewhere in

Angul, India

19

this or other associated documents specific to the equipment / instrument.

20

STANDARDS

21

Acceptable Standards

22

Applicable Standards

23

Flanges

ANSI B31.3

24

Piping

ANSI B31.3

25

Noise

OSHA, AMCA

26

Inspection

27

Manufacturer Certificates

28

Electrical Equipment

29

Electrical Certificates

30

REFERENCE DOCUMENTS

31

&AD B-SP 4100 Technical Specification

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

50

51

52

NOTES

(*)

to be filled by vendor

API 560

NEMA, NEC, ISA, IEC

Average: 27.3 C

Max: 48 C

Heaviest (24h): 257 mm

Komm.- Nr. / Job-No.

Burner - Datasheet

SELAS-LINDE

GMBH

7618 3258

Iss-Nr./No.

vom/of

6

1

&AD B-DE 4100

Seite/Page

06.08.15

Seiten/Pages

von/of

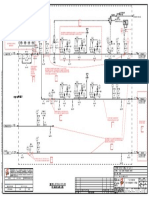

GENERAL DATA

7

Rev.

Manufacturer

Zeeco, Inc., Tulsa, OK, USA

Burner designation

Q10HEA01BRN A01-A10, B01-B10, C01-C10, D01-D10, E01-E10

Number of burners

30 x 100 % burners, 20 x 60 % burners

Scope of delivery

50 replacement tips for increased syngas capacity and new COG fuel + spares 5)

Type of burner

Low NOx

Standard

Location

Floor

Arch

Flame direction

horizontal

parallel to wall

Sidewall

vertical upwards

vertical downwards

Fuel

Gas

Oil

11

Air feed

Forced draft

Natural draft

12

Type of furnace

Cracking furnace

Refinery furnace

Incinerator

Reduction gas heater

Main flame

Pilot flame

10

13

14

Flame safeguard

15

16

Gas/Oil Combination

Reformer

5

GUARANTEE DATA

17

Type of burner

18

Fuel Oil / Gas

19

Heat duty (LHV-Basis)

20

21

Pressure at burner inlet

100 %

MW

60 %

F1/F2

F1/F2

F3

F4

F5

F6

5 (7)

3 (7)

F1/F4

F2

22

Fuel gas

bar,g

1.9

0.1

23

Fuel oil

bar,g

Atomising medium

24

bar,g

25

Combustion air pressure drop

mbar

26

Turndown

20

8:1 (6)

5:1

27

Excess air

10

28

Combustion Air Temperature

225

29

Emission (guaranteed) (1)

30

NOx

mg/Nm

320 (8)

31

CO (2)

mg/Nm

50

Dust

mg/Nm

32

33

Noise data (3)

34

Sound Pressure Level (4)

dB(A)

35

Sound Power Level

dB(A)

36

Flame dimensions

75

(9)

37

Max. flame diameter

<1

38

Max. flame length

< 7.9

39

40

NOTES

41

(*)

to be filled by vendor

42

(1)

Based on dry fluegas at 0C and 1013,25 mbar (abs), corrected to 3 Vol% O2, 1090 C bridgewall temperature,

43

225 C combustion air temp. and 10 % excess air. Emission guarantee for Fuel F1 / F2 from min. to 110 %

44

burner load.

45

(2)

46

(3)

47

48

CO levels at the tube walls must be below 250 mg/Nm (dry, no O2 correction) at all points.

No measuring tolerances are accepted.

The sound pressure level measurements are performed in accordance with DIN 45 635 (Part 1 and 8).

(4)

at 1 m distance from the outer contours of the equipment.

49

(5)

Spares: 3 tips for 100 % burner, 2 tips for 60 % burner

50

(6)

Maximum turndown for F1 is occurs when available amount of F2 is not sufficient for heat input and hence

51

a small amount of F1 is needed. Vendor to advise the maximum turndown for this operation. Given value is for

52

F1/F4-only operation with 2 vol-% oxygen in the flue gas.

