Professional Documents

Culture Documents

Turbofan Engine

Uploaded by

Krishna MyakalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbofan Engine

Uploaded by

Krishna MyakalaCopyright:

Available Formats

Seminar Report

Turbo Fan Engine

ABSTRACT

Engines used in the earlier parts of 20th century had deficiencies in spite

of their advantages. The advantages used in those times were Turboprop

engines. These engines could produce only 10% of their thrust from the exhaust

jet. They could not attain high speed.

Researches were conducted further, which led to the developments of

Turbofan engines. Turbofan engines combined the hot air jet with bypassed air

from a fan. This created a quieter engine with greater boost at low speeds,

making it a popular choice for commercial airplanes. And due to generation of

more thrust for nearly the same amount of fuel, it is highly fuel-efficient.

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

CONTENTS

CHAPTERS

PAGE NO

1. INTRODUCTION

2. HISTORY

3. THEORY

i.

PROPULSION

ii.

TURBOFAN ENGINE

iii.

JET ENGINE THRUST

iv.

THRUST EUATION FOR TURBOJET

TYPE ENGINE

4. PARTS OF TURBOFAN ENGINE

10

5. WORKING PRINCIPLE

14

6. WORKING STAGES OF TURBOFAN ENGINE

18

7. TYPES OF JET ENGINE

23

8. DIFFERENT TYPES OF ENGINES

24

REFRENCES

LIST OF FIGURES

FIG 1

FIG 2

FIG 3

FIG 4

FIG 5

FIG 6

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

TURBOFAN ENGINES

INTRODUCTION

Jet Propulsion is the thrust imparting forward motion to an object, as a

reaction to the rearward expulsion of a high-velocity liquid or gaseous stream.

A simple example of jet propulsion is the motion of an inflated balloon when

the air is suddenly discharged. While the opening is held closed, the air pressure

within the balloon is equal in all directions; when the stem is released, the internal

pressure is less at the open end than at the opposite end, causing the balloon to dart

forward. Not the pressure of the escaping air pushing against the outside atmosphere

but the difference between high and low pressures inside the balloon propels it.

An actual jet engine does not operate quite as simply as a balloon, although the

basic principle is the same. More important than pressure imbalance is the

acceleration due to high velocities of the jet leaving the engine. This is achieved by

forces in the engine that enable the gas to flow backward forming the jet. Newton's

second law shows that these forces are proportional to the rate at which the

momentum of the gas is increased. For a jet engine, this is related to the rate of mass

flow multiplied by the rearward-leaving jet velocity. Newton's third law, which states

that every force must have an equal and opposite reaction, shows that the rearward

force is balanced by a forward reaction, known as thrust. This thrusting action is

similar to the recoil of a gun, which increases as both the mass of the projectile and its

muzzle velocity are increased. High-thrust engines, therefore, require both large rates

of mass flow and high jet-exit velocities, which can only be achieved by increasing

internal engine pressures and by increasing the volume of the gas by means of

combustion.

Jet-propulsion devices are used primarily in high-speed, high-altitude aircraft,

in missiles, and in spacecraft. The source of power is a high-energy fuel that is burned

at intense pressures to produce the large gas volume needed for high jet-exit

velocities. The oxidizer required for the combustion may be the oxygen in the air that

is drawn into the engine and compressed, or the oxidizer may be carried in the

vehicle, so that the engine is independent of a surrounding atmosphere. Engines that

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

depend on the atmosphere for oxygen include turbojets, turbofans, turboprops,

ramjets, and pulse jets. Non atmospheric engines are usually called rocket engines.

HISTORY

Jet power as a form of propulsion has been known for hundreds of years,

although its use for propelling vehicles that carry loads is comparatively recent. The

earliest known reaction engine was an experimental, steam-operated device developed

about the first century B.C. by the Greek mathematician and scientist Hero of

Alexandria. Known as the Aeolipile, Hero's device did no practical work, although it

demonstrated that a jet of steam escaping to the rear drives its generator forward. The

aeolipile consisted of a spherical chamber into which steam was fed through hollow

supports. The steam was allowed to escape from two bent tubes on opposite sides of

the sphere, and the reaction to the force of the escaping steam caused the sphere to

rotate.

