Professional Documents

Culture Documents

Screw Conveyor Rating

Uploaded by

PereiraeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screw Conveyor Rating

Uploaded by

PereiraeCopyright:

Available Formats

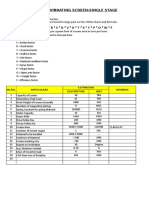

1. Screw conveyor sizing (NO INCLINATION!!

)

Woodcock

1. Power for friction (mechanical parts

Screw diameter

0.1 m

Screw lenght

1.2 m

6 Watts

0.011 CV

2. Power to convey the mat'l

2 Watts

Fs

1 1 for conventional screws

1,2 for cut flights or ribbon flights at 45% loading

1,7 for cut and folded flights at 45% loading

Fm

1 0,8 to 4 (it depends on the material).

500 kg/m

V

0.000417 m/s

1.5 m/h (volumetric flow)

g

9.81 m/s

(gravity)

Forum:

I want to build a screw conveyer with is placed under an angle, which angle isnt important.

I know that if you put a screw conveyer under an angle you have to increase the speed of the screw, but I don'

Are there tables available for this, for 0-90 degrees?

Screw Conveyor 101

by Michael P. Forcade

It is an excellant book for design of screw conveyors.

We found a formula in the literature stating:

correction factor for inclination compared with horizontal conveying (angle written in degrees) =

0.4

1 - ( angle of inclination / 50 )

with a minimum of 0,1 (45 degrees) and a maximum of 1,9 (45 degrees down).

We calculated a lot of screw conveyors with this formula, but pratice showed that the formula predicts a far low

Therefore I know the experimental graph mentioned in the above reply will be more realistic.

Instead of dividing by 50 in the formula we found, the formula would be according the graph of Mr.

0.786

factor = 1 - (angle / 140)

We know that this efficiency/correctionfactor differs very much for each product.

Vertical or almost vertical screw conveyors (inclination app. 90 degrees) work on basis of centrifugal forces and

PROBLEMS ASSOCIATED WITHINCLINED SCREWCONVEYOR

Several things can be done to overcome many of theproblems associated with inclined screwconveyor:

1) Limit the use of standard screw components to inclines of less than 25, preferably not over 15

2) Use close clearance between trough and screw

3) Increase the speed overthat applicable for a horizontal screw conveyor of the samesize

4) Use short pitch screws, 2/3 or 1/2 pitch

2. Screw conveyor sizing (NO INCLINATION!!)

2. Dubbel

Filling factor :

1. Rpm necessary

99.47 rpm

Pitch

0.1 m

0.15

heavy, friction

light, no friction

0.32 (Filling factor)

0.45

2. Power

Mass flow

f1

0.007 kW

0.010 CV

0.75 t/h

3 (Friction factor)

3. Mech Engineering paper (NO

V

1.5

ro

500

D

0.1

S

0.075

N

100

0.32

C

1

Q

565

of the screw, but I don't know how much.

4. Carlos III University (NO inc

0.32

k

0.5

co

1.2

H

1.3

P

0.012

egrees) =

C for + 45

C for - 45

0.1

1.9

ormula predicts a far lower capacity than real.

rding the graph of Mr. Peter Donecker

of centrifugal forces and there you have another calculation method.

onveyor:

f1

4

2

ngineering paper (NO inclination)

m/h

volume

kg/m

density

m

screw diameter

m

pitch

rpm

speed

filling factor

inclination factor

kg/h

capacity

II University (NO inclination)

pg 4

pg 5

m

kW

pg 6

altura

Potncia

Screw conveyor sizing (HORIZONTAL)

Woodcock

1. Power for friction (mechanical parts

Screw diameter

0.1 m

Screw lenght

2m

10 Watts

0.019 CV

2. Power to convey the mat'l

4 Watts

Fs

1 1 for conventional screws

1,2 for cut flights or ribbon flights at 45% loading

1,7 for cut and folded flights at 45% loading

Fm

1 0,8 to 4 (it depends on the material).

500 kg/m

V

0.000417 m/s

1.5 m/h (volumetric flow)

g

9.81 m/s

(gravity)

Forum:

I want to build a screw conveyer with is placed under an angle, which angle isnt important.

I know that if you put a screw conveyer under an angle you have to increase the speed of the screw, but I don'

Are there tables available for this, for 0-90 degrees?

Screw Conveyor 101

by Michael P. Forcade

It is an excellant book for design of screw conveyors.

We found a formula in the literature stating:

correction factor for inclination compared with horizontal conveying (angle written in degrees) =

0.4

1 - ( angle of inclination / 50 )

with a minimum of 0,1 (45 degrees) and a maximum of 1,9 (45 degrees down).