53

(7)

Pilot burner heat release not included

54

(8)

Re-design of the F1/F4 tip shall consider that no staged air slots are available.

55

(9)

The burner shall have a straight upwards flame for all fuels and full range of operations

Komm.- Nr. / Job-No.

Process - Datasheet

Fuel data

SELAS-LINDE

GMBH

7618 3258

Iss-Nr./No.

vom/of

6

1

&AD B-DE 4100

Seite/Page

06.08.15

Seiten/Pages

von/of

FUEL OIL

Oil Number

Low Heating Value (LHV)

kJ/kg

Wobbe number (LHV-Basis)

kJ/kg

Stoechiometric air demand

kg/kg

Density

kg/m

Viscosity by

Pas

Viscosity by

Pas

10

Pressure at burner

bar,g

11

Temperature at burner

12

H/C ratio

13

Vanadium content

ppm

14

Bounded nitrogen

Wt %

15

Sulphur

Wt-%

16

Soot

Wt%

17

Water

Wt%

18

Asphaltene / Conradson

Wt %

19

FUEL GAS

20

Fuel gas number

21

Low Heating Value (LHV)

22

High Heating Value (HHV)

23

Stoechiometric air demand

kg/kg

(*)

(*)

24

kg/kmol

13.5

16.3

bar,g

3.5

0.2

26

Molecular weight

Pressure in network

(norm/max)

Max pressure at burner

bar,g

1.9 3)

27

Temp. at burner (norm/max)

50

28

Analysis

29

H2

52.01

30

N2 + Ar

Mol-%

0.45

2.64

2.76

31

CO

Mol-%

32.21

20.13

19.81

32

CO2

Mol-%

3.04

16.03

15.96

33

H2O

Mol-%

5.69

34

CH4

Mol-%

12.01

35

O2

Mol-%

36

C2H4

37

DELETED

COG

F1

F2 Max 1)

F2 Norm 1)

F2 Min 1)

DELETED

F4 3)

kJ/kg

23413

13454

13333

12051

37500 (5)

kJ/kg

(*)

(*)

(*)

16.3

16.3

10.5 (5)

0.2

0.1

2.5

0.1

0.1

0.05

*) 3)

42

42

42

30 - 45

50.57

50.28

47.84

56 - 60

3.28

4-6

18.45

5-8

15.67

1.5 - 3

6.28

10.68

1.0 2.5

4.94

4.91

3.90

23 - 27

0.3 0.8

Mol-%

1.0

C2H6

Mol-%

0.25

1.0

38

NH3

Mol-%

0.01

39

HCN

Mol-%

0.04

40

CH3OH

Mol-%

0.03

2)

41

C3H8

ppm(vol)

30

2)

42

H2S

ppm(vol)

100

10

10

10

0.04 4)

43

44

TOTAL

100

100

100

100

45

NOTES

25

Syngas fuel

7

Rev.

FUEL DATA

Mol-%

Top gas fuel

100

46

(*)

to be filled by vendor

47

1)

Composition and heating value change with operating cases as follows: Fuel "F2 Max" shows the composition of

Case I (p.5), "F2 Norm" shows composition of Case II and "F2 Min" shows composition for case VI.

48

49

2)

Benzene: < 0.85 Mol-%, Toluene: < 0.75 Mol-%

50

3)

The new syngas tips must be suitable for syngas F1 and coke oven gas F4, all given heat releases for F1 shall be

possible with F4 as well. Tips to be designed for the available maximum pressure with F1, pressures for F4 to be

51

52

provided by Zeeco with heat release curves

53

4)

Mol-%

54

5)

Depending on composition range as given below

Komm.- Nr. / Job-No.

Process - Datasheet

Burner

SELAS-LINDE

GMBH

7618 3258 &AD B-DE 4100

Iss-Nr./No.

vom/of

6

1

Seite/Page

06.08.15

Seiten/Pages

von/of

POWER DATA AND CONSUMPTION

HEATER OPERATING CASES

Operating case

Denomination

Fired duty

Fuel

Gas

Case I

Case II

Case III

Case IV

7

Rev.