The development (1629) of the steam turbine is credited to the Italian engineer

Giovanni Branca, who directed a steam jet against a turbine wheel, which in turn

powered a stamp mill. The first recorded patent for a gas turbine was obtained in 1791

by the British inventor John Barber.

In 1910, seven years after the first flights by the American inventors Orville

and Wilbur Wright, the French scientist Henri Marie Coanda designed and built a jetpropelled biplane, which took off and flew under its own power with Coanda as pilot.

Coanda used an engine that he termed a reaction motor, but, discouraged by the lack

of public acceptance of his aircraft, he abandoned his experiments.

During the next 20 years the gas turbine was developed further in both the

United States and Europe. One result of the experimental work of that period was the

perfection in 1918 of a turbo supercharger driver by an exhaust gas turbine for

conventional aircraft engines. In the early 1930s many patents covering gas turbines

were awarded to a number of European engineers. The patent granted the British

aeronautical engineer Sir Frank Whittle in 1930 is generally conceded to have

outlined the first practical form of the modern gas turbine. In 1935 Whittle applied his

basic design to the development of the W-1 turbojet engine, which made its first flight

in 1941.

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

Meanwhile, the French aeronautical engineer Ren Leduc had exhibited

(1938) a model of the ramjet in Paris, and a jet airplane that was powered by an axialflow turbojet designed by the German engineer Hans Joachim Pabst von Ohain made

its first flight in 1939. In the following year, under the direction of the aeronautical

engineer Secundo Campini, the Italians developed an airplane powered by a turboprop

engine with a reciprocating-engine-driven compressor. The first American-built jet

airplane, the Bell XP-59, was powered by the General Electric 1-16 turbojet, adapted

from Whittle's design in 1942. The first jet engine of exclusively American design was

produced by Westinghouse Electric Corp. for the U.S. Navy in 1944.

From a principle first described in 1906, the pulse jet was developed by the

German engineer Paul Schmidt, who received his first patent in 1931. The V-1, or

buzz bomb, first flown in 1942, was powered by pulse jet. Also in the mid-1940s the

first commercial airline flights using turboprop engines occurred. In 1947 the Bell X-1

experimental airplane, powered by a four-chambered liquid-rocket engine and carried

to the stratosphere in the belly of a bomber for launching, was the first pilot-operated

craft to break the sound barrier. Subsequently the Douglas Skyrocket experimental

airplane, powered by a jet engine in addition to a liquid-rocket engine, broke the

sound barrier at low altitude after taking off under its own power.

The first commercial jet airplane, the British Comet, was flown in 1952, but

this service was stopped after two serious accidents in 1954. In the U.S., the Boeing

707 jet was the first jet airplane to be tested commercially, in 1954. Commercial

flights began in 1958.

The continuous development of jet propulsion for air power has resulted in

such advances as piloted aircraft capable of attaining speeds several times greater than

the speed of sound, and intercontinental ballistic missiles and artificial satellites

launched by powerful rockets.

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

What is propulsion?

The word is derived from two Latin words: pro meaning before or forwards

and pellere means to drive. Propulsion means to push forward or drive an object

forward. A propulsion system is a machine that produces thrust to push an object

forward. On airplanes, thrust is usually generated through some application of

Newton's third law of action and reaction. The engine accelerates a gas or working

fluid, and the reaction to this acceleration produces a force on the engine.

A general derivation of the thrust equation shows that the amount of thrust

generated depends on the mass flow through the engine and the exit velocity of the

gas. Different propulsion systems generate thrust in slightly different ways.