We calculated a lot of screw conveyors with this formula, but pratice showed that the formula predicts a far low

Therefore I know the experimental graph mentioned in the above reply will be more realistic.

Instead of dividing by 50 in the formula we found, the formula would be according the graph of Mr.

0.786

factor = 1 - (angle / 140)

We know that this efficiency/correctionfactor differs very much for each product.

Vertical or almost vertical screw conveyors (inclination app. 90 degrees) work on basis of centrifugal forces and

PROBLEMS ASSOCIATED WITHINCLINED SCREWCONVEYOR

Several things can be done to overcome many of theproblems associated with inclined screwconveyor:

1) Limit the use of standard screw components to inclines of less than 25, preferably not over 15

2) Use close clearance between trough and screw

3) Increase the speed overthat applicable for a horizontal screw conveyor of the samesize

4) Use short pitch screws, 2/3 or 1/2 pitch

Screw conveyor sizing (HORIZONTAL)

2. Dubbel

1. Rpm necessary

99.47 rpm

Pitch

0.1 m

0.32 (Filling factor)

2. Power

Mass flow

f1

Filling factor :

0.15

heavy, friction

light, no friction

0.45

0.012 kW

0.017 CV

0.75 t/h

3 (Friction factor)

3. Mech Engineering paper (IN

V

1.5

ro

500

D

0.1

S

0.1

N

75

0.32

C

0.6

Q

339

of the screw, but I don't know how much.

4. Carlos III University (INCLIN

0.32

k

0.5

co

1.2

H

1.3

P

0.018

egrees) =

C for + 45

C for - 45

0.1

1.9

ormula predicts a far lower capacity than real.

rding the graph of Mr. Peter Donecker

of centrifugal forces and there you have another calculation method.

onveyor:

f1

4

2

ngineering paper (INCLINED)

m/h

volume

kg/m

density

m

screw diameter

m

pitch

rpm

speed

filling factor

inclination factor

kg/h

capacity

II University (INCLINED)

pg 4

pg 5

m

kW

pg 6

altura

You might also like

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Susskind Quantum Mechanics NotesDocument27 pagesSusskind Quantum Mechanics NotesGary SheaNo ratings yet

- RP 37.2Document36 pagesRP 37.2Ariz Joelee ArthaNo ratings yet

- 67 31085 IM515E 2016 1 2 2 MaterialSelection 06Document21 pages67 31085 IM515E 2016 1 2 2 MaterialSelection 06GiovannaPachecoNo ratings yet

- Prospectus KsouDocument68 pagesProspectus KsouapamanNo ratings yet

- BOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFDocument8 pagesBOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFRaghavendra PrasadNo ratings yet

- Chain Breaking Load CalculationDocument1 pageChain Breaking Load CalculationDebkumar958No ratings yet

- Conveyor Belt Scale Data SheetDocument2 pagesConveyor Belt Scale Data SheetEDUARDONo ratings yet

- Beam Deflection CalculationDocument2 pagesBeam Deflection CalculationAriful IslamNo ratings yet

- BELT CONVEYOR DESIGN FORMULASDocument3 pagesBELT CONVEYOR DESIGN FORMULASwidyaditya8No ratings yet

- Conveyor CapacityDocument3 pagesConveyor Capacityx30patelNo ratings yet

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralNo ratings yet

- Screw ConveyorsDocument4 pagesScrew ConveyorsAshish SharmaNo ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Screw Conveyor Excel CalculationDocument8 pagesScrew Conveyor Excel Calculationhardik033No ratings yet

- Chain Conveyor ExampleDocument4 pagesChain Conveyor ExampledeeptidhaNo ratings yet

- DTS - Belt Bucket Elevator - DatasheetDocument3 pagesDTS - Belt Bucket Elevator - DatasheetBRUNA NASCIMENTONo ratings yet

- Screw Conveyor CalculationDocument1 pageScrew Conveyor Calculation113314No ratings yet

- Belt Tension CalculationDocument5 pagesBelt Tension Calculationmanoj983@gmail.comNo ratings yet

- Conveyor design parameters for slag ash materialDocument33 pagesConveyor design parameters for slag ash materialMustafa AkbarNo ratings yet

- Helix Delta-T6 Sample Report01Document29 pagesHelix Delta-T6 Sample Report01Khaleel PashaNo ratings yet

- Boru Bant Versiyon 3Document38 pagesBoru Bant Versiyon 3Hasan arif KısaalioğluNo ratings yet

