Professional Documents

Culture Documents

Condensation Calculation

Uploaded by

binhjukiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condensation Calculation

Uploaded by

binhjukiCopyright:

Available Formats

Proj. No.

:D0052

Project No.

DESIGN CALCULATION

Sheet No.

SHEET

Mechanical & Industrial Department

D0052

CAIRO - EGYPT

Date

3-Aug-15

Computed by

1 of 2

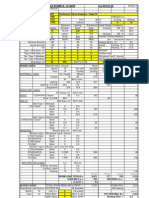

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 16C and 81%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-1473)/1.92E+10

Gt

=

1.02E-09 Kg/m2s

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 24 C & 50% rh

1 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Aug-15

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Pvo is the outside vapour pressure @ 16C and 81%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

(24-16)/5.33

1.50 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

Vapour

Saturated Vapour

Differ Result*

Pressure(calculated) Pa Pressure(Pa) From

ence

pv2= Saturated Water Tables Pa

pv1-mvG1

t1

t2

t3

t4

t5**

t6**

t7**

Pv2

Pv3

Pv4

Pv5

pv6

pv7

pv8

=

=

=

=

=

=

=

23.82

23.35

22

21.77

16.6

16.48

16.21

=

=

=

=

=

=

=

1490

1489

1484

1481

1476

1474

1473

2985

2985

2645

2645

1938

1938

1818

1495

1496

1161

1164

462

464

345

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 12.7 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

** Although the result is positivepressure difference,the difference is very low which indicates a risk

of condensation .

2 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

3 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

4 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

3-Aug-15

Computed by

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Thermal

Resitivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Sound Insulation

Air Gap (1)

Plaster Board

0.05

6.25

50.00

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 30.5C and 70%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-2972)/1.92E+10

Gt

-7.71E-08

Kg/m2s

5 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 24C and 50%rh

Pvo is the outside vapour pressure @ 30.5C and 70%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

(24-30.5)/5.33

-1.22 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

24.15 Pv2

=

1686 Tables

2985

24.53 Pv3

=

1763

3169

25.6 Pv4

=

2148

3363

25.82 Pv5

=

2379

3363

30 pv6

=

2780

4246

30.11 pv7

=

2895

4246

30.33 pv8

=

2972

4246

Differ Result*

ence

Pa

1299

1406

1215

984

1466

1351

1274

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

6 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

7 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

8 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

3-Aug-15

Computed by

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivity

Thickness

&Thermal

m

Conductivity is

assumed to be

similar to:

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 46C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistance (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistance of the structure

mv

Pvi-Pvo

(1322-2928.3)/1.92E+10

Gt

-8.37E-08

Kg/m2s

9 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Aug-15

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 46C and 29%rh

Gt is the total vapour resistance (N s/kg)

q

tai-tao

Rt

22-46/5.33

-4.50 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistance of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

Vapour

Saturated Vapour

Differ Result*

Pressure(calculated) Pa Pressure(Pa) From

ence

pv2= pv1-mvG1

Saturated Water Tables Pa

t1

t2

t3

t4

t5

t6

t7

Pv2

Pv3

Pv4

Pv5

pv6

pv7

pv8

=

=

=

=

=

=

=

22.54

23.95

27.89

28.7

44.21

44.56

45.37

=

=

=

=

=

=

=

1531

1615

2033

2284

2719

2845

2928

2810

2985

3782

4008

9110

9593

9593

1279

1370

1749

1724

6391

6748

6665

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

10 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

11 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

12 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/1.92E+10

Gt

-6.47E-07

Kg/m2s

13 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/5.33

-10.9 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

23.3

26.7

36.24

38.2

75.68

76.52

78.48

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2940

2810

Pv3

=

3587

3567

Pv4

=

6824

5947

Pv5

=

8765

6632

pv6

=

12131

40236

pv7

=

13102

41938

pv8

=

13749

45524

Differ Result*

ence

Pa

-130

-20

-877

-2133

28105

28836

31775

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

14 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

15 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

16 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.15

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.07E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