THEORY

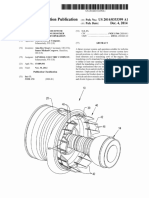

What is a Turbofan Engine?

A turbofan engine is the most modern variation of the basic gas turbine engine.

As with other gas turbines, there is a core engine. In the turbofan engine, a fan in the

front and an additional turbine at the rear surrounds the core engine. The fan and fan

turbine are composed of many blades, like the core compressor and core turbine, and

are connected to an additional shaft. All of this additional turbo machinery is colored

green on the schematic diagram as shown in Fig 1 below.

Fig 1:- Schematic diagram of turbofan engine

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

As with the core compressor and turbine, some of the fan blades turn with the

shaft and some blades remain stationary. The fan shaft passes through the core shaft

for mechanical reasons. This type of arrangement is called a two-spool engine (one

"spool" for the fan, one "spool" for the core.) Some advanced engines have additional

spools for sections of the compressor, which provides for even higher compressor

efficiency.

Jet Engine Thrust

The force produced by a jet engine is expressed in terms of kilograms of

thrust. This is a measure of the mass or weight of air moved by an engine times the

acceleration of the air as it goes through the engine. Technically, if the aircraft were to

stand still and the pressure at the exit plane of the jet engine was the same as the

atmospheric pressure, the formula for the jet engine thrust would be:

Thrust =

Weight of air in kilograms per second * velocity

___________________________________________

9.81 (normal acceleration due to gravity, in meter per second 2)

Imagine an aircraft standing still, capable of handling 97.522 kilograms of air

per second. Assume the velocity of the exhaust gases to be 1,500 feet per second. The

thrust would then be:

Thrust =

97.522 kg of air per second * 457.2 m / s

9.81 m / s 2

= 9.941 * 457.2

Thrust = 4545.025 kg.

If the pressure at the exit plane is not the same as the atmospheric pressure and

the aircraft were not standing still, the formula would be somewhat different.

It is not very practical to try to compare jet engine output in terms of

horsepower. As a rule of thumb, however, it may be noted that that at 375 miles per

hour (mph), one pound of thrust equals one horsepower, at 750 mph one pound of

thrust equals two horsepower.

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

Thrust Equation for Turbojet-Type Engines

The thrust equation for a turbojet can be derived from the general form of

Newton's second law (i.e., force equals the time rate of change of momentum),

f = d (MV) / dt.

The nozzle of the turbojet is usually designed to take the exhaust pressure back

to free stream pressure. The thrust equation for a turbojet is then given by the general

thrust equation with the pressure-area term set to zero. If the free stream conditions

are denoted by a "0" subscript and the exit conditions by an "e" subscript, the thrust F

is equal to the mass flow rate m times the velocity V at the exit minus the free stream

mass flow rate times the velocity.

F = [m * V]e - [m * V]0

This equation contains two terms. Aerodynamicists often refer to the first term

m as the Gross Thrust since this term is largely associated with conditions in the

nozzle. The second term m is called the ram drag and is usually associated with

conditions in the inlet. For clarity, the engine thrust is then called the net thrust. Our

thrust equation indicates that net thrust equals gross thrust minus ram drag. If we

divide both sides of the equation by the mass flow rate, we obtain and

parameter called the specific thrust that greatly simplifies the performance

www.seminarsTopics.com

efficiency

Seminar Report

Turbo Fan Engine

PARTS OF A TURBOFAN ENGINE

The different parts of a Turbofan engine are as shown in Fig 10 below:-

Fig 10:- Parts of a Turbofan Engine

Fan - The fan is the first component in a turbofan. The fan pulls air into the

engine. The large spinning fan sucks in large quantities of air. It then, speeds the air up

and splits it into two parts. One part continues through the "core" or center of the

engine, where it is acted upon by the other engine components. The second part

"bypasses" the core of the engine, instead traveling through a duct that surrounds the

core to the back of the engine where it produces much of the force that propels the

airplane forward.