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- Screw Conveyor CalculationDocument1 pageScrew Conveyor CalculationRavindra RautNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- M 275 ContentDocument40 pagesM 275 ContentAnonymous DQ4wYUmNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- Vibrating ScreensDocument3 pagesVibrating ScreensvinodsnNo ratings yet

- RENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSDocument1 pageRENOLD CHAIN DOUBLE PITCH SPROCKET DESIGN SPECIFICATIONSWaris La Joi Wakatobi0% (1)

- Calculate Bucket Elevator CapacityDocument2 pagesCalculate Bucket Elevator CapacityBùi Hắc HảiNo ratings yet

- Dunlop Conveyor Belt Design Manual. Page 2 PDFDocument17 pagesDunlop Conveyor Belt Design Manual. Page 2 PDFMuthuvel VivekNo ratings yet

- Screw ConveyorDocument4 pagesScrew ConveyorRaji SuriNo ratings yet

- Apron Weigh FeederDocument4 pagesApron Weigh FeederRaji SuriNo ratings yet

- Slat ConveyorDocument8 pagesSlat ConveyorpkjddjsydNo ratings yet

- Selecting Screw ConveyorsDocument2 pagesSelecting Screw ConveyorsSMNCI Cadet EngineersNo ratings yet

- Bucket Elevator Calculation: Yellow Cell To Be FilledDocument2 pagesBucket Elevator Calculation: Yellow Cell To Be Filledm_verma21100% (2)

- Conveyor Chains TsubakiDocument184 pagesConveyor Chains Tsubakitepu msosaNo ratings yet

- 5566 Drag ConveyorsDocument8 pages5566 Drag ConveyorsEduardo SaucedoNo ratings yet

- Conveying Material Screw Conveyor HP CalculationDocument36 pagesConveying Material Screw Conveyor HP CalculationMugurelVasilescuNo ratings yet

- Air Slide Data SheetDocument2 pagesAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdNo ratings yet

- Belt ConveyorDocument3 pagesBelt ConveyorJawed AnsariNo ratings yet

- 1996 Edition Part-3 Under Ground Coal Mining IdlersDocument14 pages1996 Edition Part-3 Under Ground Coal Mining Idlersyadiki1964No ratings yet

- Bucket elevator chains and components guideDocument45 pagesBucket elevator chains and components guideMuhammad Irvan FNo ratings yet

- Line-by-line conveyor code for material handling parameters and calculationsDocument4 pagesLine-by-line conveyor code for material handling parameters and calculationskmats2No ratings yet

- Powder Cooler - BrochureDocument4 pagesPowder Cooler - BrochureAnonymous Cxriyx9HIX100% (1)

- Rotary Airlock FeedersDocument28 pagesRotary Airlock Feederslhphong021191No ratings yet

- Design of Belt ConveyorsDocument5 pagesDesign of Belt ConveyorsYashrajNo ratings yet

- Bucket Elevator Capacity Formulas REVISEDDocument1 pageBucket Elevator Capacity Formulas REVISEDbrpnaidu2157No ratings yet

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- Screw Conveyor Design123456789Document8 pagesScrew Conveyor Design123456789Ramsai ChigurupatiNo ratings yet

- Imososa Mining Company Crushing Plant ReportDocument14 pagesImososa Mining Company Crushing Plant ReportTawanda NyambiyaNo ratings yet

- Conveyor Belt Engineering TablesDocument5 pagesConveyor Belt Engineering Tablestaohung1120No ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- Vertical Screw Elevators PDFDocument10 pagesVertical Screw Elevators PDFtamil vaananNo ratings yet

- Belt Conveyor PowerDocument10 pagesBelt Conveyor PowerRyukiNo ratings yet

- Belt Conveyor Pulley Design - Why The Failures - Terry KingDocument11 pagesBelt Conveyor Pulley Design - Why The Failures - Terry KingJakesNo ratings yet

- Apron FeederDocument2 pagesApron FeederRaji Suri100% (1)

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocument6 pagesDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzNo ratings yet

- H-60 Manual Field Inspection Vane TesterDocument6 pagesH-60 Manual Field Inspection Vane TesterKoobecaf TnuoccaNo ratings yet

- FlowLabEOC2e CH02Document3 pagesFlowLabEOC2e CH02tomekzawistowskiNo ratings yet

- AE8612 - CAS Lab ExpDocument69 pagesAE8612 - CAS Lab ExpSahil BakkerNo ratings yet

- Chapter 1 - Section 3 When To Use NozzleproDocument3 pagesChapter 1 - Section 3 When To Use Nozzleprojohnnyr_5No ratings yet

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Document3 pagesQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliNo ratings yet