7.06

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.07E+10

Gt

-6.00E-07

Kg/m2s

17 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/7.06

-8.2 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

23

25.55

32.76

34.24

76.74

77.37

78.85

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2823

2810

Pv3

=

3423

3363

Pv4

=

6425

5034

Pv5

=

9126

5323

pv6

=

12248

41938

pv7

=

13149

41938

pv8

=

13749

45524

Differ Result*

ence

Pa

-13

-60

-1391

-3803

29690

28789

31775

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

18 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

19 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

20 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.20

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.22E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

8.78

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.22E+10

Gt

-5.60E-07

Kg/m2s

21 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/8.78

-6.6 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

22.79

24.86

30.65

31.84

77.38

77.89

79.08

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2721

2810

Pv3

=

3281

3169

Pv4

=

6080

4496

Pv5

=

9439

4759

pv6

=

12350

41938

pv7

=

13189

43700

pv8

=

13749

45524

Differ Result*

ence

Pa

89

-112

-1584

-4680

29588

30511

31775

No Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

22 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

23 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

24 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Aug-15

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.67E+10

Gt

-4.63E-07

Kg/m2s

25 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-70/5.07

-9.5 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

23.13

26.09

34.39

36.09

68.7

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2478

2810

Pv3

=

2941

3363

Pv4

=

5254

5324

Pv5

=

6642

5947

pv6

=

9047

29873

Differ Result*

ence

Pa

332

422

70

-695

20826

No Cond.

No Cond.

No Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

26 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

27 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

28 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Aug-15

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.15

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.82E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

6.80

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.82E+10

Gt

-4.24E-07

Kg/m2s

29 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-70/6.8

-7.1 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

22.85

25.05

31.25

32.52

69

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2383

2810

Pv3

=

2808

3169

Pv4

=

4930

4496

Pv5

=

6840

5034

pv6

=

9047

29873

Differ Result*

ence

Pa

427

361

-434

-1806

20826

No Cond.

No Cond.

Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

30 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

31 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

32 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

MG

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation EffecChecked by

Building Concourse 2 - Dubai International Airport

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 60C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-5784)/1.67E+10

Gt

-2.67E-07

Kg/m2s

33 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Aug-15

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

MG

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation EffecChecked by

Building Concourse 2 - Dubai International Airport

TZ

where mv is the rate of vapour mass transfer per unit area

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-60/5.07

-7.5 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

22.9

25.24

31.81

33.15

59

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

1990

2810

Pv3

=

2257

3169

Pv4

=

3593

4759

Pv5

=

4395

5034

pv6

=

5784

19039

Differ Result*

ence

Pa

820

912

1166

639

13255

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

34 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

35 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

36 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

CAIRO - EGYPT

D0052

Sheet No.

Date

3-Aug-15

Computed by

1 of 2

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Heat Gain To The Ventilated Air Gap:

Q = U A T

Where

Q is the heat gain to the ventilated air gap in W

U is the overall heat transfer coeffient in W/m 2k

A is the area in m2

T is the temperature difference in Kelvin

Q = (3.85)(6.25)(353.15-333.15)

481

W

=

1642.615

BTU/hr

Ventilation air required:

Q = cfm(1.08)T

Where

Q is the heat gain to the ventilated air gap in BTU/hr

cfm is the required ventilation air

T is the temperature difference in Fahrenheit

1648.615 = cfm(1.08)(176-140)

cfm =

42

=

20 l/s

=

30 l/s

(For Safety)

Therefore ventilation air requird is 5 l/s for each 1 m 2

Area through which air flow = 4*2.5*0.03/2

= 0.15 /2 = 0.075 m2

Velocity =

=

0.03/.075

0.4 m/s

80 ft/min

For air to enter

37 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

Mechanical & Industrial Department

CAIRO - EGYPT

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

SHEET

D0052

Sheet No.

Date

3-Aug-15

Computed by

1 of 2

Checked by

TZ

MG

Approved by

MK

38 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

39 of 40

Proj. No. :D0052

3-Aug-15

Computed by

MG

Approved by

MK

40 of 40

You might also like

- Condensation calculations for building envelopeDocument22 pagesCondensation calculations for building envelopelutfi awn100% (1)

- Condensation Calculation for Dubai Airport BuildingDocument40 pagesCondensation Calculation for Dubai Airport Buildingwado11No ratings yet

- Insulation CalcDocument4 pagesInsulation Calcjacok22No ratings yet

- P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) FormulasDocument4 pagesP&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulasjnmanivannan100% (1)