Case VI

Max. operation

Norm. operation

Min. operation

Start-up

F2 only

194

171

54.5

94

91.6

MW

F1/F4 1)

wt%

- / 11.4

- / 9.4

- / 100

- / 100

-/-

F2

wt%

- / 88.6

- / 90.6

-/-

-/-

- / 100

F3

wt%

-/-

-/-

-/-

-/-

-/-

1090

1069

928

941

980

10

11

12

13

Bridgewall temperature

14

15

BURNER OPERATING CONDITIONS

16

Load case

17

Denomination

18

Fuel (Oil / Gas)

19

Heat duty (LHV basis) 3)

MW

20

Fuel gas pressure at burner

bar,g

21

Fuel gas temperature at burner

22

Fuel oil pressure at burner

23

Fuel oil temperature at burner

24

25

Comb. Air temperature at

burner

Excess air (Max/Norm/Min)

26

Pressure drop, Air side

27

Draft at burner

28

norm

29

max

MAX (110%)

NORM (87%)

MIN (27%)

MAX F1/F4

60 % / 100 % burn.

60 % / 100 % burn.

60 % / 100 % burn.

60 % / 100 % burn.

F2

2.27 /

3.78

0.1

F1/F4

0.35 /

0.59

(*)

F2

2.06 /

3.44

0.1

F1/F4

0.75 /

1.25

(*)

F2

F1/F4

0/0

1.34 / 2.24

1.9

42

50

42

50

42

42

bar,g

225

228

111

Amb. - 225

10

10

10

10

mbar

15

(*)

(*)

(*)

mbar,g

-2.3

-2.3

-2.3

-2

mbar,g

-2.8

-2.8

-2.8

-2.8

30

Atomising medium pressure

bar,g

31

Atomising medium temperature

32

Atomising medium

consumption

Flame dimensions (expected)

kg/kg

33

F1/F4

0.76 /

1.26

(*)

Flame diameter

(*)

(*)

35

Flame length

(*)

(*)

36

Emissions (expected)

34

37

NOx (Oil / Gas)

mg/Nm

(*)

(*)

(*)

38

CO (Oil / Gas)

mg/Nm

(*)

(*)

(*)

39

Dust (Oil / Gas)

mg/Nm

40

Noise data (expected)

41

Sound Pressure Level

dB(A)

42

Sound Power Level

dB(A)

43

< 75

(at 1 m distance from the outer contours of the equipment)

Octave band

44

Frequency

Hz

63

125

250

500

1k

2k

4k

8k

45

Sound

dB

75

79

72

76

66

62

64

62

46

47

NOTES

48

(*)

to be filled by vendor.

49

1)

Fraction of F1 can drop to 1.3 wt-% in split operation with F2. Vendor to advise maximum turndown for F1

50

during F2 in operation and vice versa. Pilot fraction of F1 only considered in Case V.

51

52

53

3)

Without pilot burner

Komm.- Nr. / Job-No.

Mechanical Datasheet

Burner

SELAS-LINDE

GMBH

7618 3258

Iss-Nr./No.

vom/of

6

1

2

&AD B-DE 4100

Seite/Page

06.08.15

Seiten/Pages

von/of

MECHANICAL REQUIREMENTS

7

Rev.