Compressor - The compressor is the first component in the engine core. The

compressor squeezes the air that enters it into smaller areas, resulting in an increase in

the air pressure. This results in an increase in the energy potential of the air. The

squashed air is forced into the combustion chamber.

www.seminarsTopics.com

Seminar Report

Turbo Fan Engine

Combustor - In the combustor the air is mixed with fuel and then ignited.

This process results in high temperature, high energy airflow. The fuel burns with the

oxygen in the compressed air, producing hot expanding gases.

Turbine - The high energy airflow coming out of the combustor goes into the

turbine, causing the turbine blades to rotate. This rotation extracts some energy from

the high-energy flow that is used to drive the fan and the compressor. The gases

produced in the combustion chamber move through the turbine and spin its blades.

The task of a turbine is to convert gas energy into mechanical work to drive the

compressor.

Nozzle - The nozzle is the exhaust duct of the engine. The energy depleted

airflow that passed the turbine, in addition to the colder air that bypassed the engine

core, produces a force when exiting the nozzle that acts to propel the engine, and

therefore the airplane, forward. The combination of the hot air and the cold air are

expelled and produce an exhaust which causes a forward thrust. The nozzle may be

preceded by a mixer, which combines the high temperature air coming from the

engine core with the lower temperature air that was bypassed in the fan. This results

in a quieter engine than if the mixer was not present.

www.seminarsTopics.com

10

Seminar Report

Turbo Fan Engine

Afterburner - In addition to the basic components of a gas turbine engine,

one other process is occasionally employed to increase the thrust of a given engine.

Afterburning (or reheat) is a method of augmenting the basic thrust of an engine to

improve the aircraft takeoff, climb and (for military aircraft) combat performance.

Afterburning consists of the introduction and burning of raw fuel between the engine

turbine and the jet pipe propelling nozzle, utilizing the unburned oxygen in the

exhaust gas to support combustion. The increase in the temperature of the exhaust gas

increases the velocity of the jet leaving the propelling nozzle and therefore increases

the engine thrust. This increased thrust could be obtained by the use of a larger

engine, but this would increase the weigh and overall fuel consumption. In other

words Afterburner is a device for increasing the thrust (forward-directed force) of a

gas-turbine (jet) airplane engine. Additional fuel is sprayed into the hot exhaust duct

between the turbojet (engine) and the tailpipe. The fuel ignites, providing a burst of

speed. Afterburning is used for a short increase of power during takeoff, or during

combat in military aircraft.

WORKING PRINCIPLE

How does a turbofan engine work?

The engine inlet captures the incoming air. Some of the incoming air passes

through the fan and continues on into the core compressor and then the burner, where

it is mixed with fuel and combustion occurs. The hot exhaust passes through the core

and fan turbines and then out the nozzle, as in a basic turbojet. This airflow is called

the core airflow and is denoted by m . The rest of the incoming air, colored blue on

the figure, passes through the fan and bypasses, or goes around the engine, just like

the air through a propeller. The air that goes through the fan has a velocity that is

www.seminarsTopics.com

11

Seminar Report

Turbo Fan Engine

slightly increased from free stream. This airflow is called the fanflow, or bypass flow,

and is denoted by m . The ratio of m to m is called the bypass ratio. So a turbofan

gets some of its thrust from the core and some of its thrust from the fan. The ratio of

the air that goes around the engine to the air that goes through the core is called the

bypass ratio.