- Heat Exchanger CalcDocument34 pagesHeat Exchanger Calcميثة الغيثيةNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuNo ratings yet

- Liquid Overfeed Systems by R. P. ParanjpeyDocument15 pagesLiquid Overfeed Systems by R. P. Paranjpeyurp30234No ratings yet

- Moist Air PropertiesDocument12 pagesMoist Air PropertiesLily DianaNo ratings yet

- TEMA SheetDocument2 pagesTEMA SheetFrancisco RenteriaNo ratings yet

- CDA Data CollectionDocument2 pagesCDA Data Collectiondford8583No ratings yet

- Coil Selection FormatDocument6 pagesCoil Selection FormatTanveer AzizNo ratings yet

- Forced Convection H T Coeff Turb Pipe Flow Si UnitsDocument3 pagesForced Convection H T Coeff Turb Pipe Flow Si UnitsSouvik Roy ChowdhuryNo ratings yet

- Make Up Water Calc.Document2 pagesMake Up Water Calc.hera4u2No ratings yet

- HVAC CalcDocument68 pagesHVAC CalcBen ClackNo ratings yet

- Thermal Insulation Thickness Calculation (By James)Document1 pageThermal Insulation Thickness Calculation (By James)Ah BengNo ratings yet

- Room ventilation options comparisonDocument9 pagesRoom ventilation options comparisonSamved PatelNo ratings yet

- Process Calculation - Purge Gas CalculationDocument1 pageProcess Calculation - Purge Gas CalculationmakamahamisuNo ratings yet

- Rahul Kumar B Electrical Dept. Abhijeet Projects LimitedDocument23 pagesRahul Kumar B Electrical Dept. Abhijeet Projects LimitedrahulengineerNo ratings yet

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDocument6 pagesChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- TES Storage Tank All CalculationDocument45 pagesTES Storage Tank All CalculationmitulNo ratings yet

- Thermal InsulationDocument27 pagesThermal Insulationmkchy12No ratings yet

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Document1 pageRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNo ratings yet

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocument1 pagePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- Plate Heat Exchanger DesignDocument1 pagePlate Heat Exchanger Designrick_owen82001No ratings yet

- AF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us UnitsDocument8 pagesAF84C8 Excel Template Prelim Double Pipe Heat Exchanger Design Us Unitss111_sunilNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatingAnand BhiseNo ratings yet

- Heat loss from a buried oil line: Conduction shape factor and insulation effectDocument20 pagesHeat loss from a buried oil line: Conduction shape factor and insulation effectJuan Pablo ApazaNo ratings yet

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNo ratings yet

- K-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Document1 pageK-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Ah BengNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Load Check FiguresDocument1 pageLoad Check FiguresArshavin Watashi WaNo ratings yet

- Cooling Towers & Desiccant Dehumidification GuideDocument23 pagesCooling Towers & Desiccant Dehumidification Guideesojsuil_tgNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Welded Beam CalculationDocument2 pagesWelded Beam CalculationVeenoyNo ratings yet

- Exhaust Gas Pressure Drop in DuctDocument6 pagesExhaust Gas Pressure Drop in DuctMyungkwan HaNo ratings yet

- Pressure Drop Calculation For Rect. DuctsDocument2 pagesPressure Drop Calculation For Rect. Ductsmahmutovicm3488No ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Waste Heat Recovery (Mech-31)Document18 pagesWaste Heat Recovery (Mech-31)shammiNo ratings yet

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- PAU Calculation Sheet Vr.0Document1 pagePAU Calculation Sheet Vr.0Arshavin Watashi Wa100% (1)

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinNo ratings yet

- Assessment of Heat ExchangersDocument14 pagesAssessment of Heat ExchangersranveerNo ratings yet

- Design Calculation Sheet: 1-AbbreviationsDocument2 pagesDesign Calculation Sheet: 1-AbbreviationsOltun KAYANo ratings yet

- XXXDocument88 pagesXXXHenry LimNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Head Calculation Hydronic PipingDocument18 pagesHead Calculation Hydronic Pipingjomy_pj8106No ratings yet

- STEAMcalcDocument3,269 pagesSTEAMcalcneel100% (1)

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNo ratings yet

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Psychrometric CalculatorDocument4 pagesPsychrometric CalculatorArie Emmanuel ListonNo ratings yet