FURNACE CONSTRUCTION DATA

3

4

Burner Position (2)

mm

Burner CL to tubes CL

Burner CL to unshielded

refractory side wall // end wall

Clearance between burners

CL- CL

Burner Circle Diameter

mm

Burner CL to arch / roof tube CL

mm

13600 / 13200

6

7

60 % burner / 100 % burner

1380 / 1750

mm

1130 / - // 1650 / 1650

mm

1580 / 1580

10

11

Insulation thickness / Type

12

Floor

mm

406 + 15 mm projecting length

13

Sidewall

mm

X + 15 mm projecting length

14

Arch

mm

X + 15 mm projecting length

mm

15

Furnace casing thickness

16

17

BURNER REFRACTORY BLOCK / FASTENINGS

18

Material

19

Min. allowable temperature (3)

20

Bulk density

kg/m

21

Seger cone

S-K

22

Cold crushing strength

N/mm

23

State of supply

(4)

24

Number of segment(s) (1)

25

Mortar

26

Burner tile fastening

27

28

MATERIAL

29

Medium

30

Burner tip

31

Burner gun

32

Burner casing

33

Mounting bolts

Burner tile

> 60% Al2O3

Burner tile

1650C

Fastening

(*)

Fastening

(*)

2600

burnt

(min. 350 C)

unburnt

1

lower part welded / upper part screwed

Fuel Gas F1/F4

Fuel Gas F2

Comb. Air

UV Scanner

Pilot

1.4841

1.4841

A297-HK

SS

SS

A312 TP304

CS

Casing thickness

mm

26 Cr Mo 4

34

Silencer casing

35

Perforated plate in silencer

36

Air tube

37

Gas Flange

38

CONNECTIONS / NOZZLES

39

Medium

40

Type

41

Size

42

Rating

43

Gasket form

Spiral wound

44

Norm / Standard

ASME B16.20

45

Hose connection

46

47

48

NOTES

60 % / 100 %

Fuel Gas F1/F4

Fuel Gas F2

Comb. Air

UV Scanner

Pilot

flanged

flanged

flanged

flanged

(*)/(*)

DN 100 / DN 150

DN 300 / DN 400

DN 15 / DN 15

300

150

150

300

Spiral wound

Spiral wound

Spiral wound

ASME B16.20

ASME B16.20

ASME B16.20

49

(*)

to be filled by vendor.

50

(1)

If the burner blocks are to be delivered in segments, the mortar is to be supplied by the vendor

51

(2)

supplier to adjust flame dimensions so that below mentioned installation conditions do not influence burner

53

(3)

Max. service temp. of fastenings shall be designed with at least 120C safety margin.

54

(4)

Blocks pre-fired according requirements in &AD B-SP 4100. Chemically bonded tiles may be supplied without pre-firing.

52

performance, emissions etc.

Komm.- Nr. / Job-No.

Mechanical Datasheet

Burner / Pilot Burner

SELAS-LINDE

GMBH

7618 3258 &AD B-DE 4100

Iss-Nr./No.

vom/of

6

1

2

Seite/Page

06.08.15

Seiten/Pages

von/of

MECHANICAL REQUIREMENTS

7

Rev.

COATING / PAINTING

Coating system

Treatment of surface

See attached client specification &AD A-PE 3843 GN-12S

4

5

6

Colour

Coat thickness, dry

Prime coat

Intermediate coat

Top coat

Dimetcote 9,

Inorganic Zink Primer

55-75

Amercoat 385,

Epoxy

100-150

Amercoat 450HS,

Alipahtic Polyurethane

40-60

4

4

8

9

WEIGHT

10

Burner tile

kg

11

Burner with/without packaging

kg

210

12

13

OTHERS

14

Burner outside wall temperature C

(1)

15

16

PILOT BURNER

17

GENERAL

18

Manufacturer

19

Denomination

20

Number per burner/total

21

Type (2)

Forced draft

Natural draft

22

Type of ignition

Manual

Electrical

23

Operation

Intermittent

24

Flame safeguard

Zeeco

1 / 50

Continuous

Ionisation rod deactivated

Design : 60, Normal operation: 40

25

26

PROCESS DATA

27

Heat duty

kW

28

Pilot gas type

F1 / F3

1.5 / 0.8

29

Pilot gas pressure

bar,g

30

Pilot air pressure

mbar,g

n.a.