Fig 4:- Thrust of a Turbofan engine

The total mass flow rate through the inlet is the sum of the core and fan flows

m= m + m

A turbofan gets some of its thrust from the core and some of its thrust from the

fan. If we denote the exit of the core as station "e", the exit of the fan as station "f",

and the free stream as station "0", we can use the basic thrust equation for each stream

to obtain the total thrust:

F = m - m * V0 + (m * V)e - m * V0

We can combine the terms multiplying V0 and use the definition of the bypass

ratio bpr to obtain the final thrust equation:

F = (m * V)e + bpr * m * Vf - (m * V)0

Because the fuel flow rate for the core is changed only a small amount by the

addition of the fan, a turbofan generates more thrust for nearly the same amount of

fuel used by the core. This means that a turbofan is very fuel efficient. In fact, high

www.seminarsTopics.com

12

Seminar Report

Turbo Fan Engine

bypass ratio turbofans are nearly as fuel efficient as turboprops. Because the fan is

enclosed by the inlet and is composed of many blades, it can operate efficiently at

higher speeds than a simple propeller. That is why turbofans are found on high speed

transports and propellers are used on low speed transports. Low bypass ratio turbofans

are still more fuel efficient than basic turbojets. Many modern fighter planes actually

use low bypass ratio turbofans equipped with afterburners. They can then cruise

efficiently but still have high thrust when dog fighting. Even though the fighter plane

can fly much faster than the speed of sound, the air going into the engine must travel

less than the speed of sound for high efficiency. Therefore, the airplane inlet slows the

air down from supersonic speeds.

www.seminarsTopics.com

13

Seminar Report

Fig 5:-

Turbo Fan Engine

ROLLS-ROYCE TAY TURBOFAN ENGINE

As an example for the turbofan engine consider the Rolls-Royce Tay turbofan

engine as shown in the Fig 5.This Rolls-Royce Tay turbofan engine pushes nearly

three times as much air through the bypass ducts as it pushes through the central core

of the engine, where the air is compressed, mixed with fuel, and ignited. Turbofan

engines like the Rolls-Royce Tay are not as powerful as turbojets, but they are quieter

and more efficient.

The turbofan engine is an improvement on the basic turbojet. Part of the

incoming air is only partially compressed and then bypassed in an outer shell beyond

the turbine. This air is then mixed with the hot turbine-exhaust gases before they reach

the nozzle. A bypass engine has greater thrust for takeoff and climb, and increased

efficiency; the bypass cools the engine and reduces noise level.

In some fan engines the bypass air is not remixed in the engine but exhausted

directly. In this type of bypass engine, only about one-sixth of the incoming air goes

through the whole engine; the remaining five-sixths is compressed only in the first

compressor or fan stage and then exhausted. Different rotational speeds are required

for the high- and low-pressure portions of the engine. This difference is achieved by

having two separate turbine-compressor combinations running on two concentric

shafts or twin spools. Two high-pressure turbine stages drive the 11 high-pressure

compressor stages mounted on the outer shaft, and 4 turbine stages provide power for

the fan and 4 low-pressure compressor stages on the inner shaft. To move an airplane

www.seminarsTopics.com

14

Seminar Report

Turbo Fan Engine

through the air, thrust is generated by some kind of propulsion system. Most modern

airliners use turbofan engines because of their high thrust and good fuel efficiency.

An example of an engine of this type is the JT9D-3 jet engine, which weighs

about 3850 kg (about 8470 lb) and can develop a takeoff thrust of about 20,000 kg

(about 44,000 lb). This is more than double the thrust available for the largest

commercial planes before the Boeing 747.

WORKING STAGES OF THE TURBOFAN ENGINE

1.

2.

www.seminarsTopics.com

15

Seminar Report

Turbo Fan Engine

3.

4.

www.seminarsTopics.com

16

Seminar Report

Turbo Fan Engine

5.

6.

7.

www.seminarsTopics.com

17

Seminar Report

Turbo Fan Engine

8.