- Tutorial Sheets (Based On Lecture of The Week) : Department of Aerospace EngineeringDocument5 pagesTutorial Sheets (Based On Lecture of The Week) : Department of Aerospace EngineeringJASHANPREET SINGHNo ratings yet

- Exergy - FinlandDocument130 pagesExergy - FinlandPereiraeNo ratings yet

- Work, Power and MachinesDocument9 pagesWork, Power and MachinesPereiraeNo ratings yet

- Stress StatesDocument7 pagesStress StatesPereiraeNo ratings yet

- Stress StatesDocument7 pagesStress StatesPereiraeNo ratings yet

- Bend Drop Pressure in Pneumatic ConveyDocument1 pageBend Drop Pressure in Pneumatic ConveyPereiraeNo ratings yet

- Silver Tongue - TablaturaDocument3 pagesSilver Tongue - TablaturaPereiraeNo ratings yet

- PPRV 30 I 3 FinalDocument89 pagesPPRV 30 I 3 FinalFebriano SobbaNo ratings yet

- Science Activity Sheet Quarter 3 - MELC 1 Week 2: Physical Properties of MatterDocument8 pagesScience Activity Sheet Quarter 3 - MELC 1 Week 2: Physical Properties of MatterStephen Gimotea100% (3)

- Process Dynamics and Control: By: Gemechu Bushu (AAU)Document32 pagesProcess Dynamics and Control: By: Gemechu Bushu (AAU)gebreslassie gereziherNo ratings yet

- FM End-Sem Question Paper - 2021Document1 pageFM End-Sem Question Paper - 2021Anshu MeenaNo ratings yet

- Science of Musical Sound (Physics)Document8 pagesScience of Musical Sound (Physics)Mark Morones100% (1)

- Experiment #5 Pulse Response of Simple RC & RL CircuitsDocument11 pagesExperiment #5 Pulse Response of Simple RC & RL CircuitsAhmed HamoudaNo ratings yet

- Fa 2 Brood 3Document8 pagesFa 2 Brood 3LanceDavidNo ratings yet

- Radio Propagation and Network PlanningDocument46 pagesRadio Propagation and Network Planningمحمد فاضلNo ratings yet

- Constitutive and Navier-Stokes EquationsDocument5 pagesConstitutive and Navier-Stokes Equationslin huNo ratings yet

- 1.1.2.A Investigating Basic Circuits - DMSDocument8 pages1.1.2.A Investigating Basic Circuits - DMSBilly bobsNo ratings yet

- Numerical Modeling of Physical Process of Far Field Underwater ExplosionsDocument11 pagesNumerical Modeling of Physical Process of Far Field Underwater ExplosionsKristjan TabriNo ratings yet

- Converting Sound Energy To Electric Energy: November 2012Document5 pagesConverting Sound Energy To Electric Energy: November 2012qasim shahNo ratings yet

- Electrostatics A Powerpoint Presentation by Paul e Tippens Professor of PhysicsDocument17 pagesElectrostatics A Powerpoint Presentation by Paul e Tippens Professor of PhysicsDhynelle Muyco100% (1)

- Converting Units Maths Practice QuestionsDocument13 pagesConverting Units Maths Practice QuestionsSavitri BajajNo ratings yet

- Chapter 4 PDFDocument47 pagesChapter 4 PDFAdolfo ElizondoNo ratings yet

- Shear design of hollow core slabs using modified compression field theoryDocument17 pagesShear design of hollow core slabs using modified compression field theoryjrandeepNo ratings yet

- Stepchem 11 PDFDocument13 pagesStepchem 11 PDFSyeda Fatima ZahraNo ratings yet

- MicromagnetsDocument5 pagesMicromagnetsTa BarNo ratings yet

- MOHR'S CIRCLE ANALYSISDocument26 pagesMOHR'S CIRCLE ANALYSISMuthoka VincentNo ratings yet

- EQUILIBRIUMDocument1 pageEQUILIBRIUMMohammed IliasNo ratings yet

- ES191 Electrical and Electronic CircuitsDocument43 pagesES191 Electrical and Electronic CircuitsAbisan ArulananthamNo ratings yet

- MATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.5Document5 pagesMATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.5John Bofarull GuixNo ratings yet

- Physics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuDocument2 pagesPhysics of The Impossible: A Scientific Exploration Into The World of Phasers, Force Fields, Teleportation, and Time Travel by Michio KakuHomeroom TabNo ratings yet

- COE SyllabusDocument46 pagesCOE SyllabusCharuNo ratings yet

- Superconducting Fault Current LimiterDocument15 pagesSuperconducting Fault Current Limiterumesh kadNo ratings yet