31

Draft at pilot burner

mbar,g

norm: -2.36

32

33

MATERIAL

34

Ignition tube

35

Venturi

IN 800 H for Firebox Temperature > 1000C

SS 310 (1.4841) for Firebox Temperature < 1000C

A732GR1A-1020

36

Pilot gas tip

37

Silencer

A297HK

38

Ignition electrode

Kanthal

39

Ionisation electrode

Kanthal

40

Insulation of electrode

41

NOTES

Dense Ceramics e.g Alsint 99

42

(1)

Based on XXC ambient air temperature and X m/s wind velocity.

43

(2)

Vendor to advise

44

45

46

47

48

49

50

51

52

53

You might also like

- High Pressure Steam Let Down Station Data SheetDocument5 pagesHigh Pressure Steam Let Down Station Data SheetSabeeh AhmedNo ratings yet

- N2 P&idDocument2 pagesN2 P&idMathivanan AnbazhaganNo ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Ultrasonic Level Transmitter Datasheet Rev.0Document7 pagesUltrasonic Level Transmitter Datasheet Rev.0Phạm Tấn PhướcNo ratings yet

- Bunner ControlDocument19 pagesBunner ControlHai NguyenNo ratings yet

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- Thermal Fluid Heaters Technical GuideDocument50 pagesThermal Fluid Heaters Technical GuideMuhamad Saukie100% (1)

- MM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1Document10 pagesMM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1gracemanotocNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- Steam DumpingDocument9 pagesSteam DumpingsrinivasanNo ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- Control Valve Data Sheet Form S20 50 PDFDocument4 pagesControl Valve Data Sheet Form S20 50 PDFPanner2009No ratings yet

- Preliminary Datasheets For Analysers: PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument43 pagesPreliminary Datasheets For Analysers: PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Calc No's: 2468712 Layout: L3 Case: C1 PFF: Doc: PFD01Document8 pagesCalc No's: 2468712 Layout: L3 Case: C1 PFF: Doc: PFD01Raju GummaNo ratings yet

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Document10 pagesDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182No ratings yet

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDocument3 pagesBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloNo ratings yet

- 14 ACC Air Side PerformanceDocument24 pages14 ACC Air Side PerformanceShivakumarNo ratings yet

- Stack Damper FATDocument13 pagesStack Damper FATSureandran SabadiNo ratings yet

- BFP temperature and vibration transmitter typical drawingDocument34 pagesBFP temperature and vibration transmitter typical drawingRolando SeclenNo ratings yet

- Pid Btorf - Rev 0 HighlightDocument20 pagesPid Btorf - Rev 0 HighlightBayuPawitraBrodjonegoroNo ratings yet

- Costos de Flete y Operacion MUYYY BUENODocument84 pagesCostos de Flete y Operacion MUYYY BUENOB6D4N0100% (1)

- PZ D CS Pi SP 015 02Document60 pagesPZ D CS Pi SP 015 02epbamdadNo ratings yet

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- 40863-001 Calc - Inline Heater PDFDocument3 pages40863-001 Calc - Inline Heater PDFomar equihuaNo ratings yet

- QIPP MPN018 J00 2304 (1) Instr ListDocument9 pagesQIPP MPN018 J00 2304 (1) Instr Listsivasri999No ratings yet

- Datasheet-Process CompressorDocument1 pageDatasheet-Process CompressorZaw Htet WinNo ratings yet

- Data Sheet for Amine ReboilerDocument7 pagesData Sheet for Amine Reboilerengr anharNo ratings yet

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisNo ratings yet

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocument2 pagesSCR Mean - Metal - Temps For Heat Exchanger TubescranderiNo ratings yet

- Petrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectDocument10 pagesPetrovietnam Fertilizer and Chemicals Corporation (Pvfcco) Ammonia Plant Revamp ProjectNcTungNo ratings yet