9.

www.seminarsTopics.com

18

Seminar Report

Turbo Fan Engine

TYPES OF JET ENGINES

Fig 7:- JET ENGINES

The three most common types of jet engines are the turbojet, turboprop, and

turbofan. Air entering a turbojet engine is compressed and passed into a combustion

www.seminarsTopics.com

19

Seminar Report

Turbo Fan Engine

chamber to be oxidized. Energy produced by the burning fuel spins the turbine that

drives the compressor, creating an effective power cycle. Turboprop engines are

driven almost entirely by a propeller mounted in front of the engine, deriving only 10

percent of their thrust from the exhaust jet. Turbofans combine the hot air jet with

bypassed air from a fan, also driven by the turbine. The use of bypass air creates a

quieter engine with greater boost at low speeds, making it a popular choice for

commercial airplanes.

FAQs

Why are there different types of engines?

If we think about Newton's first law of motion, we realize that an airplane

propulsion system must serve two purposes. First, the thrust from the propulsion

system must balance the drag of the airplane when the airplane is cruising. And

second, the thrust from the propulsion system must exceed the drag of the airplane for

the airplane to accelerate. In fact, the greater the difference between the thrust and the

drag, called the excess thrust, the faster the airplane will accelerate.

Some aircraft, like airliners and cargo planes, spend most of their life in a

cruise condition. For these airplanes, excess thrust is not as important as high engine

efficiency and low fuel usage. Since thrust depends on both the amount of gas moved

and the velocity, we can generate high thrust by accelerating a large mass of gas by a

small amount, or by accelerating a small mass of gas by a large amount. Because of

the aerodynamic efficiency of propellers and fans, it is more fuel efficient to

accelerate a large mass by a small amount. That is why we find high bypass fans and

turboprops on cargo planes and airliners.

Some aircraft, like fighter planes or experimental high speed aircraft require

very high excess thrust to accelerate quickly and to overcome the high drag associated

with high speeds. For these airplanes, engine efficiency is not as important as very

high thrust. Military aircraft typically employ afterburning turbojets. Future

hypersonic aircraft will employ some type of ramjet or rocket propulsion.

www.seminarsTopics.com

20

Seminar Report

Turbo Fan Engine

Why are Turbofan Engines so popular?

The turbofan engine has gained popularity for a variety of reasons. As shown

in Fig 6 below, one or more rows of compressor blades extend beyond the normal

compressor blades. The result is that four times as much air is pulled into the turbofan

engine as in the simple turbojet. However, most of this excess air is ducted through

bypasses around the power section and out the rear with the exhaust gases. Also, a fan

burner permits the burning of additional fuel in the fan air stream. With the burner off,

this engine can operate economically and efficiently at low altitudes and low speeds.

With the burner on, the thrust is doubled by the burning fuel, and it can operate on

high speeds and high altitudes fairly efficiently. The turbofan has greater thrust for

takeoff, climbing, and cruising on the same amount of fuel than the conventional

turbojet engine.

With better all-around performance at a lower rate of fuel consumption, plus

less noise resulting from its operation, it is easy to understand why most new jetpowered airplanes are fitted with turbofan engines. This includes military and civilian

types.

Fig 6: - Turbofan Engine

REFERENCES

www.seminarsTopics.com

21

Seminar Report

Turbo Fan Engine

1. www.howstuffworks.com

2. www.grc.nasa.govt/WWWK-12

www.seminarsTopics.com

22

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ToLiss AirbusA320 AircraftManualDocument59 pagesToLiss AirbusA320 AircraftManualNinjaGamerTheEpic 2ndNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Airbus A32X NEO LEAP DifferenciesDocument124 pagesAirbus A32X NEO LEAP Differenciesxristophoros100% (14)

- Pratt and Whitey PW1100 Engine Development Overview Airbus A320 NEODocument6 pagesPratt and Whitey PW1100 Engine Development Overview Airbus A320 NEOJames Richardson100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CAA - C++ API Documentation Generator (CDG) - 2 PDFDocument3 pagesCAA - C++ API Documentation Generator (CDG) - 2 PDFKrishna MyakalaNo ratings yet

- Engineering Drawing ManualDocument128 pagesEngineering Drawing Manualadnan100% (6)

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- Cj4 Startup Guide 1.02Document40 pagesCj4 Startup Guide 1.02Jose Otero De SantiagoNo ratings yet