- M'Sia Fire Stair Pressurization SampleDocument10 pagesM'Sia Fire Stair Pressurization Samplenim_gourav1997No ratings yet

- Shell & Tube Heat Exchange DesignDocument6 pagesShell & Tube Heat Exchange DesignRushikesh uNo ratings yet

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- Condensation Calculation Design ReportDocument12 pagesCondensation Calculation Design ReportfebousNo ratings yet

- Calculation CCR (RC)Document123 pagesCalculation CCR (RC)bonnicoNo ratings yet

- 220 KV Sag Tension Calculation - ThyottarDocument13 pages220 KV Sag Tension Calculation - Thyottarannuvyas100% (3)

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- HVAC Duct Sizing GuideDocument91 pagesHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- Design Options For HVAC Distribution SystemsDocument68 pagesDesign Options For HVAC Distribution Systemscathybravo100% (3)

- Fire Service Features of Buildings and Fire Protection SystemsDocument129 pagesFire Service Features of Buildings and Fire Protection Systemsyêu animeNo ratings yet

- HVAC Design For Pharmaceutical FacilitiesDocument57 pagesHVAC Design For Pharmaceutical FacilitiesShams MInhaz Monzur100% (4)

- HVAC Design For Healthcare FacilitiesDocument60 pagesHVAC Design For Healthcare Facilitiesaymanibrahim_71No ratings yet

- Duct SystemsDocument19 pagesDuct SystemsShiyamraj ThamodharanNo ratings yet

- Heat Recovery VentilatorsDocument36 pagesHeat Recovery VentilatorsShiyamraj ThamodharanNo ratings yet

- HVAC System PDFDocument79 pagesHVAC System PDFBülent KabadayiNo ratings yet

- Ventilation and Exhaust SystemsDocument95 pagesVentilation and Exhaust SystemsbinhjukiNo ratings yet

- Cooling Towers PDFDocument60 pagesCooling Towers PDFRamakrishnaNo ratings yet

- Engine Cooling and Lubrication Systems R1Document43 pagesEngine Cooling and Lubrication Systems R1pasu pathiNo ratings yet

- Description of Useful HVAC TermsDocument64 pagesDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- Battery Room Ventilation and SafetyDocument62 pagesBattery Room Ventilation and SafetyingatvNo ratings yet

- HVAC Cooling Systems for Data CentersDocument65 pagesHVAC Cooling Systems for Data CentersShiyamraj Thamodharan100% (1)

- Duct Sealing in Large BuildingsDocument31 pagesDuct Sealing in Large BuildingsShiyamraj ThamodharanNo ratings yet

- Hvac GreenDocument201 pagesHvac GreenShiyamraj ThamodharanNo ratings yet

- HVAC Design for Cleanroom Facilities CourseDocument55 pagesHVAC Design for Cleanroom Facilities CourseMadhu Gajulapalli100% (1)

- MEP Design of Building Services CourseDocument98 pagesMEP Design of Building Services CourseMoideen Thashreef100% (3)

- Edmt34-635a VRV3S PDFDocument308 pagesEdmt34-635a VRV3S PDFbinhjuki100% (1)

- Stairwell Pressurization SystemsDocument67 pagesStairwell Pressurization SystemsShiyamraj ThamodharanNo ratings yet

- HVAC Cooling Systems for Data CentersDocument65 pagesHVAC Cooling Systems for Data CentersShiyamraj Thamodharan100% (1)

- Pipe Spacing CalculatorDocument9 pagesPipe Spacing CalculatorJuan Pablo ApazaNo ratings yet

- Att WY CatalogDocument8 pagesAtt WY CatalogbinhjukiNo ratings yet

- HVAC Design For Healthcare FacilitiesDocument60 pagesHVAC Design For Healthcare Facilitiesaymanibrahim_71No ratings yet

- HVAC System PDFDocument79 pagesHVAC System PDFBülent KabadayiNo ratings yet

- Steam Distribution CourseDocument79 pagesSteam Distribution CoursebinhjukiNo ratings yet

- Siemens Building ManagementDocument266 pagesSiemens Building ManagementGirish Jha100% (2)

- IMF Flyer 100-200 PDFDocument2 pagesIMF Flyer 100-200 PDFbinhjukiNo ratings yet