- 4000046273-PGCA-EA-C16-001 - 5.2 - 3 - Cause and Eff PDFDocument20 pages4000046273-PGCA-EA-C16-001 - 5.2 - 3 - Cause and Eff PDFrajindo1No ratings yet

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsDocument22 pagesIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianNo ratings yet

- HRSG Water Chemistry and Inspection OverviewDocument5 pagesHRSG Water Chemistry and Inspection OverviewRahul ChoubeyNo ratings yet

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDocument3 pagesBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNo ratings yet

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocument1 pagePages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNo ratings yet

- Purge Complete Control NarrativeDocument1 pagePurge Complete Control NarrativehadNo ratings yet

- Pressure Releaving StationDocument11 pagesPressure Releaving StationSreejesh Sundaresan100% (1)

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 pagesVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangNo ratings yet

- Datasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...Document10 pagesDatasheet For Nitrogen Bottle Rack 4B.4300 SAI S0003 ISGP U48000 MS 2105...vydaniNo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Designing Large Package BoilersDocument3 pagesDesigning Large Package BoilersdemonarundoNo ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument32 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- 112-DS-6000-4 (5 of 5) - P&ID Typical Details Standard DrawiDocument5 pages112-DS-6000-4 (5 of 5) - P&ID Typical Details Standard Drawiusaid saifullahNo ratings yet

- Waste Heat Recovery Equipment ProcurementDocument13 pagesWaste Heat Recovery Equipment ProcurementSubrata Das0% (1)

- Material Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)Document28 pagesMaterial Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)saptarshi jashNo ratings yet

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterBangkiyak LanangNo ratings yet

- Developing New Prereforming CatalystsDocument13 pagesDeveloping New Prereforming CatalystsReza RhiNo ratings yet

- E0909Document6 pagesE0909ahmedbeaetNo ratings yet

- EH Coriolis & Ultrasonic DSDocument5 pagesEH Coriolis & Ultrasonic DSsendutdutNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- General Perlite Filling ProcedureDocument17 pagesGeneral Perlite Filling ProcedureWilfredo Porco Estrada100% (1)

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Inputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)Document3 pagesInputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)SIVANo ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- BHEL Gas Turbines - Correction CurvesDocument27 pagesBHEL Gas Turbines - Correction CurvesRajagopala Sarma Sundar100% (1)

- 30 Data SheetDocument3 pages30 Data SheetGermán AndrésNo ratings yet

- LadleRefractoryMonitoringAx5 LR 2018Document2 pagesLadleRefractoryMonitoringAx5 LR 2018INDRAJIT SAONo ratings yet

- BOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFDocument12 pagesBOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFINDRAJIT SAONo ratings yet

- Understanding Infrared Thermography Reading 6 (PDFDrive) PDFDocument510 pagesUnderstanding Infrared Thermography Reading 6 (PDFDrive) PDFINDRAJIT SAONo ratings yet

- Understanding Infrared Thermography Reading 6 (PDFDrive) PDFDocument510 pagesUnderstanding Infrared Thermography Reading 6 (PDFDrive) PDFINDRAJIT SAONo ratings yet

- Action Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!Document1 pageAction Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!INDRAJIT SAONo ratings yet

- BOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFDocument12 pagesBOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFINDRAJIT SAONo ratings yet

- Estad-Jsi 2014Document3 pagesEstad-Jsi 2014INDRAJIT SAONo ratings yet

- BOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFDocument12 pagesBOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFINDRAJIT SAONo ratings yet

- V-Imp - USA-Diagonostics Important PaperDocument81 pagesV-Imp - USA-Diagonostics Important PaperINDRAJIT SAONo ratings yet

- A Temperature Prediction Model of Converters Based On Gas AnalysisDocument6 pagesA Temperature Prediction Model of Converters Based On Gas AnalysisINDRAJIT SAONo ratings yet

- Action Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!Document1 pageAction Plan Sars-Cov 19: MANDATORY Else We Cannot Monitor Who Is Sick and Who Is Not!INDRAJIT SAONo ratings yet

- BOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFDocument12 pagesBOF Refractory and Bottom Stirring - A CASE STUDY AT MEISHAN STEEL IN CHINA PDFINDRAJIT SAONo ratings yet

- LubricationDocument45 pagesLubricationAlvaro VelardeNo ratings yet

- General Plant Operation EnggDocument243 pagesGeneral Plant Operation Enggsumusail100% (3)

- A Temperature Prediction Model of Converters Based On Gas AnalysisDocument6 pagesA Temperature Prediction Model of Converters Based On Gas AnalysisINDRAJIT SAONo ratings yet

- Oxy-Fuel Control Equipment Specification REVE-11Aug2016Document6 pagesOxy-Fuel Control Equipment Specification REVE-11Aug2016INDRAJIT SAONo ratings yet

- 6thEuropeanOxygenSteelmakingConferenceEOSCStockholm07 - 09 September2011Document12 pages6thEuropeanOxygenSteelmakingConferenceEOSCStockholm07 - 09 September2011INDRAJIT SAONo ratings yet

- Metric Standard Parallel Keyway and Key SizesDocument1 pageMetric Standard Parallel Keyway and Key SizesINDRAJIT SAONo ratings yet

- A Temperature Prediction Model of Converters Based On Gas AnalysisDocument6 pagesA Temperature Prediction Model of Converters Based On Gas AnalysisINDRAJIT SAONo ratings yet

- Metric Standard Parallel Keyway and Key SizesDocument1 pageMetric Standard Parallel Keyway and Key SizesINDRAJIT SAONo ratings yet

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- Three Common Mistakes in LubricationDocument11 pagesThree Common Mistakes in LubricationINDRAJIT SAONo ratings yet

- Oil Analysis Laurentide ControlsDocument6 pagesOil Analysis Laurentide ControlsINDRAJIT SAONo ratings yet

- Practical Approach for Evaluating Oil Analysis ResultsDocument12 pagesPractical Approach for Evaluating Oil Analysis ResultsINDRAJIT SAONo ratings yet

- Oil AnalysisDocument41 pagesOil AnalysisMuhammad TahaNo ratings yet

- Chevron - LubeWatch User GuideDocument12 pagesChevron - LubeWatch User GuideINDRAJIT SAONo ratings yet

- Practical Approach for Evaluating Oil Analysis ResultsDocument12 pagesPractical Approach for Evaluating Oil Analysis ResultsINDRAJIT SAONo ratings yet

- Analysis Oil Hand Book For Motor PDFDocument106 pagesAnalysis Oil Hand Book For Motor PDFDonald VasquezNo ratings yet

- Tags and Labels Billet MarkingDocument2 pagesTags and Labels Billet MarkingINDRAJIT SAONo ratings yet

- Billet MarkerDocument4 pagesBillet MarkerINDRAJIT SAONo ratings yet

- Tata Motors and CSRDocument16 pagesTata Motors and CSRSiva Krishna Reddy NallamilliNo ratings yet

- Masonry TutorialDocument45 pagesMasonry TutorialGajendra Joshi100% (2)

- G8D Process: A Methodical 8-Step Problem Solving ToolDocument34 pagesG8D Process: A Methodical 8-Step Problem Solving Toolpkrganesh100% (1)

- Aditya Birla Grasim Chemicals Limited": Presented By: Chiranjeevi M Gouda Guided By: Prashanth U GujanalDocument11 pagesAditya Birla Grasim Chemicals Limited": Presented By: Chiranjeevi M Gouda Guided By: Prashanth U GujanalChiru GoudaNo ratings yet

- White America vs. Other Americas. TALKING To The DEADDocument2 pagesWhite America vs. Other Americas. TALKING To The DEADRadu BortesNo ratings yet

- Dissertation Herbal MedicineDocument5 pagesDissertation Herbal MedicineBestOnlinePaperWritingServiceUK100% (1)

- Kobalt Spray Gun ManualDocument39 pagesKobalt Spray Gun ManualChris ReddersenNo ratings yet