- Scramjet EngineDocument23 pagesScramjet EngineKrishna MyakalaNo ratings yet

- Compressor Surge and Rotating Stall PDFDocument233 pagesCompressor Surge and Rotating Stall PDFQuân Chu Hoàng100% (1)

- TM 1Document278 pagesTM 1Rodrigo AcevesNo ratings yet

- L 39NG LeafletDocument2 pagesL 39NG LeafletSilentisticsNo ratings yet

- Aerospace Engine DataDocument5 pagesAerospace Engine DatapbonnetNo ratings yet

- Gas Turbine ResearchDocument13 pagesGas Turbine ResearchKrishna MyakalaNo ratings yet

- Pressure-Gain Combustion For Gas Turbines: Dan Paxson NASA John H. Glenn Research Center Cleveland, OHDocument35 pagesPressure-Gain Combustion For Gas Turbines: Dan Paxson NASA John H. Glenn Research Center Cleveland, OHernestozagNo ratings yet

- Mechanical Be002Document5 pagesMechanical Be002Krishna MyakalaNo ratings yet

- JRF DLRL 17042018Document3 pagesJRF DLRL 17042018Krishna MyakalaNo ratings yet

- Contract Engineer For MMF Division-Advertisement PDFDocument2 pagesContract Engineer For MMF Division-Advertisement PDFKrishna MyakalaNo ratings yet

- The Unsung Heroes of India'S Freedom Struggle: Employment NewsDocument40 pagesThe Unsung Heroes of India'S Freedom Struggle: Employment NewsKrishna MyakalaNo ratings yet

- Application Form - Non-Teaching Positions 21 To 23Document5 pagesApplication Form - Non-Teaching Positions 21 To 23Krishna MyakalaNo ratings yet

- Jawaharlal Nehru Technological University, HyderabadDocument5 pagesJawaharlal Nehru Technological University, HyderabadKrishna MyakalaNo ratings yet

- Introduction To Gas Turbines For Non-EngineersDocument9 pagesIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaNo ratings yet

- Syllabus For Direct Recruitment To The Posts of Assistant/Upper Division Clerk in Level 4 of Pay MatrixDocument1 pageSyllabus For Direct Recruitment To The Posts of Assistant/Upper Division Clerk in Level 4 of Pay MatrixKrishna MyakalaNo ratings yet

- Ijctt V4i7p168 PDFDocument6 pagesIjctt V4i7p168 PDFKrishna MyakalaNo ratings yet

- Welding GuidelinesDocument8 pagesWelding Guidelinesarunraj002100% (1)

- Defence Research and Development Organisation (Drdo) Recruitment & Assessment Centre (Rac)Document4 pagesDefence Research and Development Organisation (Drdo) Recruitment & Assessment Centre (Rac)Himanshu MudgalNo ratings yet

- From: Powered byDocument16 pagesFrom: Powered byKrishna MyakalaNo ratings yet

- Catia v5 - Questions & AnswersDocument67 pagesCatia v5 - Questions & AnswersKrishna MyakalaNo ratings yet

- GDT Trainer Fund 2009Document2 pagesGDT Trainer Fund 2009GopinathNo ratings yet

- Mechanical Engineering 0Document3 pagesMechanical Engineering 0Krishna MyakalaNo ratings yet

- Rect Mate Ce SWCDocument27 pagesRect Mate Ce SWCKrishna MyakalaNo ratings yet

- JRFDST ProjectCENIST1443411167Document4 pagesJRFDST ProjectCENIST1443411167Krishna MyakalaNo ratings yet

- To, The Zonal Manager Bank of India Indore ZoneDocument3 pagesTo, The Zonal Manager Bank of India Indore ZoneKrishna MyakalaNo ratings yet

- 1101201315rocket ProppellantDocument47 pages1101201315rocket ProppellantKrishna MyakalaNo ratings yet