- 141 Dke FF BD MB 443 PDFDocument1 page141 Dke FF BD MB 443 PDFbinhjukiNo ratings yet

- Specification FFU (Model 2x4 AH) PDFDocument3 pagesSpecification FFU (Model 2x4 AH) PDFbinhjukiNo ratings yet

- 2023 2024 Sanwa enDocument27 pages2023 2024 Sanwa enleo14pochNo ratings yet

- Heat Transfer Nov2002 NR 310803Document6 pagesHeat Transfer Nov2002 NR 310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Diffusion IntroductionDocument14 pagesDiffusion IntroductionPrabhavJainNo ratings yet

- LP-Sept. 5 - Electric SymbolsDocument4 pagesLP-Sept. 5 - Electric SymbolsDiona Bangga - ModestoNo ratings yet

- P1 Chapter 1Document1 pageP1 Chapter 1Rehan ShahNo ratings yet

- Ahi Evran Sunum enDocument26 pagesAhi Evran Sunum endenizakbayNo ratings yet

- CFD Heat Exchanger OptimizationDocument4 pagesCFD Heat Exchanger Optimizationusmanwahla100% (1)

- Mean Flange Thickness T Overall Depth DDocument3 pagesMean Flange Thickness T Overall Depth DAkhil BabuNo ratings yet

- Astm A312 PDFDocument10 pagesAstm A312 PDFTam Huynh ThanhNo ratings yet

- Effect of Substrate-Induced Strain in The Transport Properties of Algan/Gan HeterostructuresDocument5 pagesEffect of Substrate-Induced Strain in The Transport Properties of Algan/Gan HeterostructuresA Mohan BabuNo ratings yet

- Mechanics of Solid Problems On Stress and StrainDocument4 pagesMechanics of Solid Problems On Stress and StrainYogeswaranNo ratings yet

- Arstruct Reviewer Compilation (GRP 7)Document9 pagesArstruct Reviewer Compilation (GRP 7)Nicole FrancisNo ratings yet

- Modelling Composite Materials PDFDocument22 pagesModelling Composite Materials PDFchetan_thakur4278No ratings yet

- Quiz 1 - Transport PhenomenaDocument3 pagesQuiz 1 - Transport PhenomenaDaffa IbrahimNo ratings yet

- Liquid Vapor Equilibrium NotesDocument10 pagesLiquid Vapor Equilibrium NoteshumejiasNo ratings yet

- Phys HW20Document1 pagePhys HW20Adam LiangNo ratings yet

- Stress Analysis ReportDocument153 pagesStress Analysis ReportErarunv100% (5)

- A - Rock Properties & SaturationDocument29 pagesA - Rock Properties & SaturationTemitope BelloNo ratings yet

- Du Dub PDFDocument55 pagesDu Dub PDFSURESH100% (1)

- Geotextiles and GeomembranesDocument12 pagesGeotextiles and Geomembranesjavad khosraviNo ratings yet

- Module 3 - 1Document26 pagesModule 3 - 1Biswajit LME016100% (1)

- HM225.Xx Flow Around Bodies EnglishDocument1 pageHM225.Xx Flow Around Bodies EnglishsaintanddevilNo ratings yet

- OPTI Course ListDocument3 pagesOPTI Course ListironbatjediNo ratings yet

- Inspection Certificate: (EN10204 3.1/ISO 10474 3.1)Document1 pageInspection Certificate: (EN10204 3.1/ISO 10474 3.1)Faishal Khairul UmamNo ratings yet

- Chapter-9 Ray Optics and Optical InstrumentsDocument3 pagesChapter-9 Ray Optics and Optical Instrumentssamkal2830No ratings yet

- Medium/Phase Dispersed Phase GAS Liquid SolidDocument2 pagesMedium/Phase Dispersed Phase GAS Liquid SolidIrvandar NurviandyNo ratings yet

- ConductivityDocument36 pagesConductivityThangadurai Senthil Ram PrabhuNo ratings yet

- Design of RCC T - Girder Deck Using Morice & Little MethodDocument33 pagesDesign of RCC T - Girder Deck Using Morice & Little Methodvasu7900100% (4)

- Load Bearing Bahaviour of Cast in Shear Dowels PDFDocument7 pagesLoad Bearing Bahaviour of Cast in Shear Dowels PDFToan PhamNo ratings yet