- T S Form 3Document2 pagesT S Form 3Lubinda Lubinda Jr.No ratings yet

- Bisnu Presentation Bakery (Bäckerei)Document11 pagesBisnu Presentation Bakery (Bäckerei)bisnunepmanyNo ratings yet

- Listen Up! How To Be Appropriately AssertiveDocument20 pagesListen Up! How To Be Appropriately AssertiveMuddassir Ehsan FaheemNo ratings yet

- Tooth Extraction NotesDocument4 pagesTooth Extraction NotesjosephNo ratings yet

- How Your Personality Changes As You AgeDocument5 pagesHow Your Personality Changes As You AgeJulia BuslaevaNo ratings yet

- Delivering Leftover Bread to Singapore's NeedyDocument14 pagesDelivering Leftover Bread to Singapore's Needywisemaverick_5084303No ratings yet

- Aqu4518r0 PDFDocument3 pagesAqu4518r0 PDFNak SandyNo ratings yet

- Daftar Pustaka: Selma Mutiara Hani, Dr. Moh Nailul Fahmi, SP - OG Dr. Fatwa Sari Tetra Dewi, MPH., PH.DDocument10 pagesDaftar Pustaka: Selma Mutiara Hani, Dr. Moh Nailul Fahmi, SP - OG Dr. Fatwa Sari Tetra Dewi, MPH., PH.DRohadatul Aisy Kurnia PutriNo ratings yet

- BS EN 206-1 and BS 8500 Concrete Standards GuideDocument23 pagesBS EN 206-1 and BS 8500 Concrete Standards GuideJasmine SmithNo ratings yet

- Pablo-Gualberto v. Gualberto v. (Ocampo)Document1 pagePablo-Gualberto v. Gualberto v. (Ocampo)resjudicataNo ratings yet

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument6 pagesSafety Data Sheet: 1. Chemical Product and Company IdentificationNguyễn Thị ThúyNo ratings yet

- Budget Planner For EsakalDocument7 pagesBudget Planner For Esakalapi-19417993No ratings yet

- (PPT) Arresting Cracks in Steel BridgesDocument61 pages(PPT) Arresting Cracks in Steel BridgesShaileshRastogiNo ratings yet

- 2024-01-19 - ScienceDocument123 pages2024-01-19 - Scienceppsjyjm87xNo ratings yet

- STPDDocument9 pagesSTPDAmit GoelNo ratings yet

- Energy Series Dynamic Dome SkylightsDocument2 pagesEnergy Series Dynamic Dome SkylightsoutmatchNo ratings yet

- CPCCSP3003A Apply Trowelled Texture Coat Finishes LR NewDocument71 pagesCPCCSP3003A Apply Trowelled Texture Coat Finishes LR NewFfdsfdsNo ratings yet

- Promotion of Tax Culture in Pakistan: Perspective, Prospects and ChallengesDocument5 pagesPromotion of Tax Culture in Pakistan: Perspective, Prospects and ChallengesRaheel JoyiaNo ratings yet

- DgaDocument17 pagesDgaMohit VermaNo ratings yet

- Federal Employees' Group Life Insurance Program (FEGLI) Life Insurance Open Season GuidanceDocument9 pagesFederal Employees' Group Life Insurance Program (FEGLI) Life Insurance Open Season GuidanceFedSmith Inc.No ratings yet

- Ointment BMRDocument22 pagesOintment BMRspp80% (5)

- March 21, 2015Document16 pagesMarch 21, 2015The Delphos HeraldNo ratings yet

- Manfaat Yang Didapatkan Mahasiswa Dalam Mengikuti: Interprofessional Education (Ipe) Dengan Pendekatan Case StudyDocument5 pagesManfaat Yang Didapatkan Mahasiswa Dalam Mengikuti: Interprofessional Education (Ipe) Dengan Pendekatan Case StudyganditNo ratings yet