- Notification For Selection of Managing Director Chief Executive OfficerDocument7 pagesNotification For Selection of Managing Director Chief Executive OfficerKrishna MyakalaNo ratings yet

- Admission Notification-2015 For MBA (Evening - Part Time)Document1 pageAdmission Notification-2015 For MBA (Evening - Part Time)Krishna MyakalaNo ratings yet

- Principles of Flight: Chapter 6 - HelicoptersDocument11 pagesPrinciples of Flight: Chapter 6 - HelicoptersKrishna MyakalaNo ratings yet

- Ijaiem 2013 05 24 052Document6 pagesIjaiem 2013 05 24 052Krishna MyakalaNo ratings yet

- Seminar Report Stealth FighterDocument30 pagesSeminar Report Stealth FighterAnchalGuptaNo ratings yet

- Thrust Reverser System with Translating-Rotating Blocker DoorsDocument14 pagesThrust Reverser System with Translating-Rotating Blocker DoorsMarco Raneo PezzanoNo ratings yet

- Turbine Blades: CreepDocument6 pagesTurbine Blades: CreepCed SisonNo ratings yet

- Conclusion and Future ScopeDocument4 pagesConclusion and Future Scopeapi-249277319100% (1)

- AA283 Aircraft and Rocket Propulsion CH 02 BJ CantwellDocument21 pagesAA283 Aircraft and Rocket Propulsion CH 02 BJ Cantwellsamiran karNo ratings yet

- Thermal Management Trade Study for SUSAN Electrofan AircraftDocument19 pagesThermal Management Trade Study for SUSAN Electrofan AircraftanesaNo ratings yet

- Verslag 6Document50 pagesVerslag 6Anonymous C9ZNFkrb6No ratings yet

- Conventional and Model Based Test AnalysisDocument21 pagesConventional and Model Based Test AnalysisHalil İbrahim KüplüNo ratings yet

- Module 14 Propulsion Questions ExplainedDocument30 pagesModule 14 Propulsion Questions ExplainedBahadorNo ratings yet

- Honeywell Turbofan Engine TCDSDocument10 pagesHoneywell Turbofan Engine TCDSwillalizadeNo ratings yet

- Reviewer 5Document59 pagesReviewer 5KleberNo ratings yet

- AGTE Theory 1 Chapter 1Document41 pagesAGTE Theory 1 Chapter 1Abush NigussieNo ratings yet

- Gas Turbines - Thrust and Performance ParametersDocument82 pagesGas Turbines - Thrust and Performance ParametersHamza ShahidNo ratings yet

- JournalofRoboticsandMechanicalEngineeringResearch23 PDFDocument10 pagesJournalofRoboticsandMechanicalEngineeringResearch23 PDFMoaz HussainNo ratings yet

- Lecture Notes Aerospace PropulsionDocument104 pagesLecture Notes Aerospace PropulsionJuan GarcíaNo ratings yet

- Specific Fuel ConsumptionDocument3 pagesSpecific Fuel ConsumptionMark Baguia DandoyNo ratings yet

- Aero-Engine Fan Gearbox Design: The 16 Israeli Symposium On Jet Engines and Gas Turbines November 9, 2017Document26 pagesAero-Engine Fan Gearbox Design: The 16 Israeli Symposium On Jet Engines and Gas Turbines November 9, 2017Mario RossiNo ratings yet

- Je01 Haynes Jet Engine Uk Manual Lo ResDocument11 pagesJe01 Haynes Jet Engine Uk Manual Lo ResMauricio SantanaNo ratings yet

- Aeronautical EngineeringDocument220 pagesAeronautical EngineeringHOD ILM aeroNo ratings yet

- Experimental and Numerical Methodology For The Aero-Thermal Analysis of ADocument11 pagesExperimental and Numerical Methodology For The Aero-Thermal Analysis of AMohamed Ould MoussaNo ratings yet